Patents

Literature

78results about How to "Eliminate rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

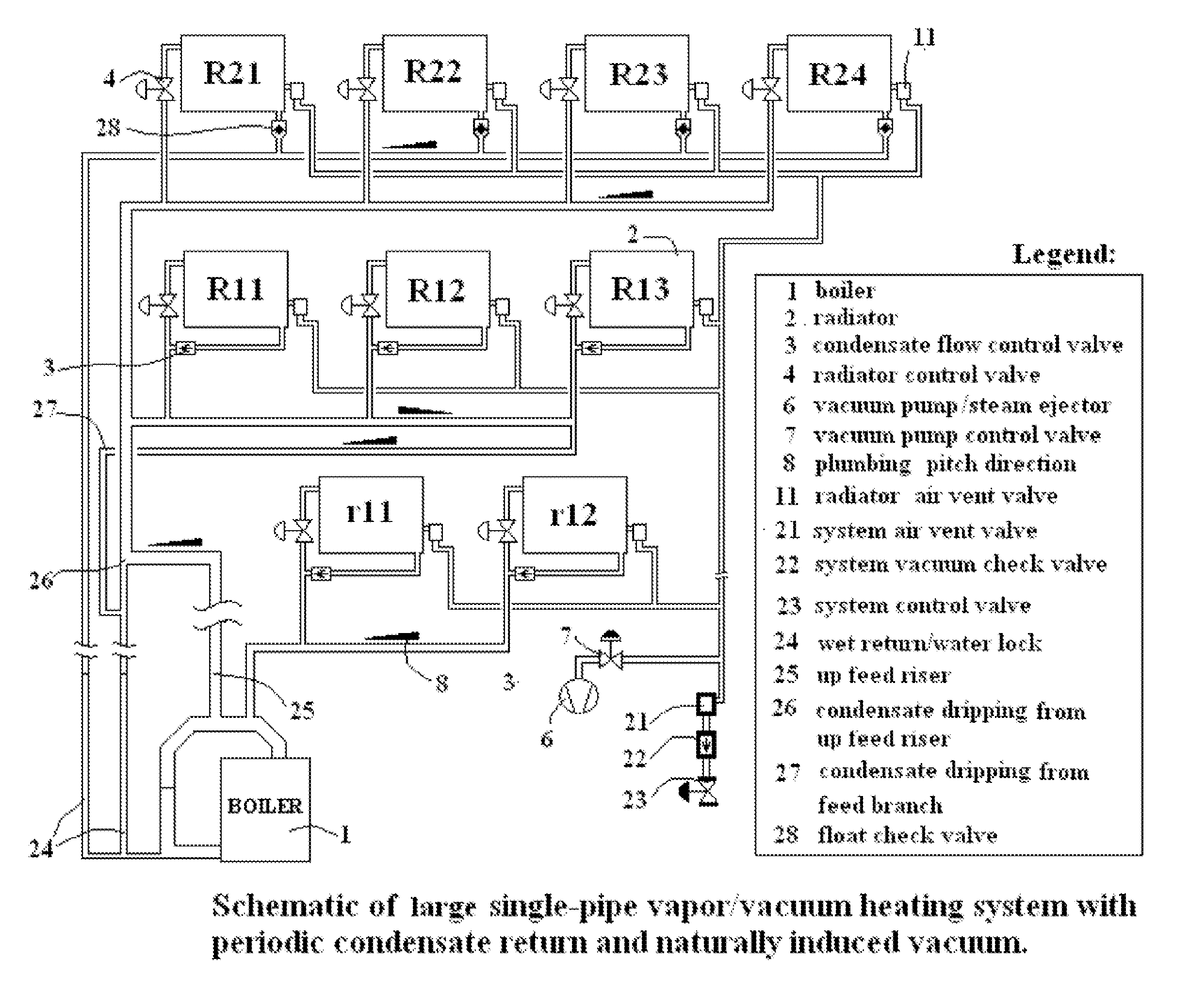

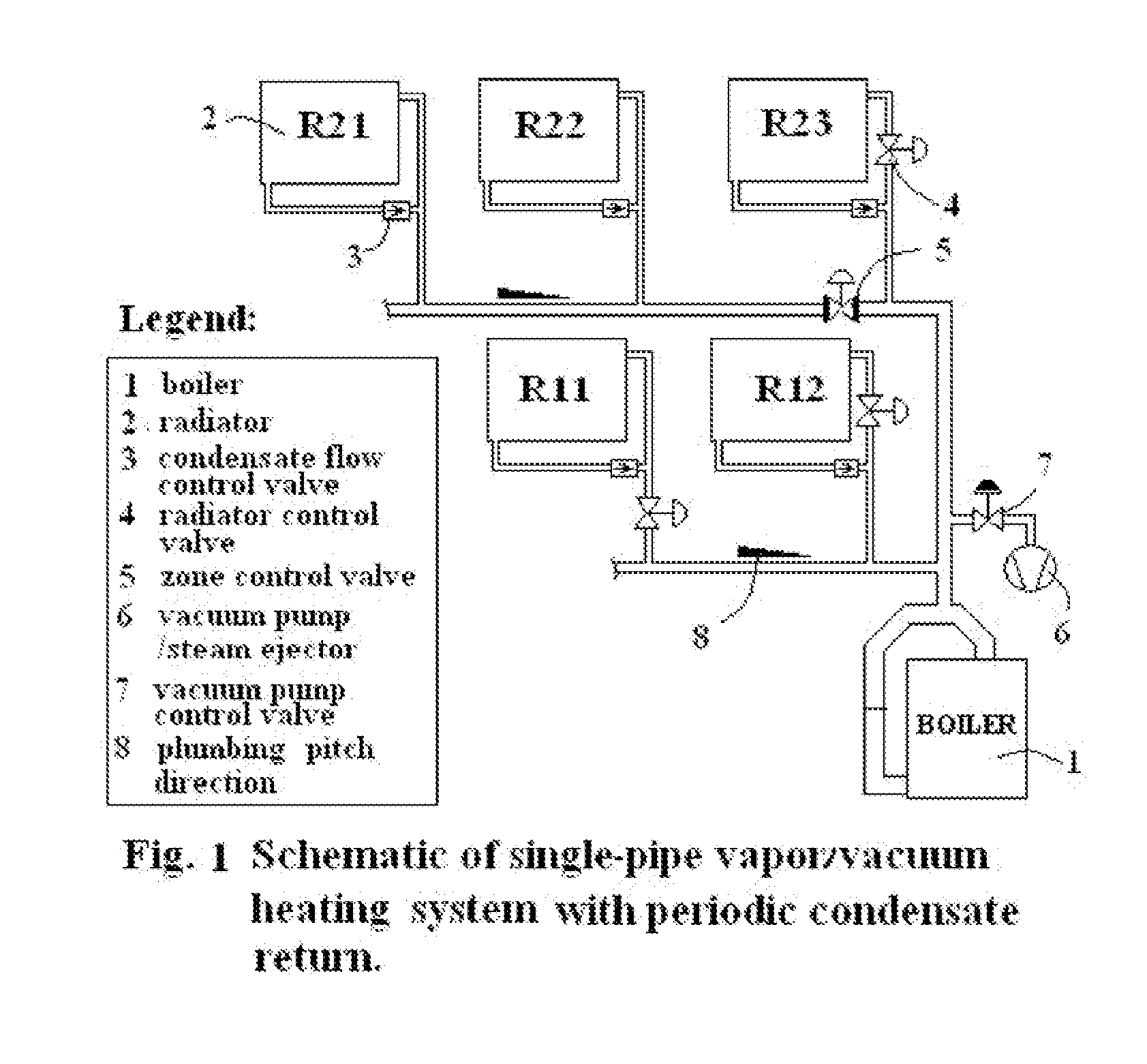

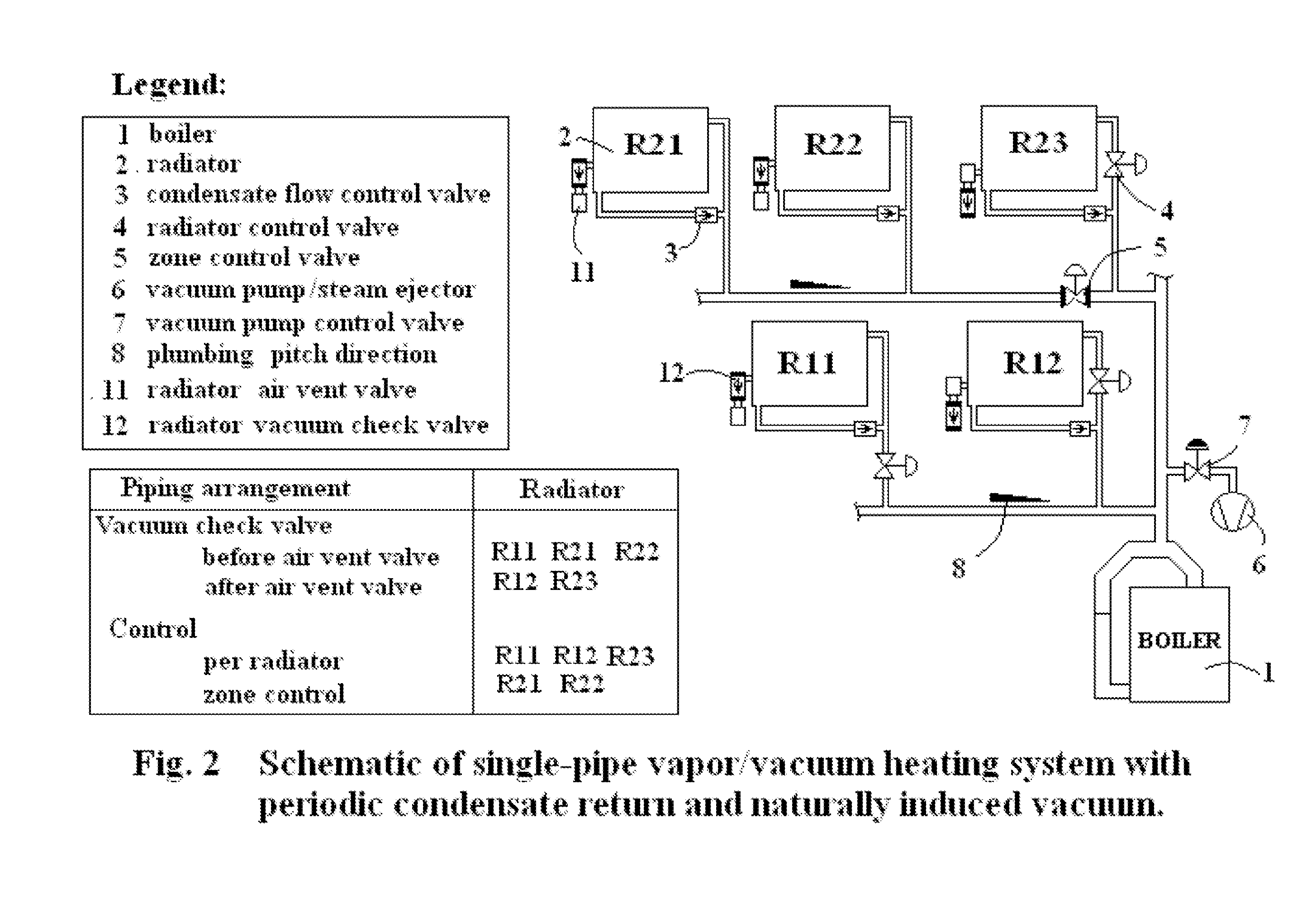

Vapor/vacuum heating system

InactiveUS20110198406A1Prevent hammeringEliminate rustAir-treating devicesCentral heating componentsTemperature conditioningEngineering

A building heating system with cycling steam source used for plurality of radiators is provided. During heating cycle condensate is retained in radiators and released later through steam supply line. Such condensate and steam flows alternation eliminates water hammering and justify usage of smaller diameter tubes and new radiator design. When air is evacuated, system operates like branched heat pipe with periodic condensate return. System may include vacuum check valve on air vent lines and operational procedure to create vacuum naturally by steam condensing in a closed space after complete air purging from the system. Steam / vapor source's cut off pressure can be adjusted to regulate the vapor's temperature depending on the outside temperature. Method is proposed for conversion of the existing steam heating systems into a vapor / vacuum system with naturally induced vacuum.

Owner:ZHADANOVSKY IGOR

Formula of material for disk type brake sheets

This invention relates to the formulation of a disk-type brake material, which is composed of: adhesive 5-10 wt.%, reinforcing material 20-30 wt.%, grinding agent 30-50 wt.%, lubricating agent 10-20 wt.%, and filler 20-30 wt.%. The adhesive is one or two of phenol formaldehyde resin, nitrile-modified phenol formaldehyde resin and Si-modified phenol formaldehyde resin. The reinforcing material is a composition of steel cotton fibers and aramid pulp or a composition of ceramic fibers and aramid pulp. The grinding agent is a composition of Fe2O3, MgO, and Al2O3 and friction powder. The lubricating agent is a composition of inorganic lubricating agent and metal sulfide or a composition of organic lubricating agent and metal sulfide. The filler is a composition of BaSO4, CaCO3 and MgO. The brake can form a layer of lubricating film on the friction interface, thus can eliminate hard particles on the surface and occurring probability of low-frequency noise and decrease low-frequency noise to below 10%.

Owner:信义集团公司

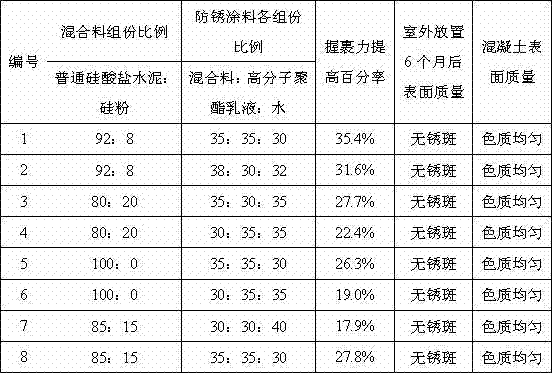

Modified polyester antirust coating for construction steel bars and construction method for modified polyester antirust coating

The invention discloses a modified polyester antirust coating for construction steel bars and a construction method for the modified polyester antirust coating. The modified polyester antirust coating for the construction steel bars consists of a mixed material, polymer polyester emulsion and water in a mass part ratio of (30-50):(25-40):(25-45), wherein the mixed material consists of portland cement and silica powder in a mass part ratio of (80-100):(0-20). The construction method comprises the following steps of: (1) weighing common portland cement and silica powder, and uniformly stirring to obtain the mixed material; (2) weighing the mixed material, the polymer polyester emulsion and water in the mass ratio, and stirring for 3 to 5 minutes to obtain modified polyester antirust coating slurry for the construction steel bars; (3) uniformly coating the modified polyester antirust coating slurry on the outer surfaces of the construction steel bars; and (4) curing in a windproof and shade place, and using the construction steel bars for construction. The modified polyester antirust coating can prevent the steel bars from generating rusty spots when the steel bars are arranged in the field for 6 months, and can improve the bond stress between concrete and the steel bars by 15-35 percent.

Owner:扬州市航道管理处 +1

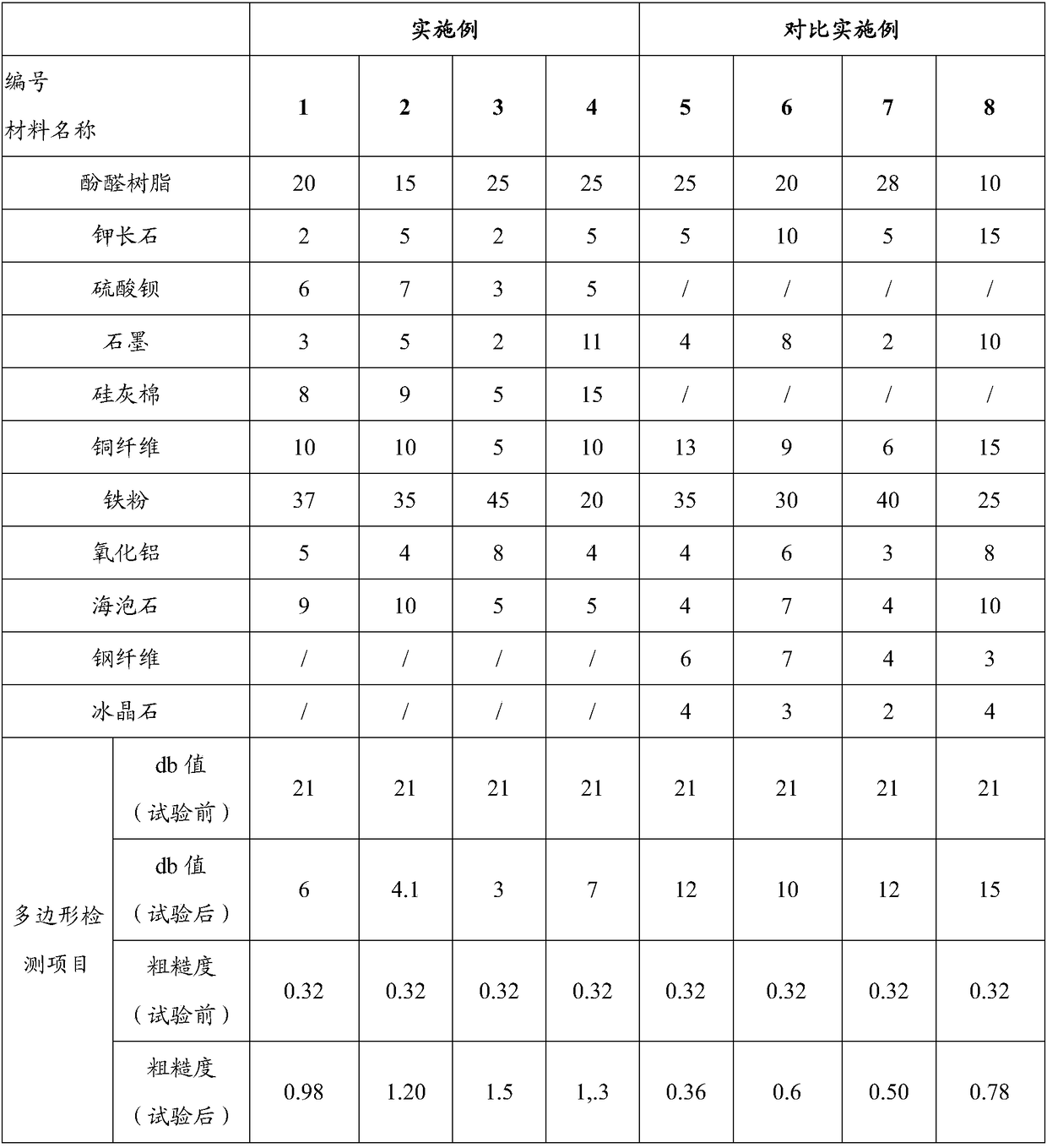

Abrasive block for rail vehicles and preparation method thereof

ActiveCN108359212AEliminate fatigueEliminate hairline cracksOther chemical processesVehicle cleaningFiberIron powder

The invention provides an abrasive block for rail vehicles and a preparation method thereof. The abrasive block includes the raw materials: phenolic resin, potassium feldspar, barium sulfate, graphite, wollastonite, copper fibers, iron powder, alumina and sepiolite; by adjusting the composition and content of the abrasive block, the abrasive block functions of repairing wheel tread defects and out-of-roundness (namely polygon) are realized, and the fatigue state and hairline cracks of a wheel surface can be eliminated in time, so a stripping phenomenon on the wheel surface is avoided and high-frequency vibration between wheels and rails is eliminated.

Owner:长春昌博众邦轨道交通科技有限公司

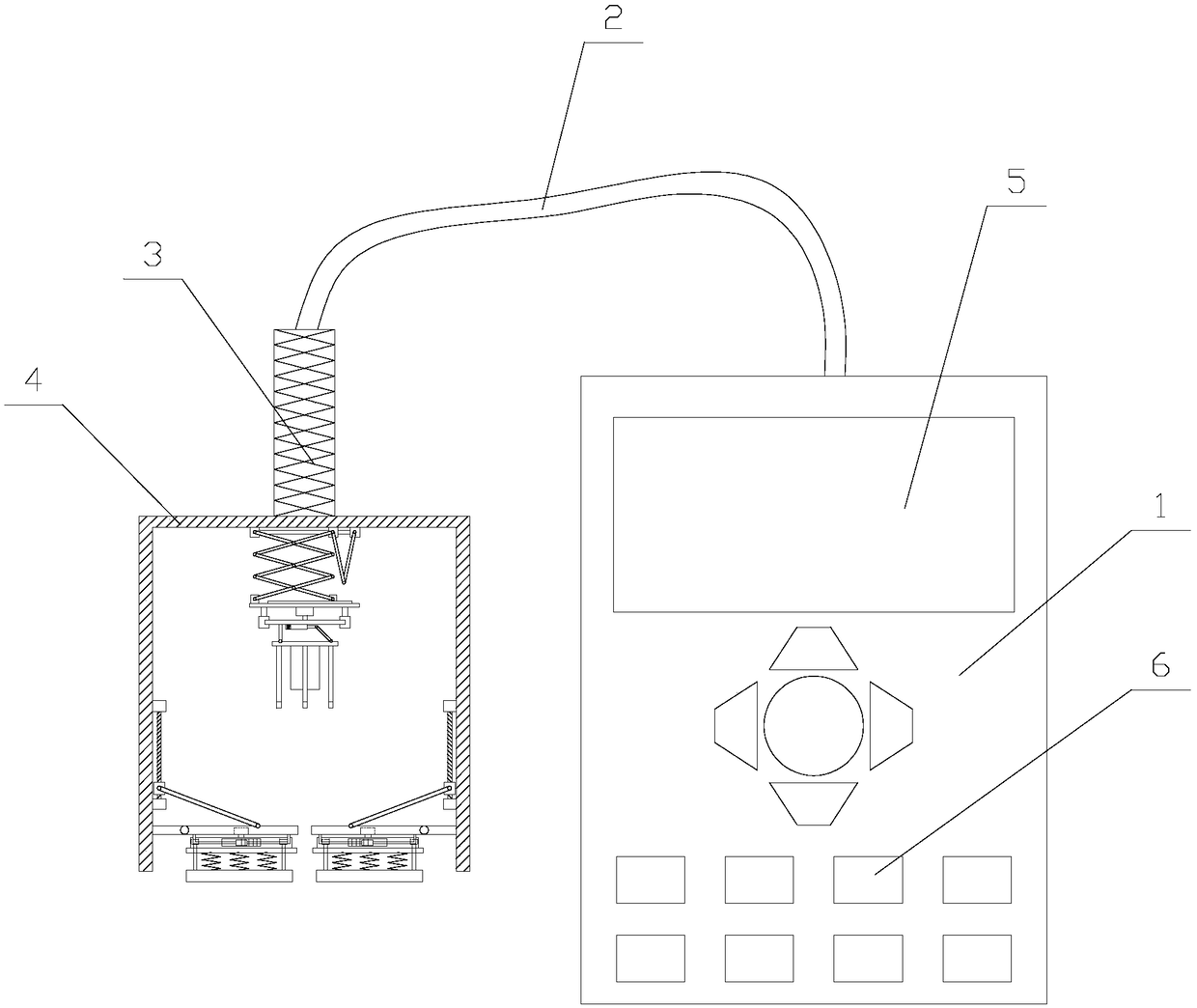

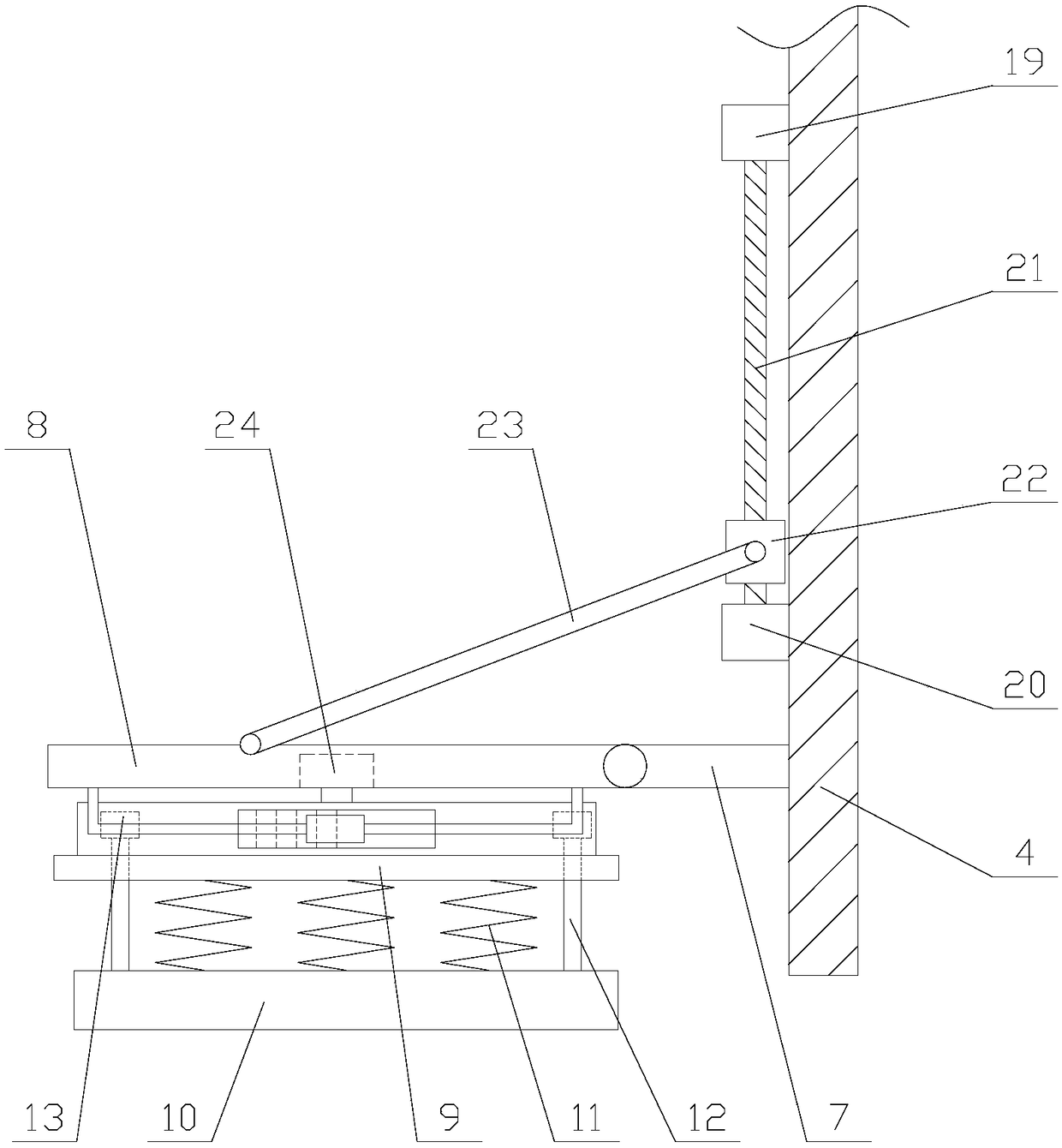

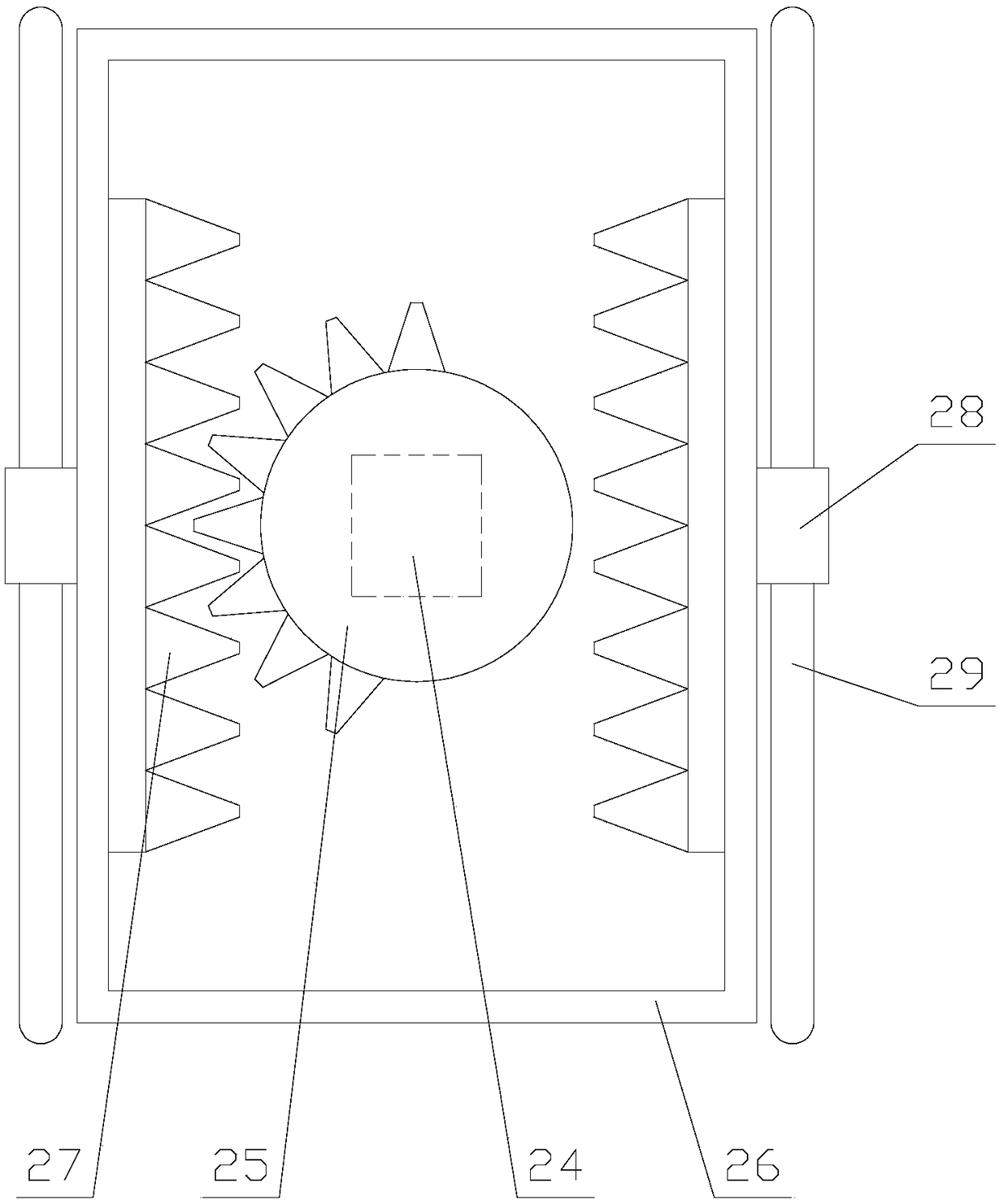

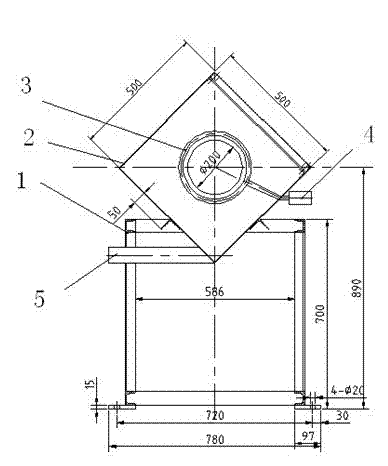

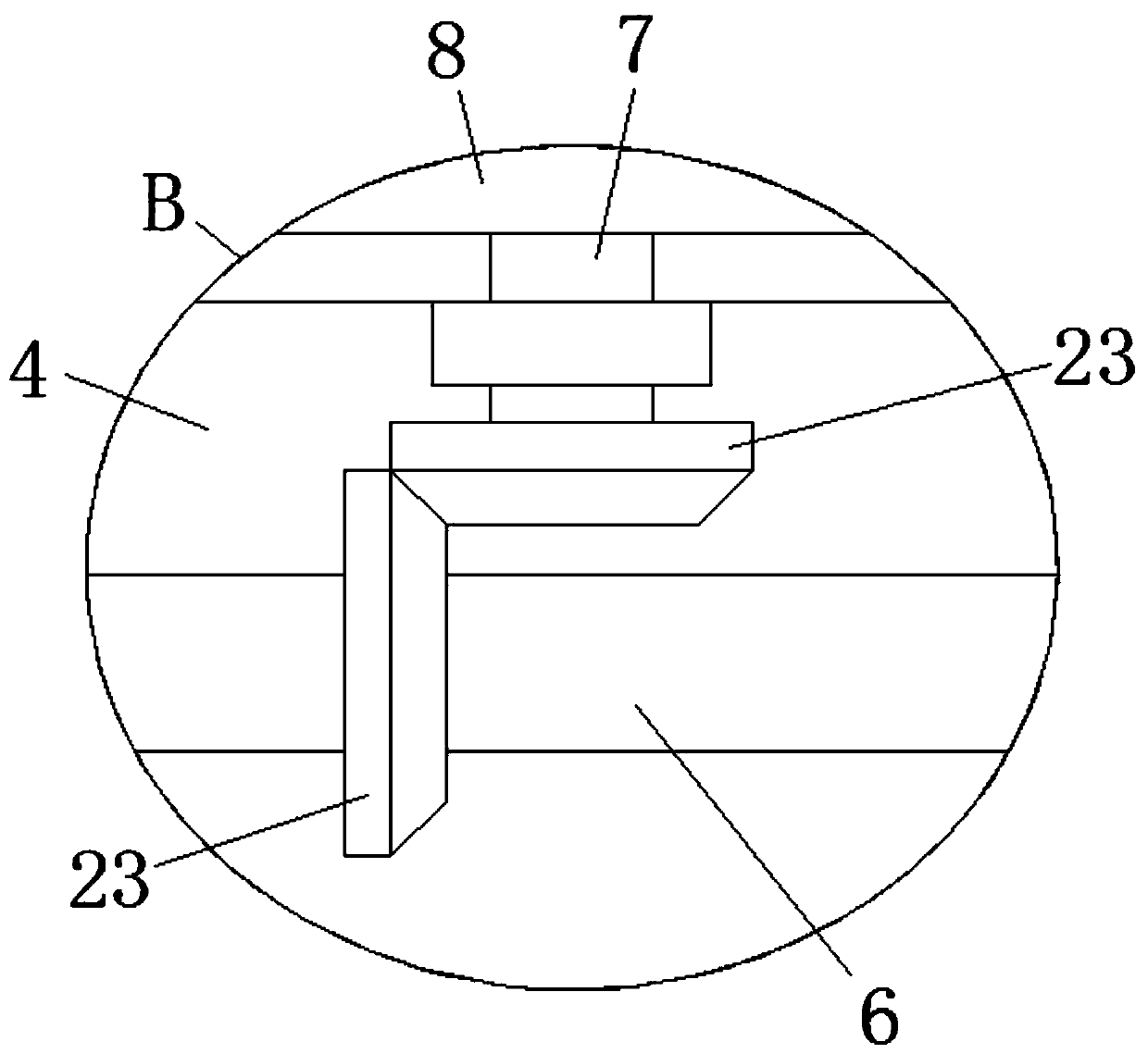

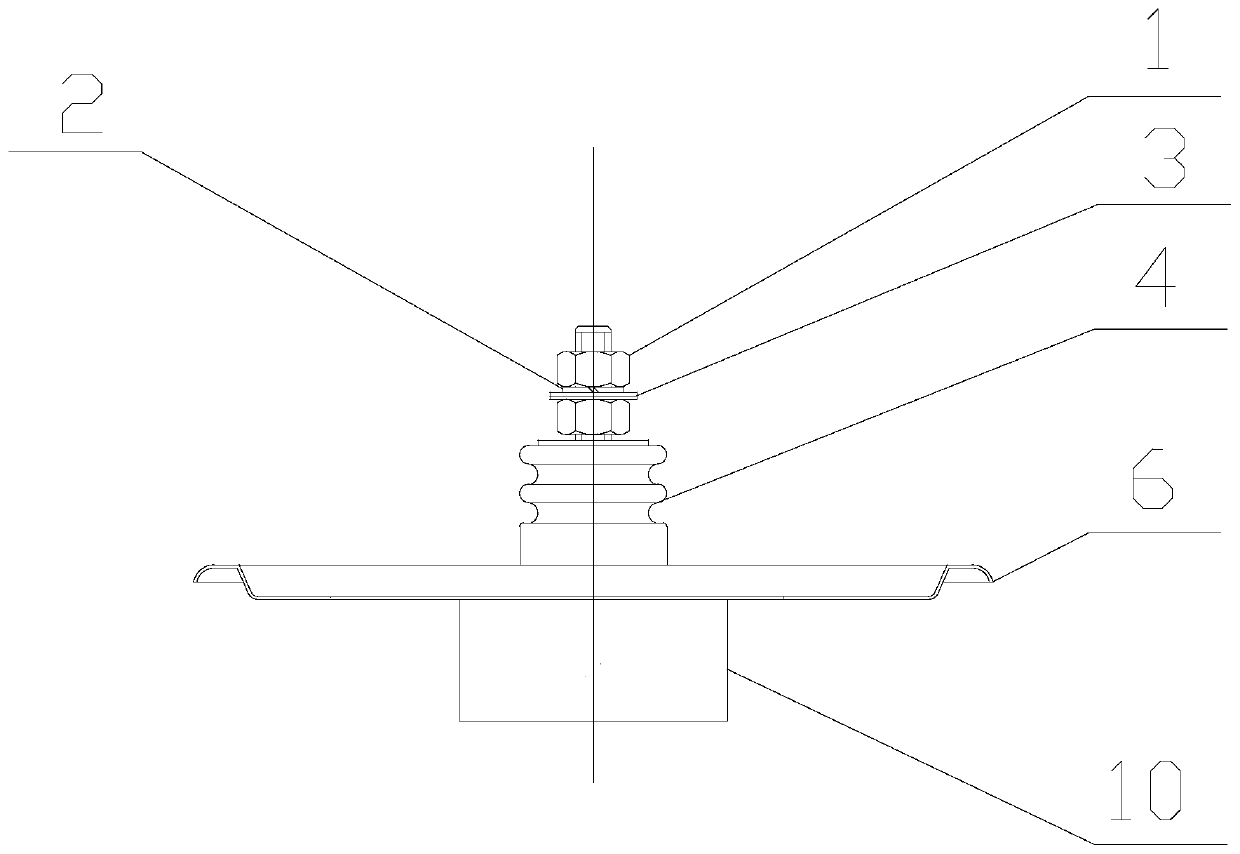

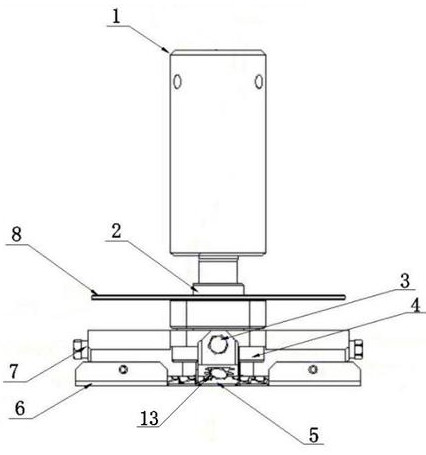

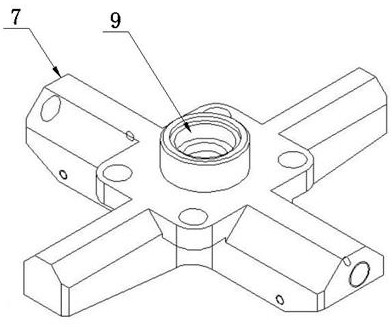

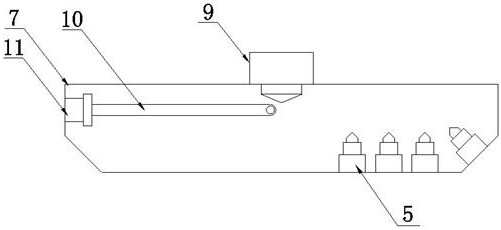

Non-contact ultrasonic thickness gauge with high detection precision

ActiveCN108716899AFlexible structureEliminate rustUsing subsonic/sonic/ultrasonic vibration meansNon-contact ultrasoundEngineering

The invention relates to a non-contact ultrasonic thickness gauge with high detection precision. The non-contact ultrasonic thickness gauge comprises a main unit, a connecting line, a holding rod anda detection box; the detection box is internally provided with a detection mechanism and two polishing mechanisms, each polishing mechanism comprises a side plate, a shrinking plate, a shrinking assembly, a reciprocating assembly, a reciprocating plate and a polishing assembly, each polishing assembly comprises a polishing block, a plurality of springs and two orientation units, each orientation unit comprises an orientation rod and a bump, and the detection mechanism comprises a lifting assembly, a lifting plate, a steering assembly, a steering plate, a probe and a plurality of contact rods.According to the non-contact ultrasonic thickness gauge with the high detection precision, the polishing blocks move back and forth on the surface of a workpiece through the polishing mechanisms, ruston the workpiece is eliminated, the workpiece is restored to be smooth, and the detection is facilitated; moreover, the direction of the probe is adjusted through the detection mechanism so that theprobe can be aligned with the workpiece, the probe is prevented from wear while the detection precision is improved, the service life of the probe is prolonged, and the practicability of the gauge isimproved.

Owner:山东天厚石油科技有限责任公司

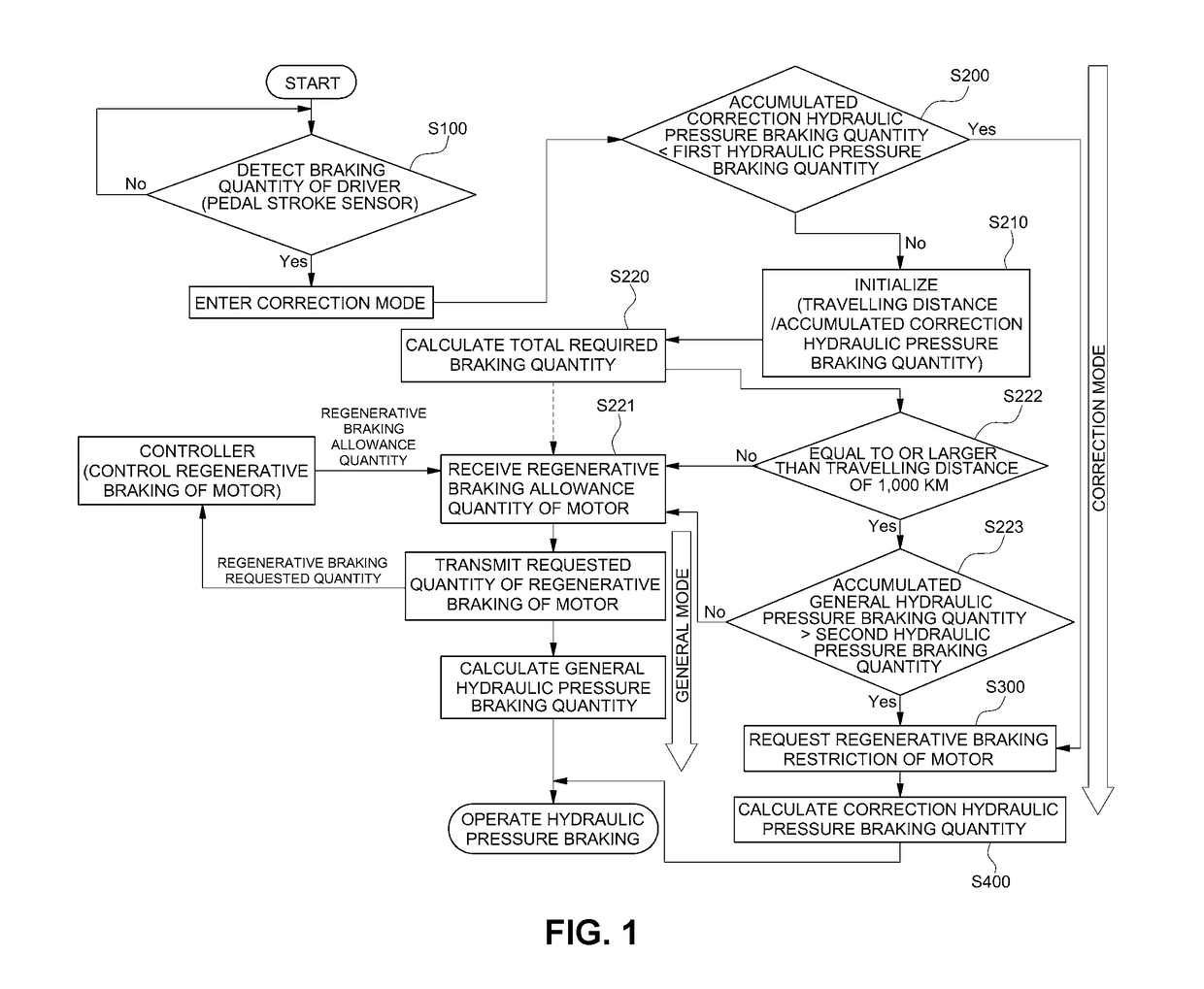

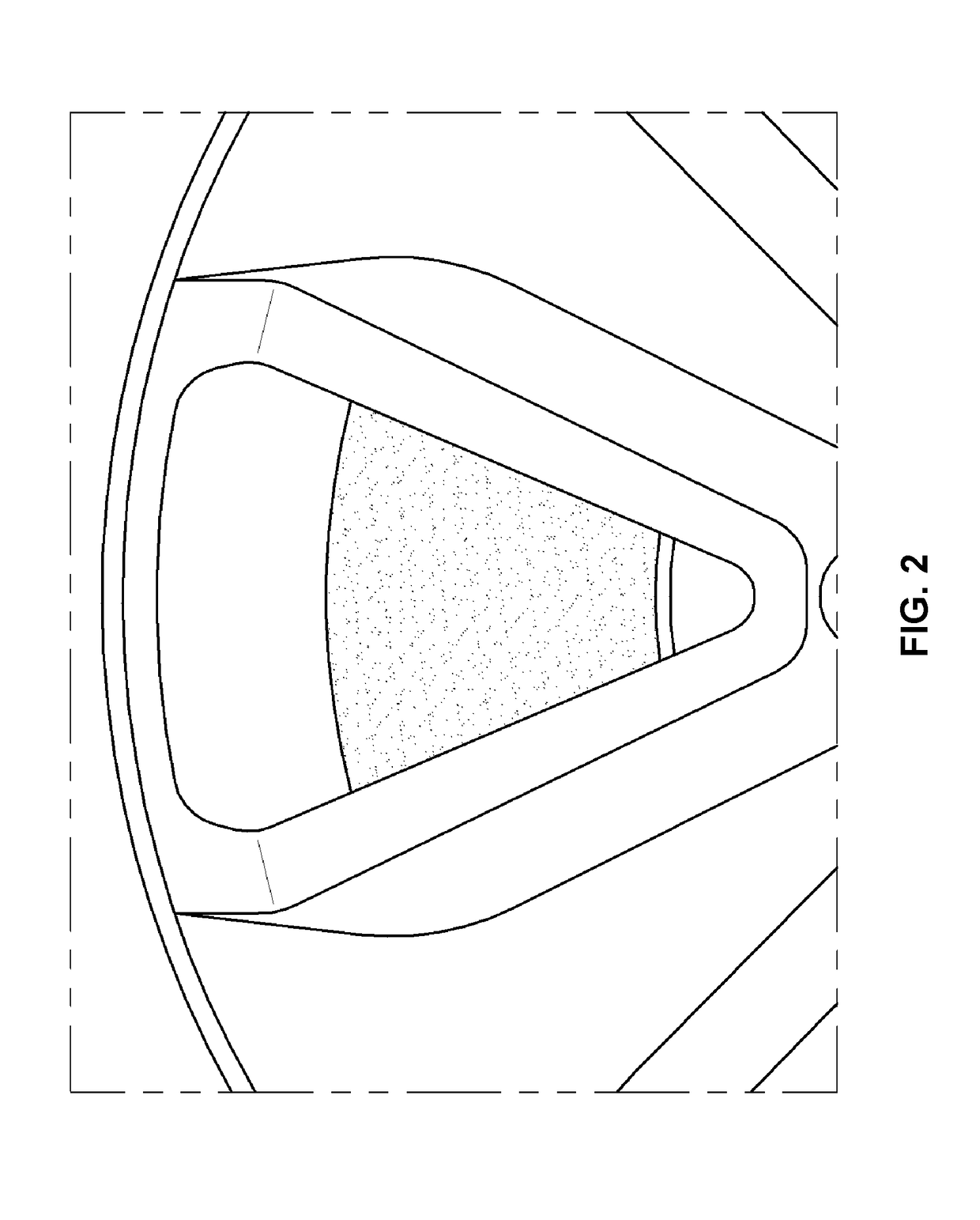

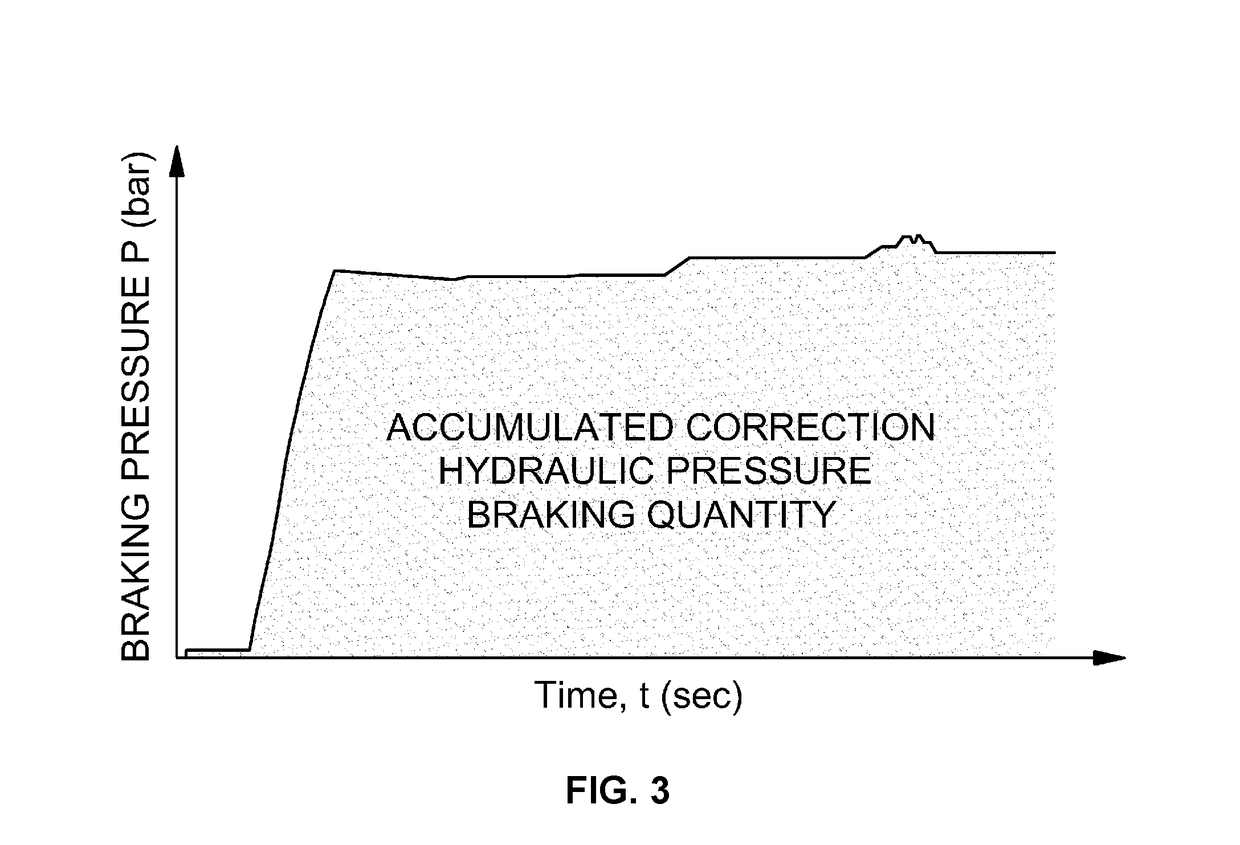

Method of controlling regenerative braking cooperation for electric vehicle

ActiveUS20170259671A1Stable coefficient of frictionEliminate rustSpeed controllerBraking element arrangementsRegenerative brakeElectric vehicle

A method of controlling a regenerative braking cooperation for an electric vehicle may include a entering a correction mode when a braking quantity of a driver is detected by a pedal stroke sensor, a first braking pattern analyzing operation, of comparing an accumulated correction hydraulic pressure braking quantity with a predetermined first hydraulic pressure braking quantity, a regenerative braking restriction requesting operation of, when the accumulated correction hydraulic pressure braking quantity is smaller than the first hydraulic pressure braking quantity, determining, that the driver has a gradual braking-centered braking pattern and transferring a signal for requesting a regenerative braking restriction of a motor to a controller, and a hydraulic pressure braking operation, of determining a correction hydraulic pressure braking quantity based on a braking quantity of the driver input into the stroke sensor in a state where regenerative braking of the motor is restricted, and performing a hydraulic pressure braking.

Owner:HYUNDAI MOTOR CO LTD

Wastewater-free reverse osmosis water purifier control method and water purifier

ActiveCN107265720ARemove sedimentEliminate rustProgramme controlWater/sewage treatment by irradiationReverse osmosisWastewater

The invention discloses a wastewater-free reverse osmosis water purifier control method. A purified water monitoring unit is disposed at a reverse osmosis filter unit water inlet end channel or concentrated water discharge port. The method specifically includes the steps that: when the water purifier is under a purified water making work state, concentrated water returns to a reverse osmosis filter unit water inlet end channel or a pre-filter unit water inlet end channel through a concentrated water backflow channel or to undergo mixing with inflow water for recycling. The technical scheme provided by the invention has the advantage of no wastewater.

Owner:深圳好甘净大健康产业科技有限公司

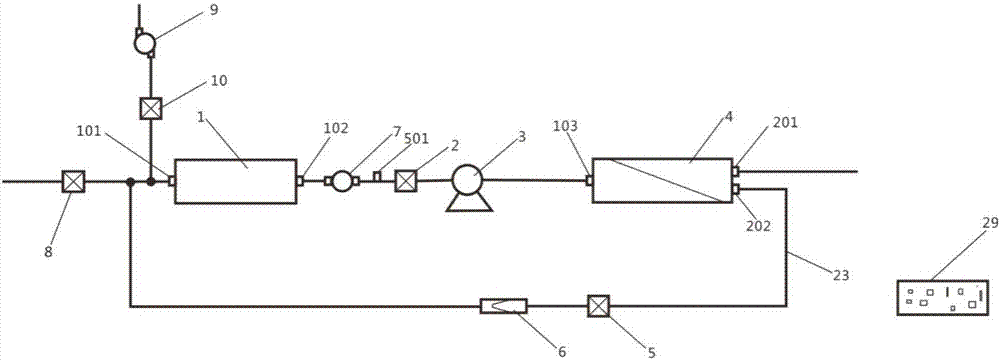

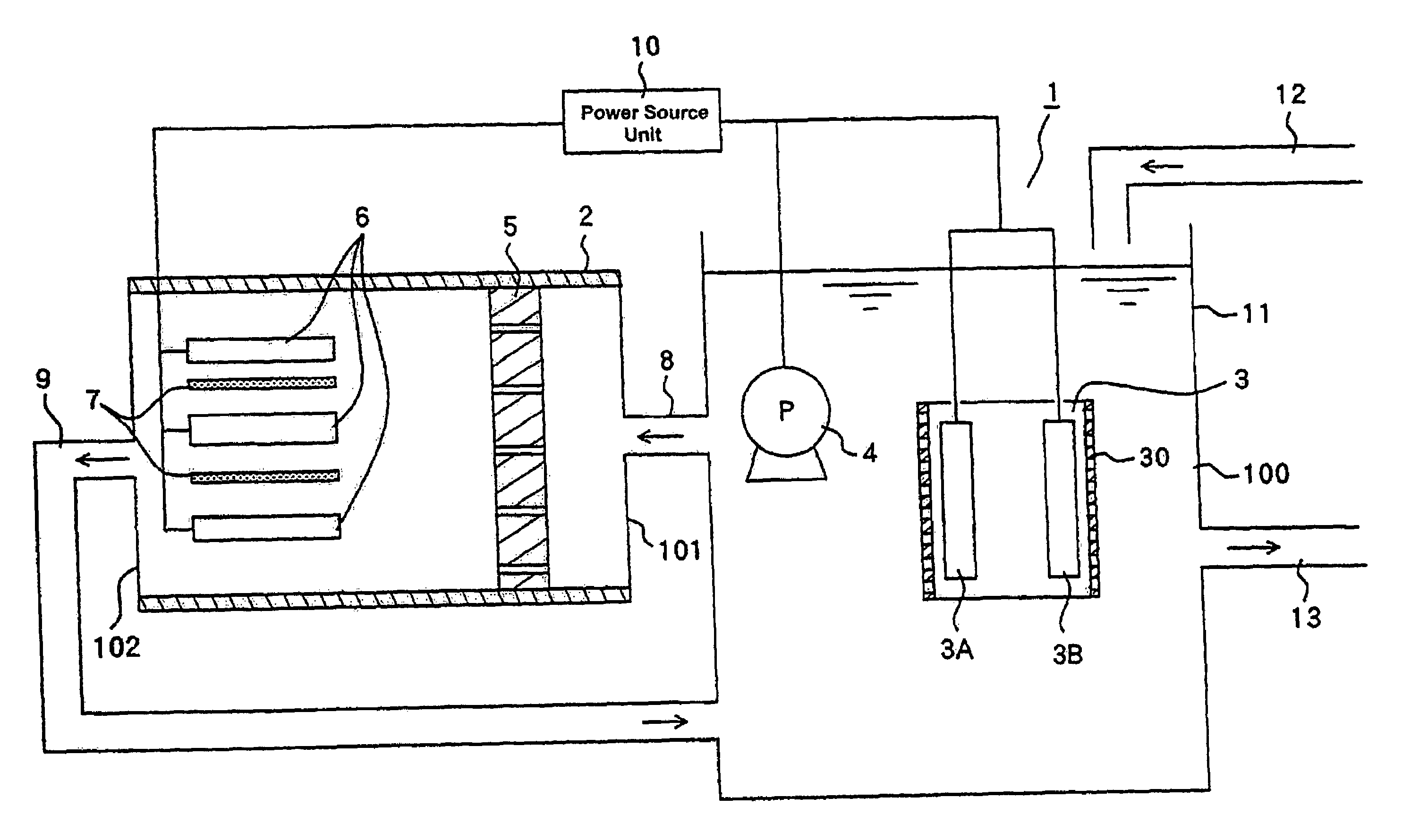

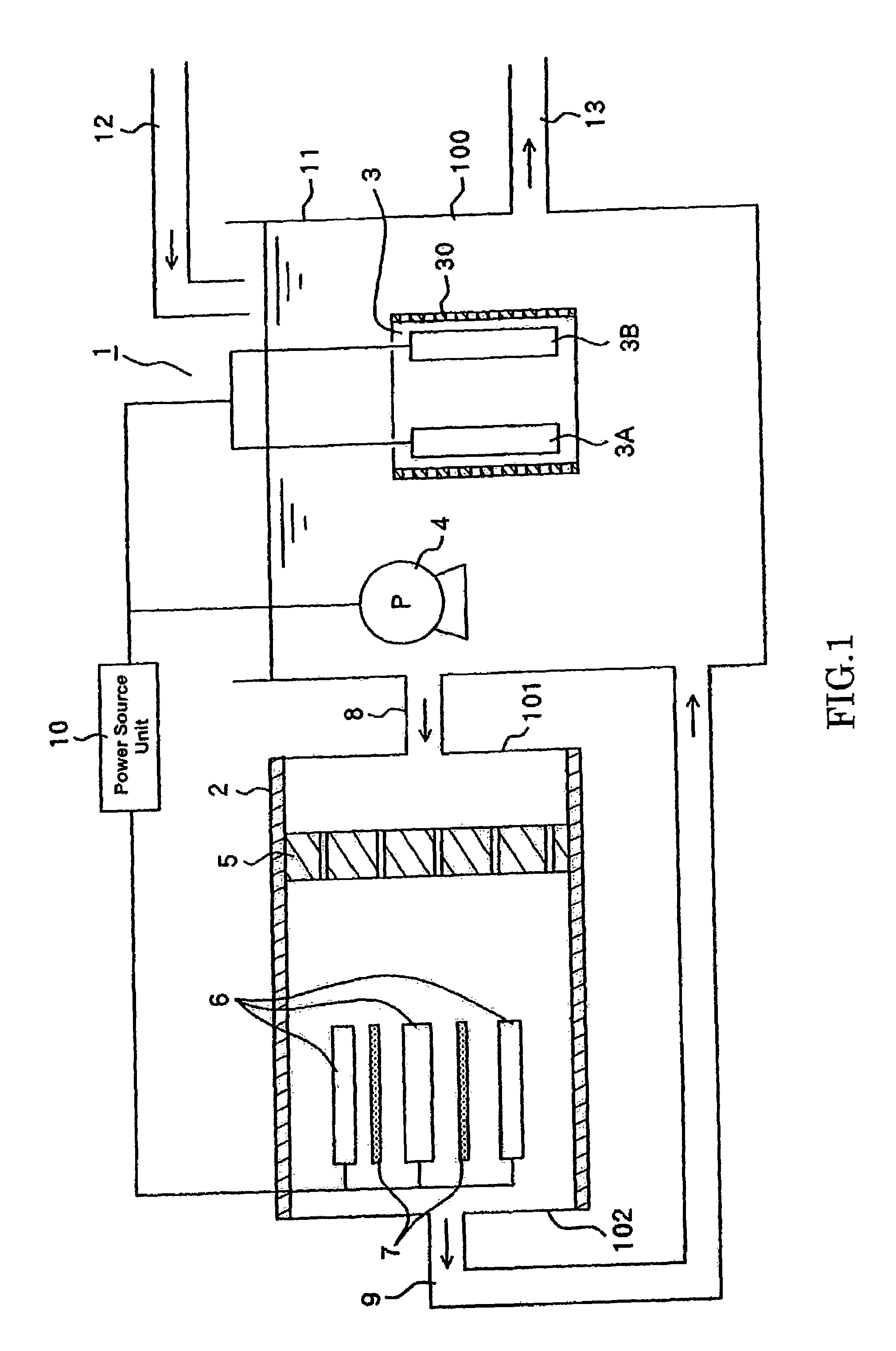

Photocatalyst water treating apparatus

InactiveUS7615195B2Prevents the deposition of scaleAvoid depositionScale removal and water softeningTreatment involving filtrationEnvironmental engineeringWater processing

A photocatalytic water-processing system decomposes organic and inorganic materials present in water. The system includes a reservoir for storing the water to be processed, a main unit formed separately and connected to the reservoir, an inlet pipe for guiding the water from the reservoir to the main unit, an outlet pipe for returning the water to the reservoir, and a pump for guiding the water from the reservoir to the main unit and returning the water. The reservoir has an electrode unit therein for electrolyzing the water so as to flocculate and precipitate the inorganic materials in the reservoir, and a filter is arranged within the main unit. Also, a photocatalytic processing device is arranged within the main unit at a downstream side of the filter for decomposing the organic material in the absence of scale formed of the inorganic materials.

Owner:REIKEN

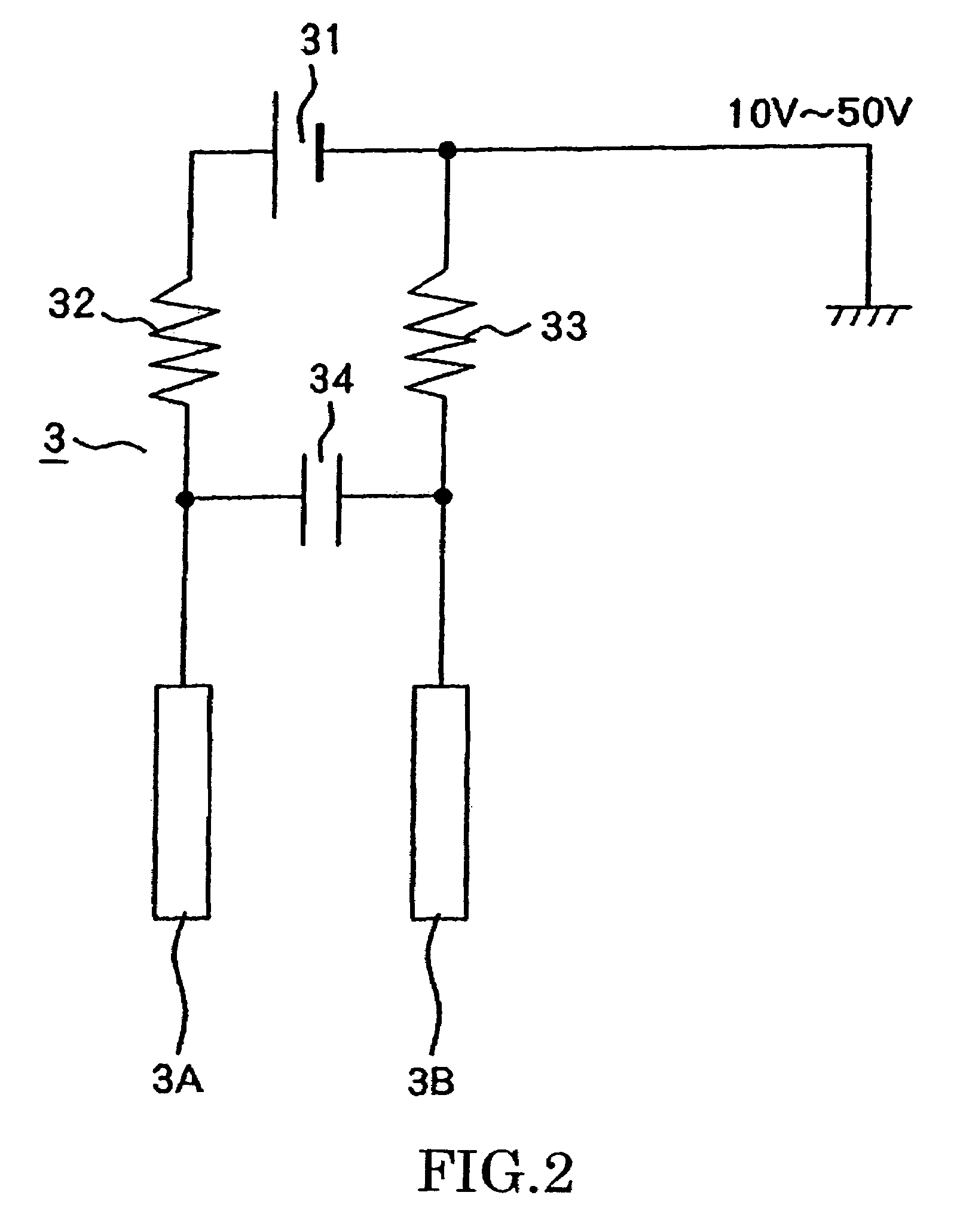

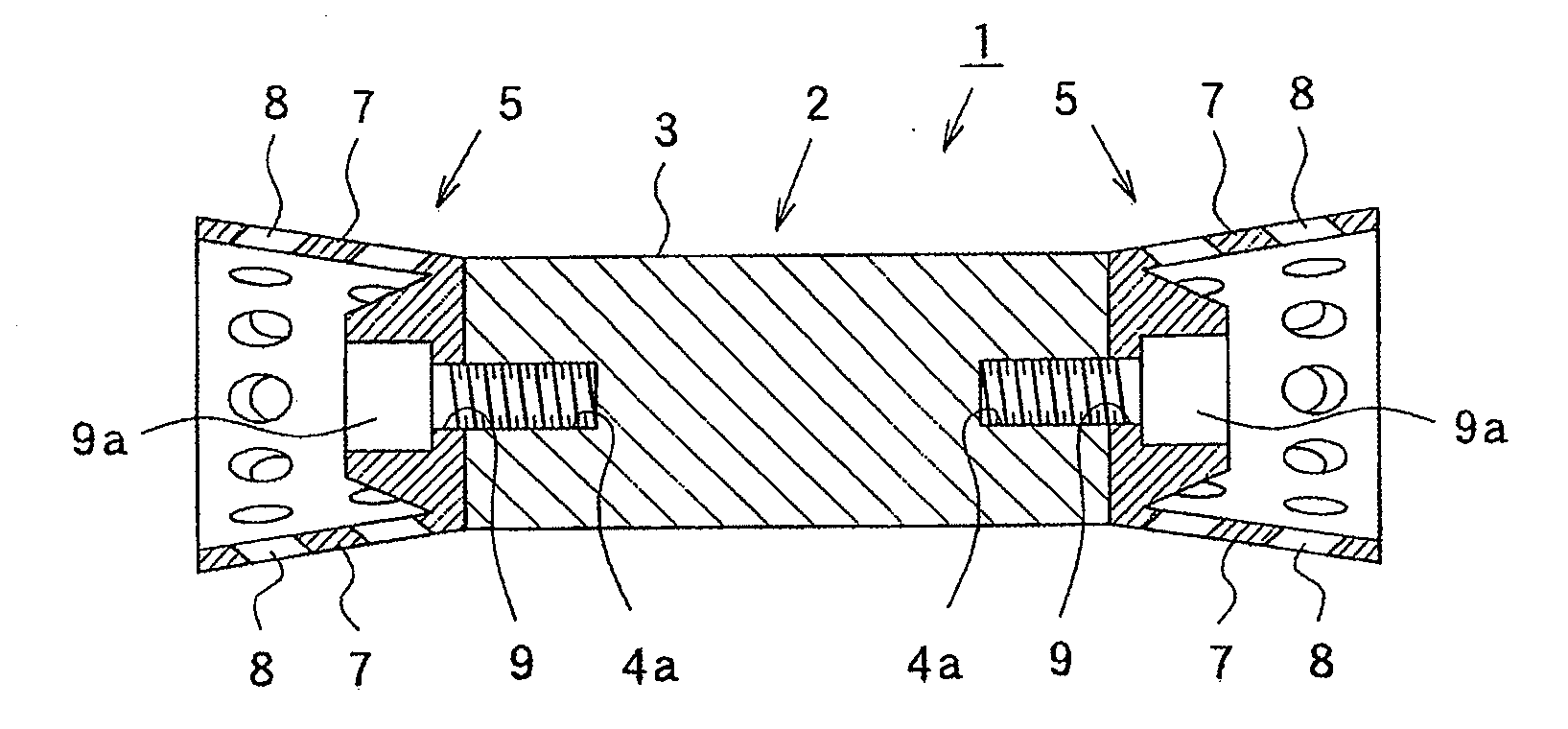

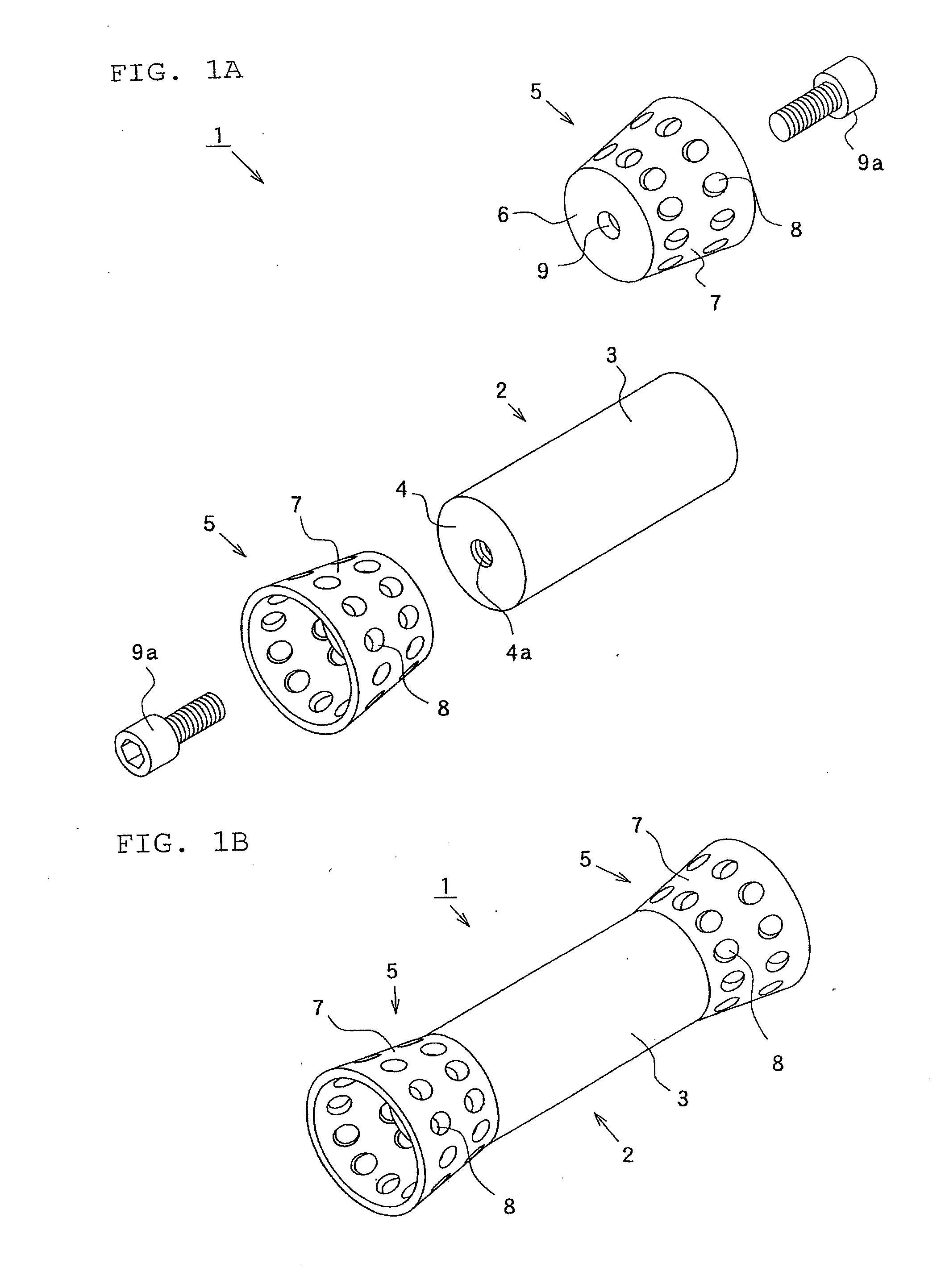

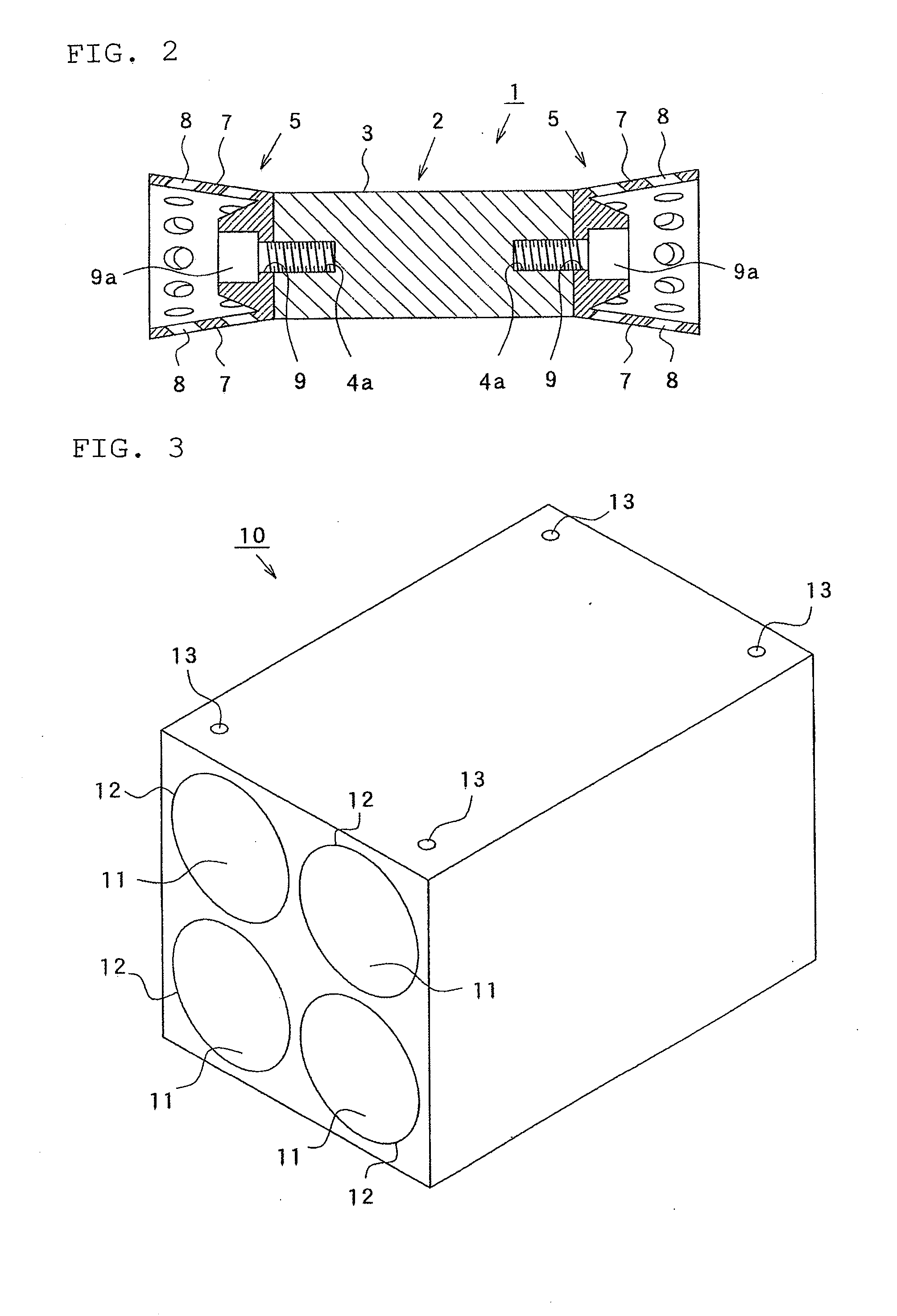

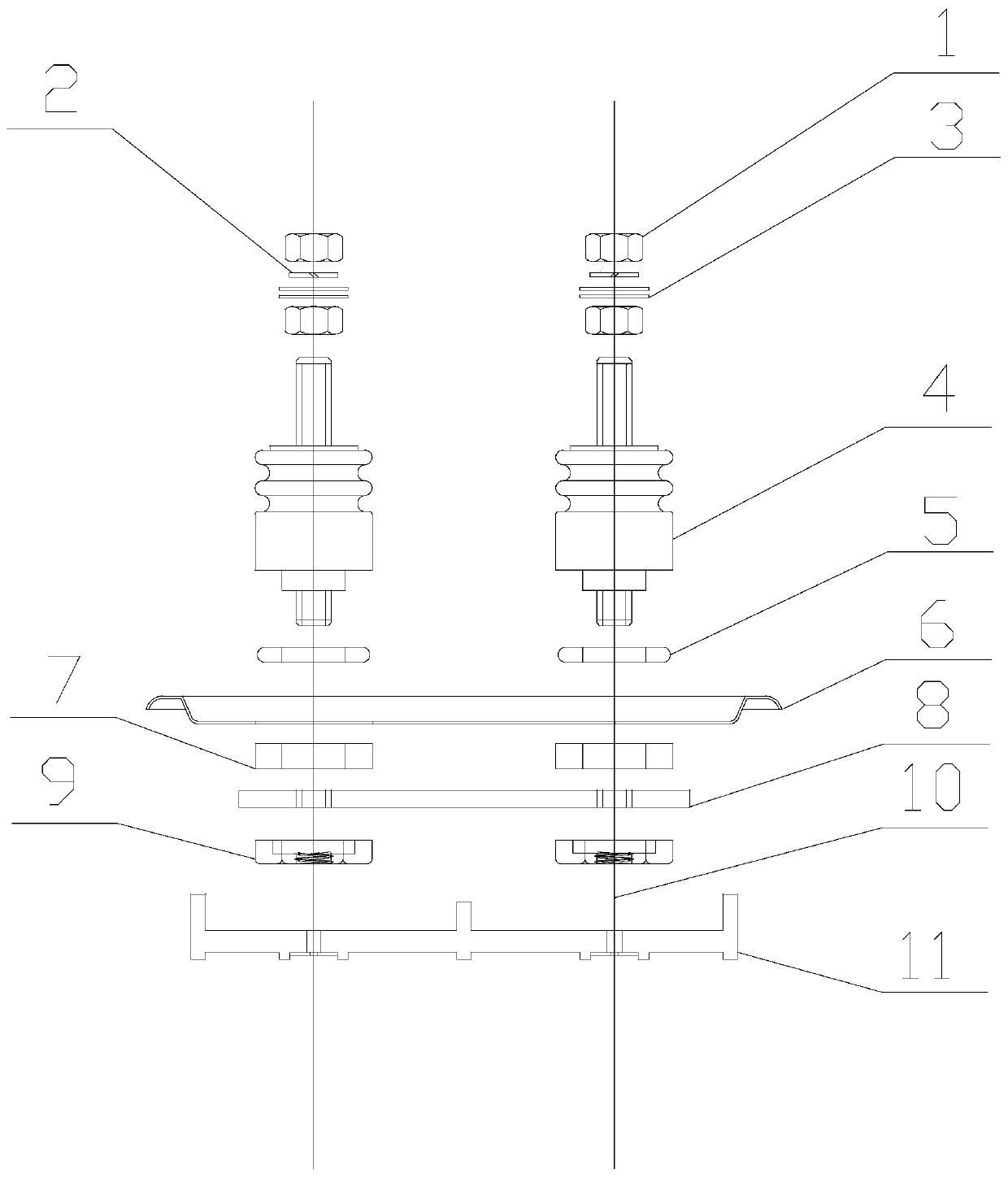

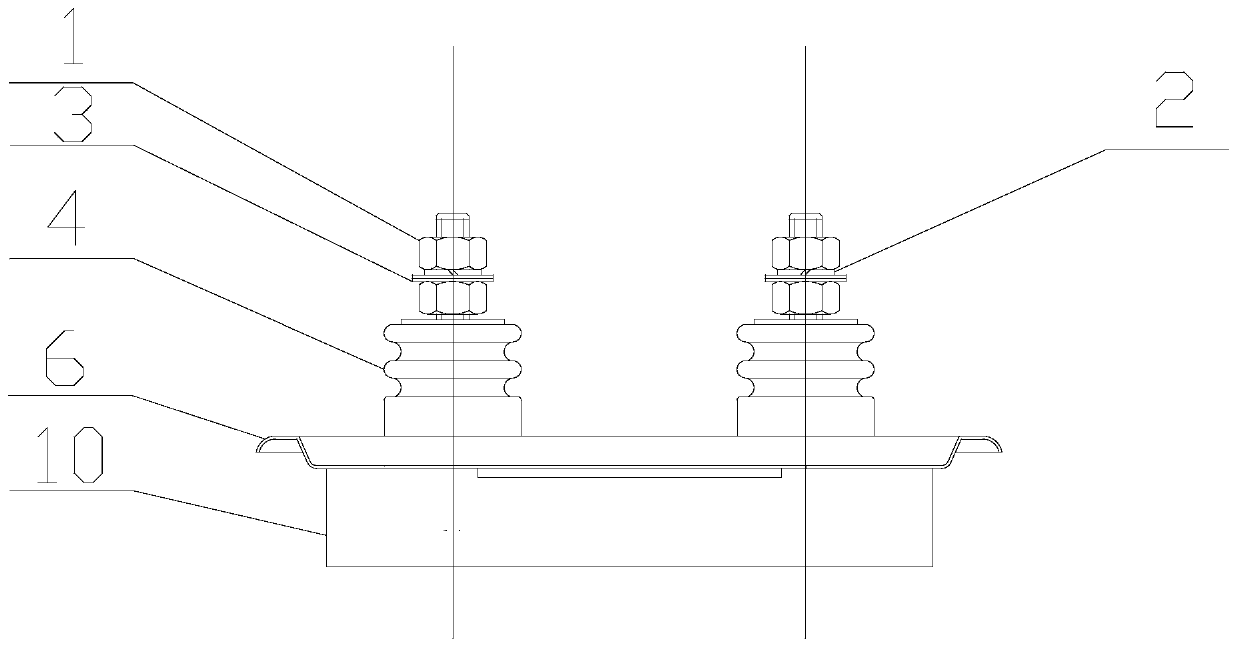

Magnetic field forming device for active water and fluid treatment apparatus using the same

ActiveUS20090261028A1Improve stabilityImprove assembly efficiencySpecific water treatment objectivesWater/sewage treatment by magnetic/electric fieldsEngineeringRust

An object of the present invention is to provide a magnetic field forming device for active water capable of uniformly forming a high magnetic field free from any unevenness in its intensity, activating a fluid regardless of the orientation of magnetic polarity of the magnets, bringing about excellent assembling efficiency not requiring assembling while checking the orientation of the magnets, being manufactured at a high product yield ratio without occurrence of defective products resulting from a difference in the orientation of the magnets, remarkably easily taking out the magnets without use of any exclusive special tool, and removing rust and stains adhered to the magnets by wiping off the magnets one by one, the maintenance efficiency of which is excellent. The magnetic field forming device for active water in which a flow path of a fluid is formed in a through hole, and the same magnetic field forming device includes a rod-shaped magnet 2 disposed with predetermined spacing from the inner wall of the through hole and having a fluid flow path formed between the inner wall and the side 3; a guide member 5 adhered to and fixed to the end part of the magnet 2, which is inserted into the interior of the through hole; and a communication portion 8 formed at the guide member 5, which communicates with the fluid flow path.

Owner:TOKO KABUSHIKI KAISHA

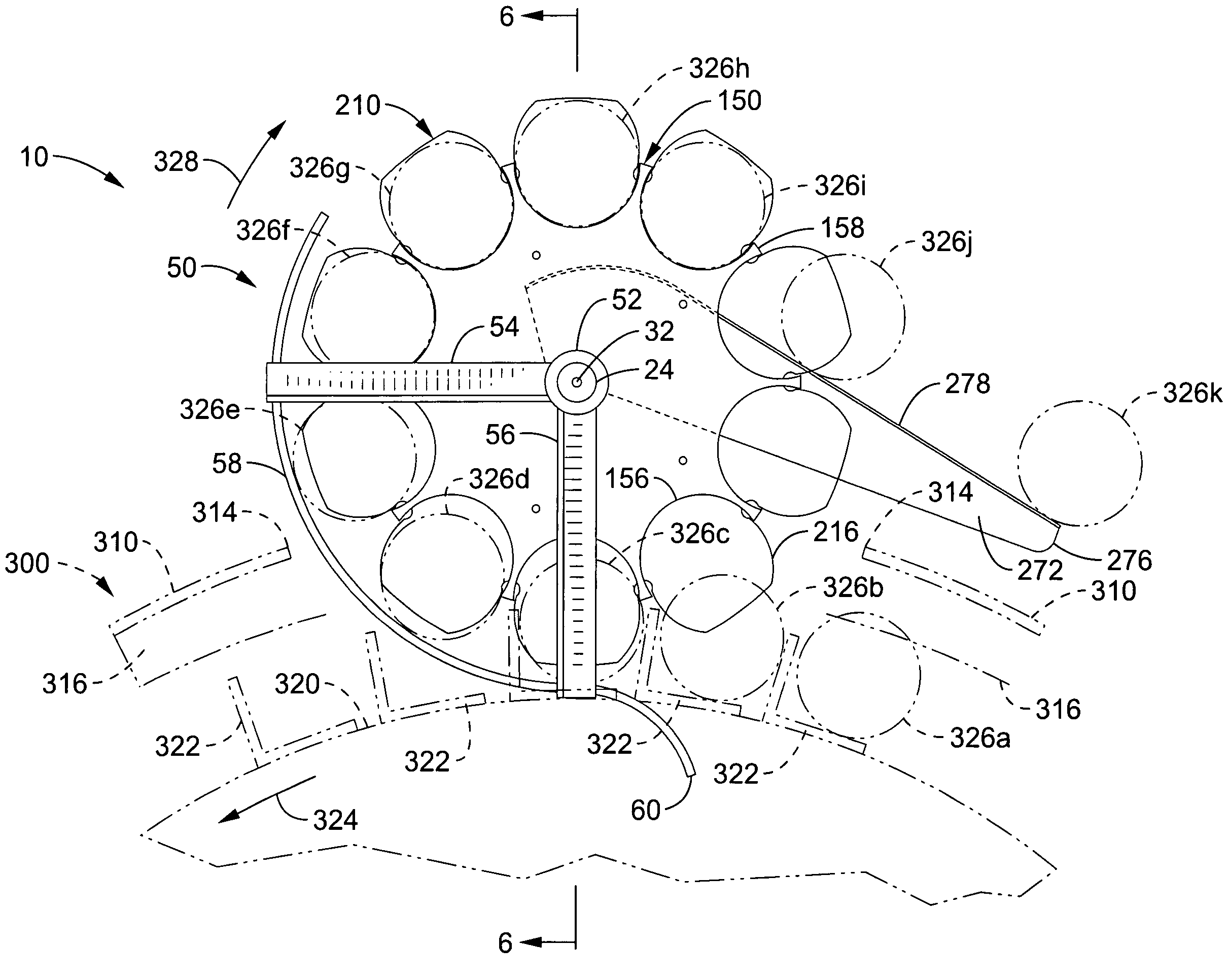

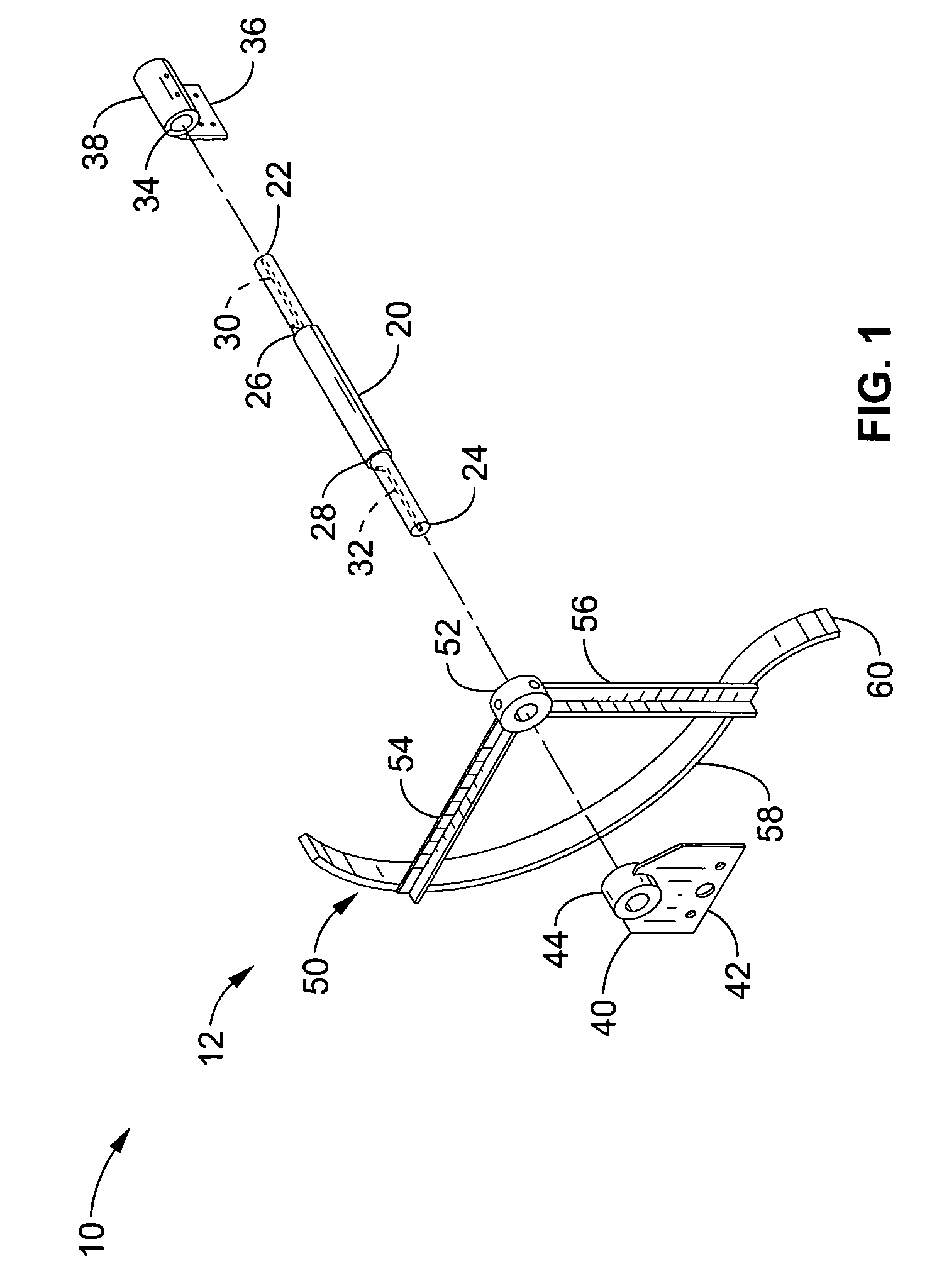

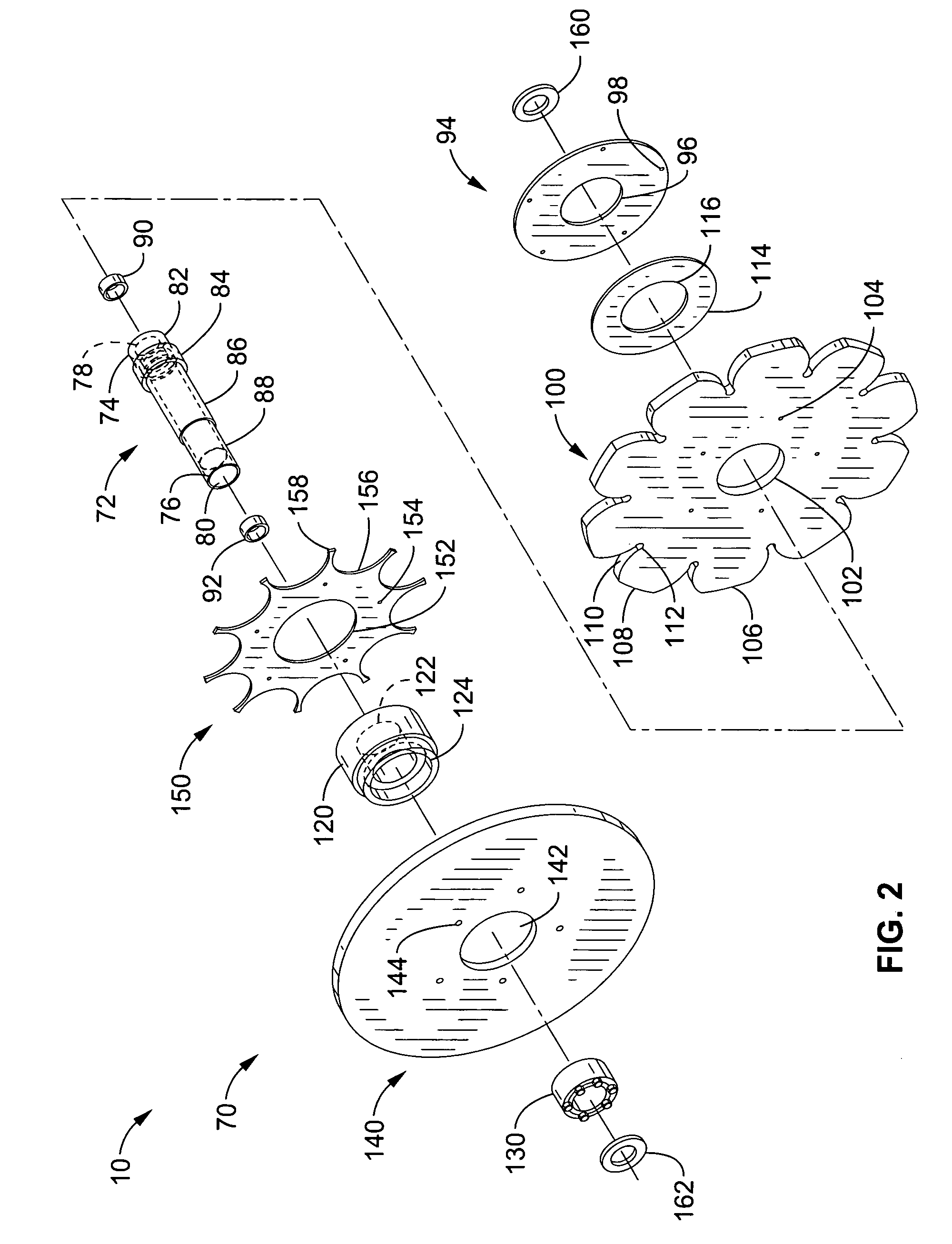

Can extractor apparatus

ActiveUS7284656B1Eliminate transferReduce scratchesFood preservationLavatory sanitoryEngineeringScratching

A can extractor for atmospheric rotary cookers and coolers has a clover wheel, a star wheel and a star wheel flange made of stainless steel. The clover wheel and star wheel are aligned and coupled to a sleeve rotating on a stationary shaft. The star wheel is coupled to the sleeve using an adjustable keyless hub / shaft locking device. The clover wheel and star wheel are spaced to accommodate bulging or deformed cans. A center discharge chute is supported on the rotating sleeve with a plastic bushing. Cans from the reel of a cooker / cooler are positioned with a can stripper between the star wheel and clover wheel while the reel rotates the clover wheel. The stainless steel components reduce scratching and eliminate transfer of rust to cans. A plastic clover wheel and a plastic star wheel flange are disclosed that do not scratch or transfer rust to the cans.

Owner:ALLIED MACHINE

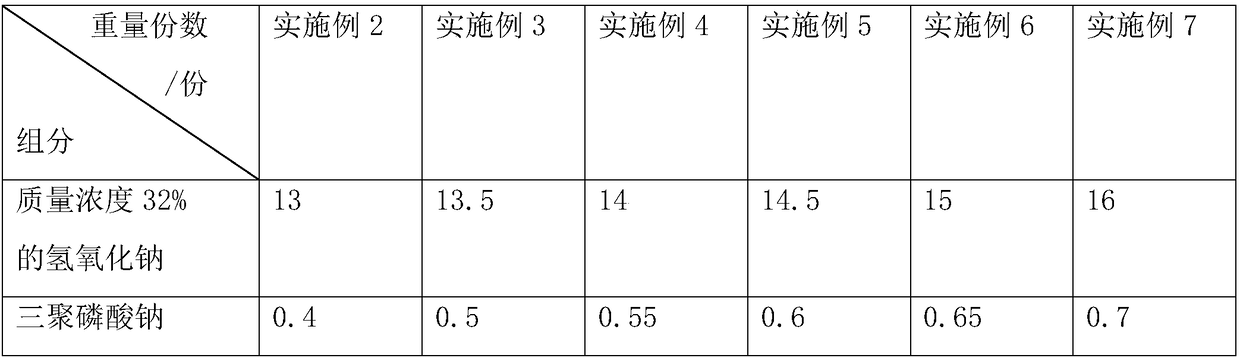

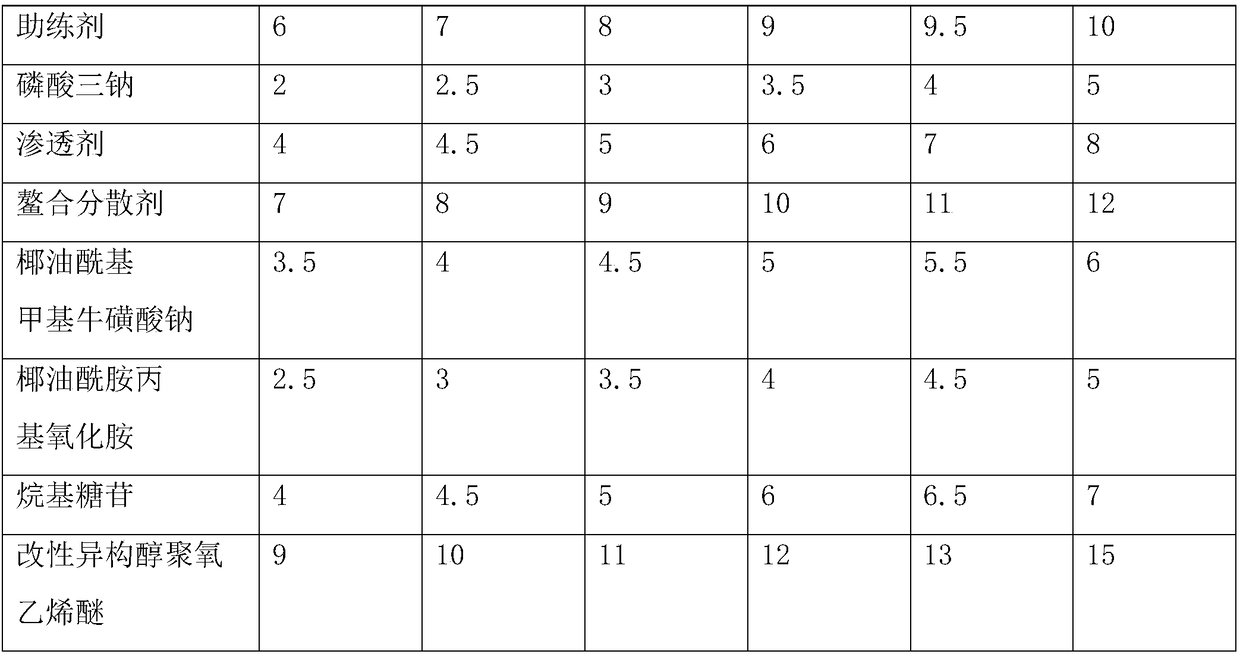

Refining desizing process for chemical fiber fabric

The invention discloses a refining desizing process for a chemical fiber fabric, and relates to the technical field of textile printing and dyeing pretreatment, and the refining desizing process comprises the following steps: (1) pre-shrinking; (2) refining, wherein a refining liquid is composed of the components, by weight, of 12-16 parts of sodium hydroxide with the mass concentration of 32%, 0.3-0.7 part of sodium tripolyphosphate, 5-10 parts of a refining aid, 1-5 parts of trisodium phosphate, 3-8 parts of a penetrating agent, 6-12 parts of a chelating dispersant, 3-6 parts of sodium cocoyl methyl taurate, 2-5 parts of cocamidopropyl amine oxide, 3-7 parts of alkyl glycoside and 8-15 parts of isomeric alcohol polyoxyethylene ether; wherein the grinding aid comprises the components of sodium hydrogen sulfite, sodium silicate and alkyl sulfate in a mass ratio of 2: 3: 3; (3) water washing; (4) steaming; (5) enzyme water washing; and (6) shaping. According to the invention, the problems that the desizing effect of the chemical fiber fabric is poor, and the dye uptake and the dyeing uniformity are poor are solved; a refining agent is used for refining and desizing the chemical fiber fabric, the desizing rate is high, and the dye uptake and the leveling property are good.

Owner:嘉兴市嘉盛印染有限公司

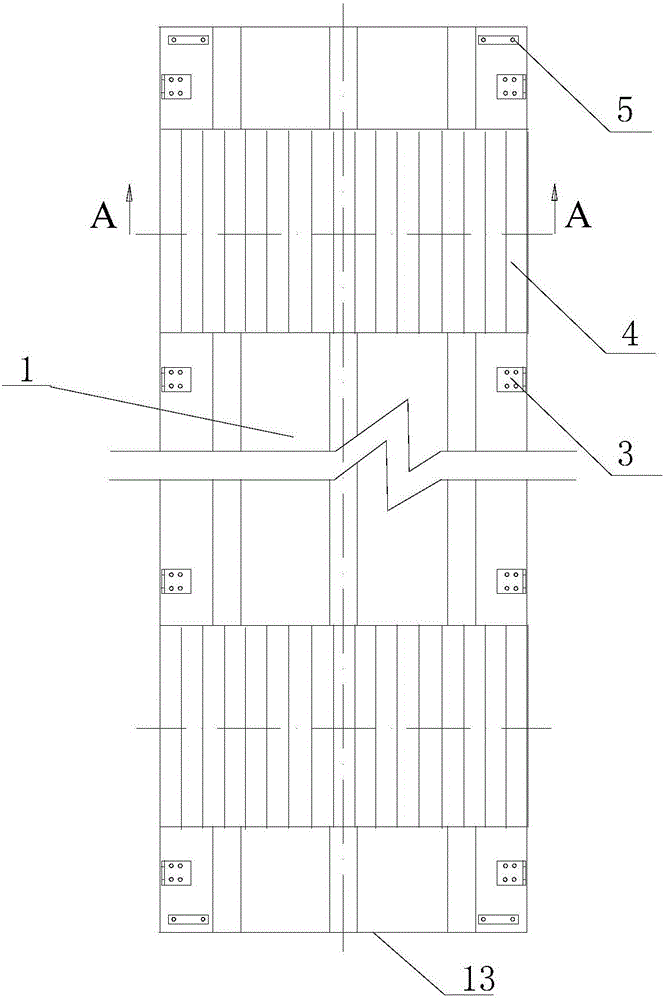

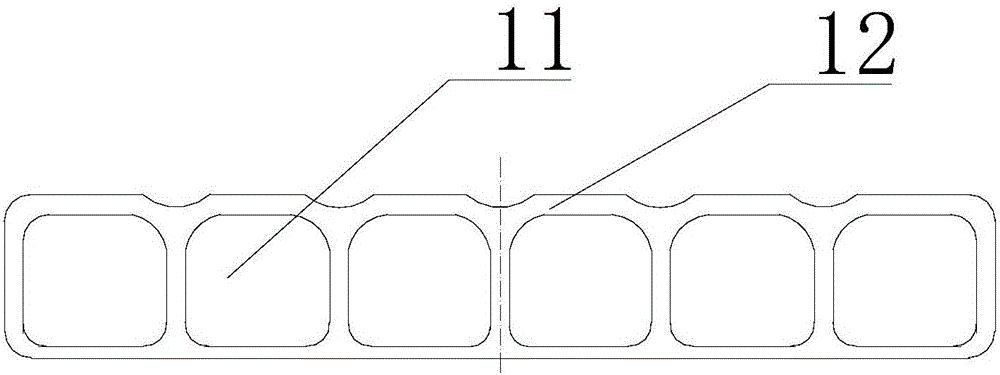

Rapidly paved road

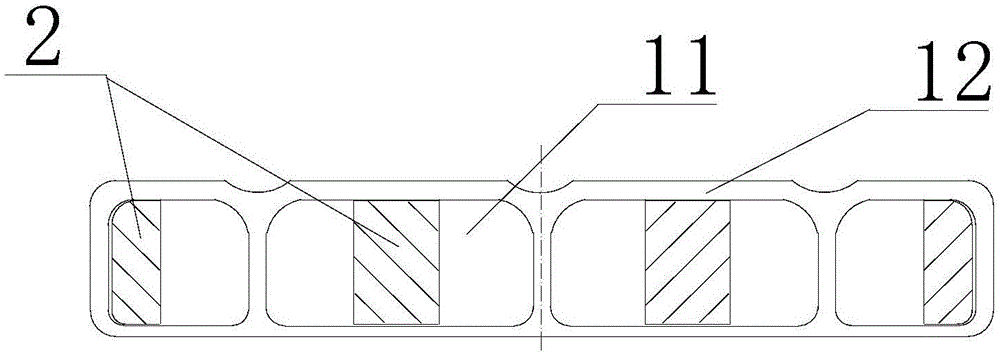

InactiveCN106284018ALight weightEasy to operateSingle unit pavingsTemporary pavingsGlass fiberRoad surface

The invention discloses a rapidly paved road which is formed by movably connecting a plurality of rectangular hollow road slab units (1) along the width direction in a foldable manner through connectors (4) among the units. A plurality of closed cavities (11) are formed in the hollow pavement road units (1) and integrally formed by glass fiber reinforced composite materials along the length direction of the units. The rapidly paved road is light in dead weight, rapid and convenient to operate, high in loading efficiency and free from rust.

Owner:PLA UNIV OF SCI & TECH

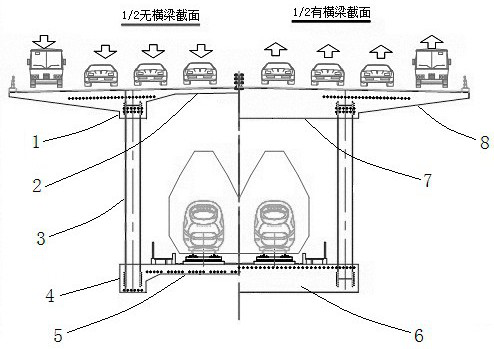

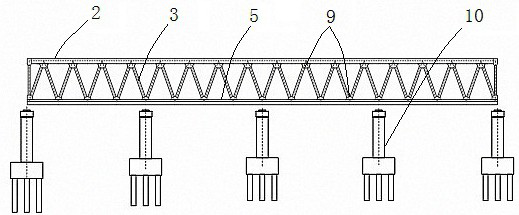

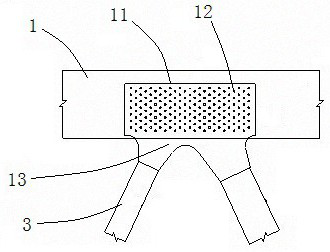

Highway-railway combined construction steel web member double-combination continuous trussed beam and construction method thereof

PendingCN111962372ALow costImprove structural rigidityTruss-type bridgeBridge structural detailsGusset plateArchitectural engineering

The invention provides a highway-railway combined construction steel web member double-combination continuous trussed beam. The highway-railway combined construction steel web member double-combination continuous trussed beam comprises an upper-layer highway concrete bridge deck slab, a lower-layer railway concrete bridge deck slab and steel web members. Upper-layer highway concrete longitudinal beams are arranged on the two sides of the upper-layer highway concrete bridge deck slab in the transverse direction of a bridge, lower-layer railway concrete longitudinal beams are arranged on the twosides of the lower-layer railway concrete bridge deck slab in the transverse direction of the bridge, and the upper ends and the lower ends of the steel web members are connected with the upper-layerhighway concrete longitudinal beams and the lower-layer railway concrete longitudinal beams on the same side through gusset plates. In addition, the invention further provides a construction method of the bridge. According to the highway-railway combined construction steel web member double-combination continuous trussed beam, a double-combination structural form that the steel web members are combined with the upper-layer bridge deck and the lower-layer bridge deck is adopted; the bridge is clear in stress, high in rigidity, high in integrity, small in maintenance workload, good in economical efficiency, capable of optimizing structural stress and engineering design, capable of being widely applied to highway-railway combined construction bridges of high-speed railways, attractive in structure and high in competitiveness, and the material performance of steel and concrete is fully utilized.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

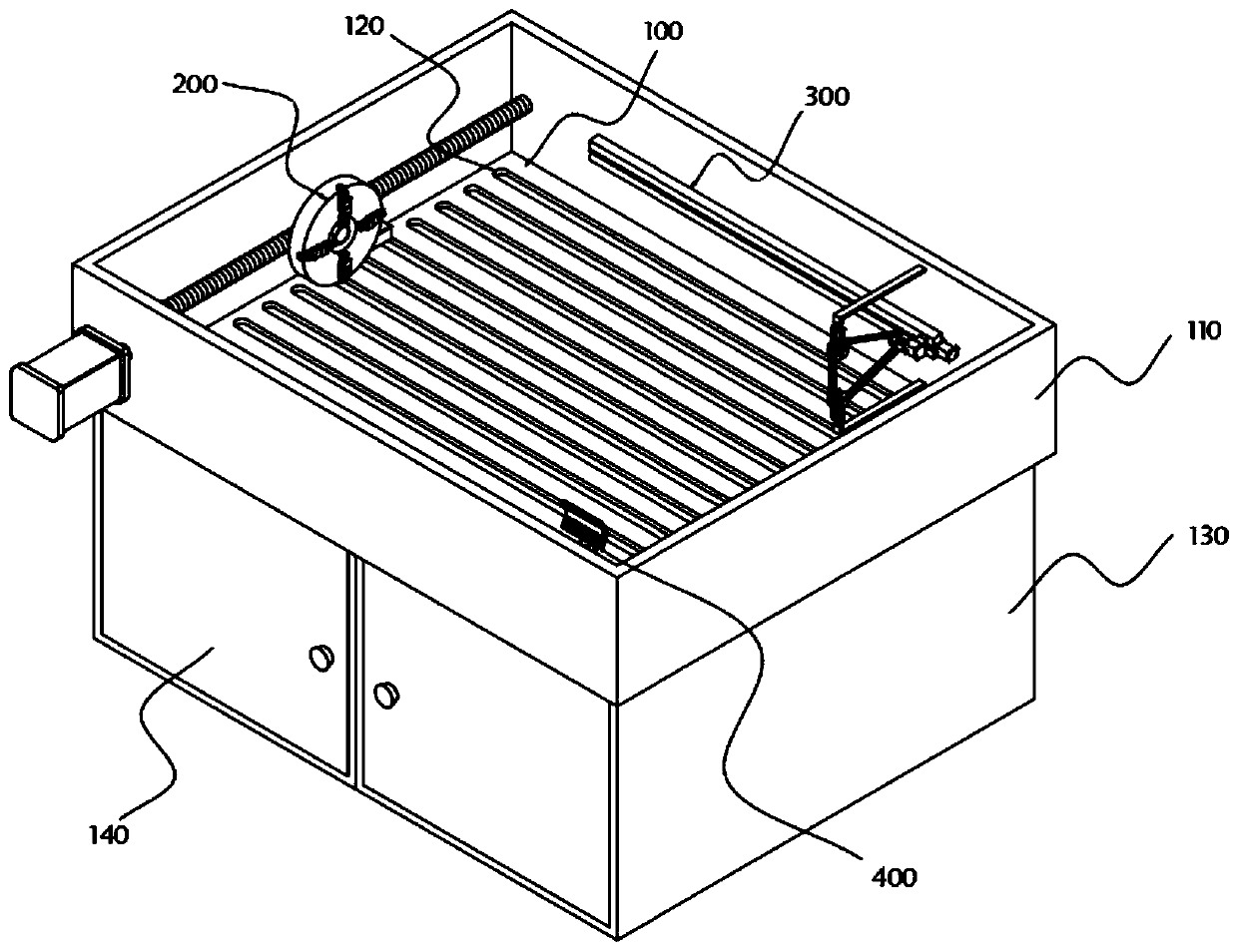

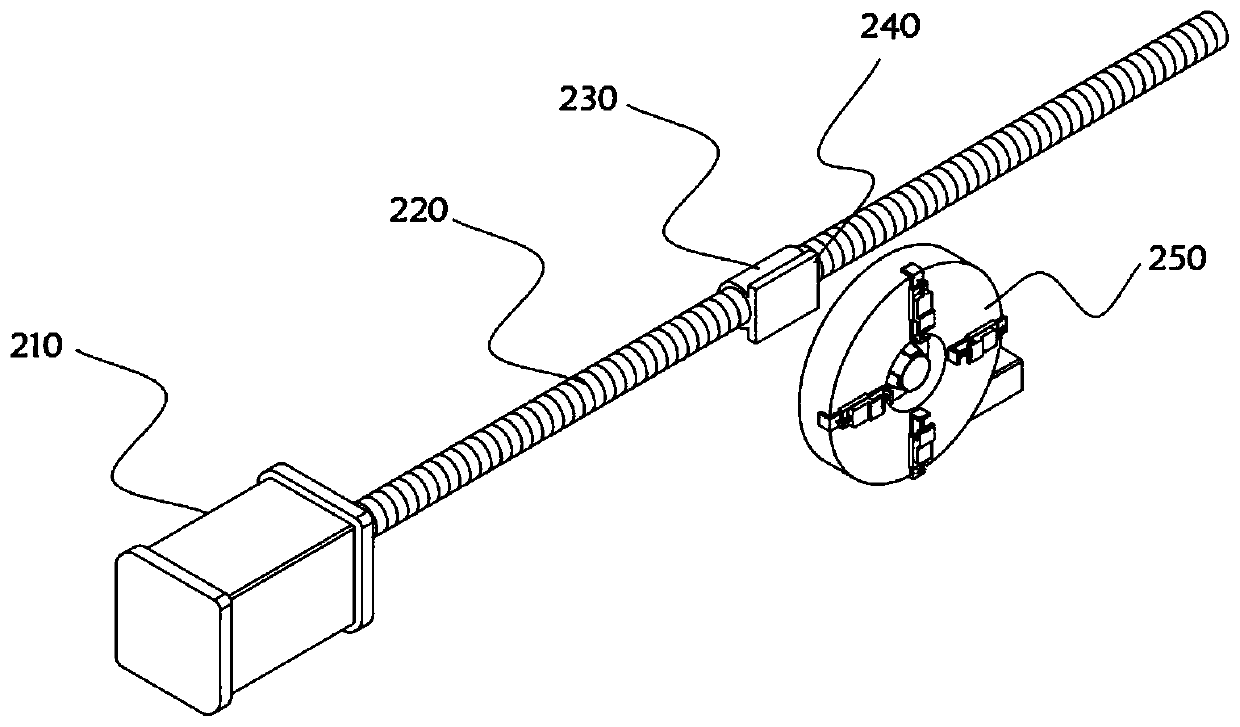

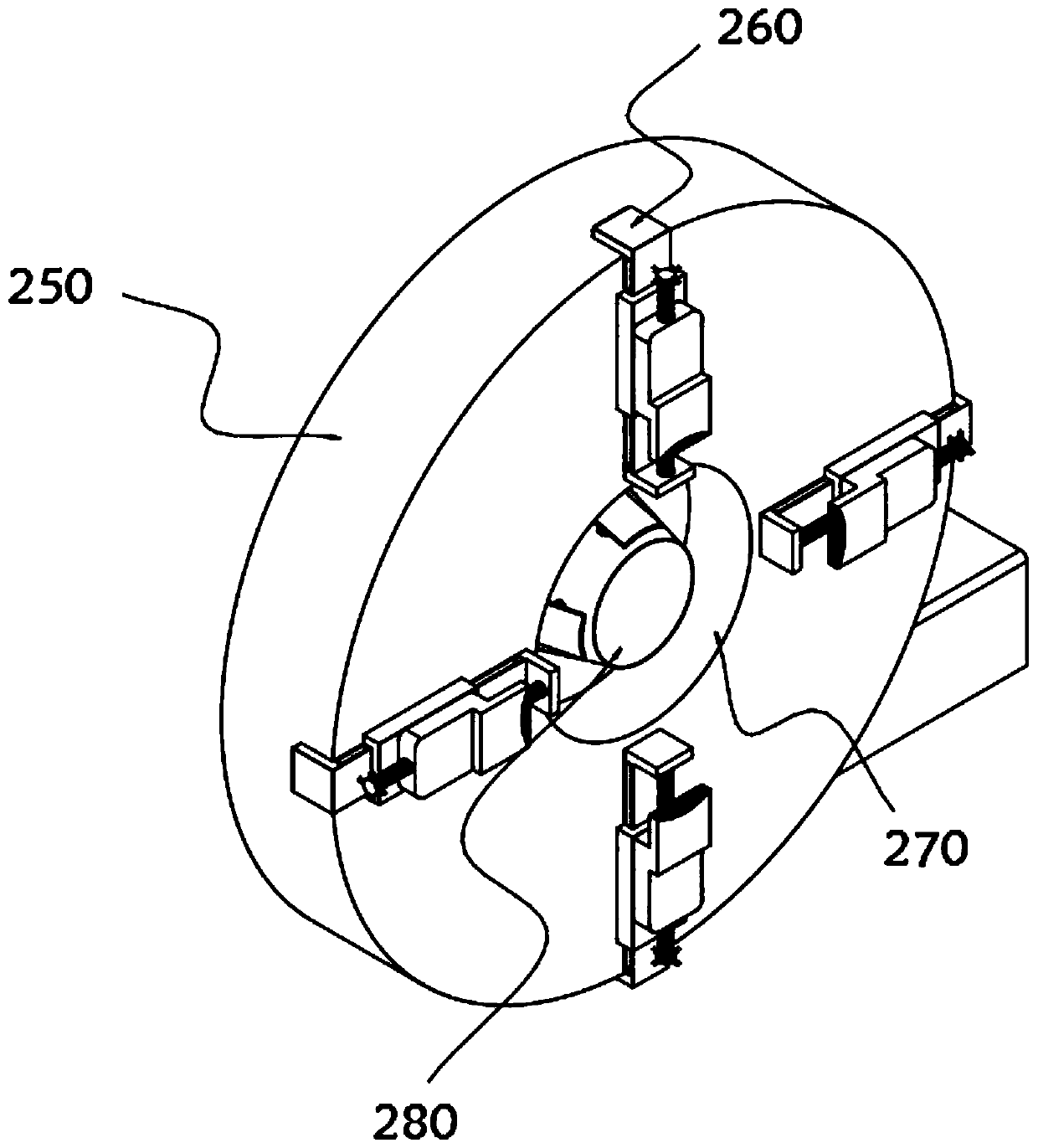

Rounding method of continuously processing metal round tube based on multiple stations

InactiveCN111571327AGuaranteed cleanlinessRealize positioning and clampingRevolution surface grinding machinesGrinding drivesPolishingMachining

The invention relates to the technical field of metal round tube machining, in particular to a rounding method of continuously processing a metal round tube based on multiple stations. The method comprises the steps of a stage of positioning the metal round tube, a stage of polishing the metal round tube, and a stage of rounding the metal round tube. The method also comprises the steps that a metal round tube clamping part is used to clamp the metal round tube, a metal round tube polishing part is used to polish the external wall of the metal round tube, and a metal round tube rounding part isused to round the metal round tube. According to the design of the method, the external wall and the internal wall of the metal round tube can be positioned, the metal round tube is prevented from skewing when operated, and meanwhile stains and rusts on the surface of the metal round tube are removed. The polishing of the external wall of the metal round tube and the all-round rounding can be achieved, and generated sundries can be uniformly recycled.

Owner:六安逸风羽信息科技有限公司

Bracket type carrier cable holder

The invention discloses a bracket type carrier cable holder. The bracket type carrier cable holder comprises a base fixed to a flat cantilever and a saddle type support on the base. The base is formed by a semicircular main hoop and a semicircular auxiliary hoop. The semicircular main hoop and the semicircular auxiliary hoop are combined into a circle which tightly holds the round tubular flat cantilever needing to be installed. A jack seat is arranged on the main hoop, and the saddle type support is inserted in the jack seat. According to the carrier cable holder made of aluminum alloy sections, the size and the weight of the holder are reduced, the production and manufacturing process of the main hoop and the auxiliary hoop is greatly simplified, and the production efficiency is improved; and meanwhile, the problem that the holder is eroded with rainwater and gets rusty is thoroughly solved.

Owner:中法高速铁路技术(西安)有限公司

Magnetic suspension collecting and blow-drying device and application thereof on magnetic particle inspection equipment

InactiveCN102778502AAvoid dryingQuick and timely dryingMaterial magnetic variablesSolenoid valveEngineering

The invention discloses a magnetic suspension collecting and blow-drying device and application thereof on magnetic particle inspection equipment. The device comprises a stand, wherein a box body is arranged on the stand, an annular gas ejector pipe is arranged in the box body, and the center level of the annular gas ejector pipe is the same as the center level of travelling of the magnetic particle inspection steel; the annular gas ejector pipe is connected with a gas source through a solenoid valve; and a recovery pipe for collecting magnetic suspension is arranged at the bottom of the box body. The device ensures effective collection of the residual magnetic suspension on a surface and drying treatment of the surface in the magnetic particle inspection process of steel products. The device can greatly lower the cost of magnetic particle inspection, reduce environmental pollution and be more favorable to improvement of the appearance quality of a high-grade inspected product. The device is suitable for on-line automatic magnetic particle inspection of steel products, especially for application on magnetic particle inspection equipment of steel bars and steel pipes.

Owner:NANJING IRON & STEEL CO LTD

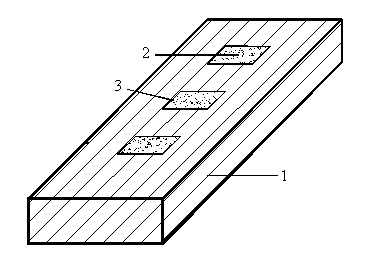

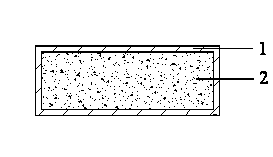

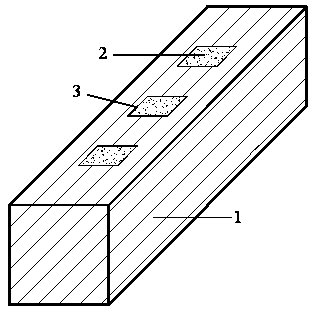

Combined FRP(Fiber Reinforced Plastic)-self prestressed concrete structure

ActiveCN102704623AEliminate rustDelay and reduce crackingStrutsSingle unit pavingsPre stressRoad surface

The invention discloses a combined FRP(Fiber Reinforced Plastic)-self prestressed concrete structure, which comprises an FRP template and self prestressed concrete, wherein the self prestressed concrete is poured in through reserved openings formed at the upper part of the FRP template, is positioned between the FRP template, and is wrapped in a totally-enclosed manner. The combined FRP-self prestressed concrete structure fully utilizes and optimally combines the tensile property and the corrosion prevention performance of FRP material as well as the expansibility and the compression resistance of the self prestressed concrete, saves the connection of the FRP material and the self prestressed concrete through totally-enclosed sheathing, and achieves the self prestressed function without bar reinforcements; in addition, the combined FRP-self prestressed concrete structure achieves favorable self prestressed performance and corrosion resistance, has the advantages of delaying and reducing concrete cracking, being simple and convenient to construct and the like, and is especially suitable for structures of newly-built bridges, road surfaces, buildings and the like.

Owner:DALIAN UNIV OF TECH

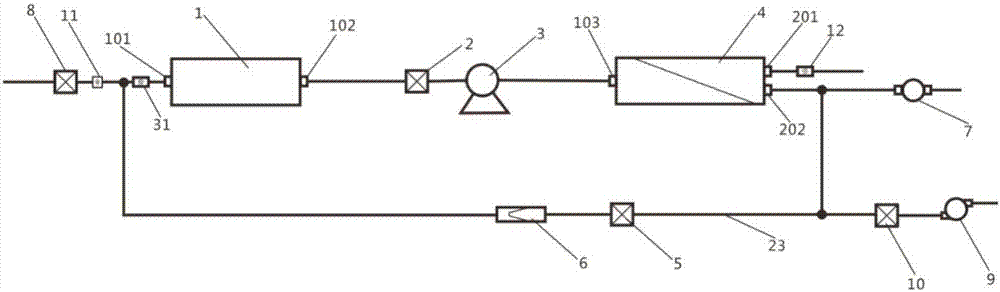

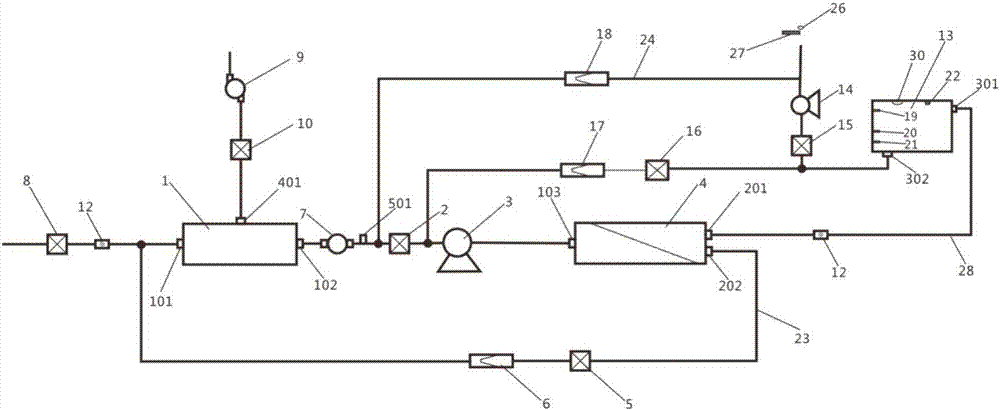

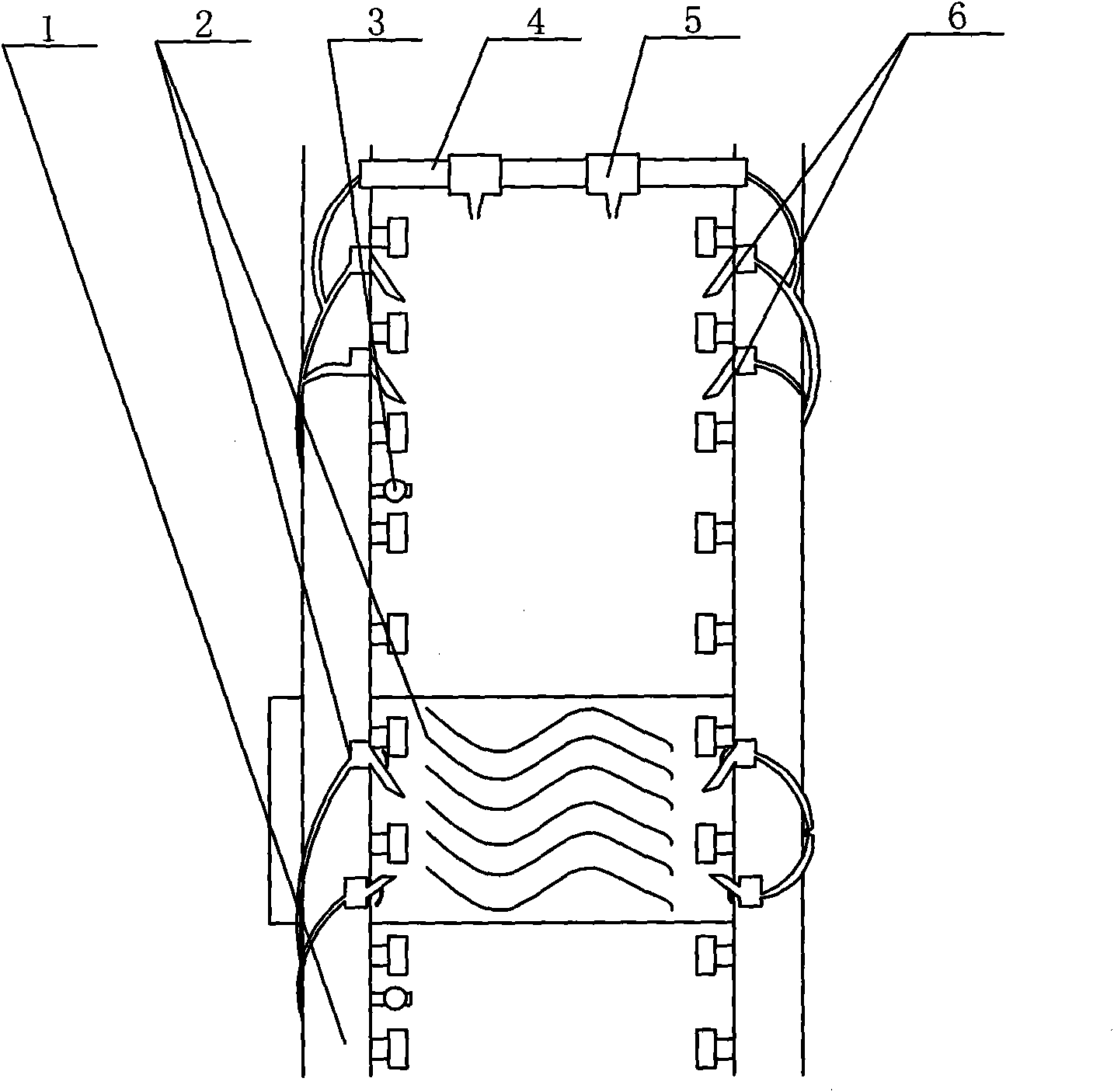

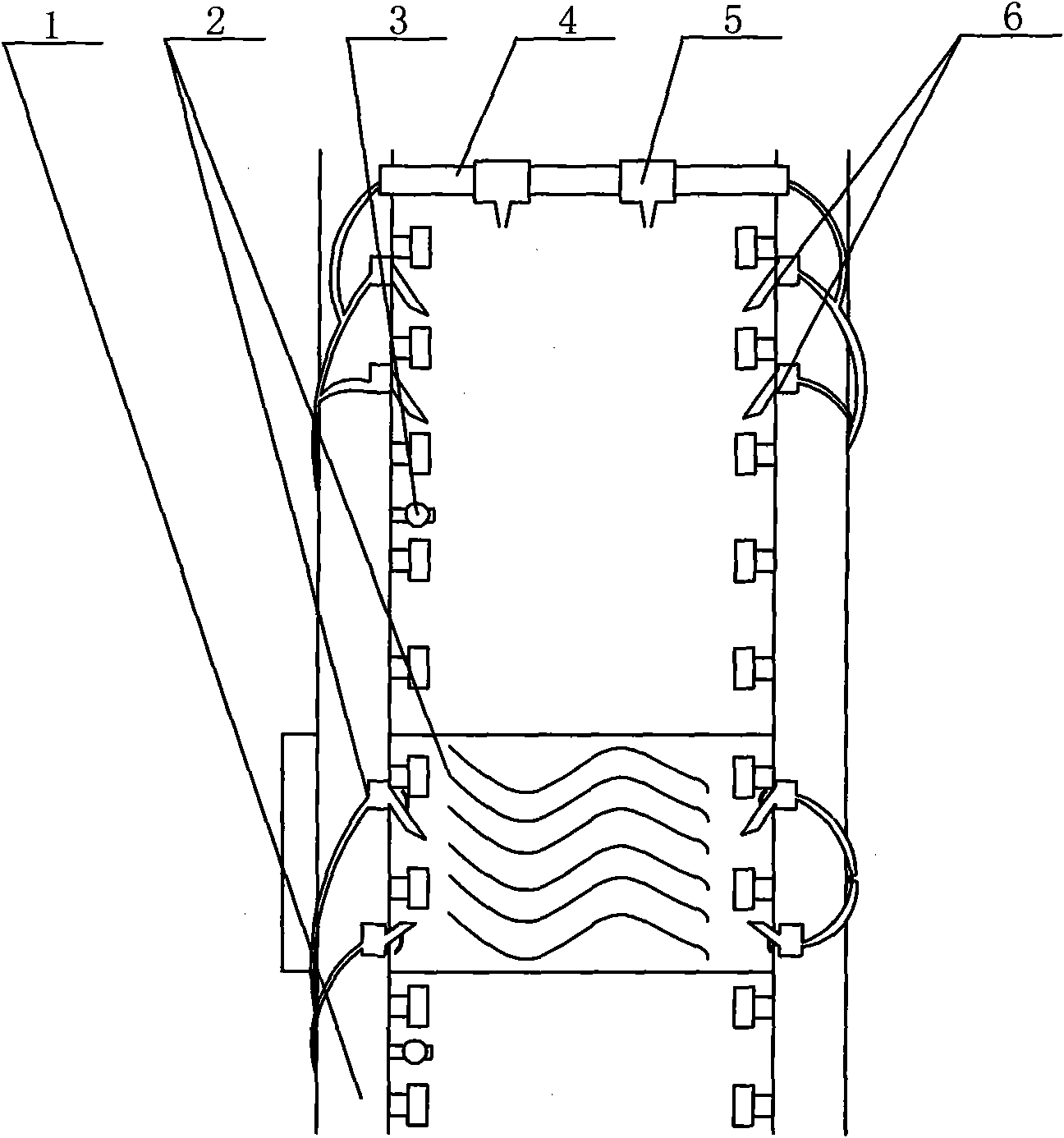

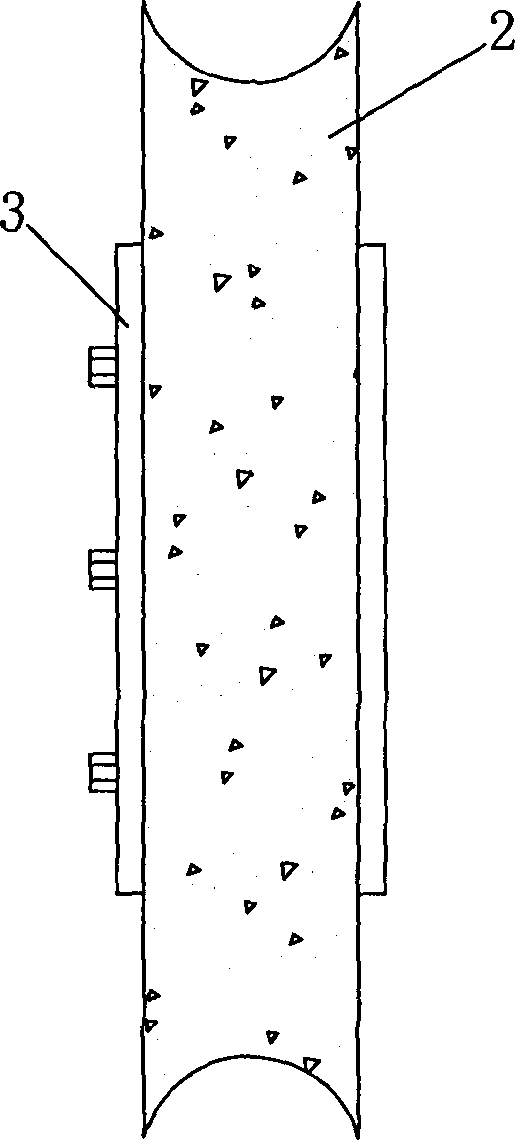

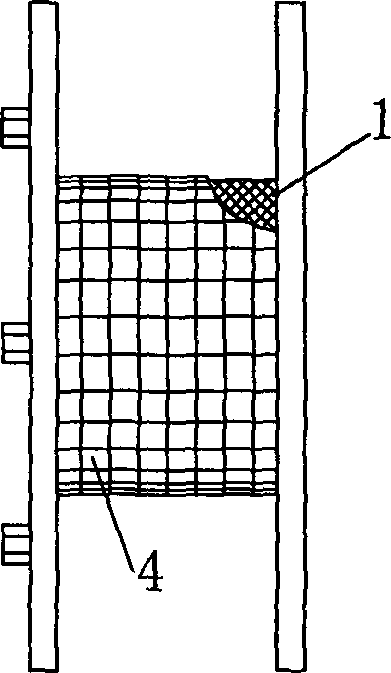

Redundant droplet processing device after water cooling of heat-radiating sheet

InactiveCN102313444AKeep dryEliminate rustDrying solid materials without heatDrying gas arrangementsHeat sinkInductor

The invention relates to the field of industrial production equipment, in particular to a redundant droplet processing device after the water cooling of a heat-radiating sheet, which comprises a transporting track (1), a water-cooling device (2), a metal inductor (3), a crossbeam (4), a main air-spraying head (5) and an auxiliary air-spraying head (6); and droplets left on the heat-radiating sheet after the water cooling are blown to fall through a high-pressure air gun, so that the surface dryness of the heat-radiating sheet is ensured, and the situation of rustiness after the water cooling is prevented from occurring.

Owner:杨明强

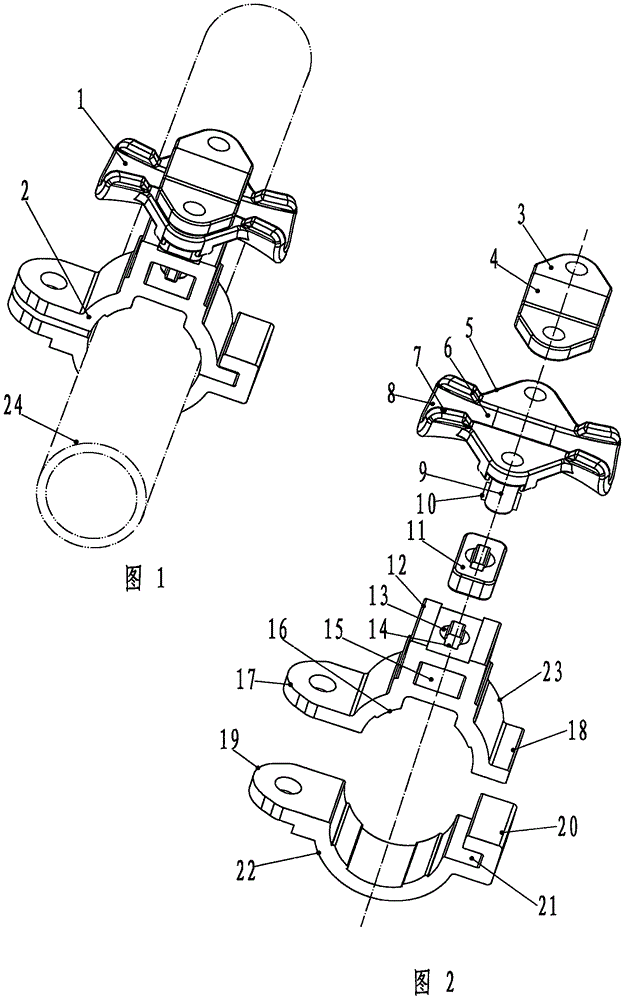

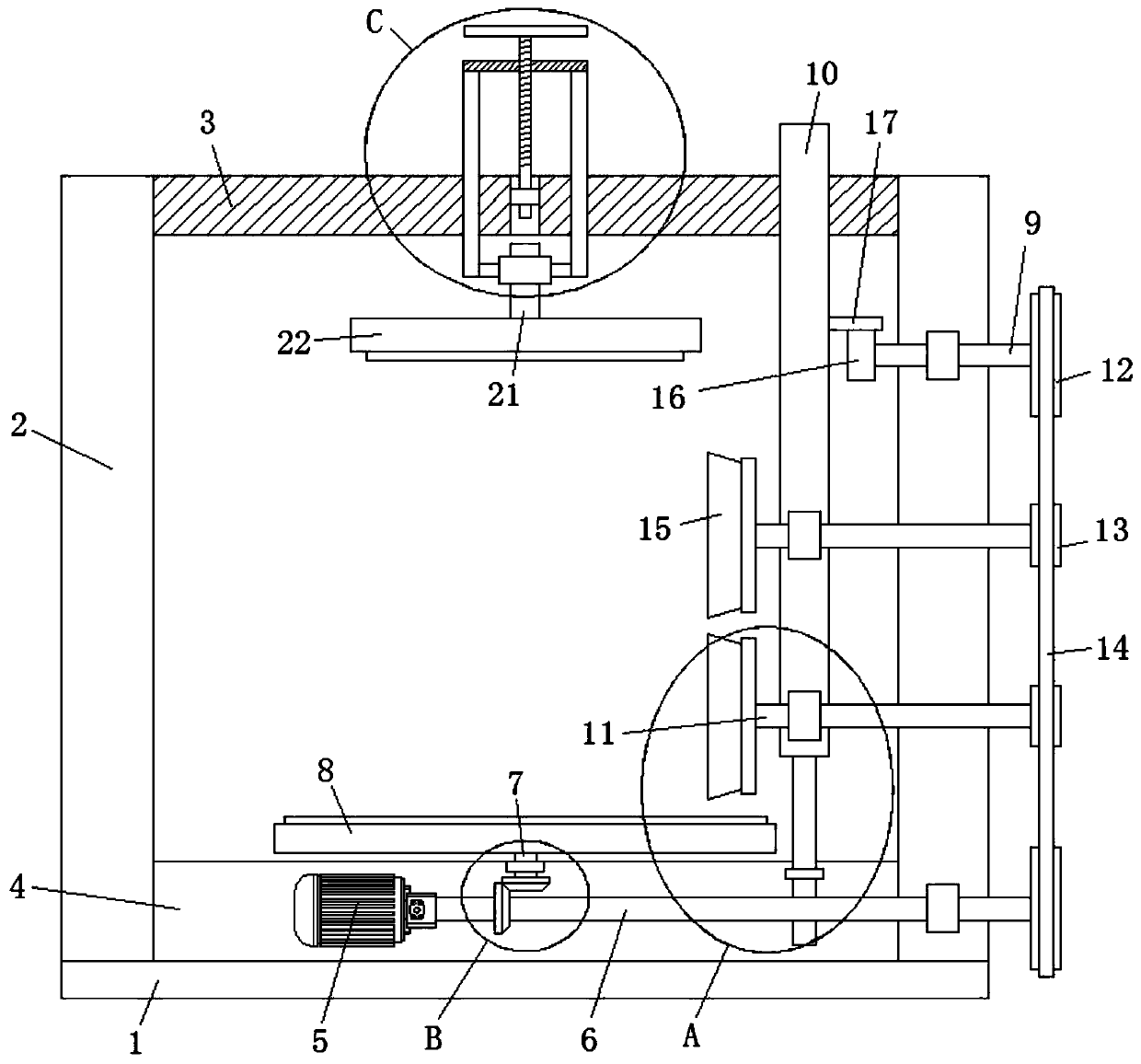

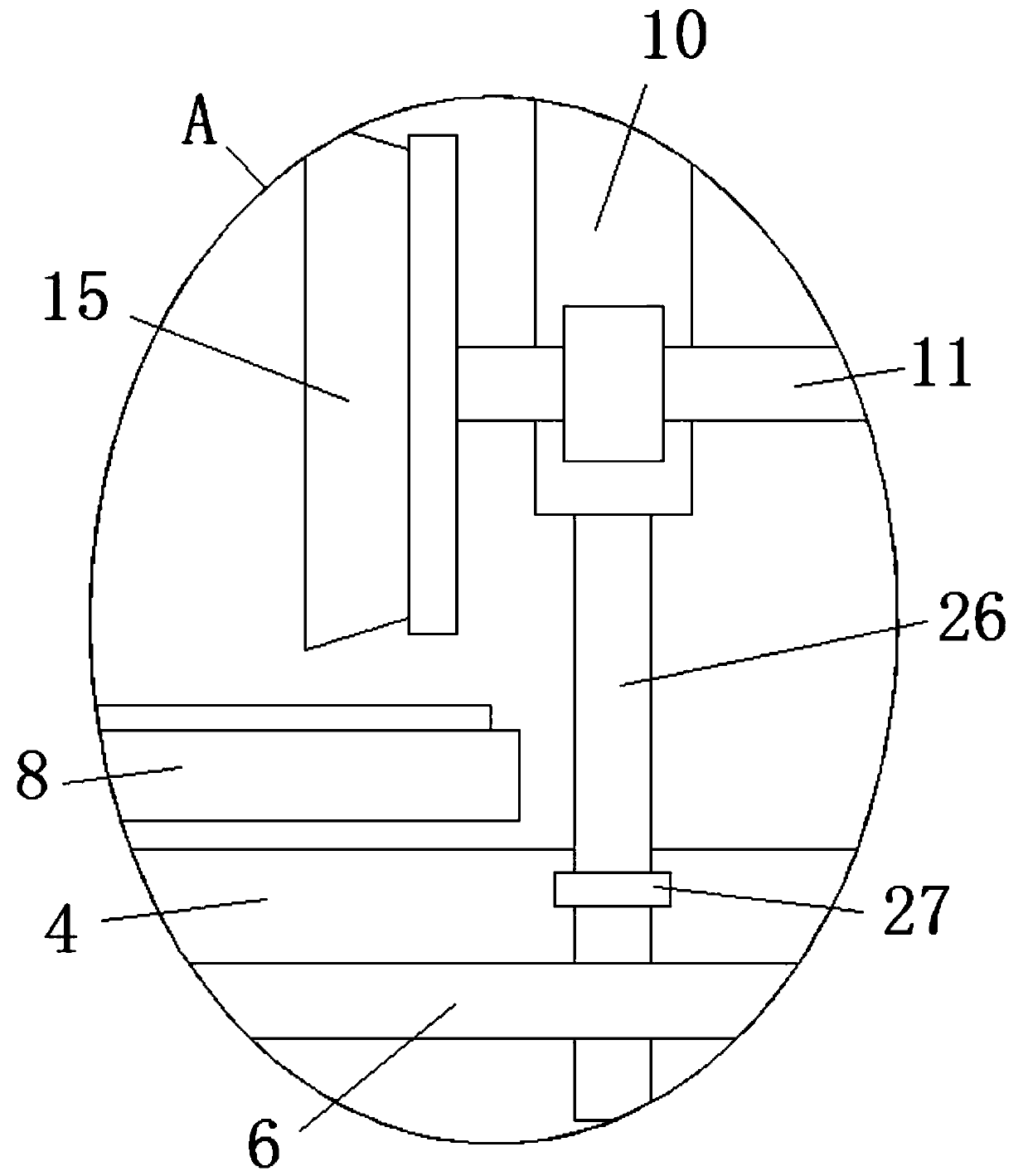

Rust removing device for automobile parts

InactiveCN111496649AEfficient removalReasonable designGrinding carriagesGrinding drivesDrive shaftElectric machinery

The invention belongs to the technical field of automobiles, and particularly relates to a rust removing device for automobile parts. The rust removing device includes a base, the two sides of the topof the base are fixedly connected with stand columns, a same beam is welded to the tops of the sides, close to each other, of the two stand columns, a same side plate is welded to the bottoms of thesides, close to each other, of the two stand columns, a motor is fixedly installed on the front side of the side plate, an output shaft of the motor is fixedly connected to one end of a rotating shaft, the tops of the front sides of the stand columns are rotatably connected with transmission shafts, a guide rod is slidably connected to the beam, and the front side of the guide rod is rotatably connected with two round shafts. One ends of the transmission shafts and the other end of the rotating shaft are fixedly sleeved with large belt pulleys, and one ends of the round shafts are fixedly sleeved with small belt pulleys. The large belt pulleys and the small belt pulleys are connected with a same triangular belt in a transmission mode, and the other ends of the round shafts are fixedly connected with brush plates. The rust removing device is reasonable in design, the brush plates can be moved up and down in a small range while rotating, rust on the surfaces of the automobile parts can be effectively removed, the degree of automation is high, and the rust removal efficiency is improved.

Owner:高筱琛

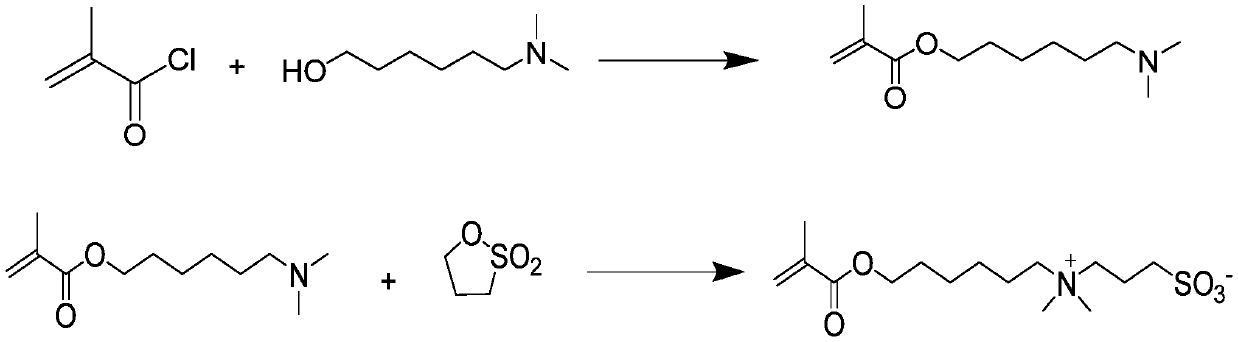

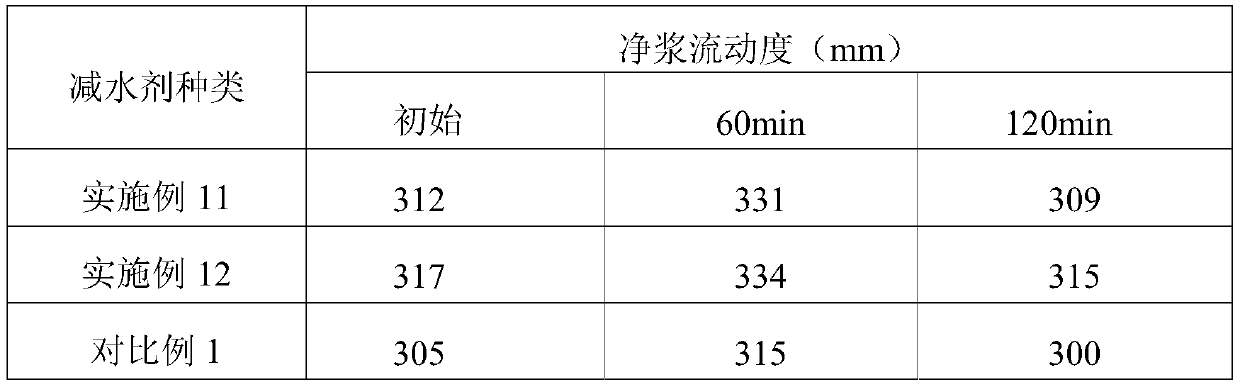

Amphoteric monomer and amphoteric polycarboxylic acid water reducer

InactiveCN110204462AThe synthesis process is simpleHigh reaction conversion rateOrganic compound preparationSulfonic acids salts preparationCarboxylic acidVacuum drying

The invention discloses an amphoteric monomer and an amphoteric polycarboxylic acid water reducer synthesized by the same. A preparation method of the amphoteric monomer includes the following steps:mixing 6-dimethylamino-1-hexanol with an organic solvent, dropping methacrylic chloride, washing an oil layer with deionized water, and removing the organic solvent to obtain a 6-dimethylaminohexyl methacrylate intermediate; mixing the 6-dimethylaminohexyl methacrylate intermediate with a polymerization inhibitor and the organic solvent, dropping a propane sultone drop concentrate, and performinga reaction for 16-28 hours; and extracting, washing and vacuum-drying an obtained crude product to obtain the amphoteric monomer. The amphoteric polycarboxylic acid water reducer is prepared by the prepared amphoteric monomer, an unsaturated carboxylic acid monomer and an unsaturated polyether macromonomer by an aqueous solution free radical polymerization method, which eliminates the corrosion ofchloride ions to reinforced concrete and has better dispersibility to cement at low dosage compared with a common anionic polycarboxylic acid water reducer.

Owner:中科广化(重庆)新材料研究院有限公司 +2

Environment-friendly antirust phosphating solution

InactiveCN101748398AWith anti-corrosion abilityExtended service lifeMetallic material coating processesPorosityLacquer

The invention relates to an environment-friendly antirust phosphating solution which has the antirust and lubricating functions used in the automobile coating process. The phosphating solution is prepared by phosphoric acid, zinc dihydrogen phosphate, zinc nitrate, sodium nitrite and hydroxylamine sulphate according to ratio of parts by weight. The phosphating solution has the advantages of high hardness of the phosphating film, low porosity, low cost, uniform, continuous and compact phosphating film, no pollution, better working condition and small damage to the operator; the corrosion during the process is basically eliminated, the phosphating film has certain corrosion resistance, and the adhesion between a paint layer and a matrix is increased; in addition, the phosphating solution has stability, long service life, quick response speed, short time, low temperature and less sludge, and can be used for automobile coating as well as home appliances coating.

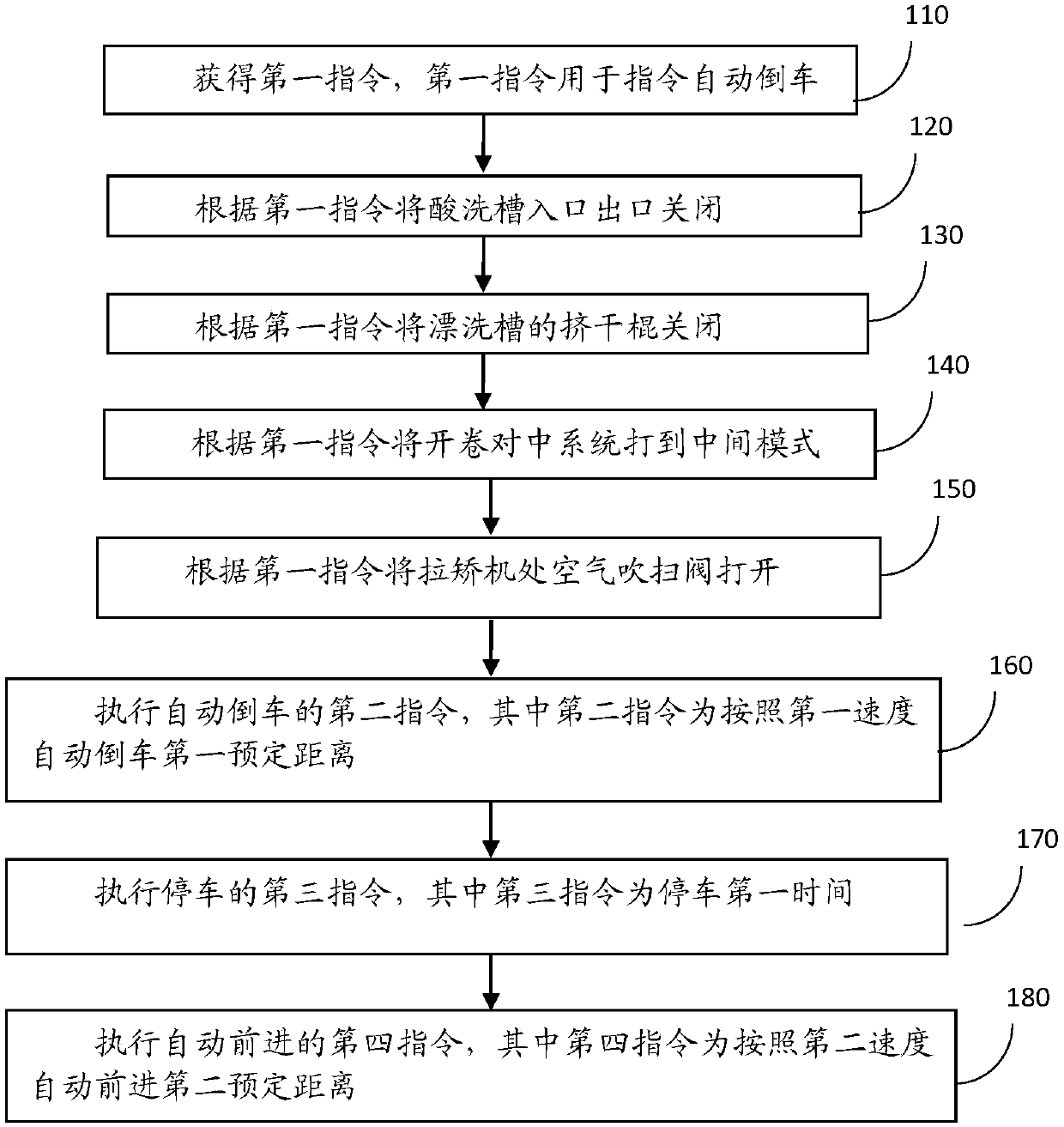

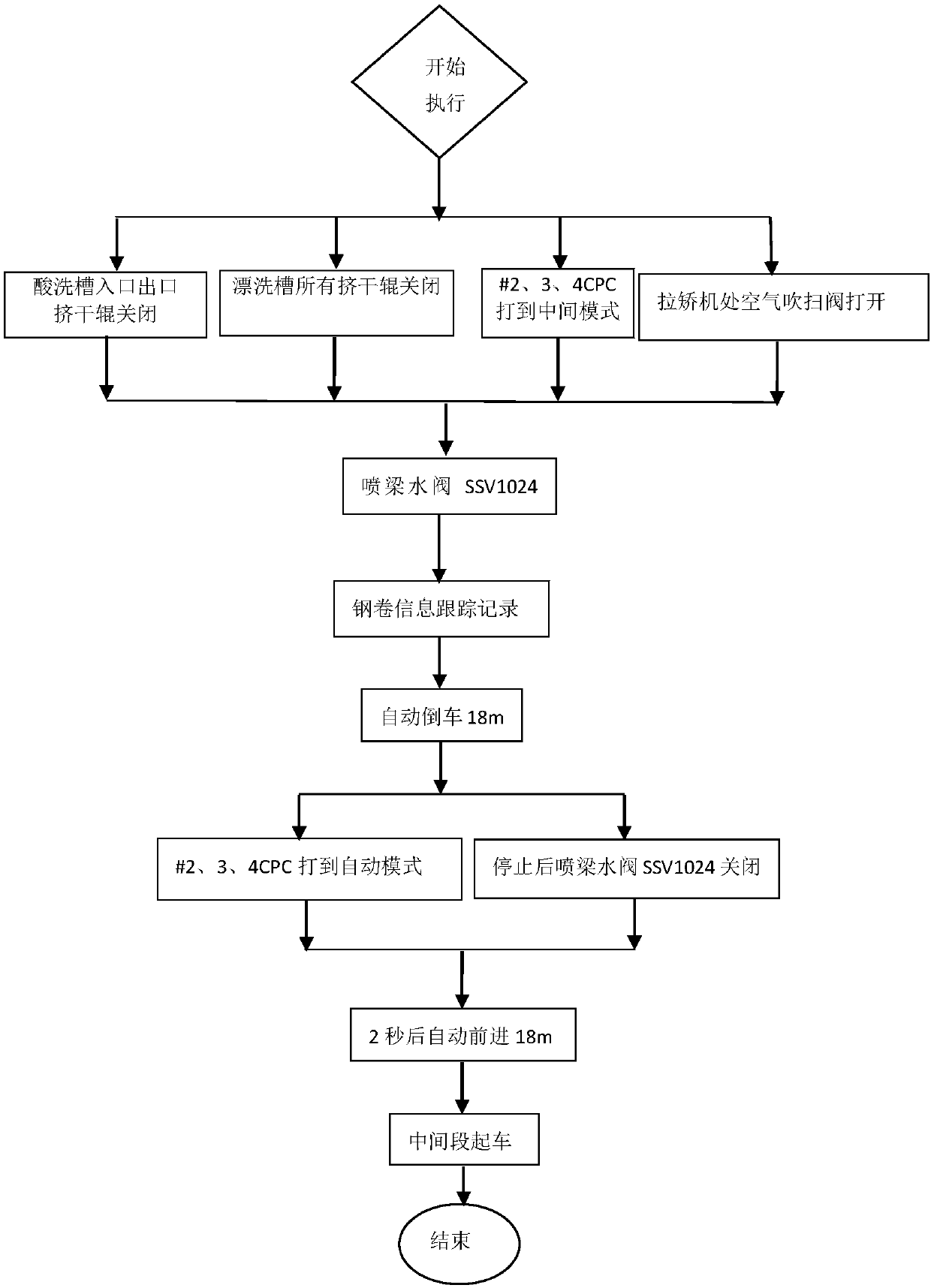

Automatic backing-up method of cold-rolled sheet material

ActiveCN107931330AHigh yieldEliminate acid spotsRoll mill control devicesWork cleaning devicesAcid washingEngineering

The invention discloses an automatic backing-up method of cold-rolled sheet material, and relates to the technical field of steel rolling. The method comprises the steps that a first instruction is obtained and is used for instructing automatic backing-up; an outlet and an inlet of an acid washing tank are closed according to the first instruction; a wringing roller of a rinsing tank is closed according to the first instruction; an uncoiling centering system is switched to an intermediate mode according to the first instruction; and an air purging valve located at a withdrawing and straightening machine is opened according to the first instruction; a second instruction for automatic backing-up is performed, wherein according to the second instruction, automatic backing-up is carried out ata first speed for a first predetermined distance; a third instruction for lathe stopping is performed, wherein according to the third instruction, a lathe is stopped for a first time; and a fourth instruction for automatic advancing is performed, wherein according to the fourth instruction, automatic advancing is carried out at a second speed for a second predetermined distance. By means of the automatic backing-up method of the cold-rolled sheet material, the problems that in the prior art, backing-up is complex, equipment is complicated to restore when generating an alarm or breaking down are solved, so that the technical effects of eliminating acid spots and rust on the surface of the sheet material, improving the yield, saving time and labor, and being safe and rapid are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

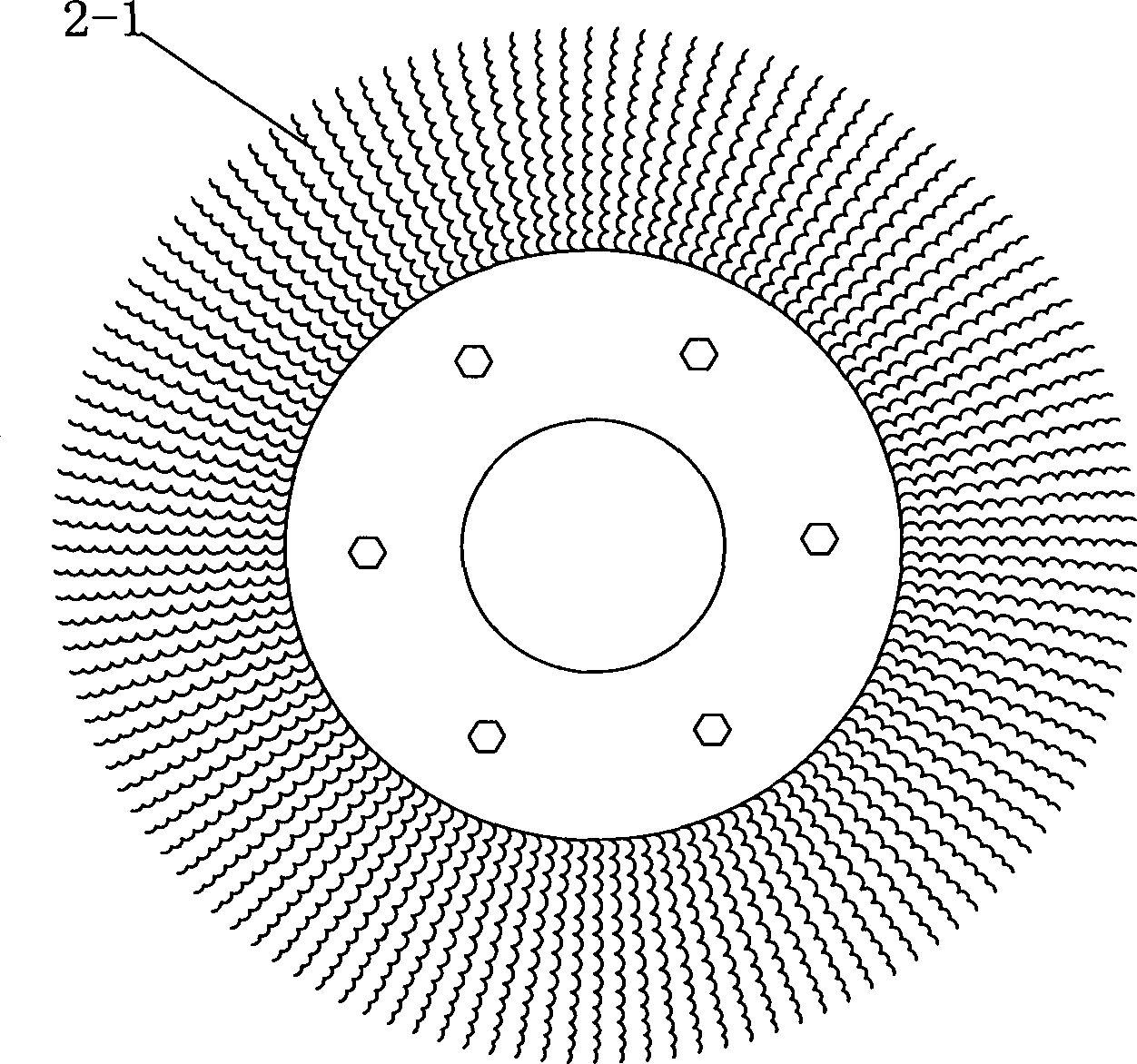

Rust removing steel brush

The invention discloses a rust removing steel brush, which comprises a framework, bristle and a cover plate. Installing holes are arranged on the surface of the framework; the bristle is arranged in the installing holes; edges of the framework press and fix the bristle through the cover plate; a steel brush action face formed by ends of the bristle has an inward arc in the direction vertical to the periphery, and a radius of the inward arc is of 30-40mm; the bristle has two shapes, one kind of the bristle is cotton-shaped steel wires subjected to bend shaping, and the other kind of the bristle is steel wire strands which are subjected to spirally tightening at root parts and decentralizing at top parts. The rust removing steel brush provided by the invention changes the material and the configuration mode of the surface bristle of the traditional steel brush and adopts 72B galvanized wires with a diameter of 0.4mm, so that over scratch on the surfaces of the wires is avoided and the service life of the bristle of the steel brush can be ensured as well; the two shapes of the bristle are adopted, so as to prevent the occurrence of the problems of wire-dropping, wire-breaking, wire-scattering, insufficient pressure and the like and greatly prolong the service life of the steel brush; and the radius of the arc on the surface of the steel brush is optimized to be 34mm, so that the rust on the surfaces of the wires can be removed furthest, and oxide skins on the surfaces of the wires can be completely removed.

Owner:SHANGHAI YIHAO ENVIRONMENTAL PROTECTION EQUIPCO

Surface cleaning method and cleaning device of sheet metal

InactiveCN109078902APromotes corrosionImprove cleaning and moisturizing effectCleaning using toolsGrinding machinesSodium carbonateIon

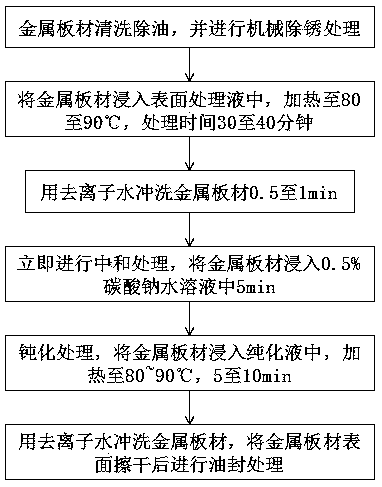

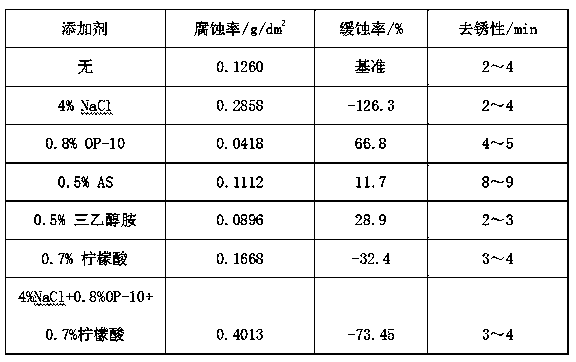

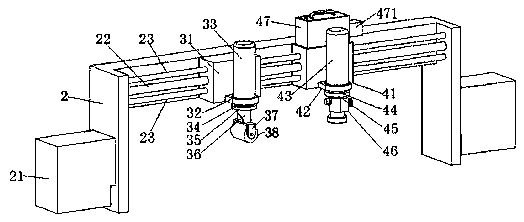

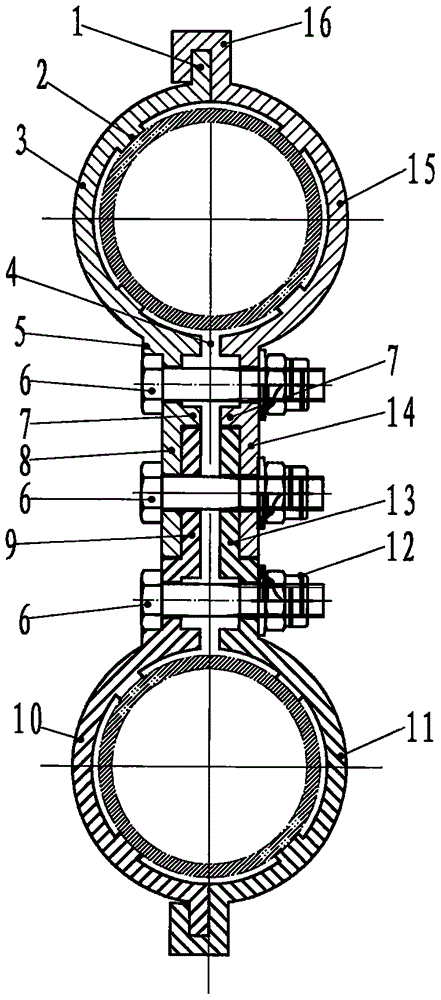

The invention relates to a surface cleaning method and a cleaning device of sheet metal. The method comprises the steps of cleaning and removing oil from the sheet metal, performing mechanical derusting treatment, immersing the sheet metal in surface treatment liquid, heating to 80-90 DEG C, treating the sheet metal for 30-40min, flushing the sheet metal for 0.5-1min with deionized water, neutralizing the flushed sheet metal immediately, immersing the sheet metal in a 0.5% sodium carbonate aqueous solution for 5min, performing passivating treatment, immersing the sheet metal in purified liquid, heating to 80-90 DEG C for 5-10min, flushing the sheet metal with the deionized water, wiping up the surface of the sheet metal, and then performing oil seal treatment. At the same time, the invention further discloses the cleaning device for the mechanical derusting treatment of the surface of the sheet metal. Rusty spots on the surface of the sheet metal can be effectively removed by the cleaning method; micro scratches generated by the mechanical derusting treatment are treated; and at the same time, the method has no influence on the size, shape, surface roughness, luster and the like ofthe sheet metal.

Owner:DONGGUAN UNIV OF TECH

Aluminum alloy profile sleeve connecting device

The invention discloses an aluminum alloy profile sleeve connecting device. The aluminum alloy profile sleeve connecting device is formed by fixedly connecting two sleeves; the sleeves are composed of two semicircle annular main hoops and two semicircle annular auxiliary hoops; the lower end of each sleeve is provided with double vertical plates with a connection hole; the double vertical plates on one of the sleeves are clamped on the outer sides of the double vertical plates on the other sleeve, and the vertical plates are connected through a fastener; the two sleeves are fixed to a horizontal cantilever and an inclined cantilever correspondingly; axial bosses are arranged on the inner annular surfaces of circular rings of the main hoops and the inner annular surfaces of circular rings of the auxiliary hoops; and the main hoops and the auxiliary hoops are all made of aluminum alloy profiles. Sleeve bases made of the aluminum alloy profiles are small in size and low in weight; the production and manufacturing process of the main hoops and the auxiliary hoops is greatly simplified, and the production efficiency is improved; and moreover, the phenomenon that parts are rusted due to rainwater erosion is completely eradicated. Meanwhile, installation is convenient, the construction and installation cost is reduced.

Owner:中法高速铁路技术(西安)有限公司

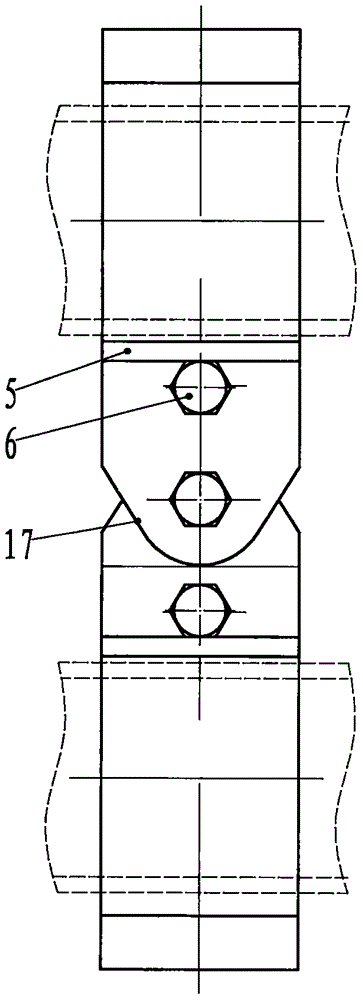

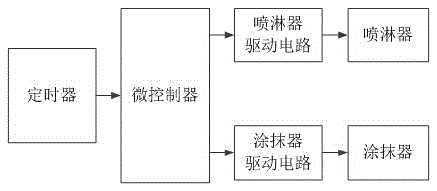

Regular rust removal device for photoelectric direct-reading long-pass valve control water meter valve

The invention discloses a regular rust removal device for a photoelectric direct-reading long-pass valve control water meter valve. The regular rust removal device for the photoelectric direct-reading long-pass valve control water meter valve comprises a timer, a microcontroller, a sprayer used for spraying a rust removal agent, and an applicator used for applying lubricating grease. The sampling signal input end of the microcontroller is connected with the timer. One control signal output end of the microcontroller is connected with the sprayer through a sprayer drive circuit, and the other control signal output end of the microcontroller is connected with the applicator through an applicator drive circuit. Rust removal is regularly conducted on the valve, rust removal is stopped after rust removal is conducted for a period of time, the applicator is started to apply a layer of lubricating grease to the valve, and the intelligence degree is high. On the rust removal basis, the valve can be effectively prevented from being rusted again through the lubricating grease, meanwhile, a very good lubricating function can be achieved, and the flexibility of the valve is guaranteed. The valve cannot be corroded or damaged through the rust removal agent, the rust on the valve can be effectively removed, meanwhile, a certain lubricating property is achieved, and the lubrication of the valve can be kept on the rust removal basis.

Owner:天津市金凤来仪科技有限公司

High-performance end cover for polypropylene film capacitor

PendingCN110033944AImprove conductivityFirmly connectedThin/thick film capacitorStacked capacitorsCardboardCopper wire

The invention relates to a high-performance end cover for a polypropylene film capacitor. According to the end cover, mounting screw caps, mounting spring washers and mounting gaskets are screwed intonuts at the upper ends of bolt lead-out ends in sequence; sealing rings are mounted in inner circular clamping grooves in the bottoms of insulators on the bolt lead-out ends; the bolt lead-out ends are connected with a tinplate sheet; sealing gaskets are mounted on hexagonal insulating columns of the bolt lead-out ends penetrating through the tinplate sheet; an insulating paper plate sleeves thebolt leading-out ends and are positioned below the sealing gaskets; and the bolt lead-out ends, the sealing rings, the tinplate sheet, the sealing gaskets, the insulating paper plate and hexagonal screw caps are fixed together, then elbow bends at the upper ends of explosion-proof copper wires are welded to the centers of nuts at the lower ends of the bolt lead-out ends, and the lower ends of theexplosion-proof copper wires penetrate into corresponding holes of an explosion-proof block and then are compressed and cut. The end cover is beneficial to the improvement of the long-term service life and reliability of the polypropylene film capacitor, and has the characteristics of high pressure resistance, corrosion resistance, excellent sealing performance and stable performance.

Owner:WUXI HONGGUANG CAPACITOR

Method for protecting and fixing assembled permanent magnet in large-power permanent magnet motor

InactiveCN102684407AReduce manufacturing costIncrease productivityManufacturing stator/rotor bodiesApplying solid insulationElectric machineProcess engineering

The invention relates to protection and fixing technology of a permanent magnet in a permanent magnet motor, in particular to a method for protecting and fixing the assembled permanent magnet in a large-power permanent magnet motor, which solves the problems that the protection and fixing methods for the permanent magnet in the existing permanent magnet motor can easily cause infirm fixing of the permanent magnet, damage on the original plating layer of the permanent magnet, high manufacturing cost of the permanent magnet motor, low production efficiency of the permanent magnet motor. The method for protecting and fixing the assembled permanent magnet in the large-power permanent magnet motor is realized by the steps as follows: adsorbing the permanent magnet on a motor iron core, and fixing the permanent magnet and the motor iron core in a mechanical manner; conducting insulated paint soaking treatment on the fixed permanent magnet and motor iron core; and drying the permanent magnet and the motor iron core which are subjected to insulated paint soaking treatment. The method is applicable to protection and fixing of the permanent magnet in the permanent magnet motor, especially protection and fixing of the permanent magnet in the large-power permanent magnet motor.

Owner:CRRC YONGJI ELECTRIC CO LTD

Nanometer carbon nanotube doped wet blasting sand material for pump body casting processing

The invention discloses a nanometer carbon nanotube doped wet blasting sand material for pump body casting processing, and relates to the technical field of wet blasting processing. The nanometer carbon nanotube doped wet blasting sand material is prepared from, by weight, 90-100 parts of quartz sand, 15-20 parts of bentonite, 5-8 parts of nanometer carbon nanotube powder, 12-15 parts of river sand, 8-11 parts of alumdum, 6-9 parts of feldspar powder, 5-8 parts of putty powder, 3-5 parts of cement, 1-2 parts of tallow amine, 0.5-1 part of zinc carbonate, 25-30 parts of ethanol and 280-300 parts of water. Bentonite is modified by the carbon nanotube, so improvement of comprehensive performances of the sand material is benefited; and the prepared sand material can be directly used in wet blasting treatment of a pump body casting, so the roughness of the casting surface is reduced, scales, rusts, oil stains and other impurities on the surface are removed, and subsequent coating spraying and pump assembling are benefited.

Owner:SANLIAN PUMP IND CO LTD

Water jet rust removal cleaning gun capable of forming gradient coating

InactiveCN112756121ATo achieve the purpose of cleaning and rust removalImprove bindingMovable spraying apparatusEngineeringHigh pressure water

The invention discloses a water jet rust removal cleaning gun capable of forming a gradient coating. The cleaning gun comprises a cleaning gun body, corresponding nozzle holes are formed in a cross-shaped spray rod on the cleaning gun body, nozzles on the outermost side of the cross-shaped spray rod are arranged outwards by 15-45 degrees in the original direction, the rest nozzles are vertically and eccentrically arranged, high-pressure water enters the cross-shaped spray rod through a rotating body and is sprayed by the nozzles to achieve the purpose of cleaning and rust removal; the nozzles are asymmetrically and eccentrically arranged to drive the cross-shaped spray rod to rotate automatically, at the moment, the jet flow vertical impact force of the middle rust removal area of the cleaning gun body is maximum, rust removal of the middle area is complete, the cleaning gun body can drive the cross-shaped spray rod to rotate automatically, extra work does not need to be applied, the nozzles in the cross-shaped spray rod are vertically installed, and the nozzles on the outermost layer are installed outwards, so that the impact force applied to the center and the impact force applied to the outer layer are different, a certain pressure difference is formed, it can be guaranteed that rust in the middle area can be completely removed, it can also be guaranteed that original good primer in the outer layer area is not damaged, the jet flow tangential force can be enlarged, and the jet flow cleaning area can be increased.

Owner:南通中远克莱芬船舶工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com