Rapid analysis method of shell resistor defective product

A fast analysis and resistance technology, applied in the direction of high resistance measurement, resistance/reactance/impedance measurement, electrical variable measurement, etc., can solve problems such as long time consumption, lower product qualification rate and equipment utilization rate, failure to perform abnormally, etc. , to achieve the effect of convenient and quick operation and promoting corrosion phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] In addition, mentioned in the embodiments of the present invention:

[0028] Soft-pack batteries refer to lithium-ion batteries packaged in aluminum-plastic film.

[0029] The insulation test refers to the insulation test between the negative tab of the lithium-ion pouch battery and the aluminum-plastic film.

[0030] Defective shell resistance products refer to products with defective insulation tests, that is, the insulation test between the negative tab of the battery and the aluminum-plastic film fails.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

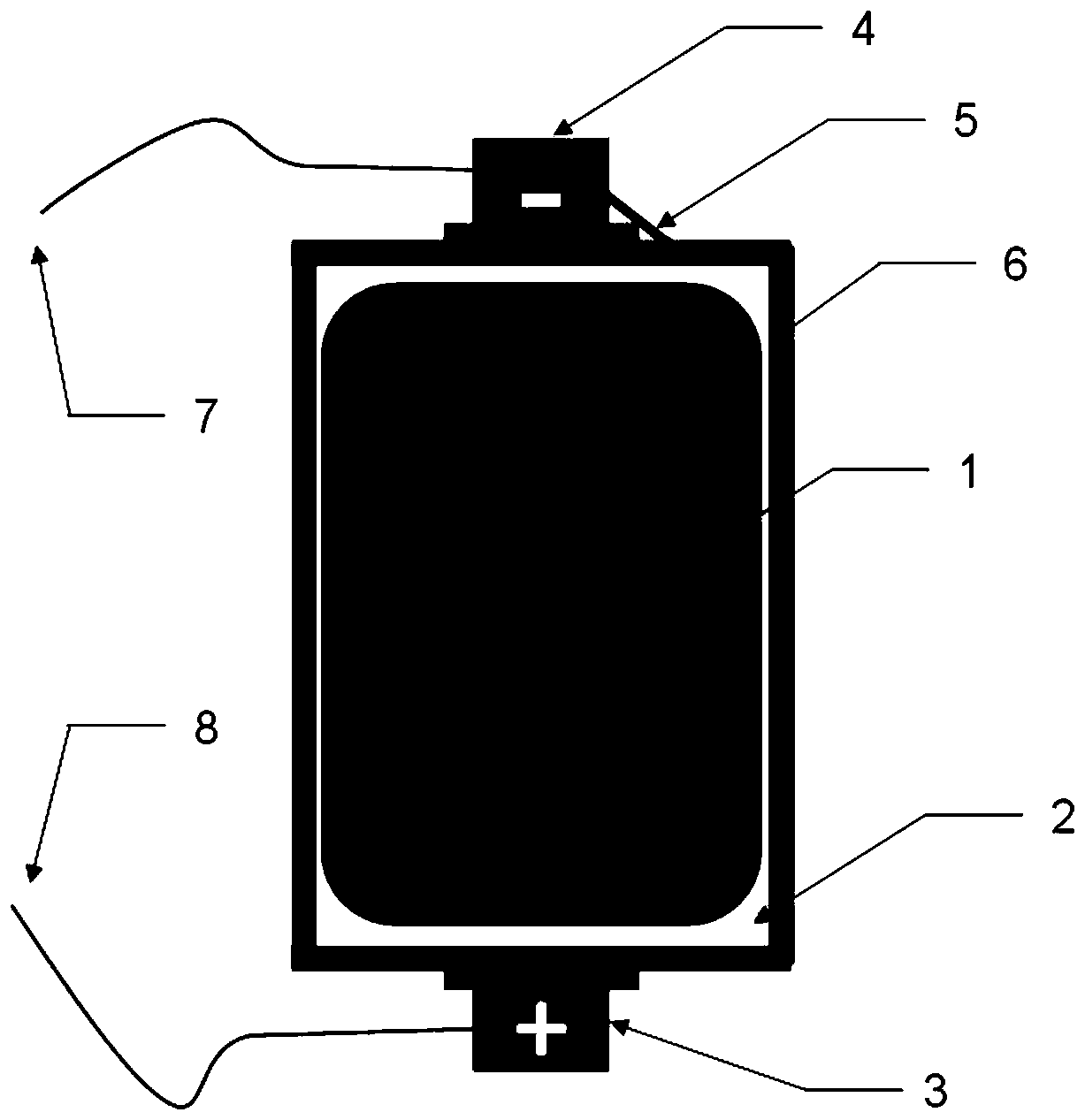

[0032] The structure of the pouch battery of the present invention is as follows: figure 1 As shown, the exterior of the battery main body 1 is aluminum-plastic film 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com