Surface cleaning method and cleaning device of sheet metal

A surface cleaning device, a technology for metal sheets, applied in cleaning methods and appliances, cleaning methods using tools, cleaning methods using liquids, etc. performance, increased wear between parts, etc., to enhance applicability, improve cleaning and wetting effects, and increase corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

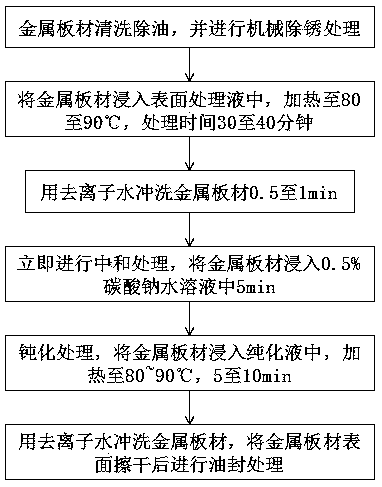

[0037] refer to figure 1 , a metal plate surface cleaning method is characterized in that: comprising the following steps:

[0038] (1) Metal plates are cleaned and degreased, and mechanically derusted;

[0039] (2) Immerse the metal plate in the surface treatment solution, heat it to 80 to 90°C, and the treatment time is 30 to 40 minutes;

[0040] (3) Rinse the metal plate with deionized water for 0.5 to 1 minute;

[0041] (4) Immediately carry out neutralization treatment, immerse the metal plate in 0.5% sodium carbonate aqueous solution for 5 minutes;

[0042] (5) Passivation treatment, immerse the metal plate in the purification solution, heat to 80 to 90 ° C, and the treatment time is 5 to 10 minutes;

[0043] (6) Rinse the metal plate with deionized water, dry the surface of the metal plate and perform oil seal treatment.

[0044] Wherein, gasoline or acetone is used for cleaning and degreasing the metal plate in the step (1).

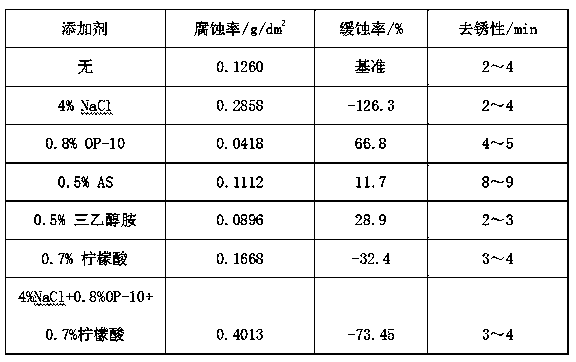

[0045] see figure 2 , figure 2sho...

Embodiment 2

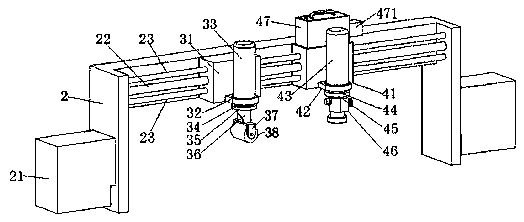

[0055] Compared with the first embodiment, the second embodiment provides a specific grinding disc structure. The grinding disc 465 includes a grinding liquid supply port 4651, several circular teeth 4652 arranged concentrically, and several arc-shaped grooves 4653 connected with the grinding liquid supply port 4651. At the same time, the circular teeth 4652 have a distance of -4654 on a circle. There is a distance two 4655 between circular teeth 4652 corresponding to different diameters along the radial direction. Since the particles after grinding decrease from the inside to the outside, the distance between the distance one 4654 and the distance two 4655 can be reduced from the inside to the outside.

[0056] The present invention first cleans and degreases the metal plate, and performs mechanical derusting treatment; then immerses the metal plate in the surface treatment solution, heats it to 80 to 90°C, and takes 30 to 40 minutes; rinses the metal plate with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com