Patents

Literature

103 results about "Non-contact ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-contact ultrasound (NCU) is a method of non-destructive testing where ultrasound is generated and used to test materials without the generating sensor making direct or indirect contact with the test material or test subject. Historically this has been difficult to do, as a typical transducer is very inefficient in air. Therefore most conventional ultrasound methods require the use of some type of acoustic coupling medium in order to efficiently transmit the energy from the sensor to the test material. Couplant materials can range from gels or jets of water to direct solder bonds. However in non-contact ultrasound, ambient air is the only acoustic coupling medium.

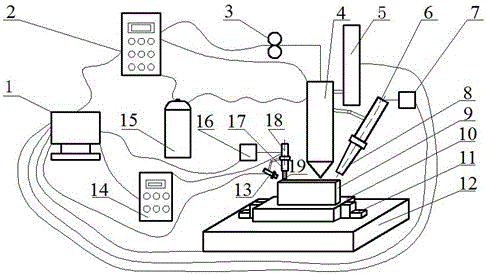

Method of shape and property control of electric arc additive manufacturing through assistance of ultrasonic vibration

InactiveCN106735967AAvoid air holesAvoid defects such as segregationArc welding apparatusIncreasing energy efficiencyNon-contact ultrasoundManufacturing technology

The invention discloses a method of shape and property control of electric arc additive manufacturing through assistance of ultrasonic vibration. In the process of electric arc additive manufacturing, non-contact ultrasonic vibration is applied to molten baths synchronously, grains in the molten baths are crushed, growth of the grains is restrained, and refinement of the grains is achieved. Meanwhile, by effectively utilizing residual heat of a formed part, the effect that a material in the position where a tool bit makes contact with the surface of a cladding layer is in a softened state is guaranteed, by applying ultrasonic vibration to the tool bit, the tool bit impacts the surface of the cladding layer at a high frequency, and finishing processing and surface reinforcing treatment are conducted on the surface, so that the dimension precision of the cladding layer is improved, the residual stress of the cladding layer is reduced, the surface grains are refined, and accordingly the purpose of shape and property control of electric arc additive manufacturing is achieved. According to the method, the roughening effect of the residual heat accumulation amount to the part grains and severe influences of warping deformation are reduced and even avoided, the service cycle of the tool bit is prolonged, and subsequent machining treatment of parts is reduced. The effective method is provided for shape and property control of the electric arc additive manufacturing technology.

Owner:XIANGTAN UNIV

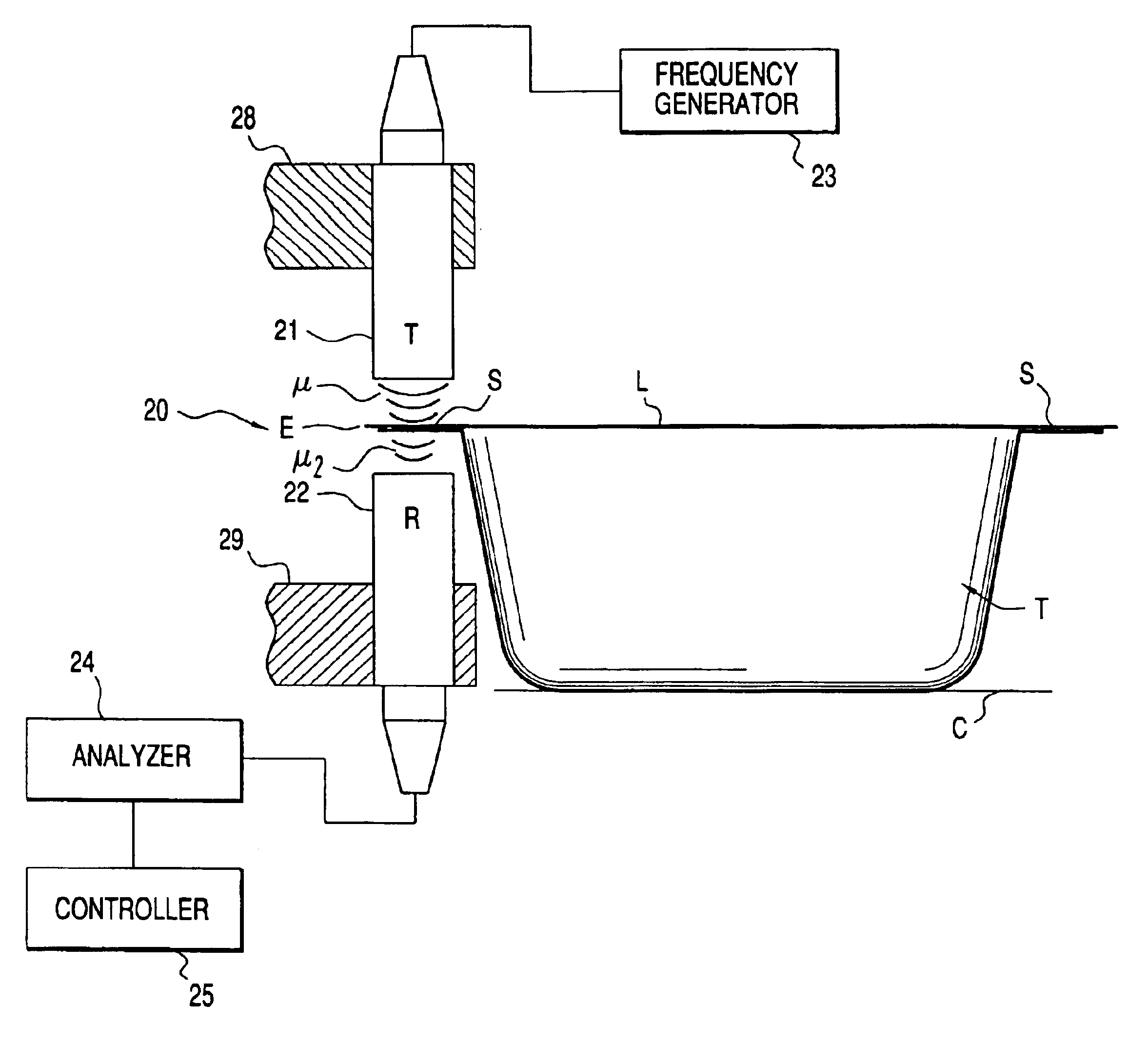

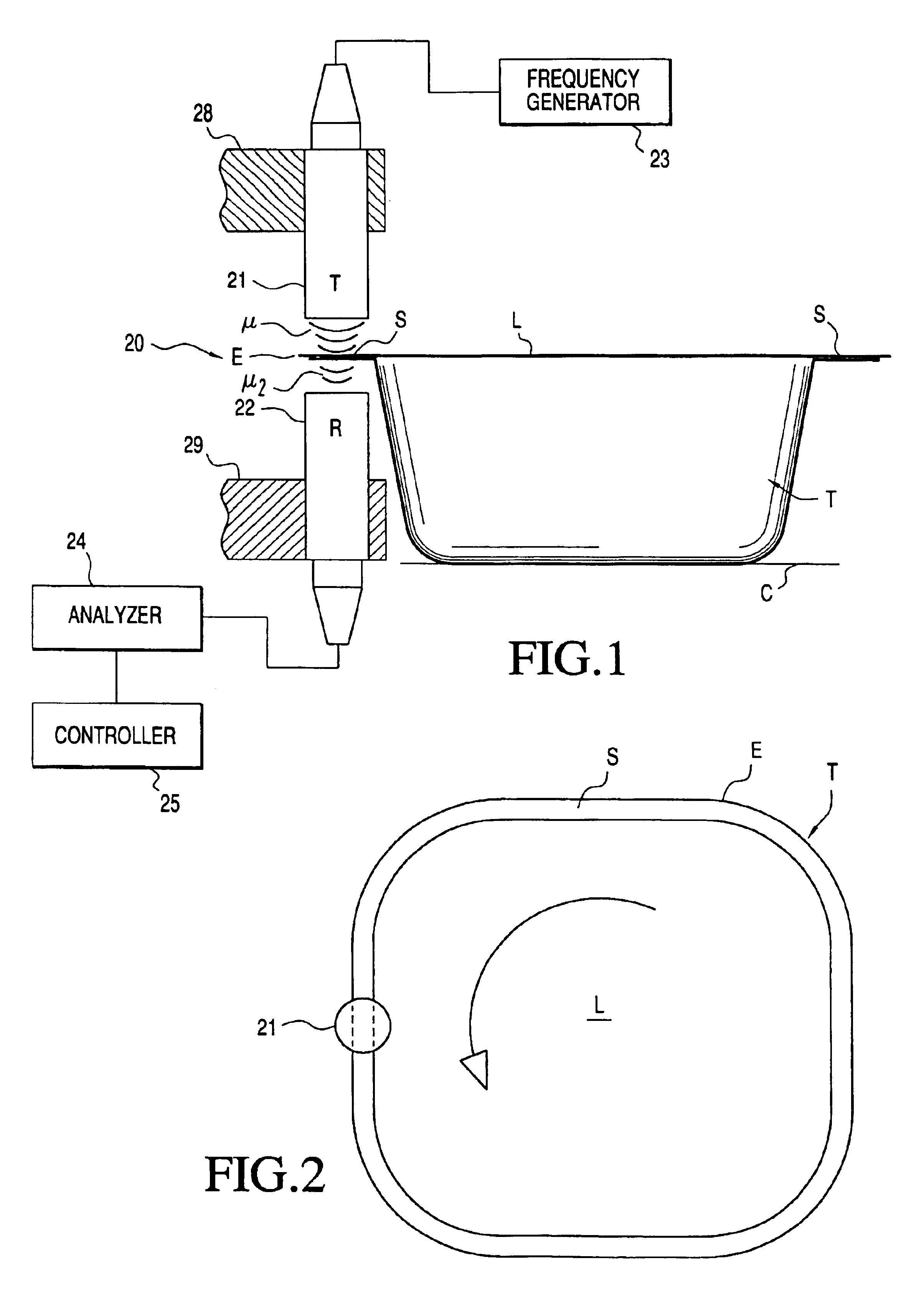

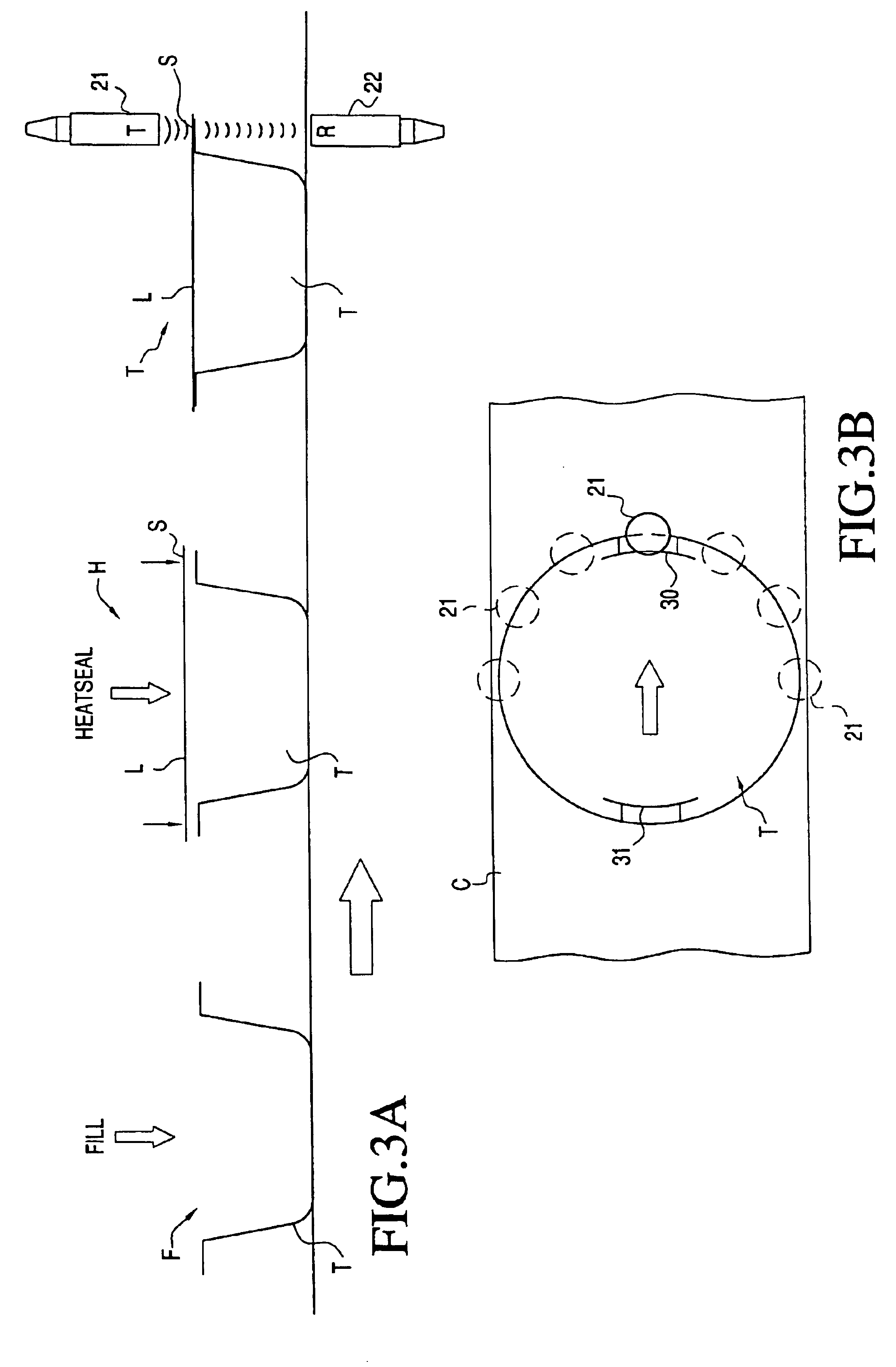

Method and apparatus for airborne ultrasonic testing of package and container seals

InactiveUS6840108B2Obstruct passageAvoid energyDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationNon-contact ultrasound

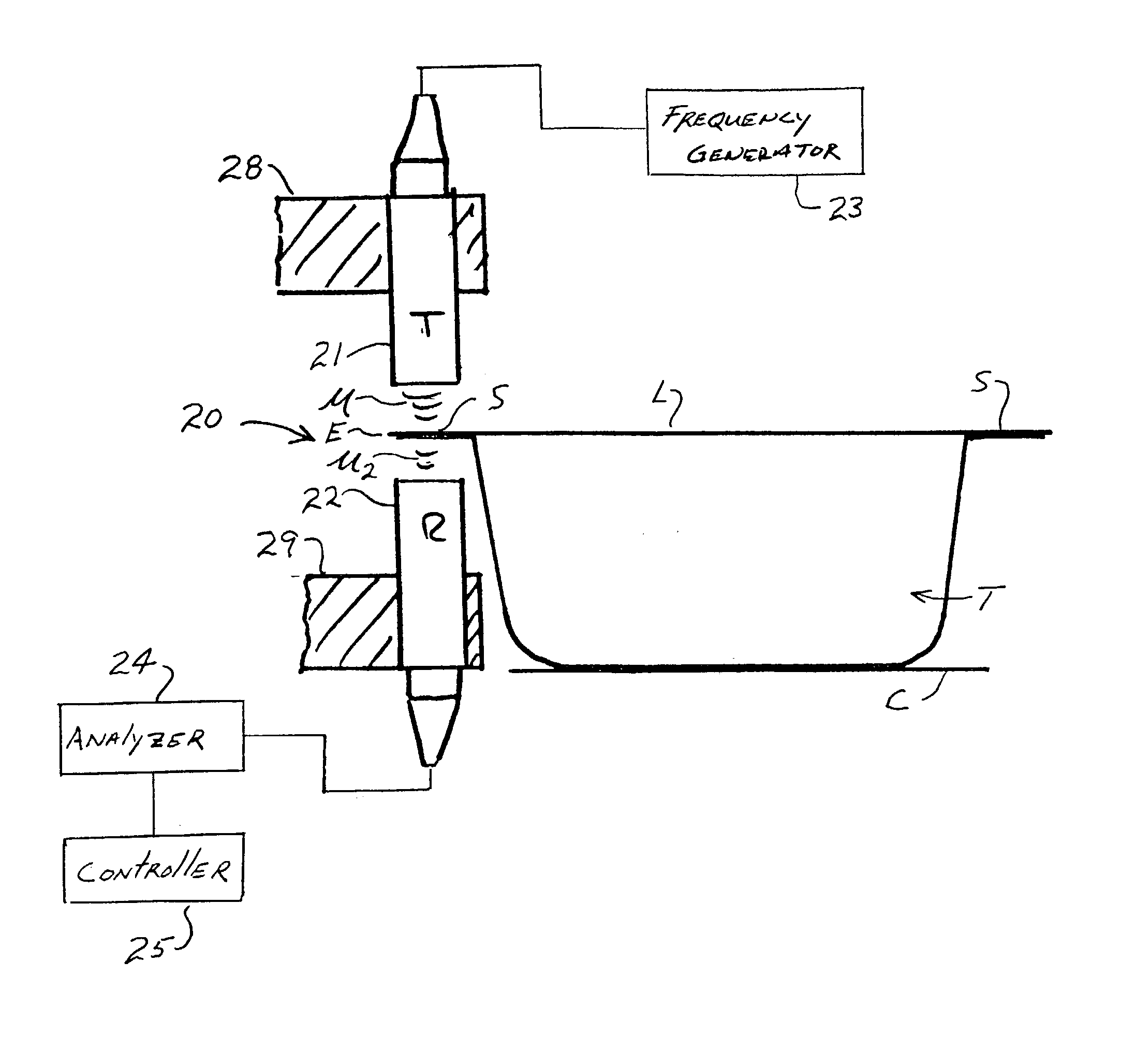

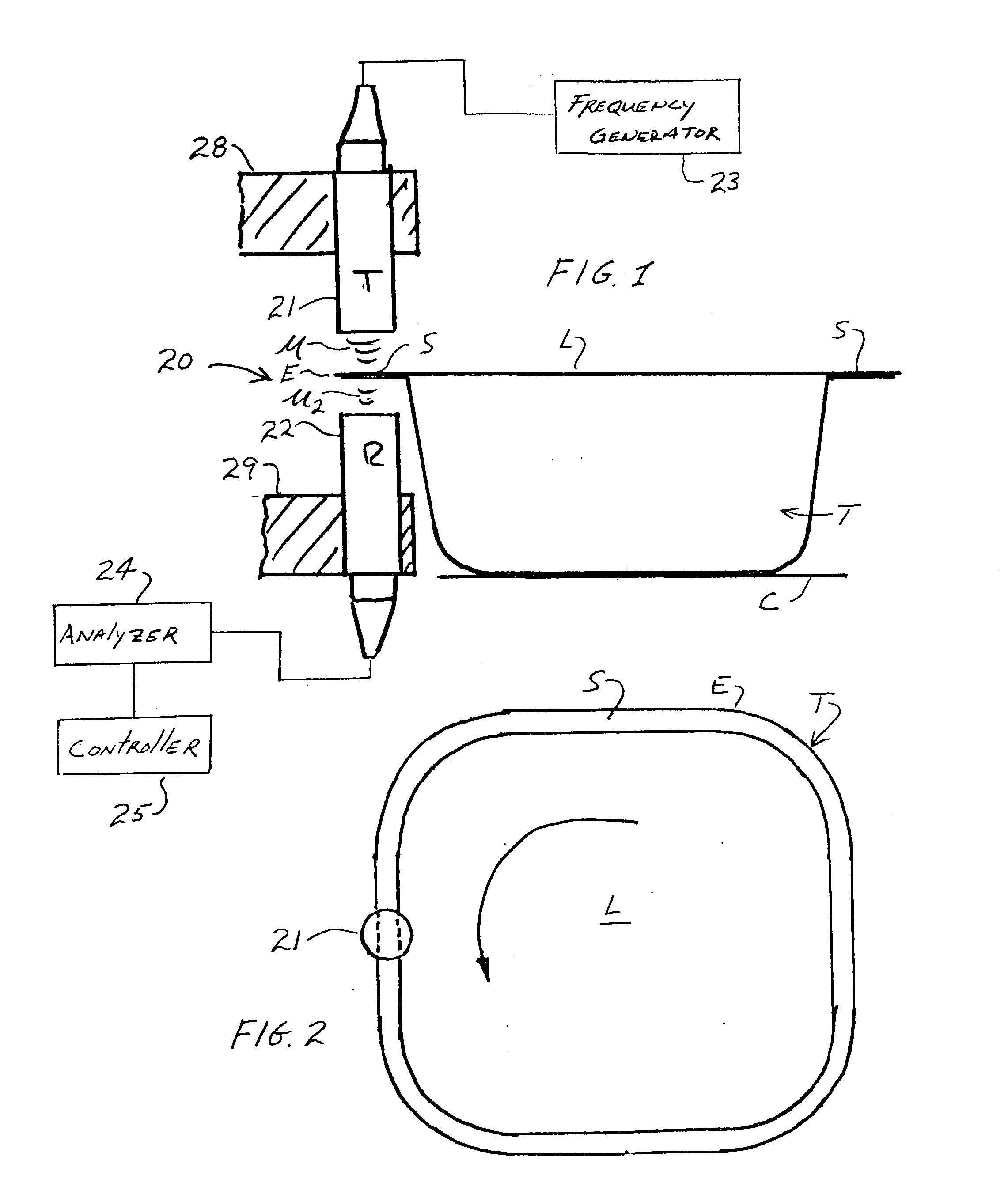

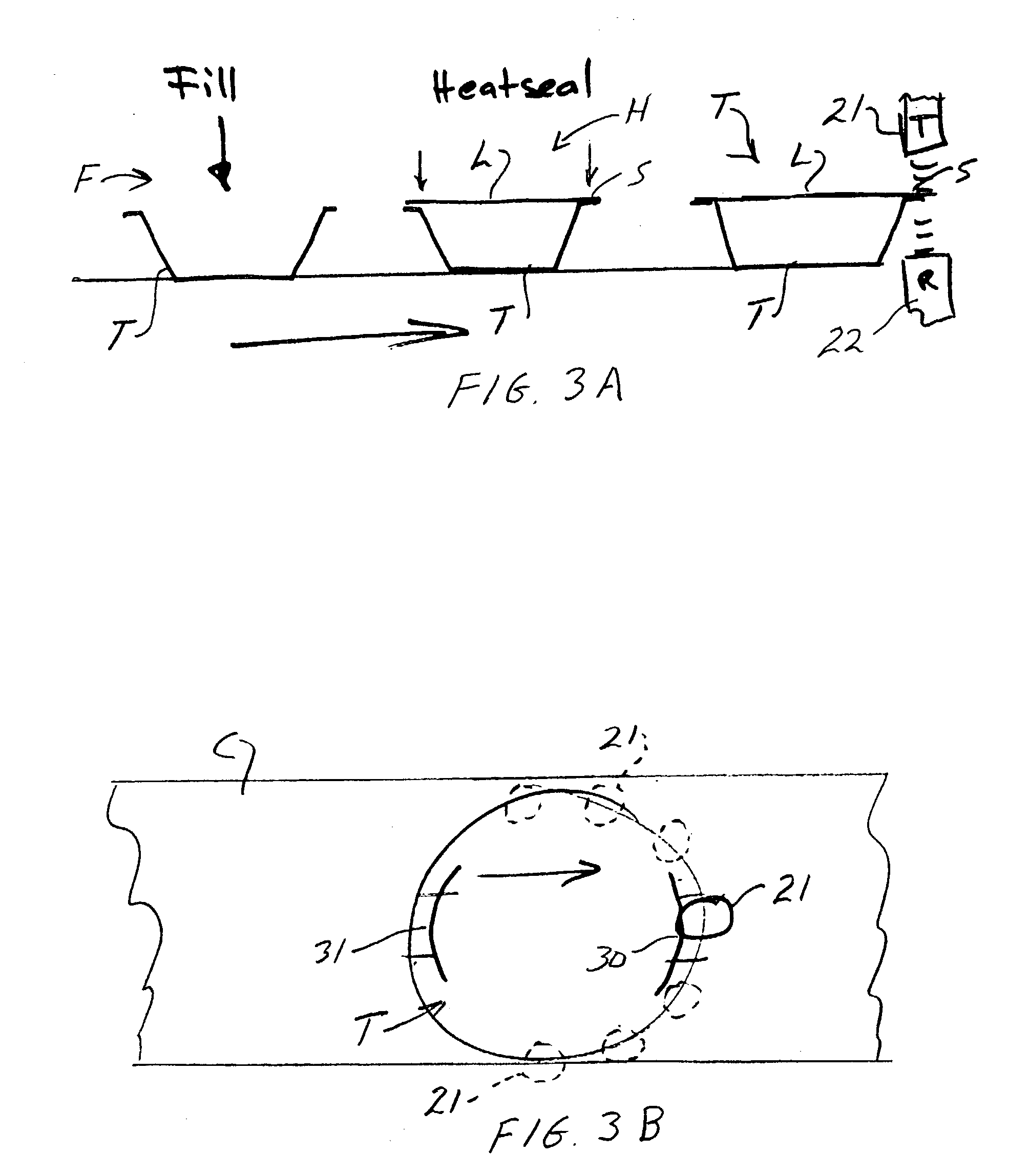

A method for testing or inspecting the integrity of package closure seals using contact and non-contact ultrasonic systems wherein a relative movement is created between a package seal and at least one ultrasonic transmitting transducer and at least one receiving transducer such that ultrasonic energy is focused so as to be transmitted toward and along a length of the seal from the transmitting transducer to the receiving transducer in a gaseous environment to thereby monitor energy signals which are analyzed to provide an indication of the seal integrity.

Owner:PACKAGING TECH & INSPECTION

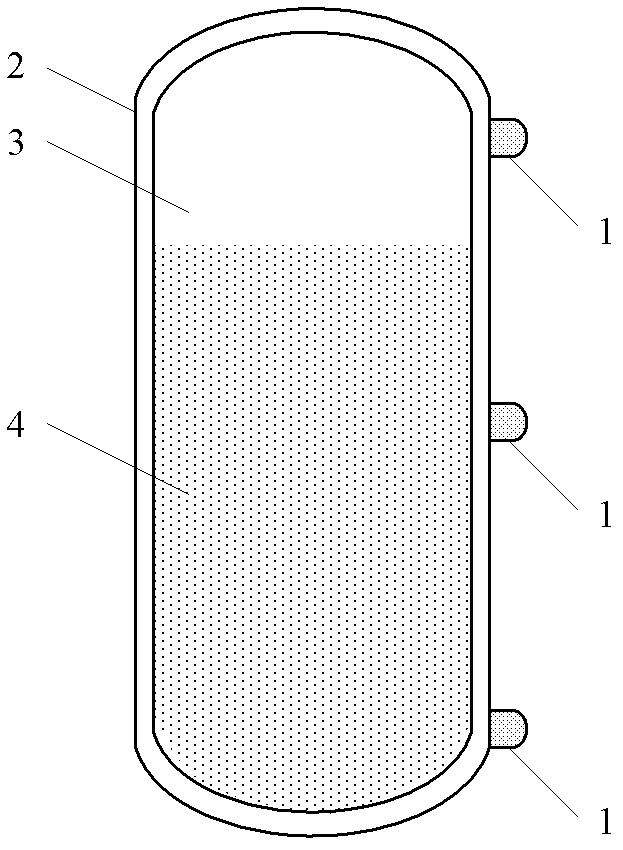

Method for measuring existence of powdery materials in specific material position of container and implementation material level switch thereof

InactiveCN102322920ASolution to short lifeReliable test resultsMachines/enginesLevel indicatorsNon-contact ultrasoundEngineering

The invention discloses a method for measuring the existence of powdery materials in a specific material position of a container and an implementation material level switch thereof. The material level switch is a non-contact type ultrasonic material level switch and is implemented at a material level detection point of the container, detection ultrasonic waves are discontinuously emitted to the container in the production operation according to the set time interval in a direction vertical to the axial line of the container from a position outside the wall surface of the container, the obtained reflection echo signals of the interface between the inner wall surface of the container and media inside the container is subject to intensity comparison with the pre-measured calibration echo signals of the interface between the inner wall surface of the container and the media inside the container stored in a memory when the powdery materials are added into or not added into the container, and whether the powdery materials exist in the material level detection point of the sealed container or not is judged, so the detection and the control on the specific material level of the powdery material container are realized. The method belongs to the technology for carrying out material level detection in a way without contacting the powdery materials in the container, and has the advantages that the detection results are reliable, the service life of the material level switch used as a detection device is long, and the like.

Owner:SICHUAN UNIV

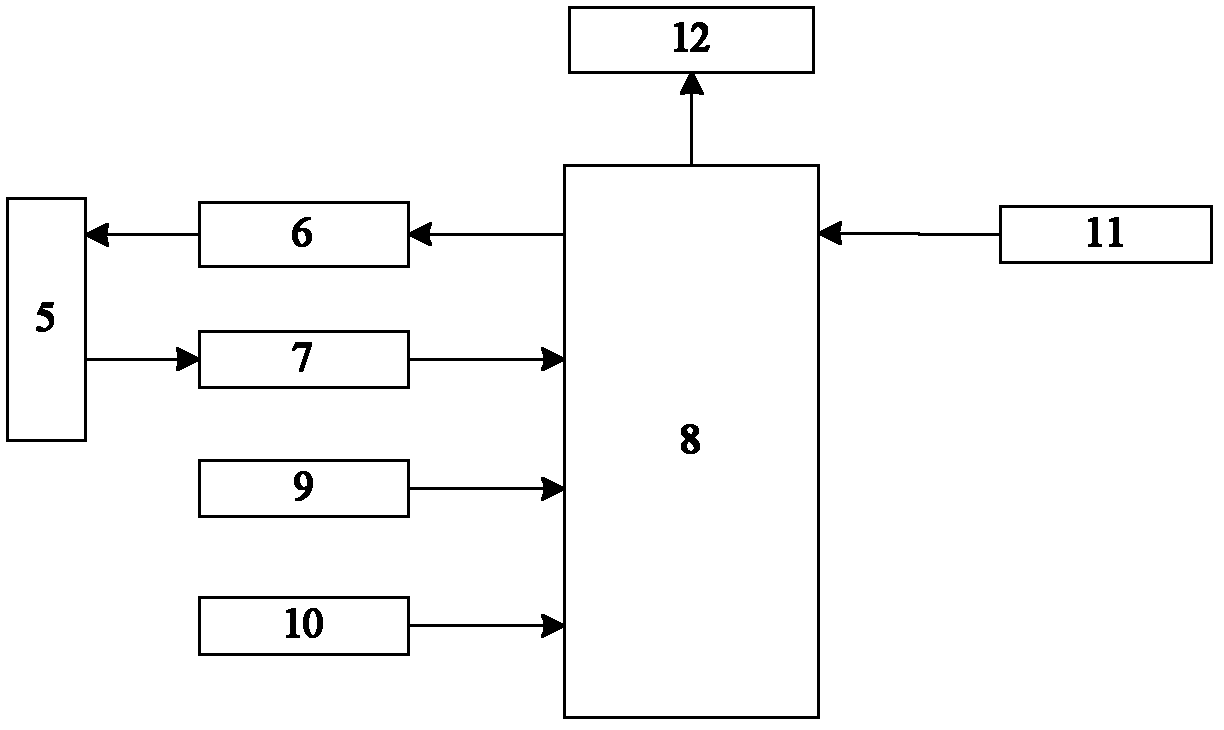

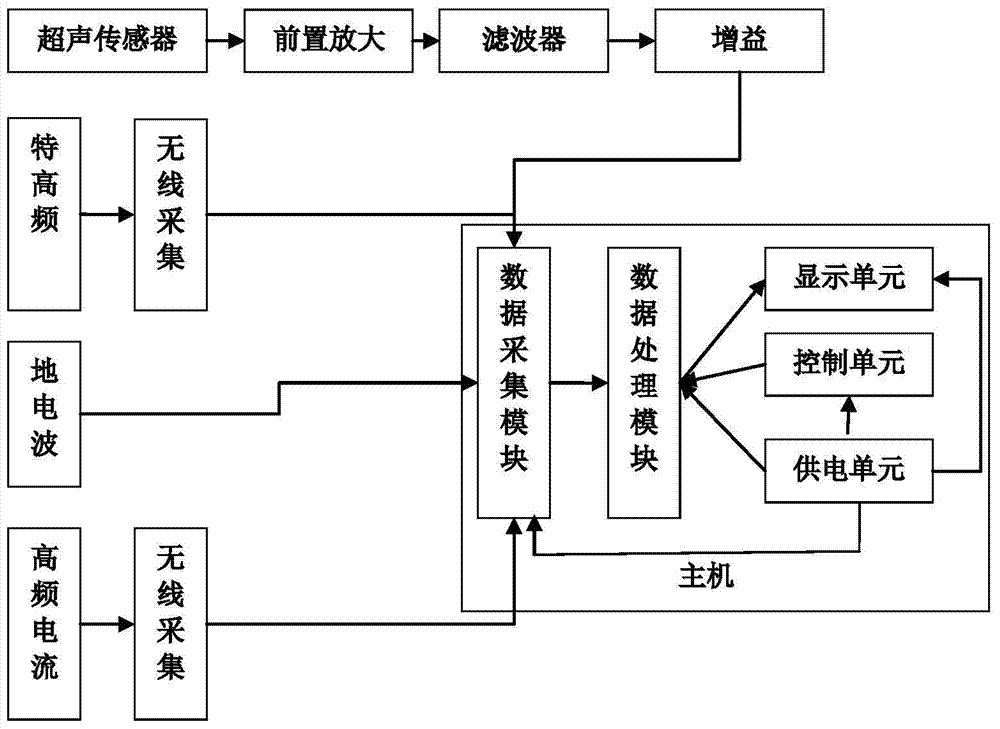

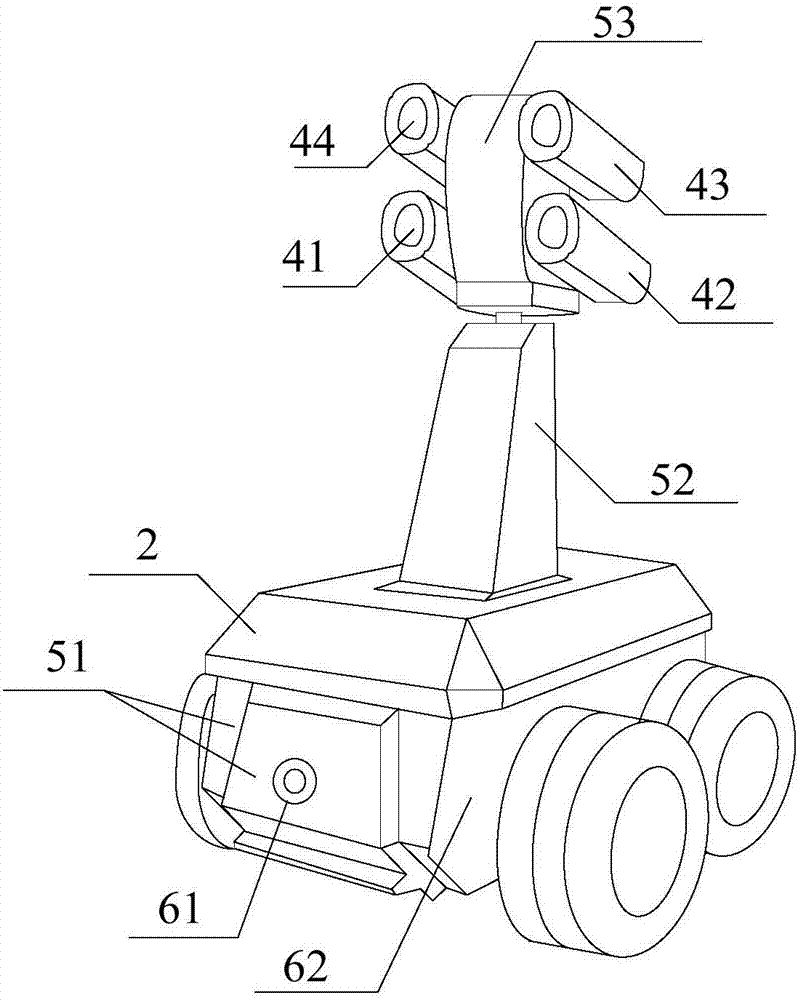

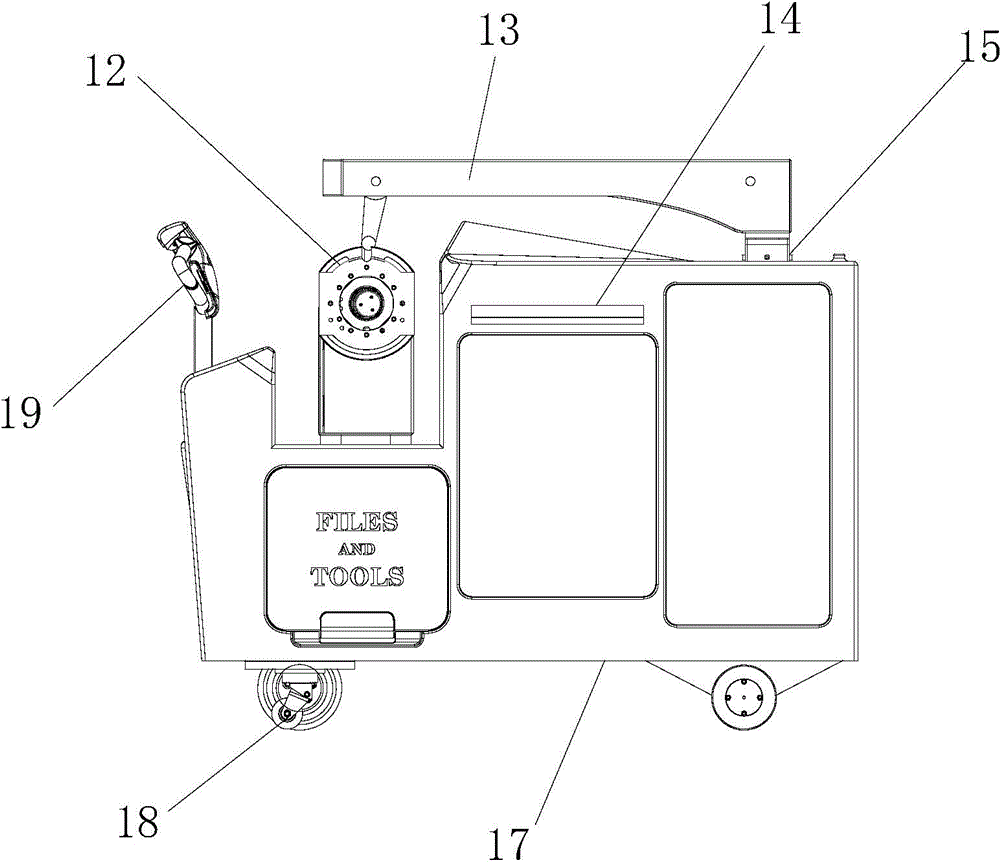

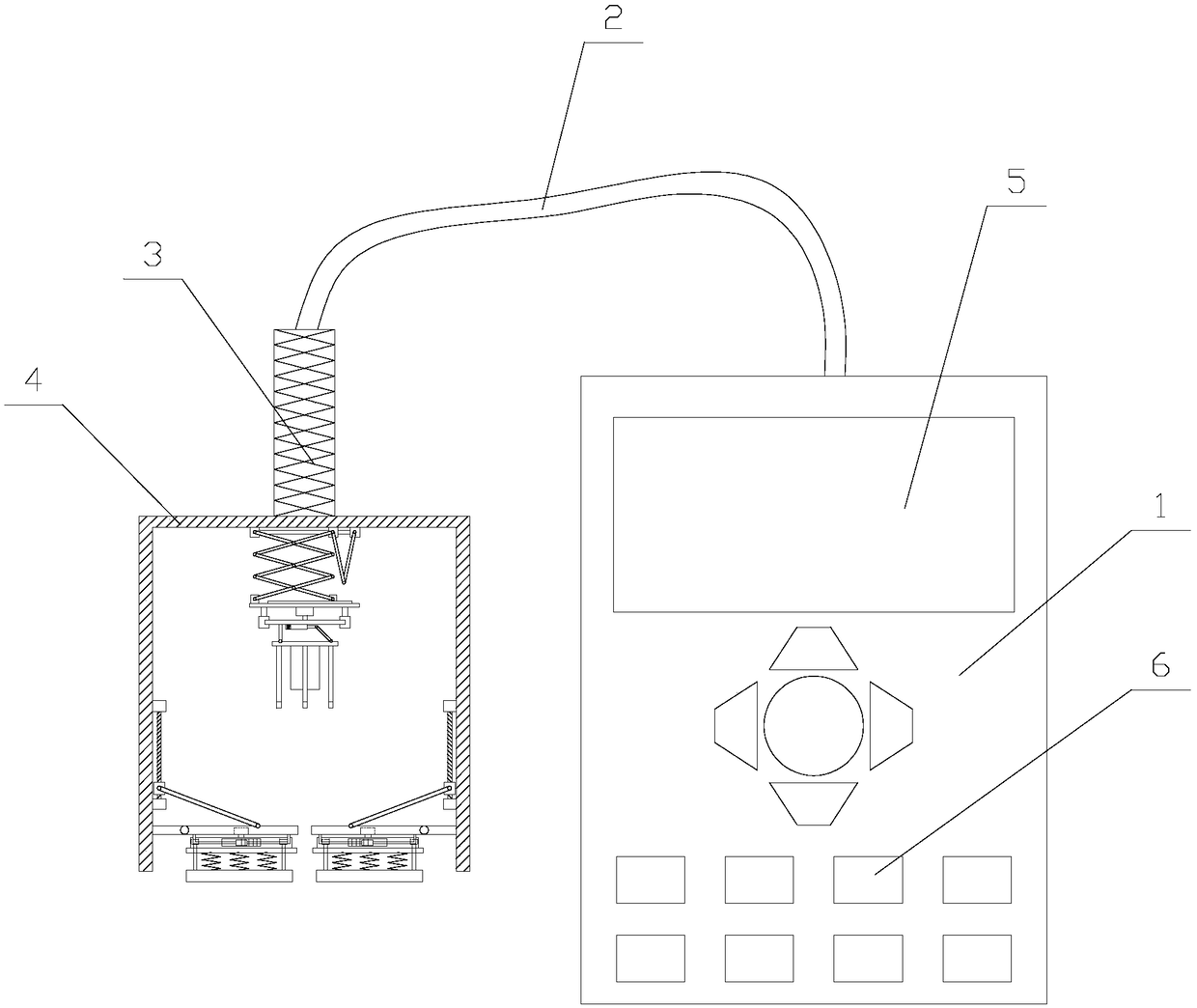

Partial discharge routing inspection device applicable to multiple detection methods

InactiveCN103884970ASave money on purchasesGuaranteed uptimeTesting dielectric strengthCurrent sensorInteraction interface

The invention discloses a partial discharge routing inspection device applicable to multiple detection methods. The device comprises an ultrahigh-frequency sensor with the frequency band ranging from 500 MHz to 1.5 GHz, a high-frequency current sensor with the frequency band ranging from 0.5 MHz to 50 MHz, a ground electric wave sensor, a contact ultrasonic sensor and a non-contact ultrasonic sensor. The ground electric wave sensor and the non-contact ultrasonic sensor are arranged inside a host, the ultrahigh-frequency sensor and the high-frequency current sensor transmit data to the host in a wireless mode through a wireless collection module, the host is mainly composed of a signal collection unit, a data processing module and a human-computer interaction interface, and the host analyzes collected partial discharge data, judges whether partial discharge exists or not, analyzes the partial discharge type and evaluates working conditions of high voltage electric power equipment. The partial discharge routing inspection device is compact in structure and convenient to carry, has multiple detection functions and effectively detects partial discharge of the high voltage electric power equipment on site with the multiple detection methods.

Owner:SHANGHAI JUFANG SOFTWARE TECH +1

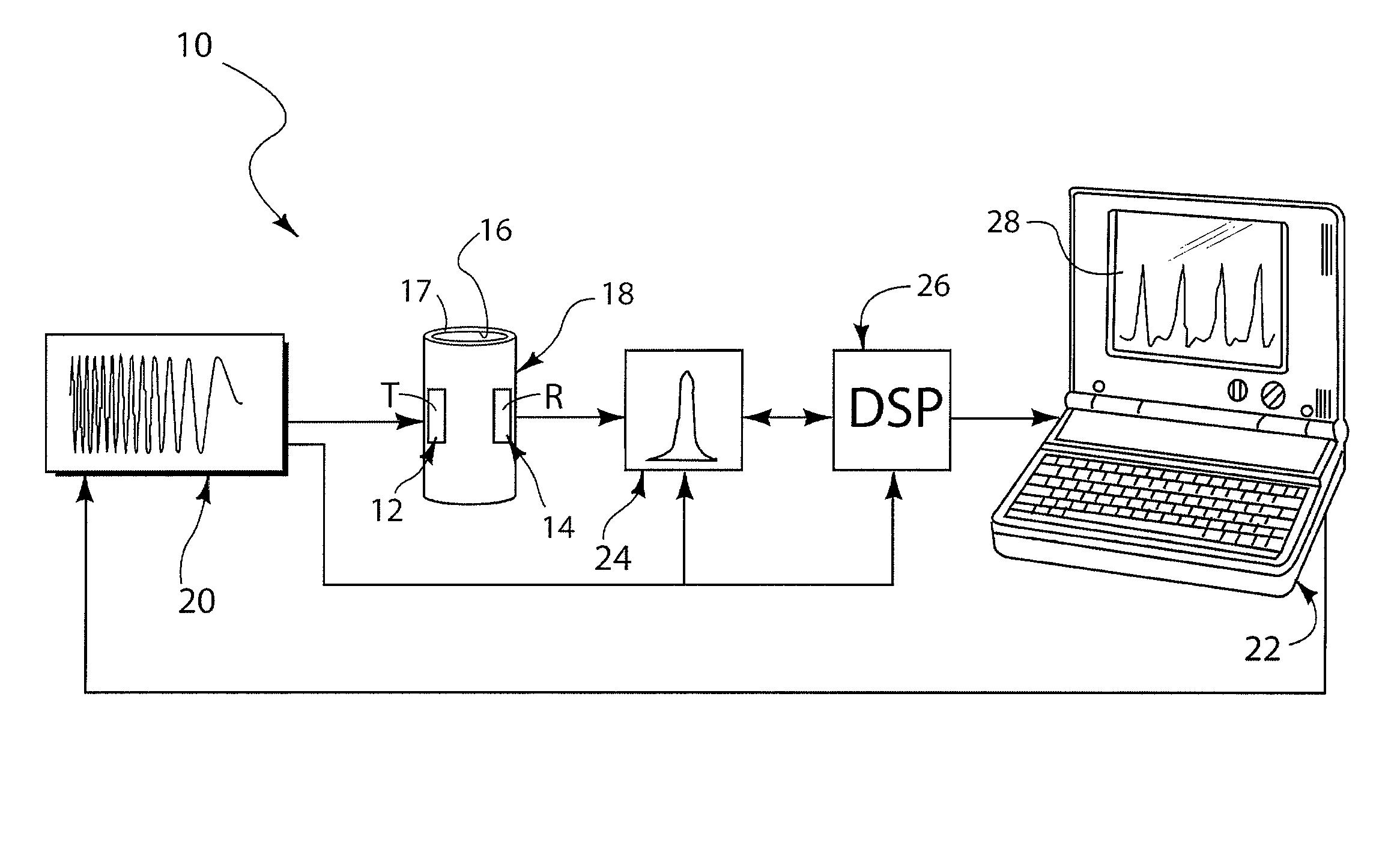

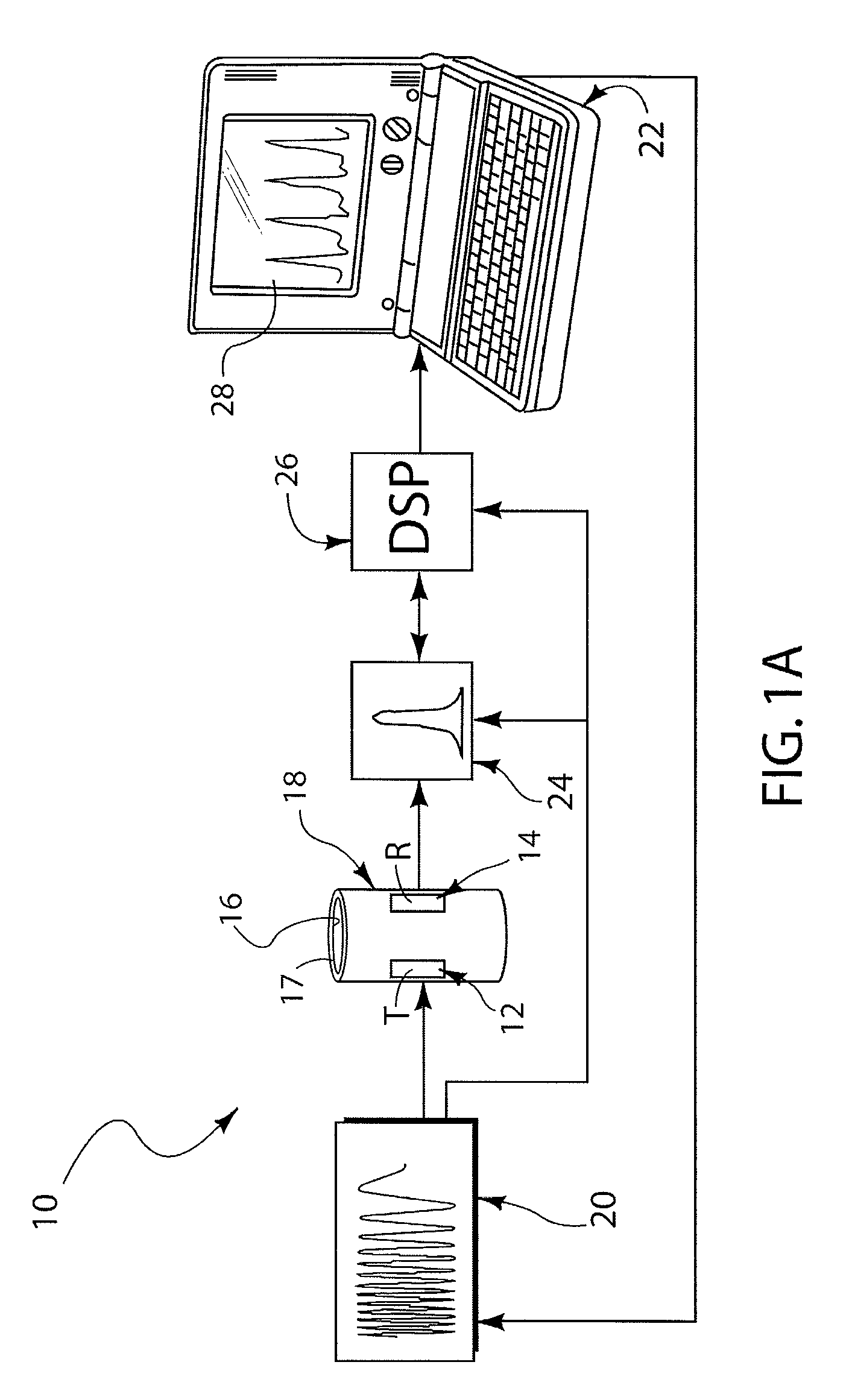

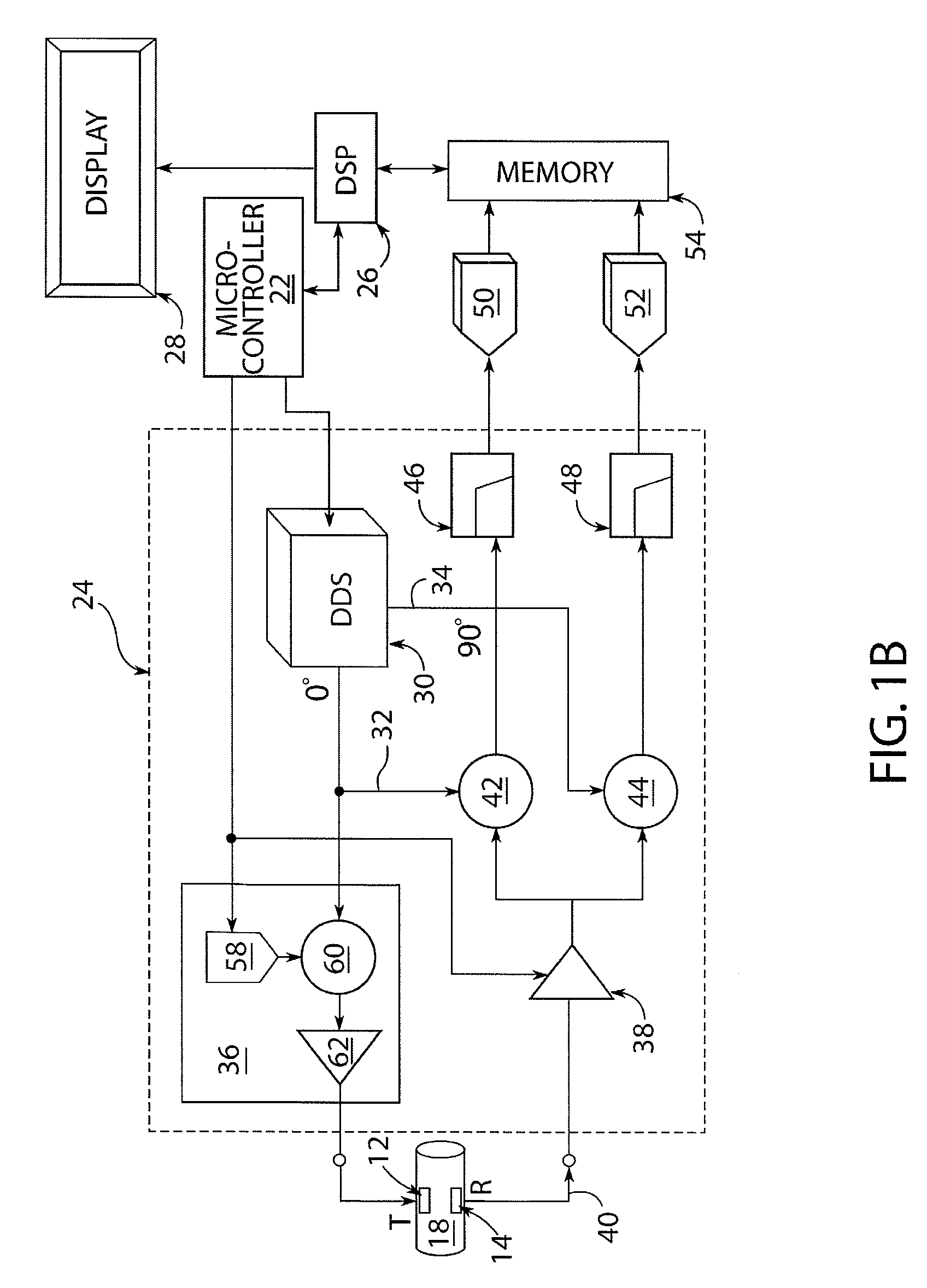

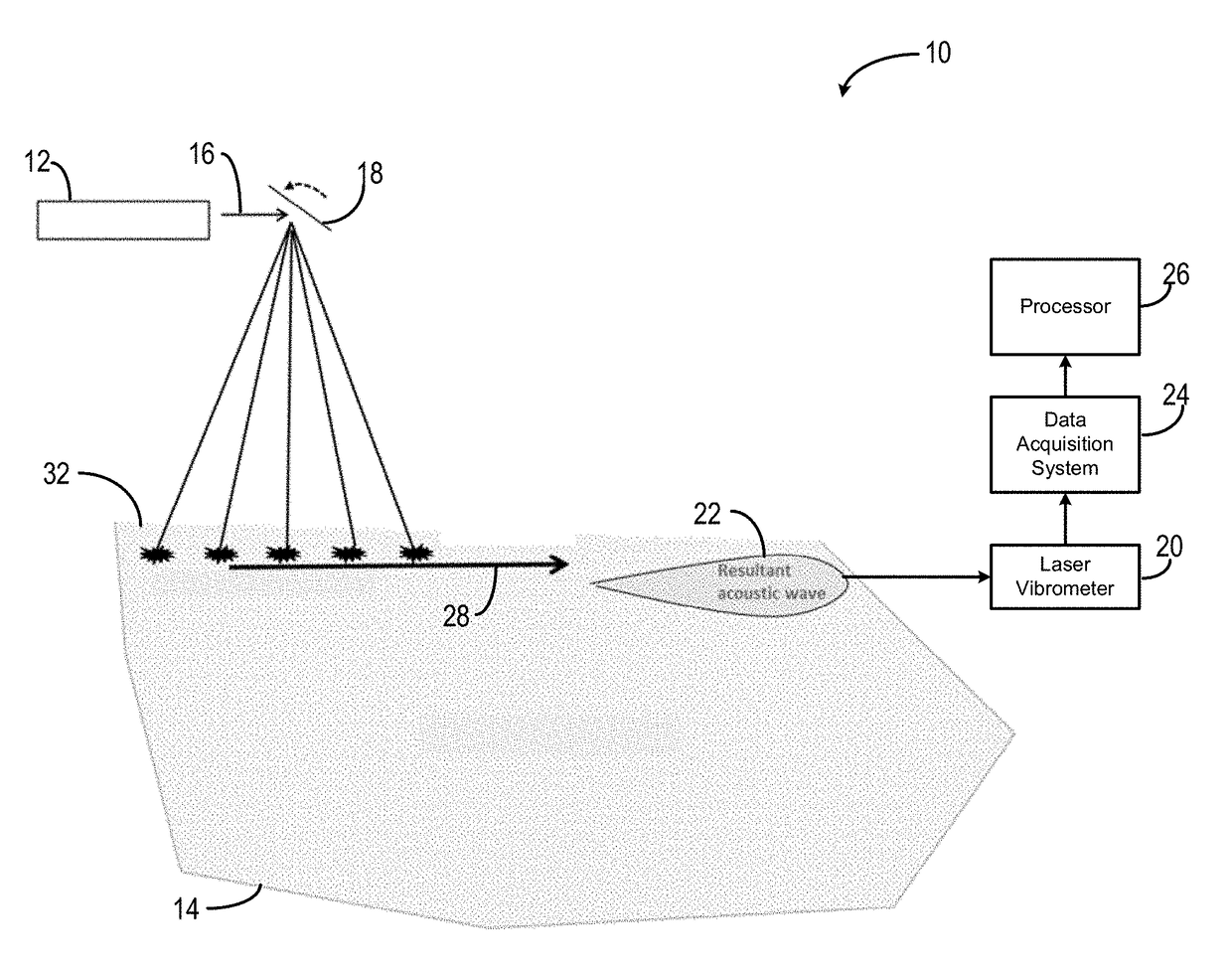

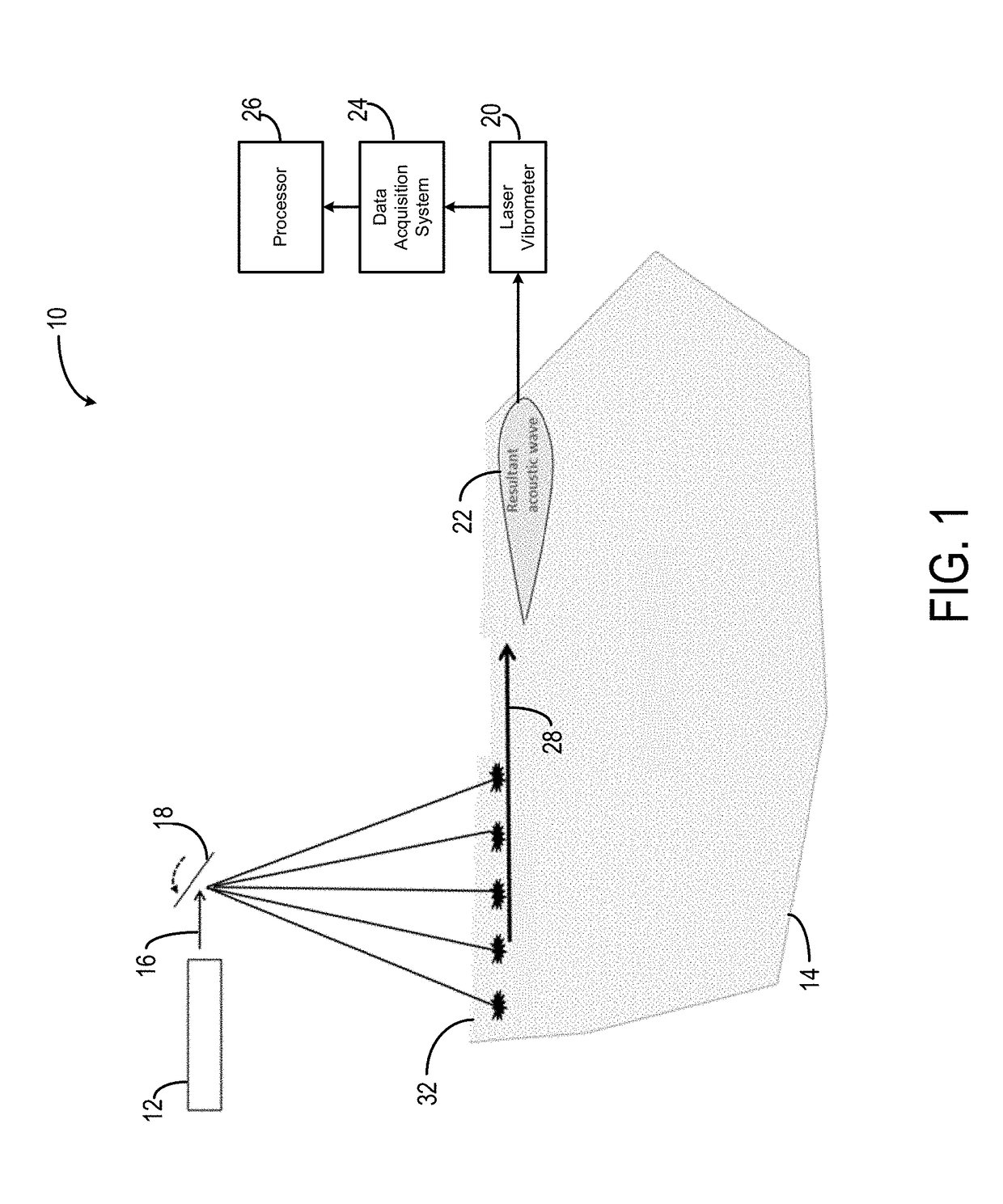

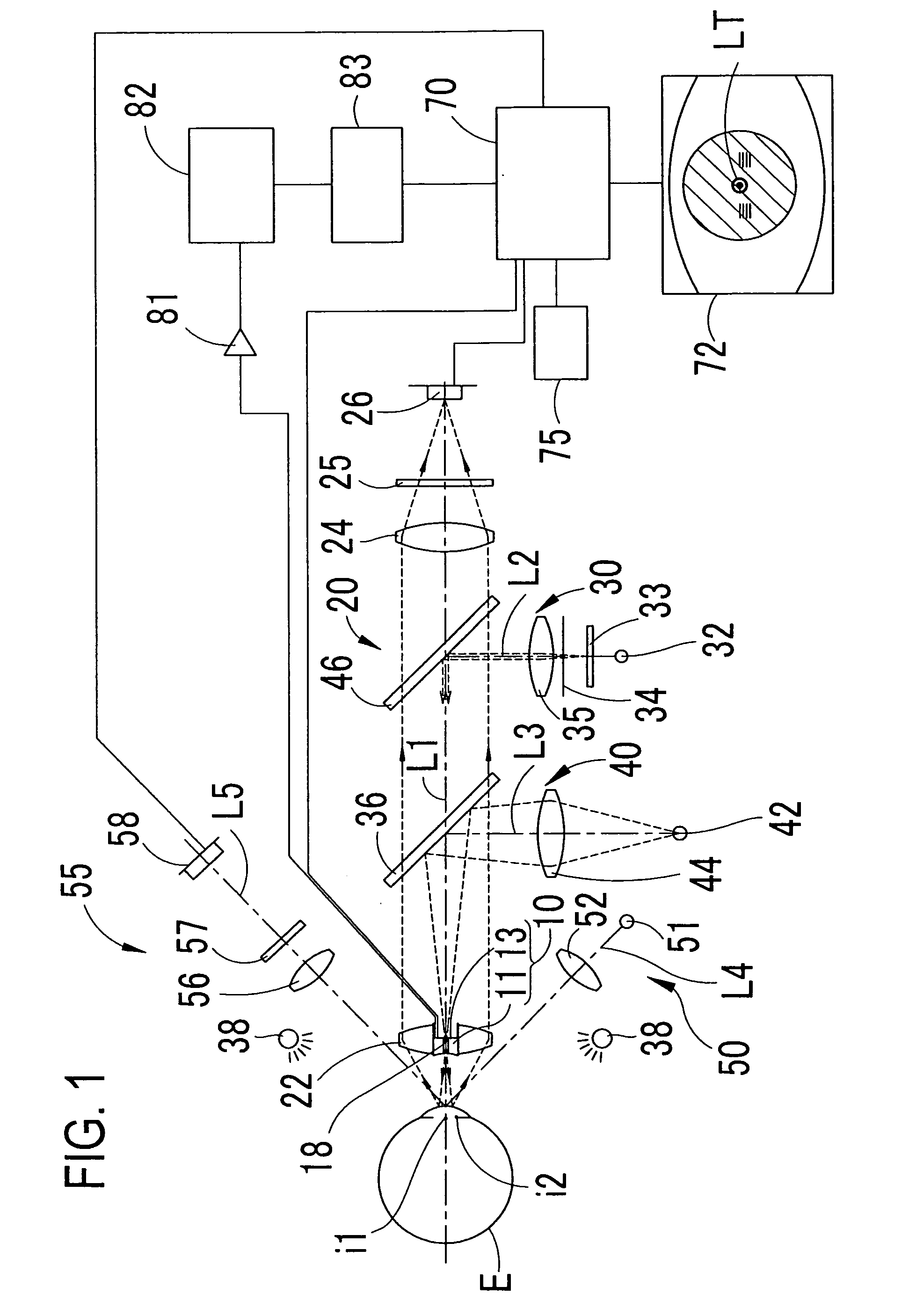

System and method for non-contact ultrasound

ActiveUS20150148655A1Overcomes drawbackLarge amplitudeOrgan movement/changes detectionAcoustic sensorsNon-contact ultrasoundSonification

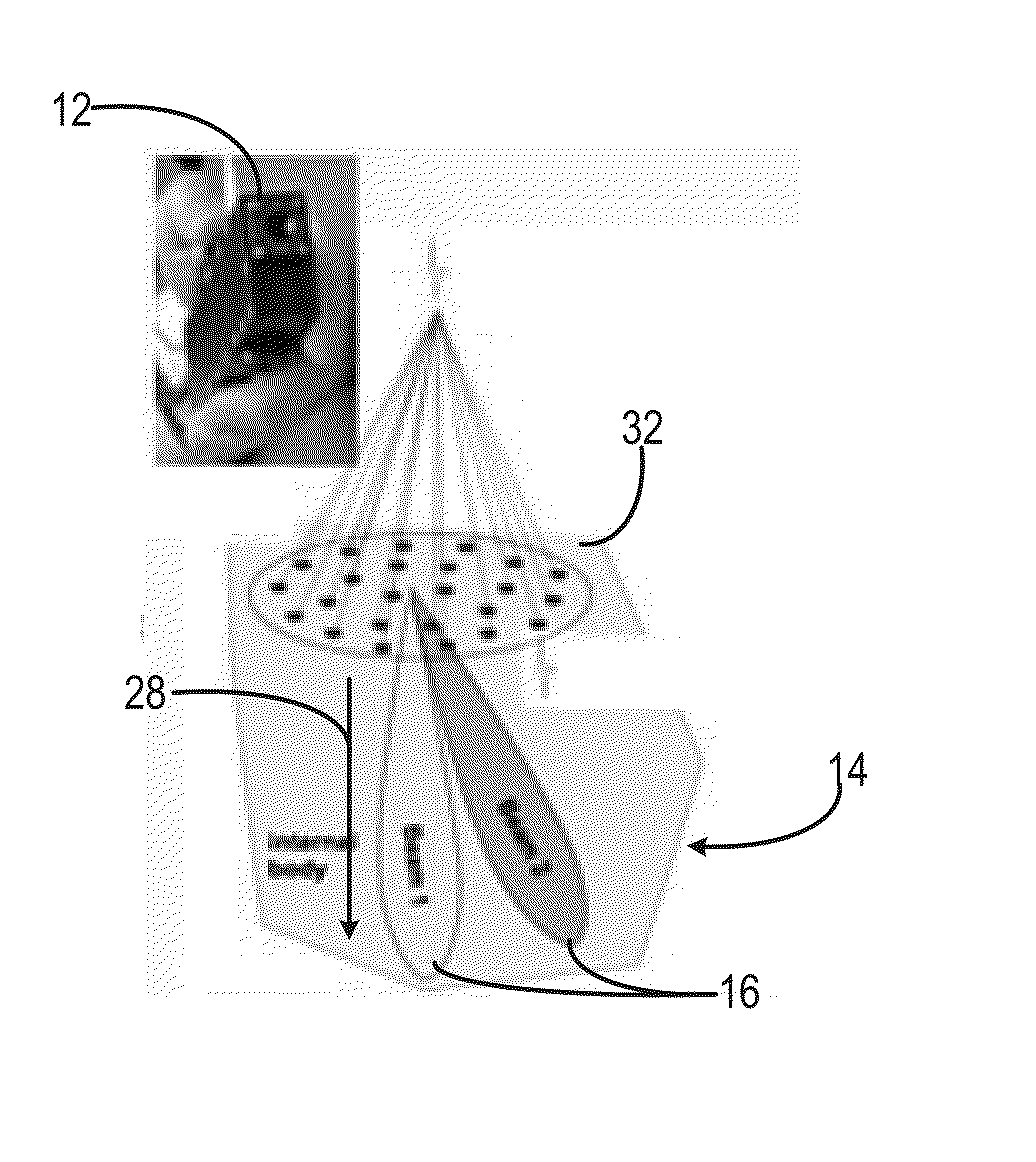

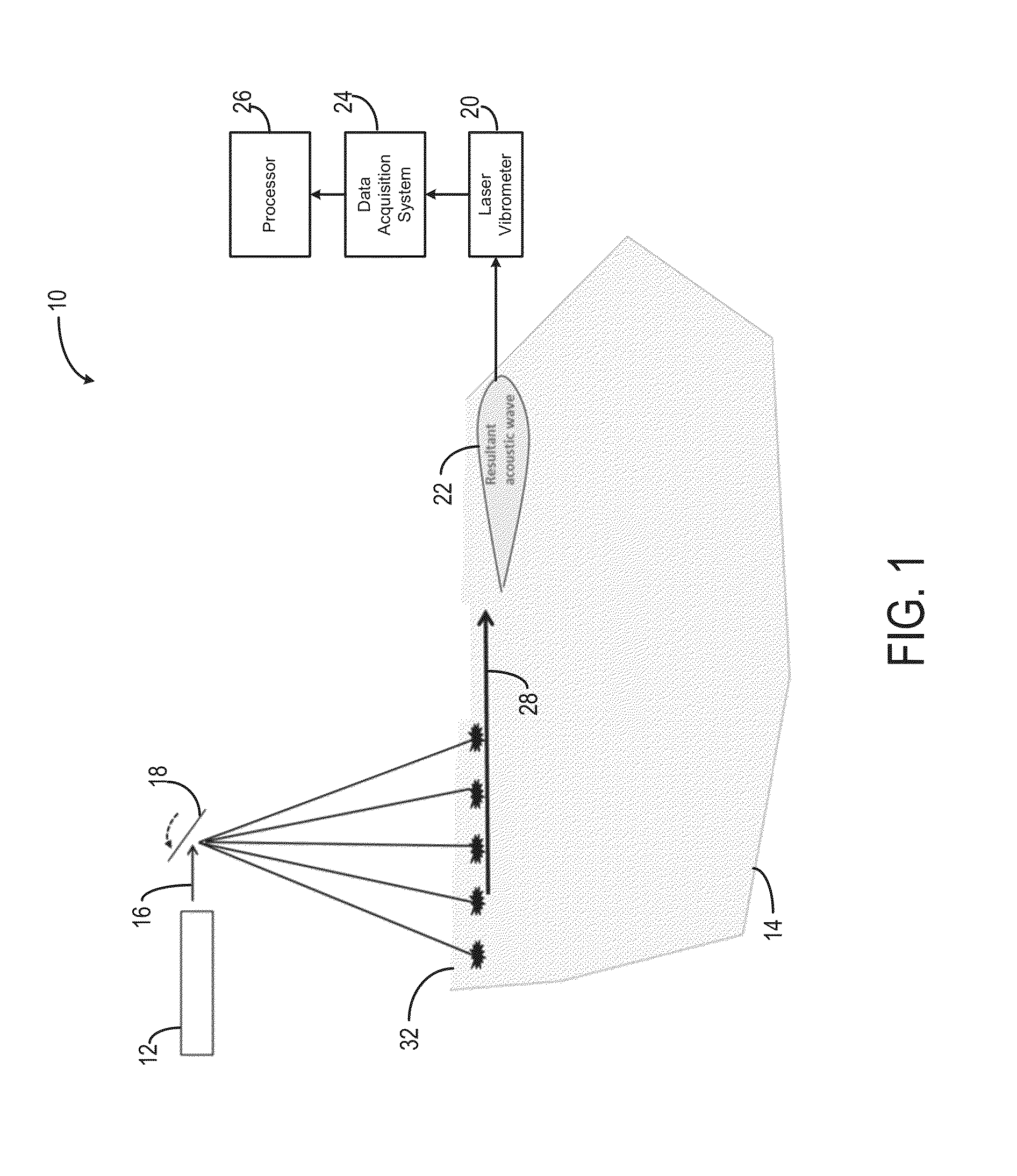

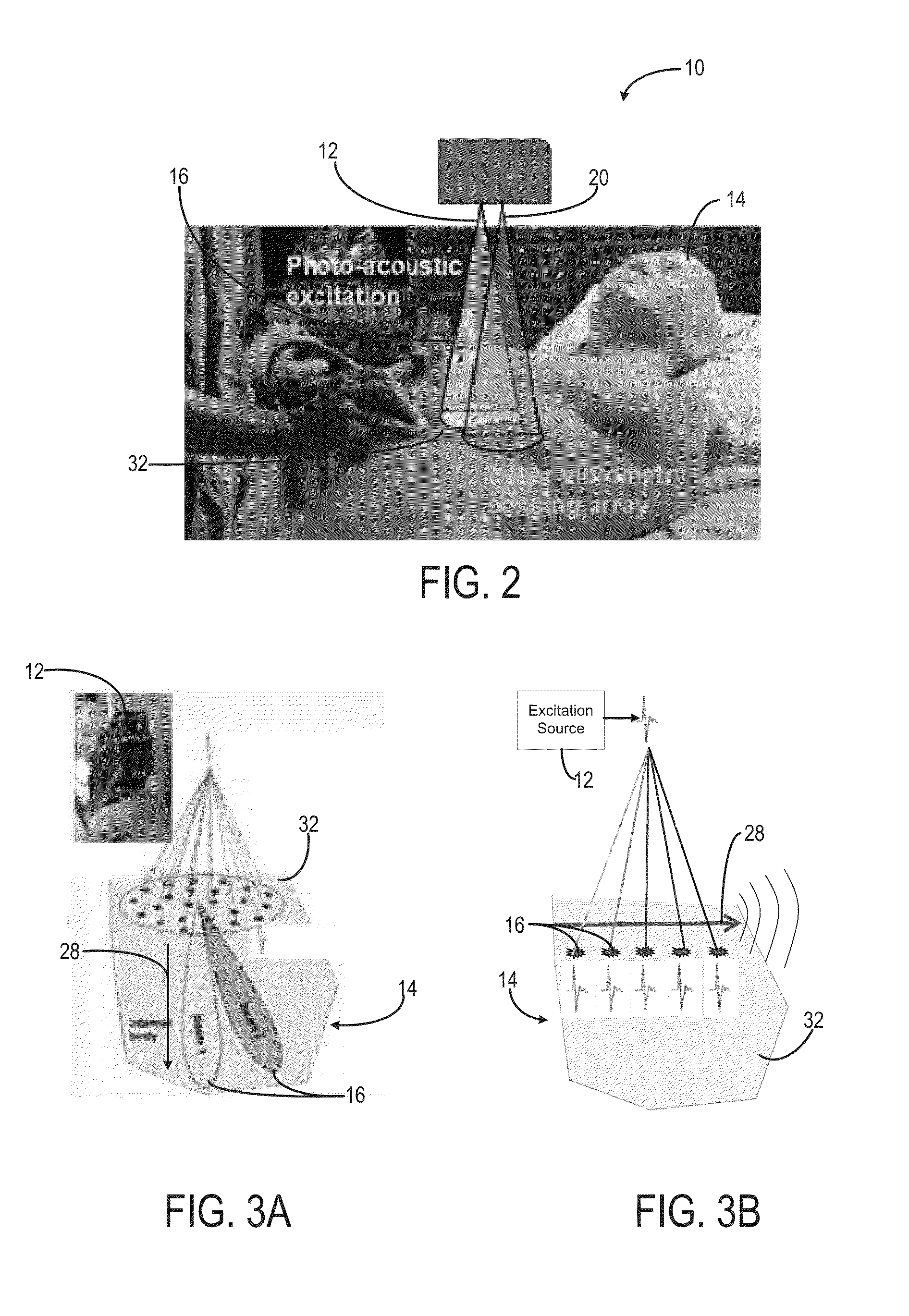

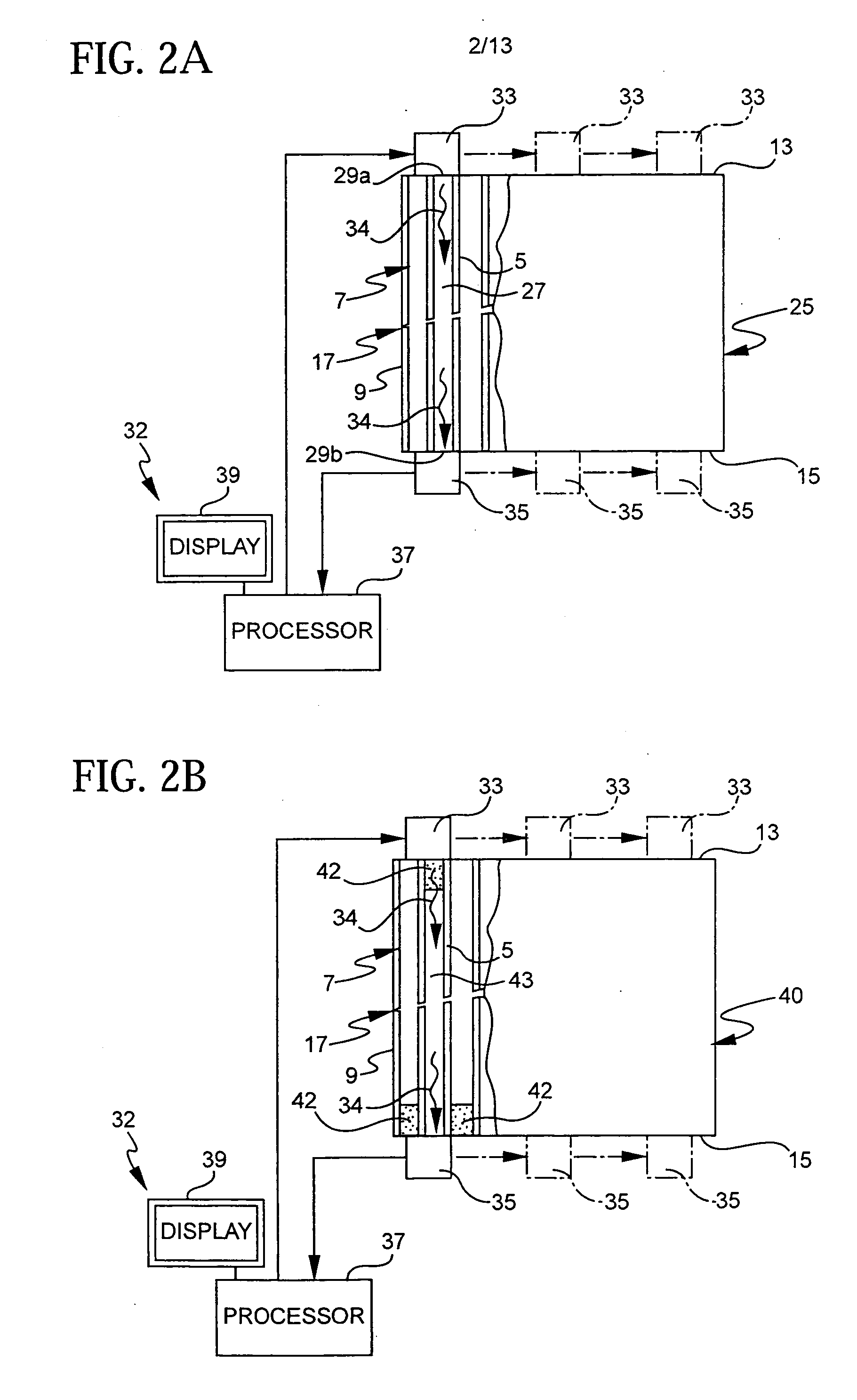

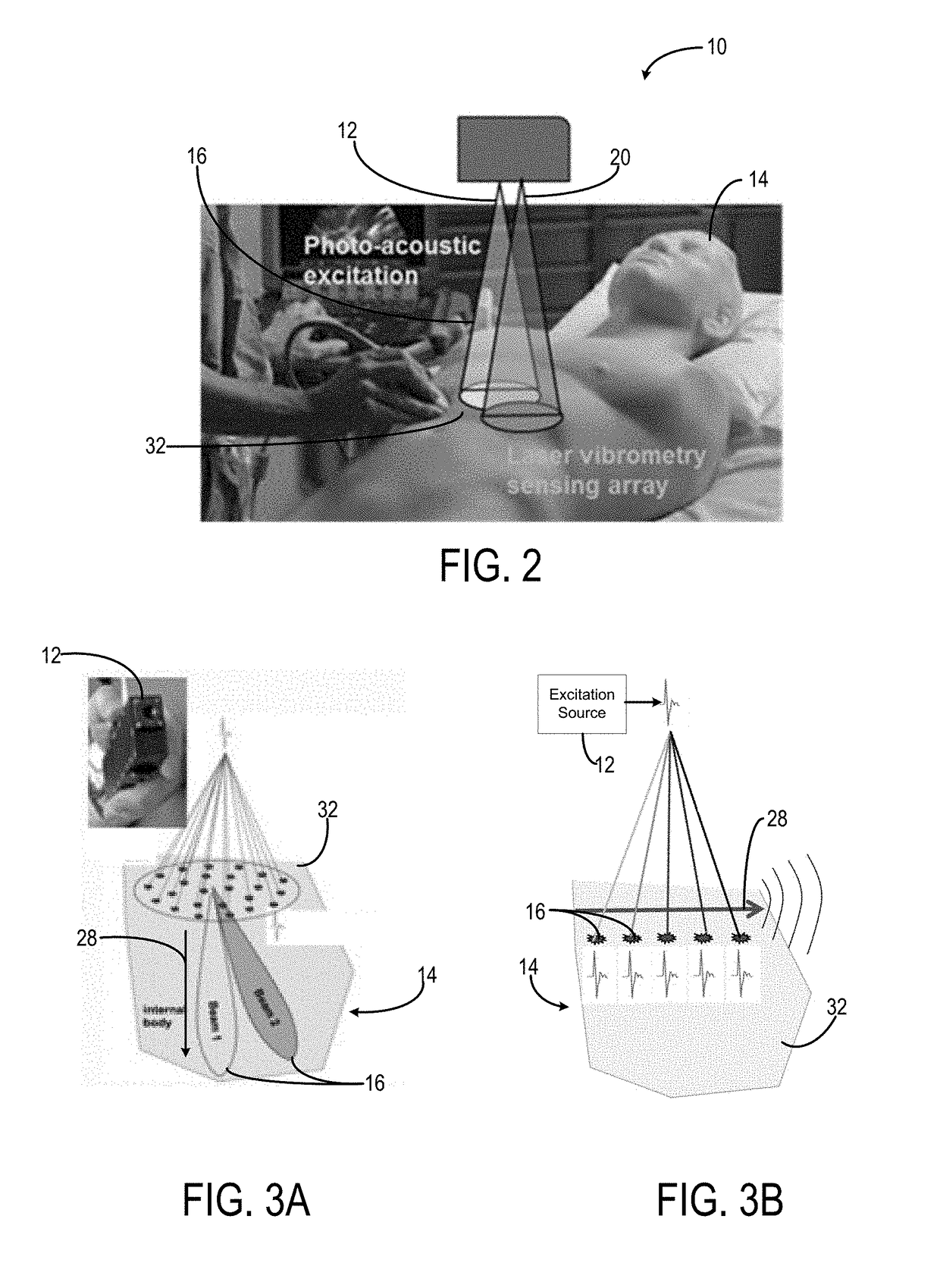

A system and method for generating ultrasound images of a subject without physically contacting the subject is provided. A photoacoustic excitation source may be employed that directed into a scanning mirror to transmit acoustic disturbances into a patient to induce propagating photoacoustic waves. The acoustic disturbances are translated along the patient in a defined direction to cause coherent summation of the propagating photoacoustic waves and, thereby, a resultant acoustic and / or elastic wave to probe structures within the patient. Vibrations created by the backscatter of the resultant wave are detected at the surface of the patient and ultrasound images of the structures within the patient are generated. Detection of the vibrations may be performed using a laser vibrometer. The excitation and detection systems may be used separately or in combination.

Owner:MASSACHUSETTS INST OF TECH

Method and apparatus for airborne ultrasonic testing of package and container seals

InactiveUS20040129081A1Analysing solids using sonic/ultrasonic/infrasonic wavesWork measurementSonificationNon-contact ultrasound

A method for testing or inspecting the integrity of package closure seals using contact and non-contact ultrasonic systems wherein a relative movement is created between a package seal and at least one ultrasonic transmitting transducer and at least one receiving transducer such that ultrasonic energy is focused so as to be transmitted toward and along a length of the seal from the transmitting transducer to the receiving transducer in a gaseous environment to thereby monitor energy signals which are analyzed to provide an indication of the seal integrity.

Owner:PACKAGING TECH & INSPECTION

Fully-automatic electrification detection method and device of high voltage switch cabinet

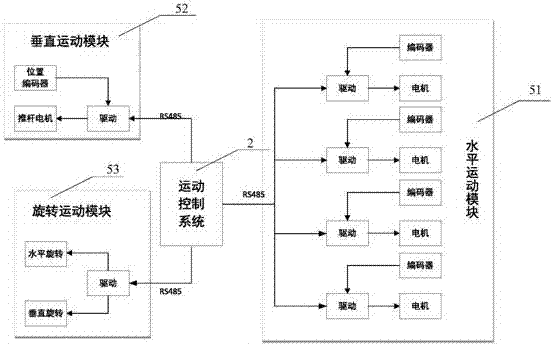

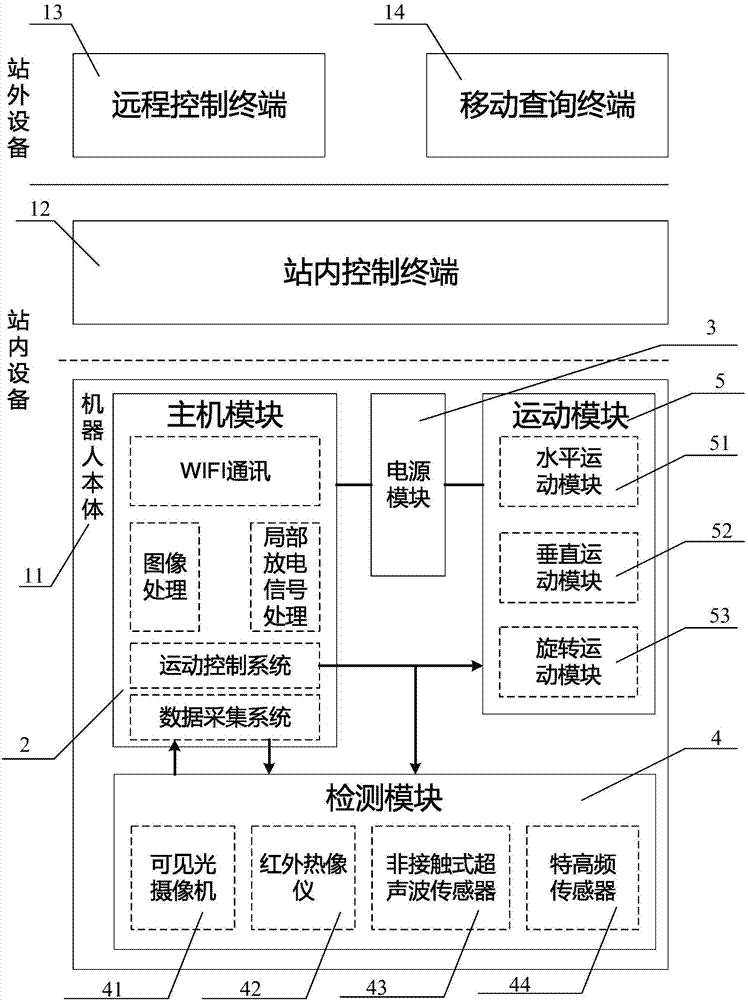

ActiveCN107367672AImplement automatic detectionRealize real-time monitoringProgramme-controlled manipulatorRadiation pyrometryNon-contact ultrasoundTransformer

The invention relates to a fully-automatic electrification detection method and device of a high voltage switch cabinet. The device comprises a robot body. The robot body comprises a host module, a power supply module, a detection module and a moving module. The power supply module is electrically connected with the host module and the moving module. The host module is in signal connection with the moving module and the detection module. The detection module comprises a visible light camera, an infrared thermal imager, a non-contact ultrasonic wave sensor and an ultra-high frequency sensor. In a detection process, a detection path is pre-planned by the detection device; a task packet is established according to the layout of the switch cabinet; after the detection device is aligned to the switch cabinet, infrared detection and local detection are performed, so fully automatic detection work of local discharging and infrared thermal imaging detection projects of the high voltage switch cabinet in a high voltage chamber of a transformer station can be achieved and labor cost for electrification detection is greatly reduced.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

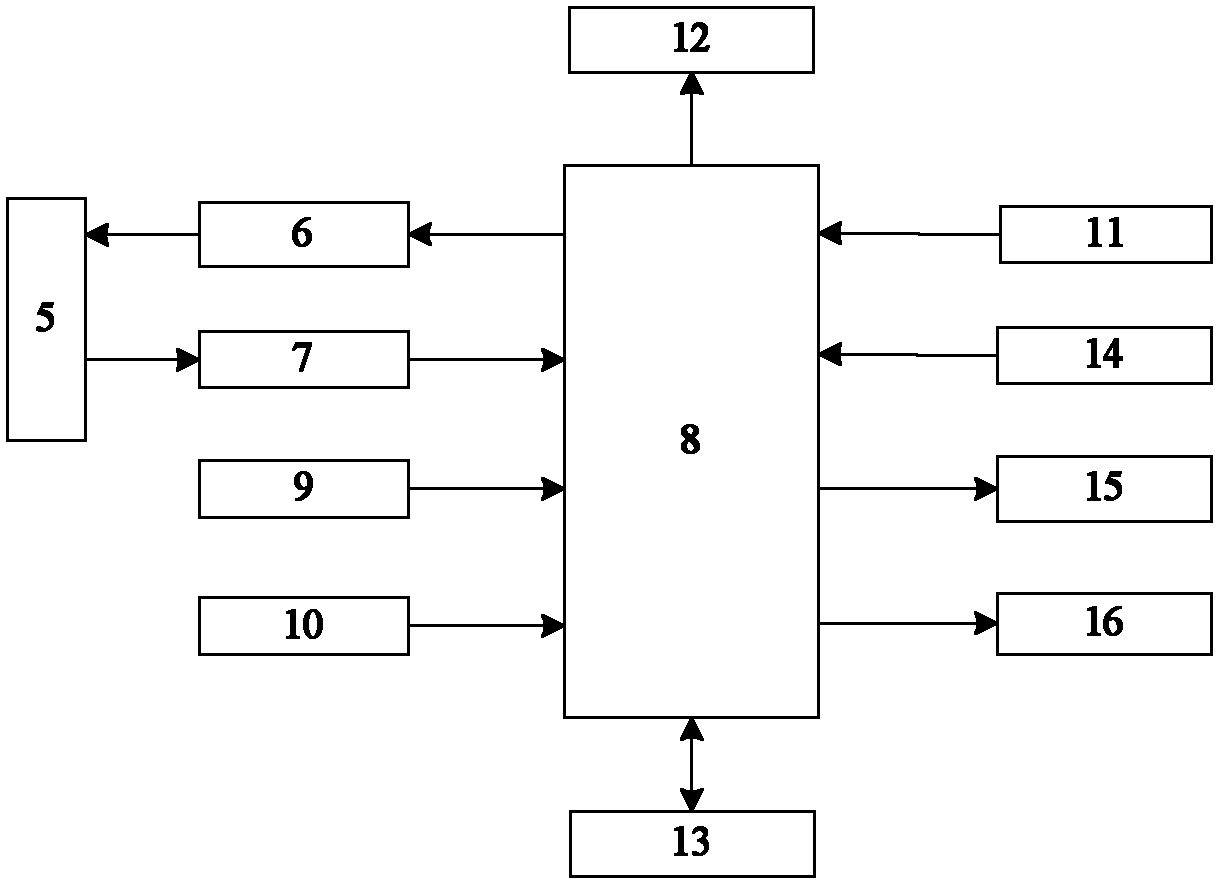

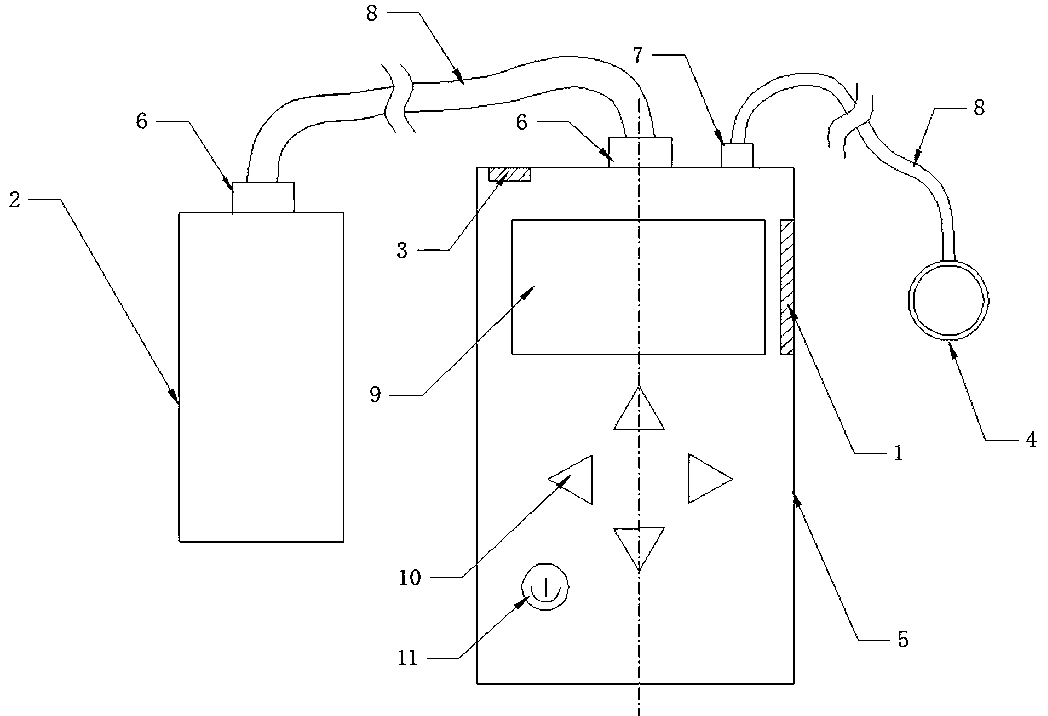

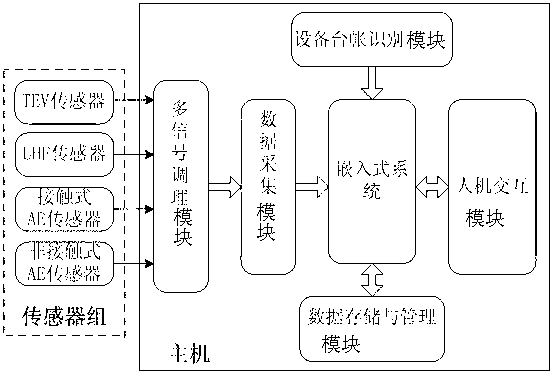

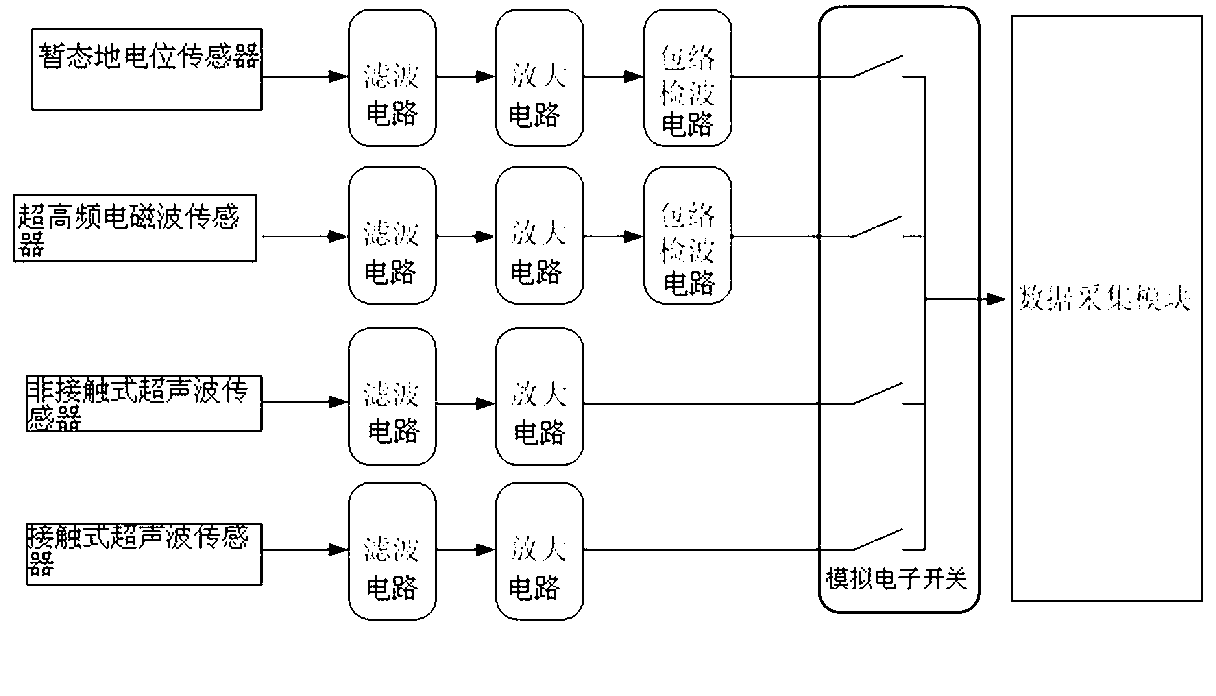

Partial discharge comprehensive itinerant detector for high voltage electric power equipment

ActiveCN103278751ARealize the comprehensive detection of partial dischargeImprove defect detection rateTesting dielectric strengthTransformerElectric power equipment

The invention discloses a partial discharge comprehensive itinerant detector for high voltage electric power equipment. The partial discharge comprehensive itinerant detector for the high voltage electric power equipment is characterized by comprising a host and a sensor group connected with the host, wherein the sensor group comprises a transient state ground potential sensor, an ultrahigh frequency electromagnetic wave sensor, a non-contacting ultrasonic sensor and a contacting ultrasonic sensor; the transient state ground potential sensor is used for detecting a current pulse signal on the shell of the electric power equipment; the ultrahigh frequency electromagnetic wave sensor is used for detecting an electromagnetic wave signal transmitted from the inside of the electric power equipment; the non-contacting ultrasonic sensor is used for detecting an ultrasonic wave signal transmitted from the inside of the electric power equipment; the contacting ultrasonic sensor is used for detecting shell vibration caused by the ultrasonic wave signal transmitted from the inside of the electric power equipment; and the transient state ground potential sensor, the ultrahigh frequency electromagnetic wave sensor, the non-contacting ultrasonic sensor and the contacting ultrasonic sensor are all connected with the host. According to the partial discharge comprehensive itinerant detector, a transformer, a composite apparatus (gas insulated switchgear) and a switch cabinet can be conveniently subjected to partial discharge electrification detection, and the partial discharge comprehensive itinerant detector for the high voltage electric power equipment has the outstanding advantages of convenience in carrying the instrument, as well as quickness and intellectualization in detection.

Owner:STATE GRID CORP OF CHINA +2

Non-contact ultrasonic testing method and device for ceramic honeycomb structures

ActiveUS20070266789A1Quick and efficientQuickly “scanMultiple-port networksAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationNon-contact ultrasound

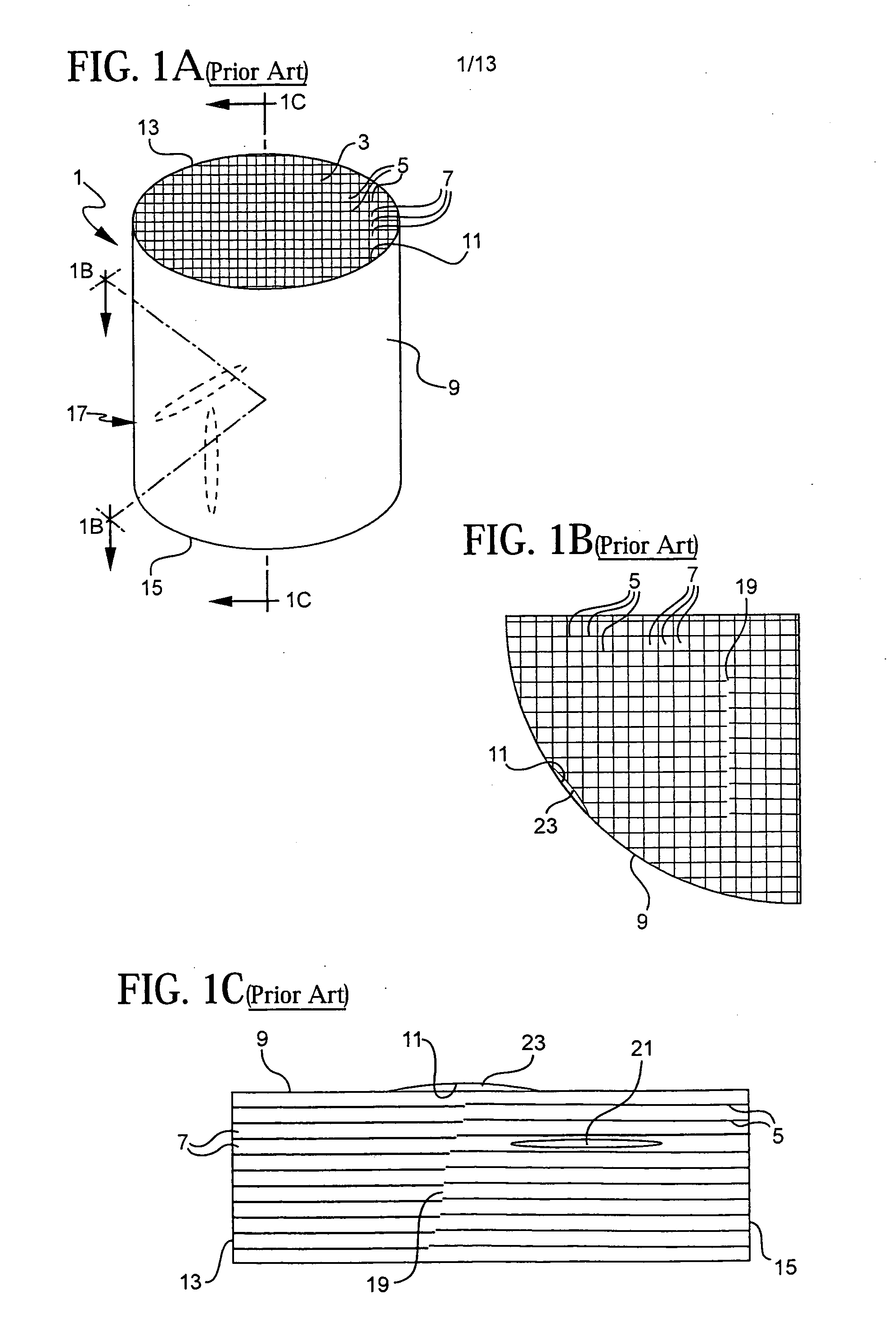

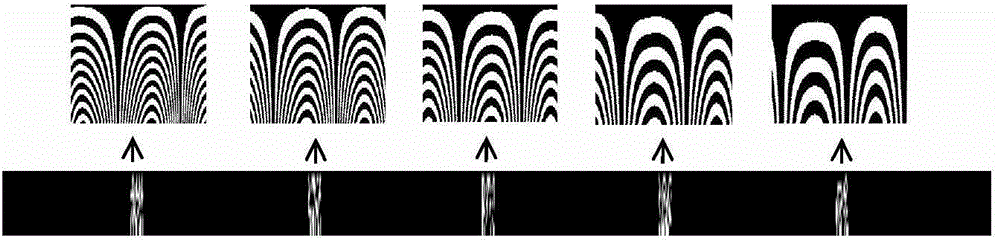

Both a method and apparatus for determining internal discontinuities or inhomogeneities in a green or fired ceramic honeycomb structure is provided. In the method of the invention, an ultrasonic transmitter is positioned adjacent to, but not in contact with, the honeycomb structure. The transmitter propagates an ultrasonic wave, of preferably less than 5 MHz, through the honeycomb structure which is received, filtered and analyzed to determine the presence or absence of internal discontinuities or inhomogenieties. The ultrasonic transmitter generates an ultrasonic wave of less than five megahertz to provide a relatively high signal-to-noise ratio in the ultrasonic wave propagated through the structure. The device of the invention may include an array of ultrasonic transmitters and receivers that generate simultaneously transmit and receive ultrasonic signals throughout the ceramic honeycomb structure as it is moved relative to the array such that the structure is quickly and efficiently scanned for discontinuities or inhomogenieties.

Owner:CORNING INC

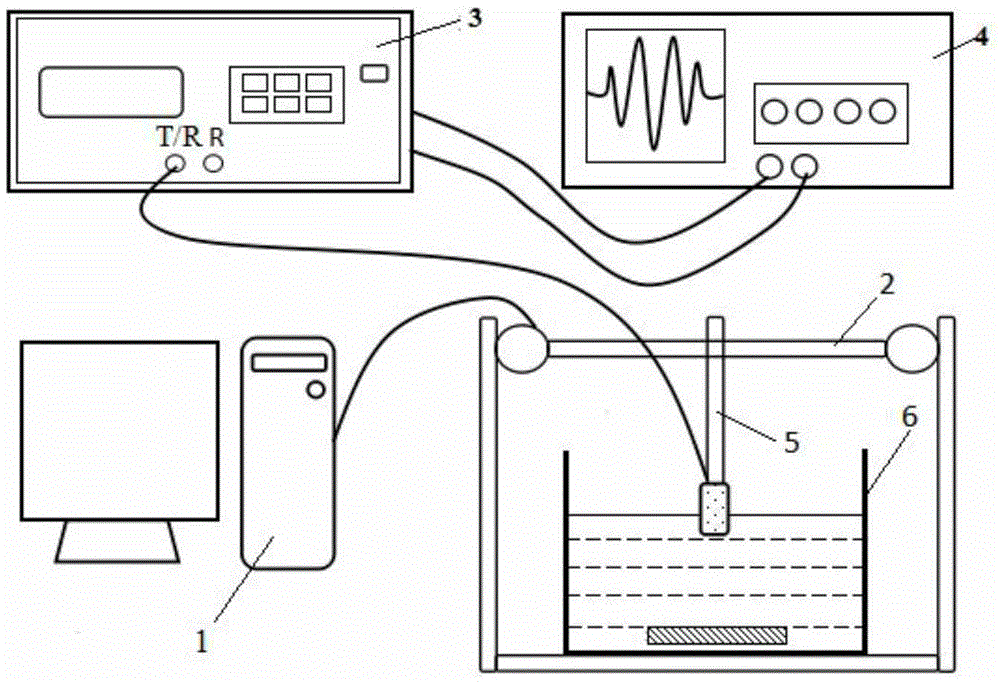

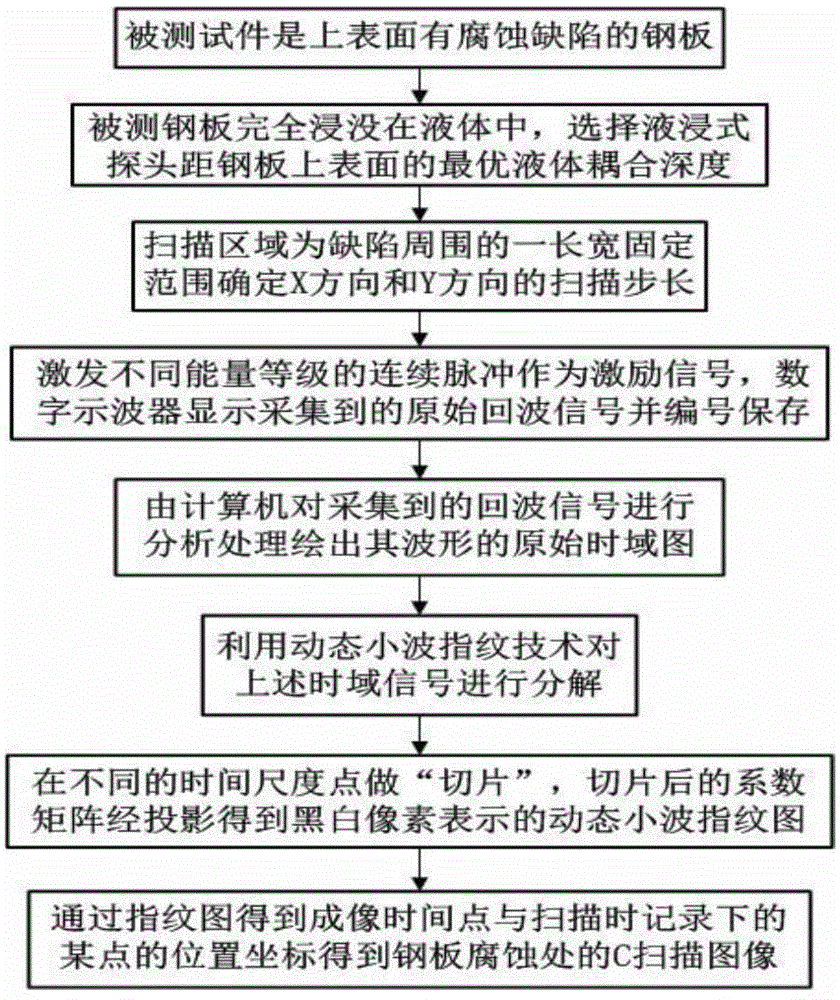

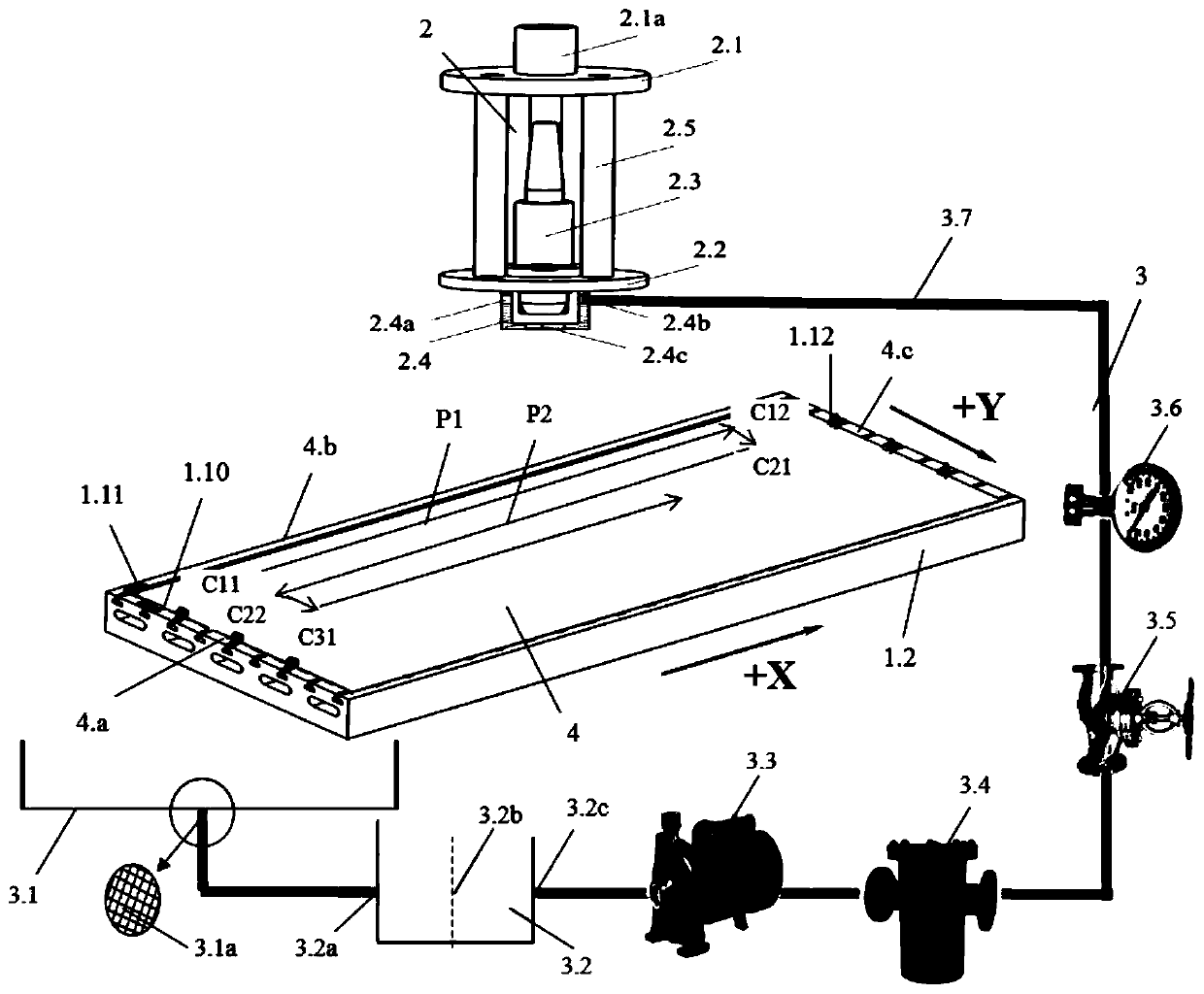

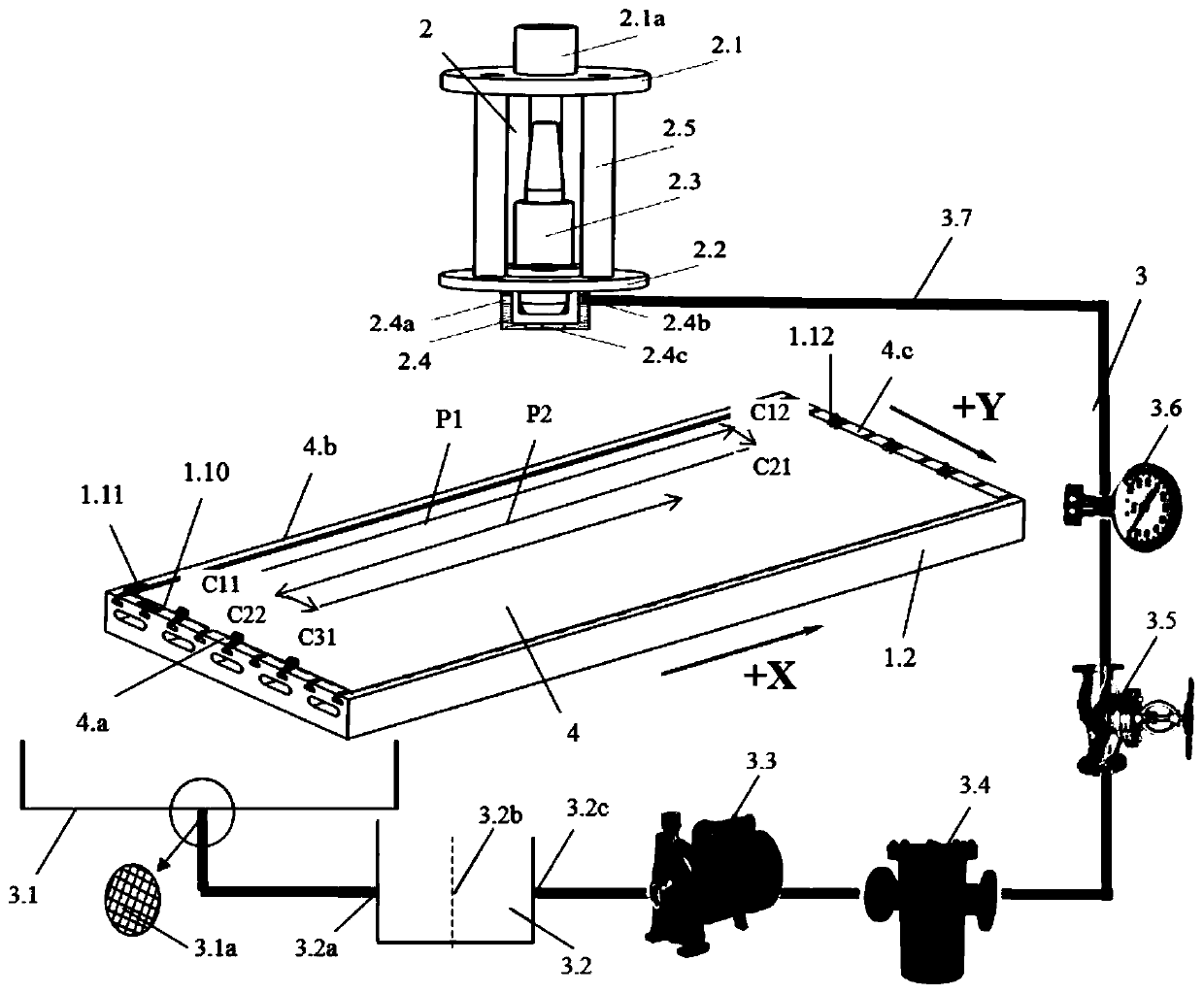

Storage tank bottom plate corrosion noncontact ultrasonic detection method based on dynamic wavelet fingerprint technology

InactiveCN104391039AAvoid Corrosion Measurement ErrorsImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationEngineering

The invention relates to a storage tank bottom plate corrosion noncontact ultrasonic detection method based on a dynamic wavelet fingerprint technology. The method is characterized by comprising the following steps: selecting a steel plate which is smaller than a water trough from a detected test piece; immersing the detected steel plate into the transparent glass water trough, and fixing an immersion-type non-focusing probe on a movable arm of a four-axis linkage scanning platform; determining a scanning step in an X direction and a Y direction; analyzing a group of acquired echo signals by virtue of a computer, and drawing an original time domain chart of waveforms of the echo signals; intercepting a section of the time domain chart as an effective detection zone; resolving an intercepted time domain signal by utilizing wavelet transformation of the dynamic wavelet fingerprint technology; conducting continuous wavelet transformation on a signal after denoising treatment to obtain a wavelet coefficient matrix; conducting normalization processing on the acquired matrix; simultaneously writing an acquired imaging time point and a location coordinate of the time point recorded during the scanning into the matrix to obtain a C scanning image. According to the method, corrosion defects on a storage tank bottom plate can be detected under the situation that a storage tank does not need to be cleaned, so that the detection efficiency can be improved, and the detection cost can be reduced.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +1

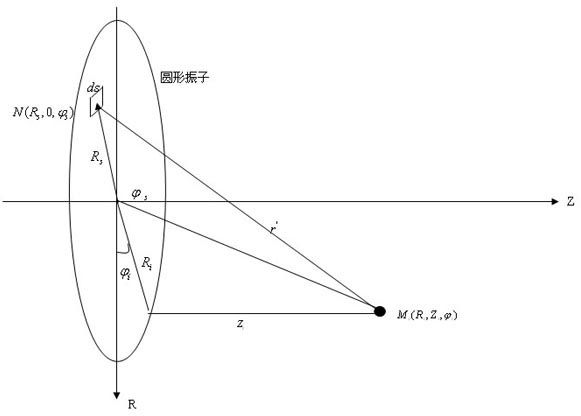

Non-contact type ultrasonic surface shape correcting and polishing method and device

InactiveCN102441820AStable removal function distributionNot affected by sound pressure distributionNumerical controlBristle

The invention relates to a high-precision aspheric surface ultrasonic polishing method for small-aperture brittle high-hardness materials, and discloses a non-contact type ultrasonic surface shape correcting and polishing method and a device thereof. A bristle hard alloy material is polished by the aid of propagation characteristics of ultrasonic simple harmonic vibration, which is generated by acircular oscillator, in liquid, and a stable material removing function in Gaussian distribution can be realized. After a polishing path covering an integral processed surface is set, dwell time of atool head at each of points on the polishing path is determined according to the obtained material removing function and residual errors of the processed surface, and a processing program is scheduled and inputted into a numerical-control machine tool to realize correcting and polishing processing. Accurate control of material removal amount of different areas of the surface by means of combiningthe numerical control technology, surface shape correcting and polishing of various optical surfaces such as planes, spherical surfaces, aspheric surfaces and the like can be realized, and optical surfaces with high surface shape precision can be obtained.

Owner:SUZHOU UNIV +1

Non-contact feature detection using ultrasonic Lamb waves

ActiveUS7963165B2Reduce power consumptionVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainNon-contact ultrasound

Apparatus and method for non-contact ultrasonic detection of features on or within the walls of hollow pipes are described. An air-coupled, high-power ultrasonic transducer for generating guided waves in the pipe wall, and a high-sensitivity, air-coupled transducer for detecting these waves, are disposed at a distance apart and at chosen angle with respect to the surface of the pipe, either inside of or outside of the pipe. Measurements may be made in reflection or transmission modes depending on the relative position of the transducers and the pipe. Data are taken by sweeping the frequency of the incident ultrasonic waves, using a tracking narrow-band filter to reduce detected noise, and transforming the frequency domain data into the time domain using fast Fourier transformation, if required.

Owner:TRIAD NAT SECURITY LLC

Non-contact ultrasonic flow velocity meter and non-contact flow velocity detection method

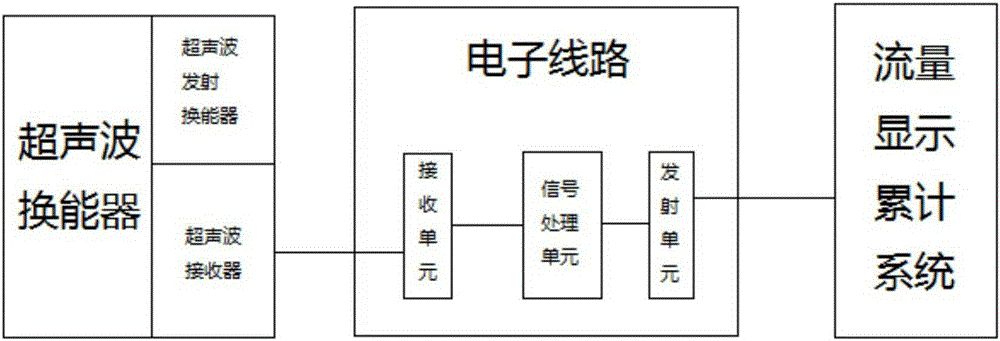

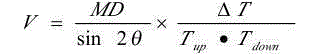

InactiveCN105181997AImprove stabilityImprove accuracyFluid speed measurementNon-contact ultrasoundWater flow

The invention discloses a non-contact ultrasonic flow velocity meter. The non-contact ultrasonic flow velocity meter comprises an ultrasonic transducer, an electronic circuit and a flow display and accumulation system, wherein the ultrasonic transducer comprises an ultrasonic emission transducer and an ultrasonic receiver; the ultrasonic emission transducer is used for converting electric energy into ultrasonic energy, and emitting the ultrasonic energy to the detected flow; the ultrasonic receiver is used for receiving ultrasonic signals and sending the ultrasonic signals to the electronic circuit; the electronic circuit comprises an emission unit, a receiving unit and a signal processing unit; the receiving unit is used for receiving the ultrasonic signals sent from the ultrasonic receiver and sending the ultrasonic signals to the signal processing unit to process the signals; and the emission unit sends the signals processed by the signal processing unit to the flow display and accumulation system. As the non-contact ultrasonic flow velocity meter installs the ultrasonic emission transducer and the ultrasonic receiver on the outer wall of a pipeline to be detected, flow detection when the water flow is opened wide can be performed, and no detection elements are required to be installed in the flow while the flowing state of the flow is not changed.

Owner:TIANJIN ZHONGZHONG SCI & TECH CO LTD

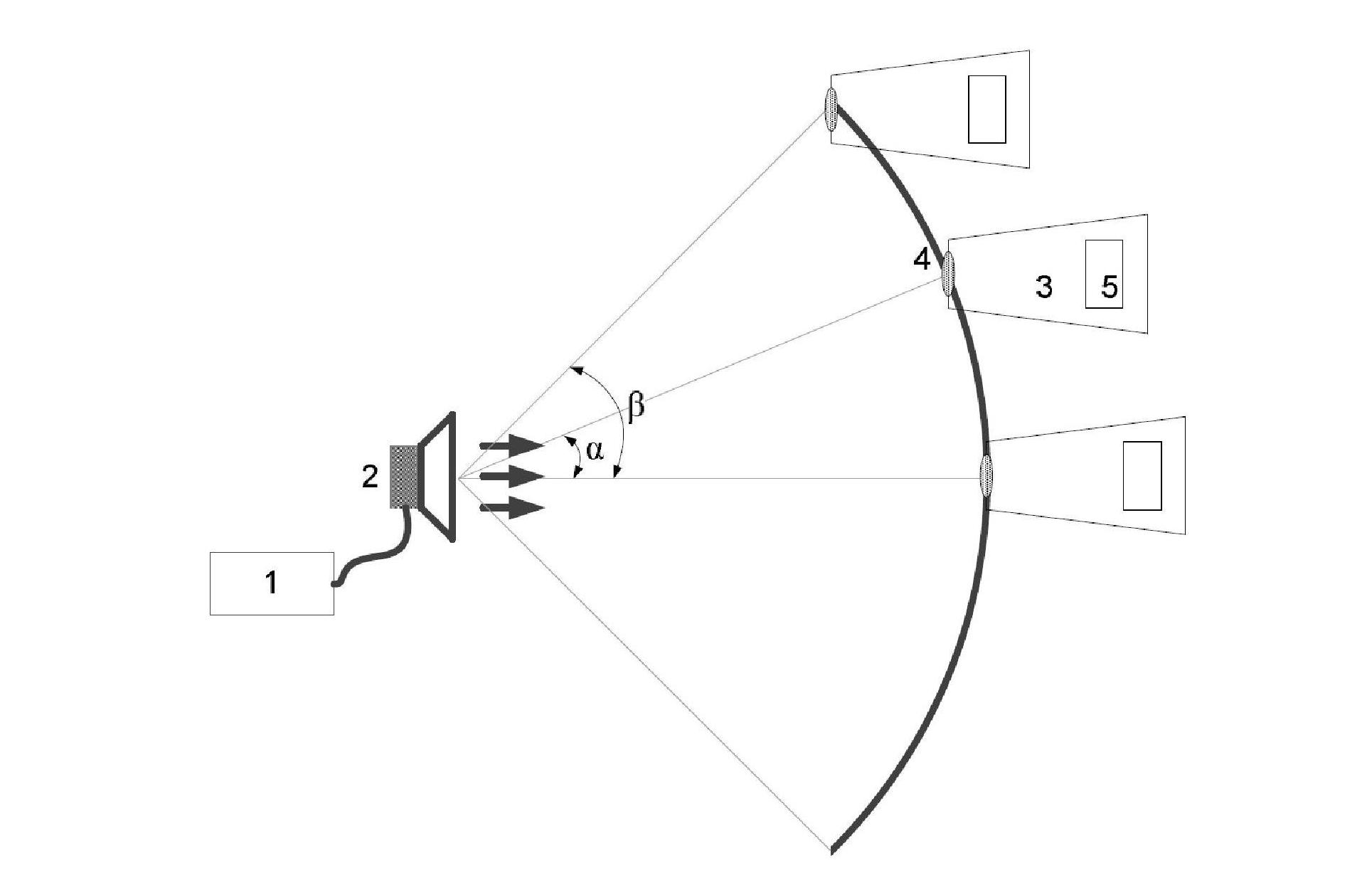

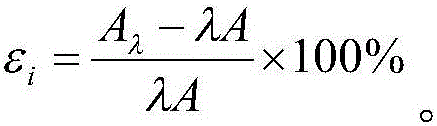

Method for assessing technical parameters of narrow-band non-contact ultrasonic partial discharge testing instruments for power systems

A method for assessing technical parameters of narrow-band non-contact ultrasonic partial discharge testing instruments for power systems is characterized in that sinusoidal analog voltage signals which are outputted by a function generator, are adjustable in amplitude value and have the frequency of 40 kHz are used for driving a narrow-band ultrasonic emitter to generate space ultrasonic waves of which the radiant power can change in the forward direction; and for an ultrasonic testing instrument adopting a narrow-band non-contact manner, the sensitivity amplitude value, the directional included angle, the effective testing distance, the rangeability and other technical parameters are assessed practically. The method is combines the characteristic of integrative packaging number value display of a narrow-band non-contact ultrasonic partial discharge testing instrument, starts with the spread principle of space ultrasonic radiation, aims at the core technical parameters such as sensitivity, directionality, attenuation characteristic and rangeability, utilizes the function generator to solve the assessment problem of such equipment from the angle of space ultrasonic radiation, and has the remarkable advantages of portability, intuitiveness, accuracy, quantification, capability of repetition measurement, and the like.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

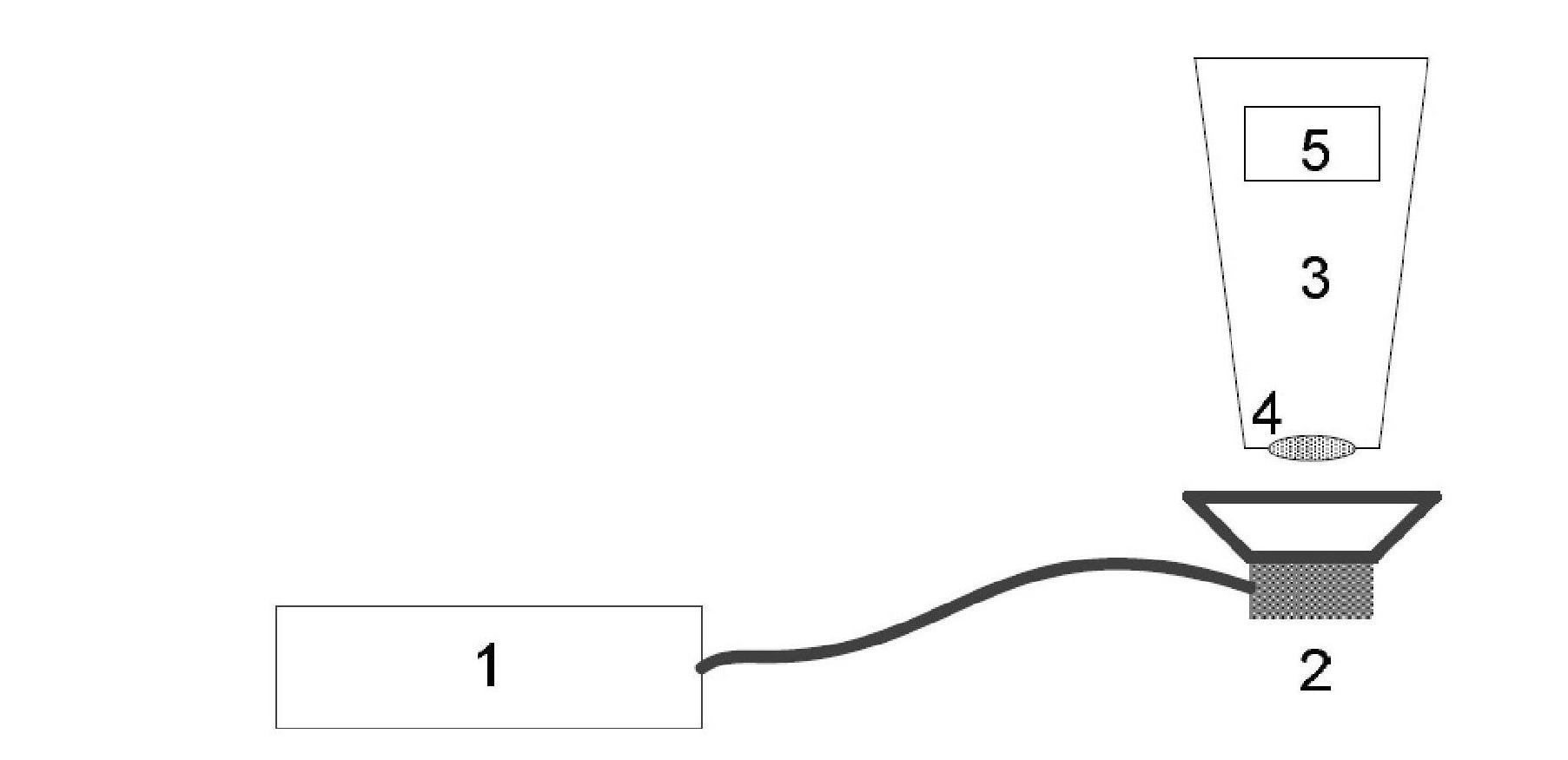

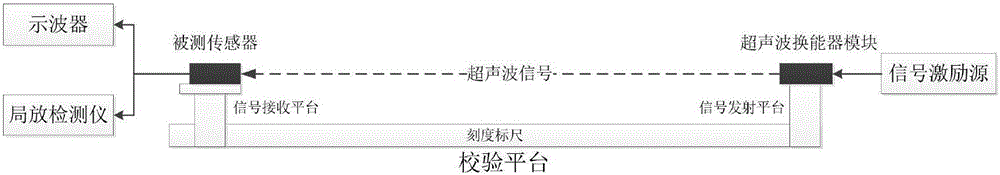

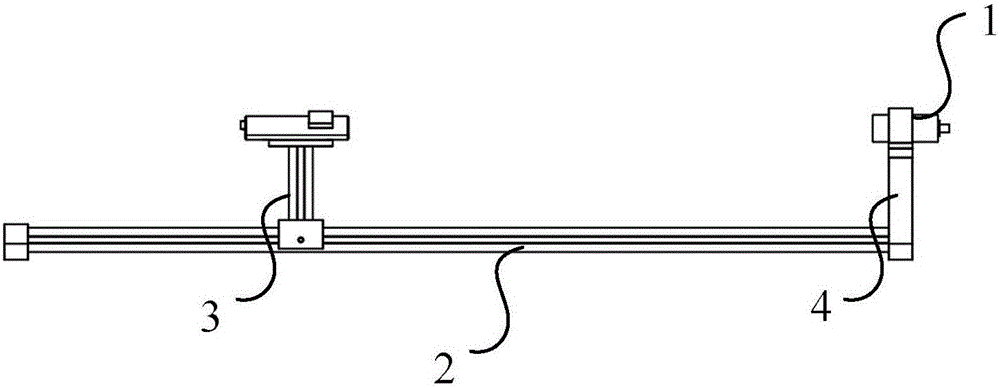

Examination and verification device for noncontact ultrasonic method partial discharge detector and examination and verification method thereof

InactiveCN105954698AGuaranteed validityGuaranteed reliabilityElectrical measurementsCoaxial cableNon-contact ultrasound

The invention discloses an examination and verification device for a noncontact ultrasonic method partial discharge detector and an examination and verification method thereof. The device part comprises a signal excitation source, an ultrasonic transducer module, a verification platform, a reference sensor, an oscilloscope and a 50ohm coaxial cable. A detected instrument comprises a detected sensor and a partial discharge detector. The detectable items include sensitivity, detection frequency band, linearity and stability. The test method is easy to realize and easy and rapid to debug, and the test process is convenient and rapid so that the device is suitable for routine maintenance, testing, correction and other performance examination of the noncontact ultrasonic method partial discharge detector of the power detection industry and can guarantee effectiveness and reliability of the detection instrument.

Owner:HANGZHOU XIHU ELECTRONICS INST

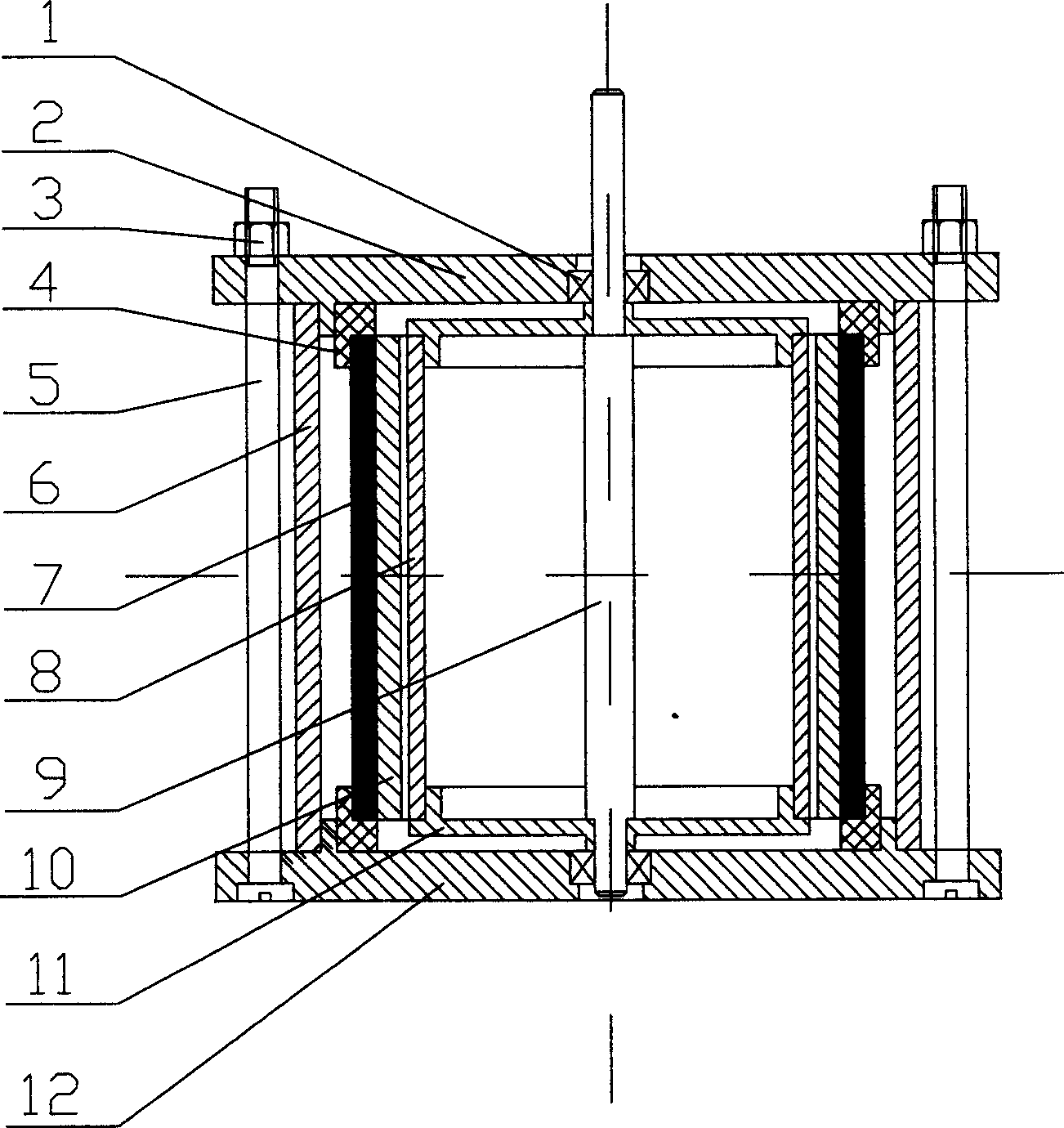

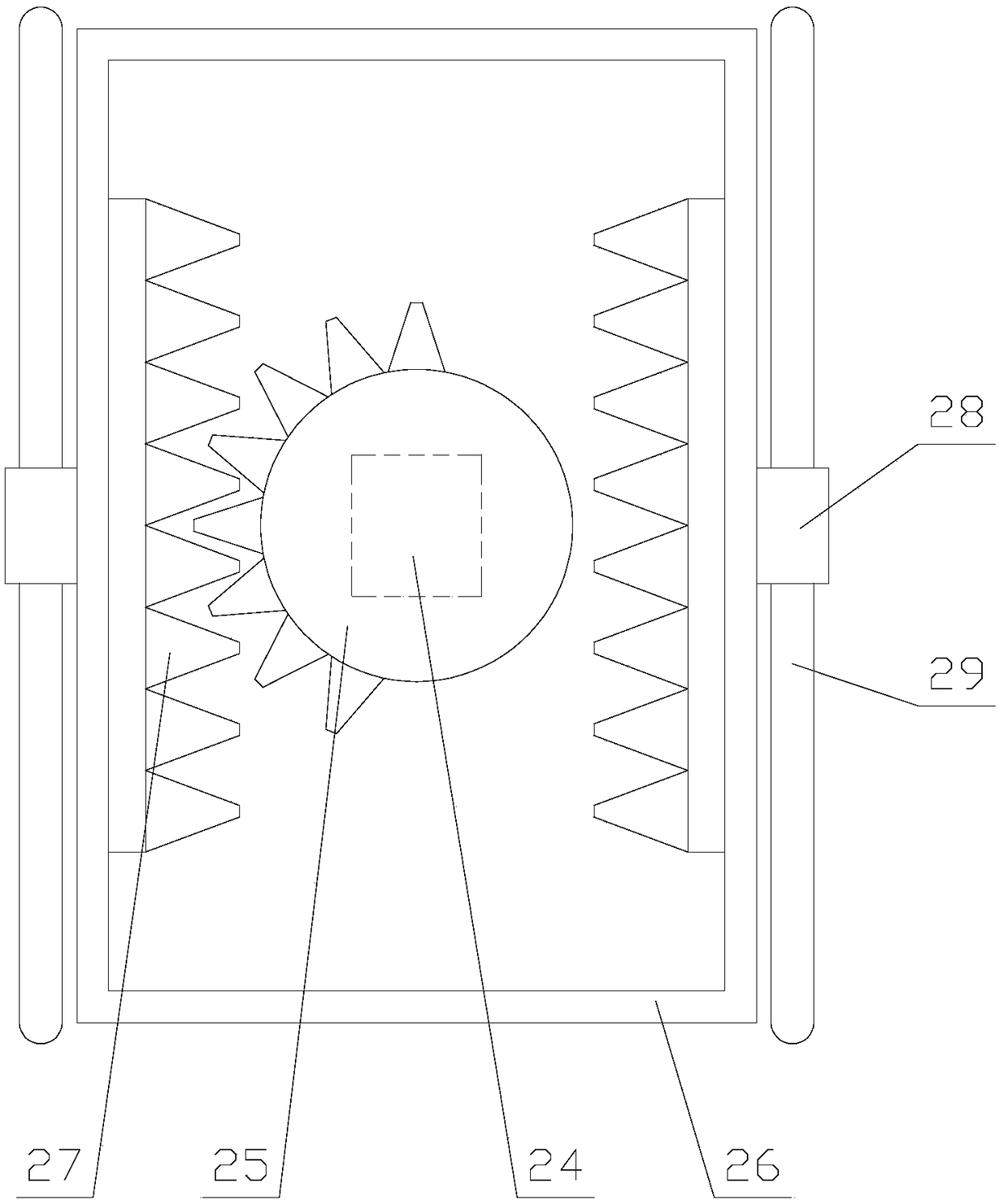

Cylinder non-contact ultrasound electric machine

InactiveCN1610239ASolution to short lifeShort lifePiezoelectric/electrostriction/magnetostriction machinesNon-contact ultrasoundElectric machine

The present invention is cylindrical non-contact ultrasonic motor, and belongs to the field of miniature motor. The motor consists of stator, rotor and seat. The motor stator consists of stator base body and piezoelectric ceramic adhered together. The motor rotor consists of rotor base body, one pair of shaft sleeve and shaft. The motor seat consists of cover plate, pedestal, sleeve, one pair of washers, one pair of bearings, screw, nut, etc. When some AC voltage in ultrasonic frequency range is applied, the stator generates ultrasonic vibration, the rotor is rotated via adhesive force, and the power is output via the shaft. The motor has the advantages of high rotation speed, long service life, simple structure, low cost, etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

System and method for non-contact ultrasound with enhanced safety

ActiveUS20170258332A1Improve securityMedical imagingMechanical vibrations separationSonificationNon-contact ultrasound

A system and method for noncontact ultrasound imagery capable of generating images in a manner that is safer for eyes and skin is provided. A photoacoustic excitation source may be employed to direct light signals with wavelengths of 1400-1600 nanometers into the patient to generate acoustic disturbances that induce propagating photoacoustic waves. The acoustic disturbances may be translated in defined directions to cause coherent summation of the propagating photoacoustic waves and, thereby, generate a resultant acoustic and / or elastic wave to probe structures within the patient. Vibrations created by the scatter of the resultant wave are detected at the surface of the patient and ultrasound images of the structures within the patient may be generated. Detection of the vibrations may be performed using a laser vibrometer. The excitation and detection systems may be used separately or in combination. Ultrasound images can be generated without physically contacting the patient.

Owner:MASSACHUSETTS INST OF TECH

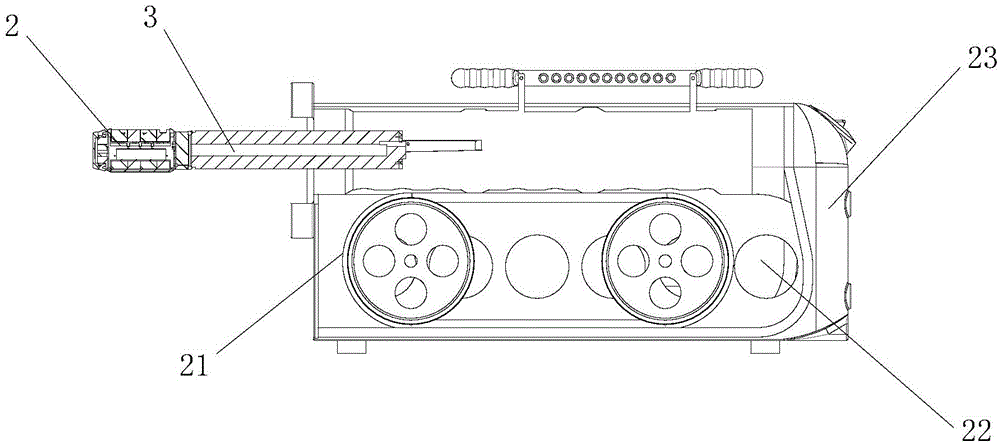

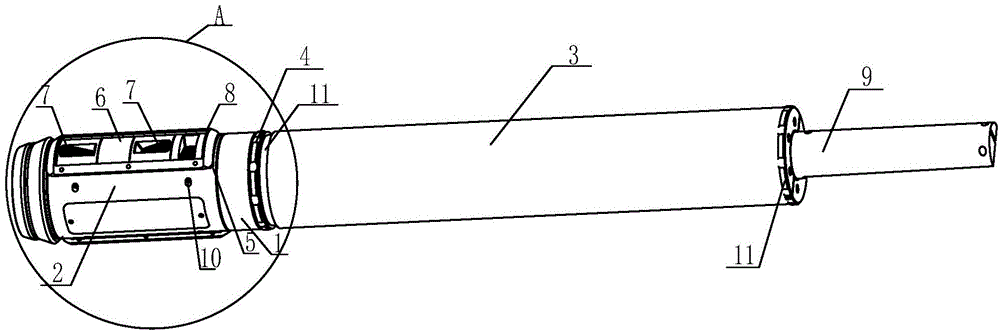

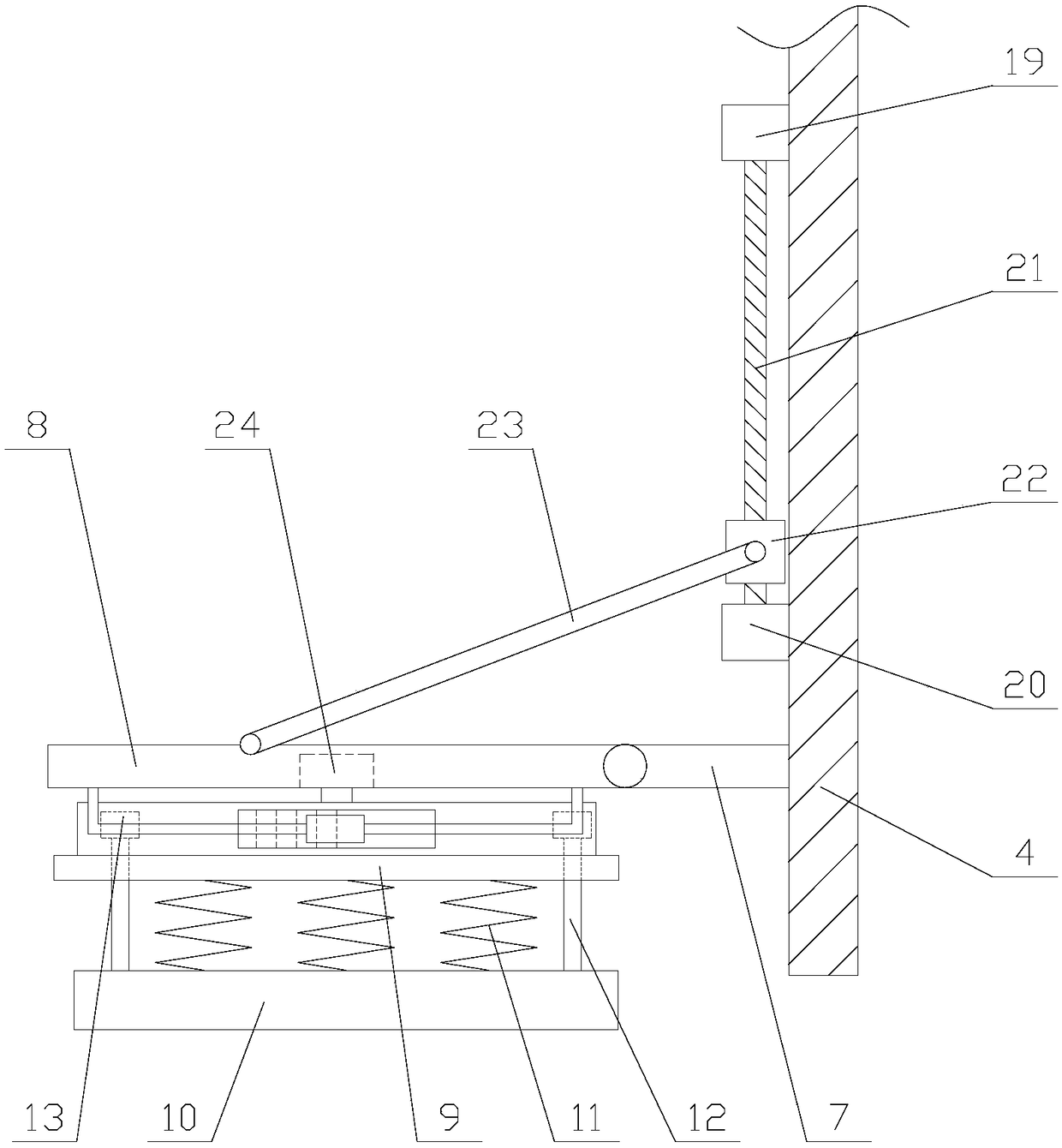

Non-contact type ultrasonic flaw-detecting machine for hollow car axle

ActiveCN104090028AEffective protectionExtended service lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesNon-contact ultrasoundControl system

The invention discloses a non-contact type ultrasonic flaw-detecting machine for a hollow car axle. The non-contact type ultrasonic flaw-detecting machine comprises a chassis, a machine body, a feeding mechanism, a detection control system and a lifting mechanism, wherein a universal walking wheel is arranged at the bottom of the chassis; a control handle is arranged on one side of the chassis; the lifting mechanism is mounted on the upper surface of the chassis which is located on the other side opposite to the control handle mounting side; the feeding mechanism is arranged on the machine body between the control handle and the lifting mechanism. Compared with the prior art, the non-contact type ultrasonic flaw-detecting machine for the hollow car axle is used for detecting the hollow car axle by using a non-contact ultrasound wave pulse reflection method; the detection control system is used for controlling the feeding mechanism to drive a flaw-detecting rod to move forth and back along with the inner surface of the hollow car axle; a probe carrier at one end of the flaw-detecting rod rotates under the driving of a rotation motor, so that a probe on the probe carrier is capable of automatically detecting the hollow axel in all directions and accurately detecting transverse flaws and vertical flaws on the inner surface and the outer surface of the hollow car axel and material defects in the hollow car axel.

Owner:南京众城亿轮轨道交通技术有限公司

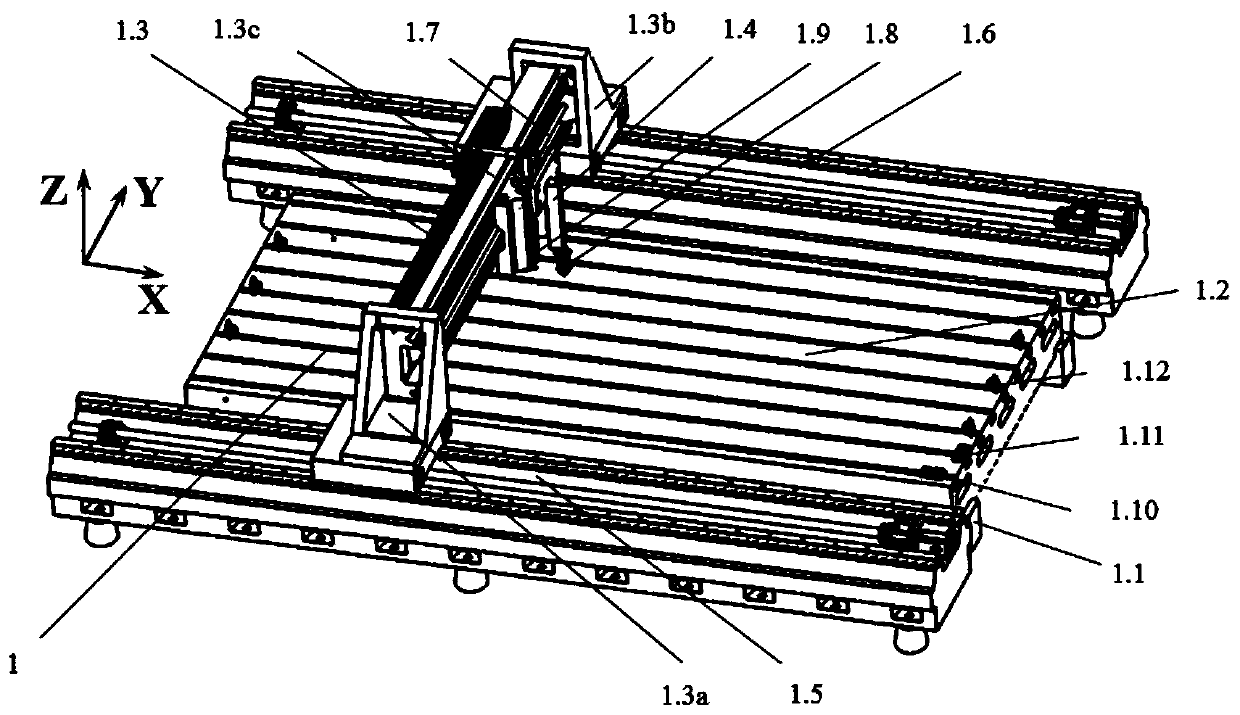

Large wall plate ultrasonic on-machine non-contact scanning thickness measuring equipment and thickness measuring method

InactiveCN109855576AHigh movement precisionHigh positioning accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansNumerical controlFiltration

Owner:DALIAN UNIV OF TECH

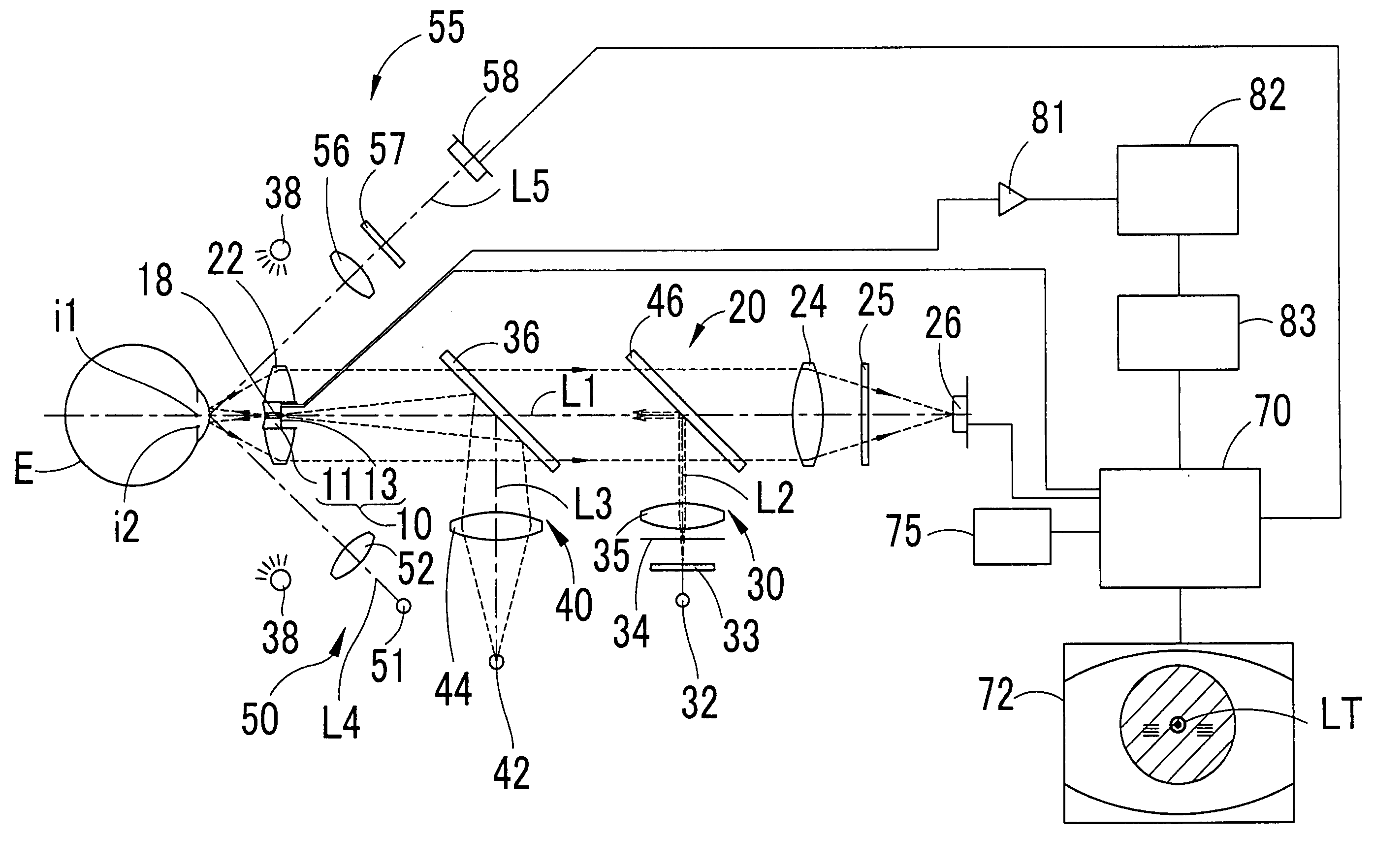

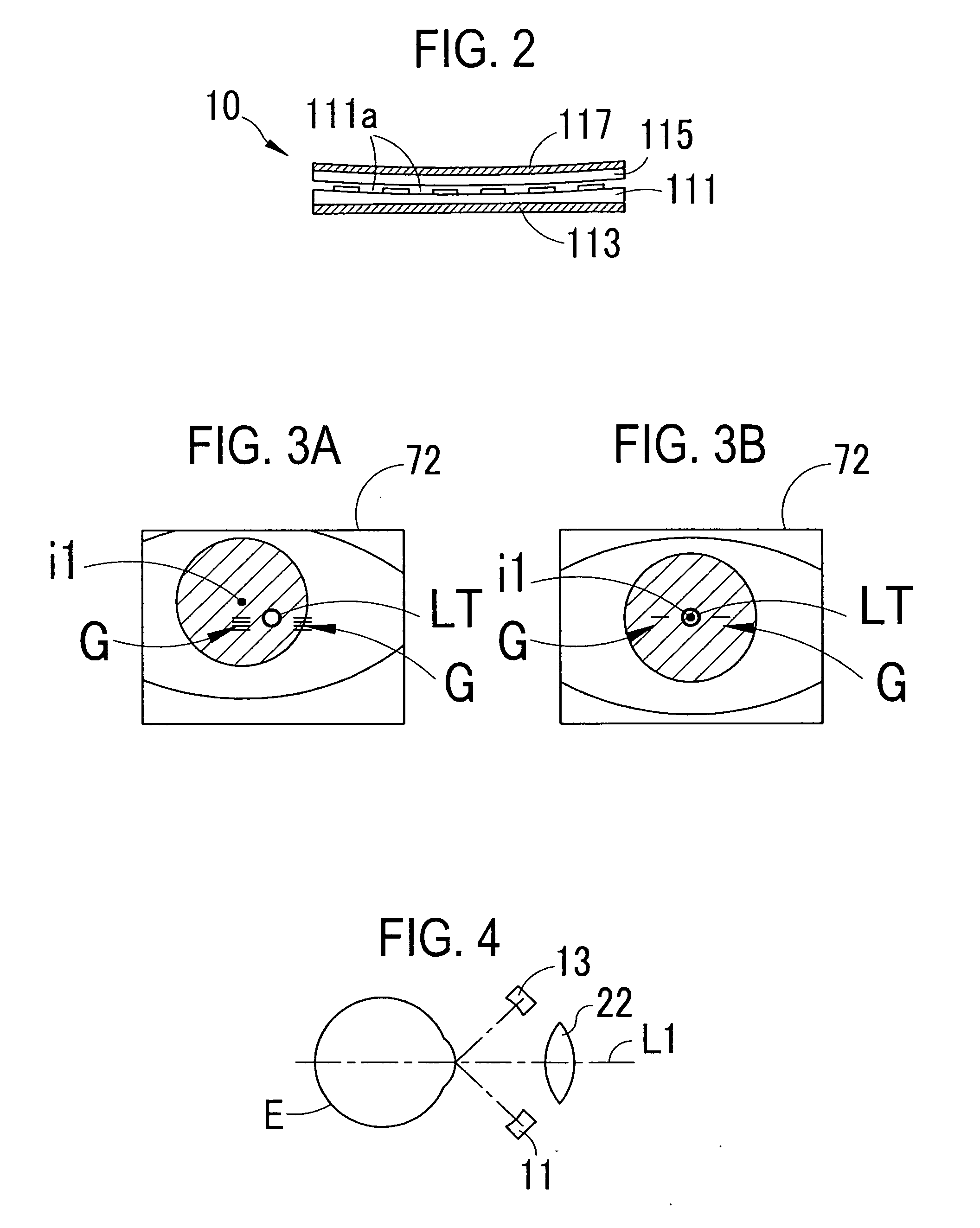

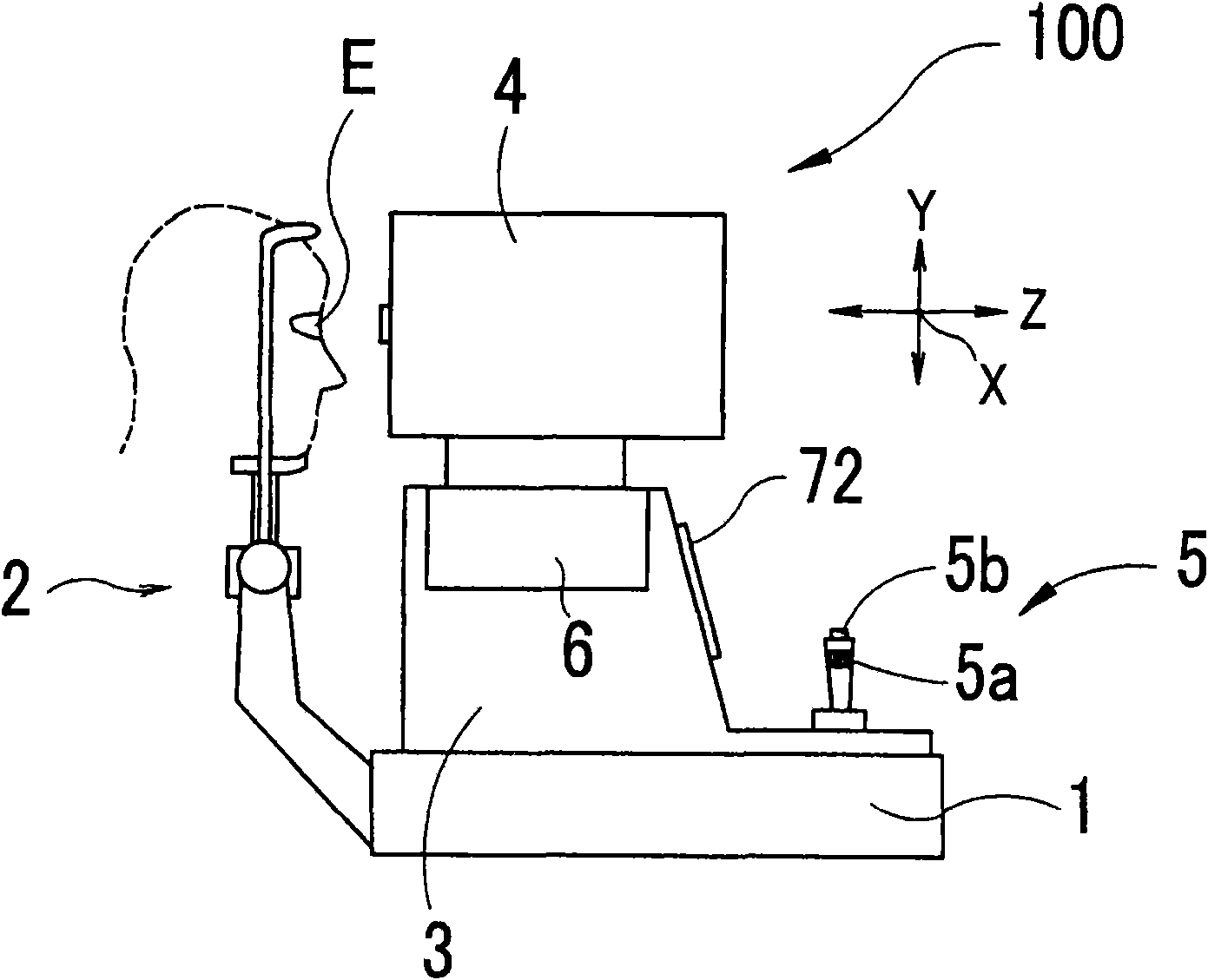

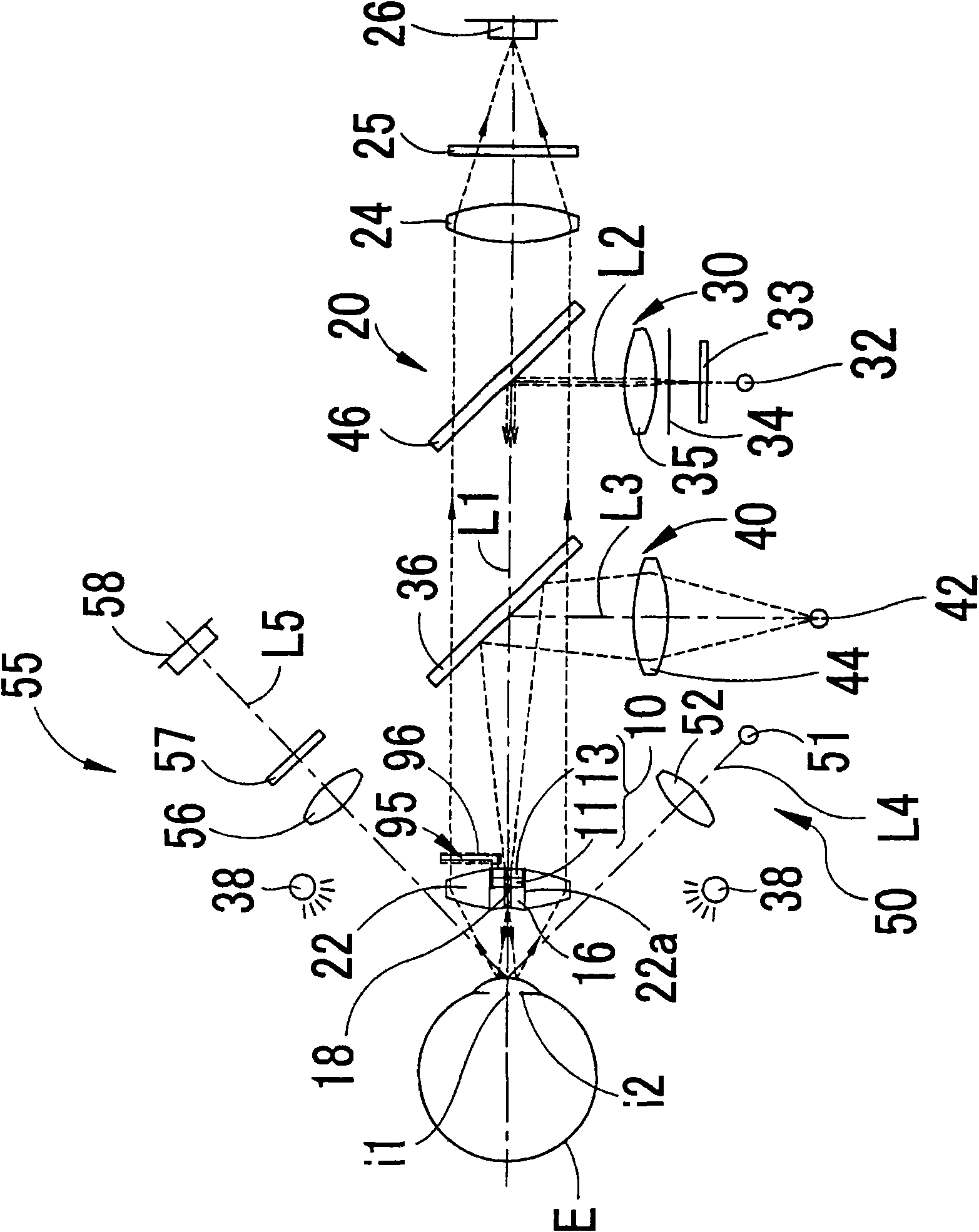

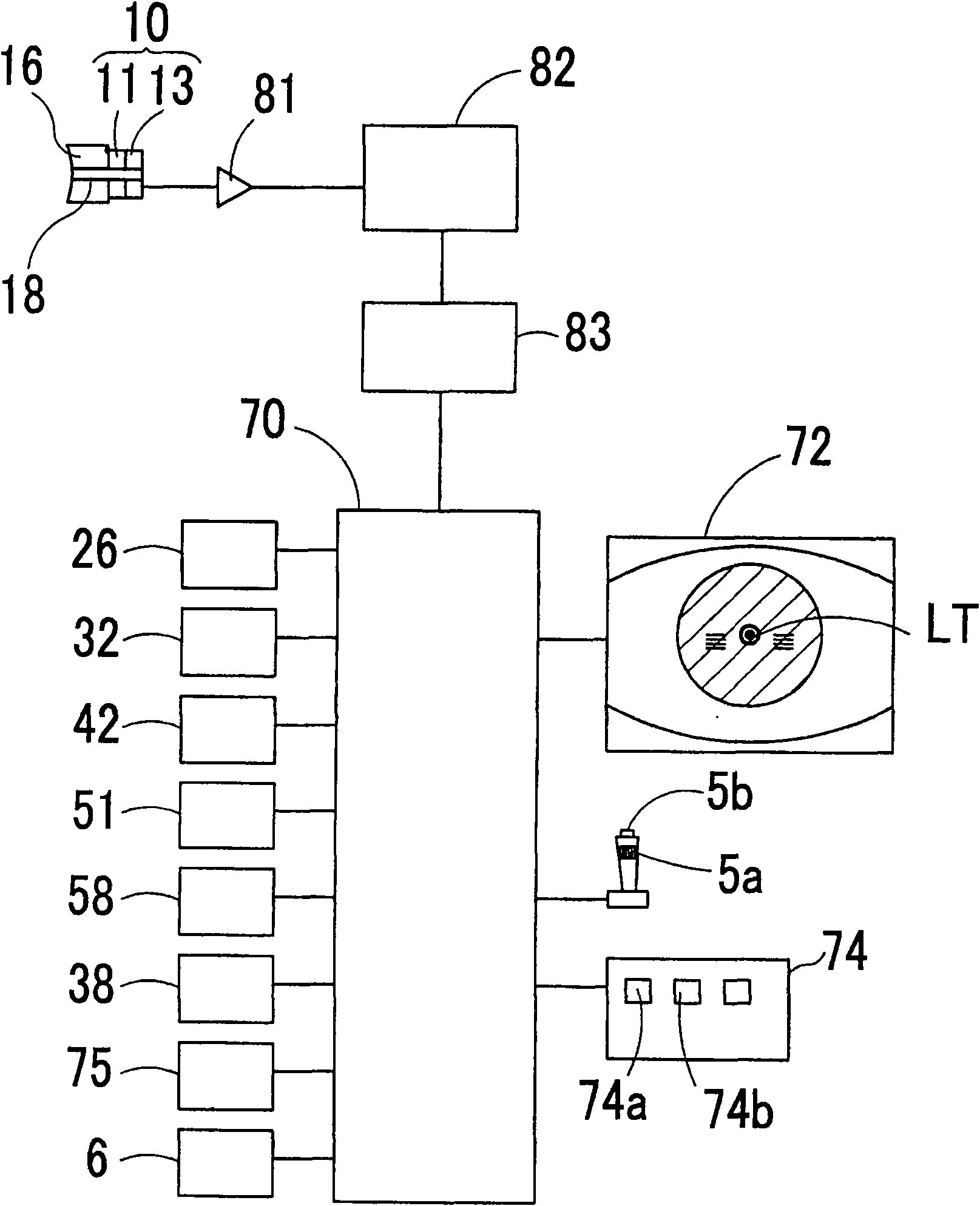

Non-Contact ultrasonic tonometer

InactiveUS20100069737A1Accurate measurementEnsure working distanceEye inspectionTonometersUltrasonic beamNon-contact ultrasound

A non-contact ultrasonic tonometer for measuring intraocular pressure of an examinee's eye in a non-contact manner by use of an ultrasonic wave comprises: a probe that emits an ultrasonic beam to be allowed to enter the eye and detects the ultrasonic beam reflected by the eye; and an arithmetic section that determines the intraocular pressure by processing an output signal from the probe, the probe including a broadband air-coupled transducer that transmits and receives the ultrasonic beam having a broadband frequency component.

Owner:NIDEK CO LTD

Non-contact ultrasonic thickness gauge with high detection precision

ActiveCN108716899AFlexible structureEliminate rustUsing subsonic/sonic/ultrasonic vibration meansNon-contact ultrasoundEngineering

The invention relates to a non-contact ultrasonic thickness gauge with high detection precision. The non-contact ultrasonic thickness gauge comprises a main unit, a connecting line, a holding rod anda detection box; the detection box is internally provided with a detection mechanism and two polishing mechanisms, each polishing mechanism comprises a side plate, a shrinking plate, a shrinking assembly, a reciprocating assembly, a reciprocating plate and a polishing assembly, each polishing assembly comprises a polishing block, a plurality of springs and two orientation units, each orientation unit comprises an orientation rod and a bump, and the detection mechanism comprises a lifting assembly, a lifting plate, a steering assembly, a steering plate, a probe and a plurality of contact rods.According to the non-contact ultrasonic thickness gauge with the high detection precision, the polishing blocks move back and forth on the surface of a workpiece through the polishing mechanisms, ruston the workpiece is eliminated, the workpiece is restored to be smooth, and the detection is facilitated; moreover, the direction of the probe is adjusted through the detection mechanism so that theprobe can be aligned with the workpiece, the probe is prevented from wear while the detection precision is improved, the service life of the probe is prolonged, and the practicability of the gauge isimproved.

Owner:山东天厚石油科技有限责任公司

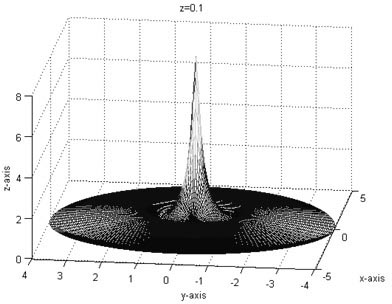

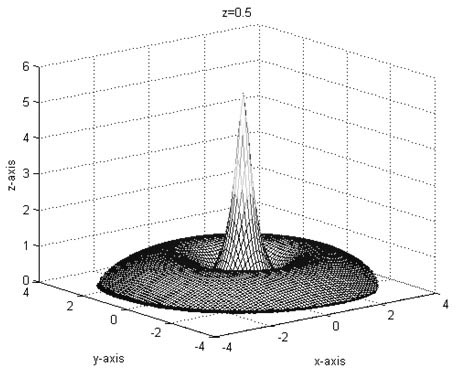

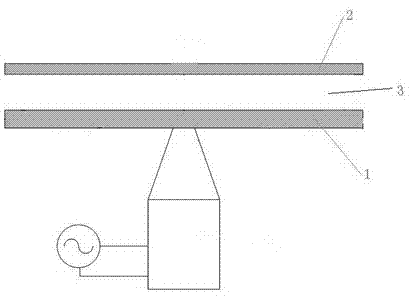

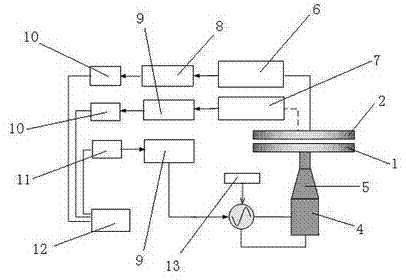

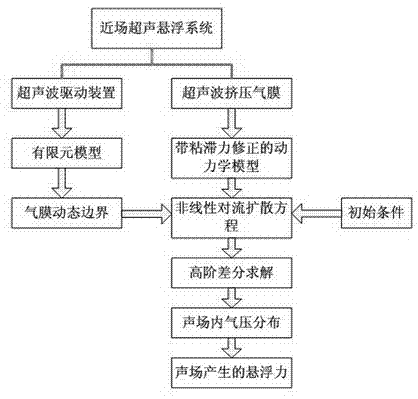

Accurately quantitative calculation method for near-field ultrasonic levitation force

InactiveCN102567563AHigh precisionTrue and effective descriptionSpecial data processing applicationsElement modelUltrasonic levitation

An accurately quantitative calculation method for near-field ultrasonic levitation force can be used for modeling, designing and optimizing of a non-contact type ultrasonic levitation system and a transmission positioning system. The accurately quantitative calculation method includes: building a finite element model of an ultrasonic generating device, performing model analysis and harmonic response analysis, building one-to-one mapping relation of driving input and output, building an extrusion gas-film kinetic model considering inertia of gas and determining parameters of the model; obtaining a specific format of numerical solution of the parameters of the model according to difference scheme; and acquiring gas pressure and levitation force of an extrusion gas film by the numerical solution. By the accurately quantitative calculation method, accuracy in modeling and solving is improved as compared with that of the prior art. Besides, the accurately quantitative calculation method is accurate and feasible for production design and optimization of ultrasonic equipment.

Owner:SHANGHAI JIAO TONG UNIV

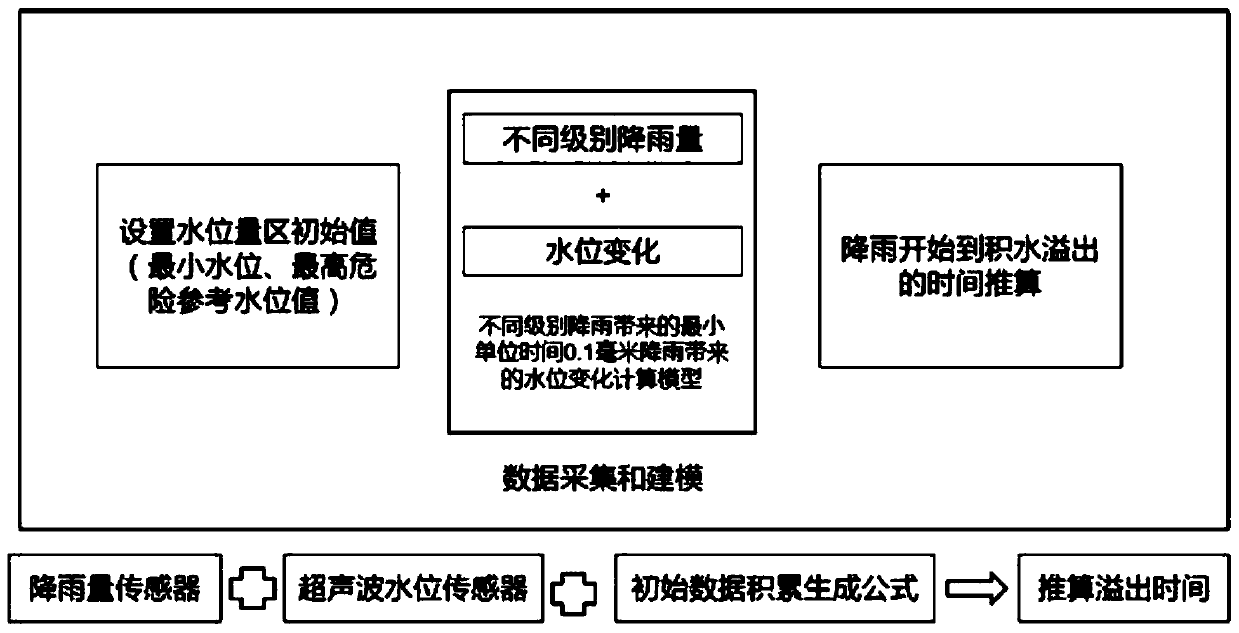

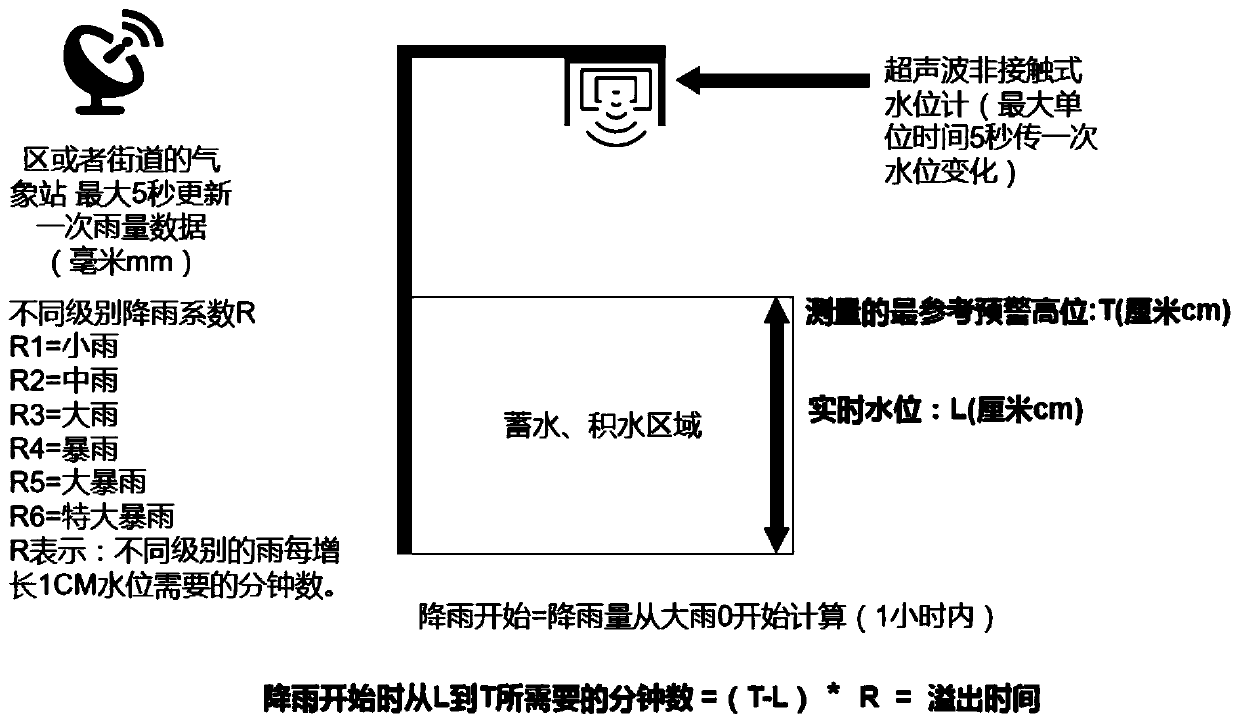

Method for reckoning flood and overflow occurrence time according to meteorological data

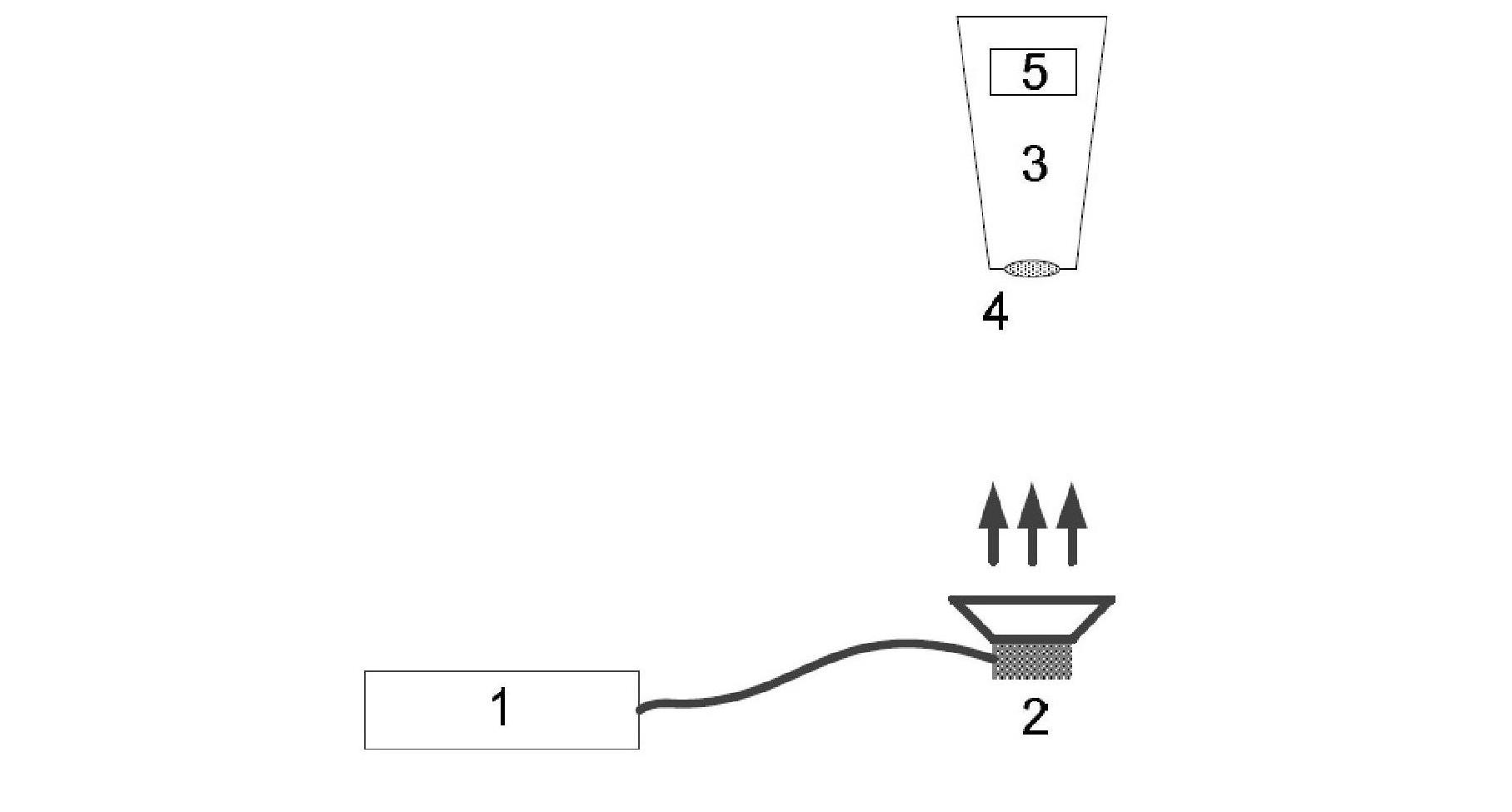

PendingCN110399638AAvoid reminding noAvoid problemsClimate change adaptationResourcesStream gaugeNon-contact ultrasound

The invention relates to the technical field of early warning equipment, and discloses a method for reckoning flood and overflow occurrence time according to meteorological data, which comprises the following steps of 1) installing non-contact ultrasonic water level gauges in culverts, pools, reservoirs, lakes and the like which need early warning in advance. According to the method for reckoningflood and overflow occurrence time according to meteorological data, associated determination is carried out through rainfall of different levels and water level changes, an initialized calculation model can be automatically established by accumulating real data to acquire and classify original data generated by rainfall of six levels in real time, therefore, the volume of an area needing to be calculated does not need to be measured manually, and the calculation accuracy is improved by refining the minimum calculation unit time and the rainfall water level. Meanwhile, the more the accumulated data is, the longer the use time is, the higher the calculated data and the foreseeable accuracy are, manual calibration is not needed; and the equipment is low in overall cost and low in human input and maintenance cost.

Owner:湖南闲暇科技有限公司

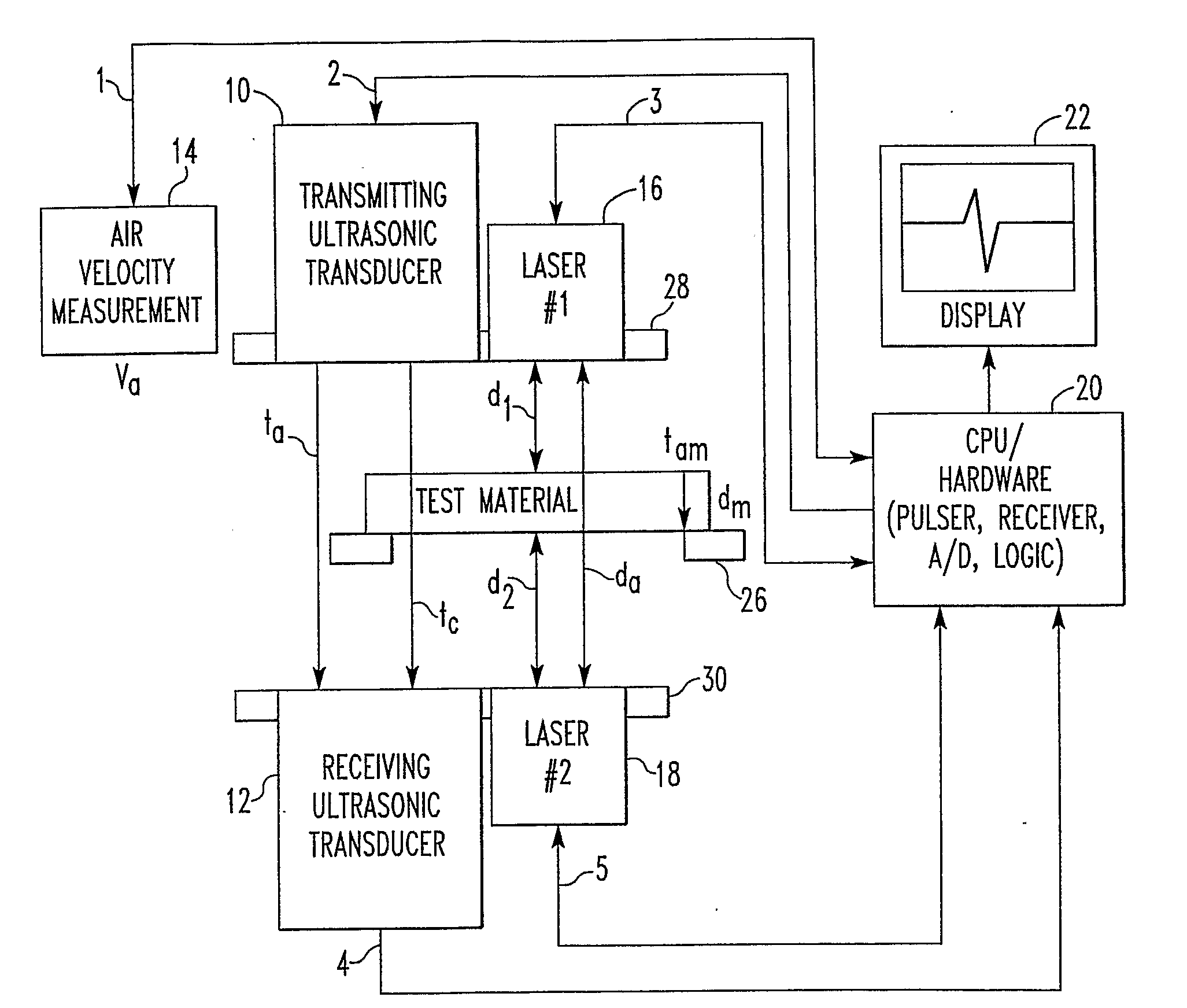

Non-contact ultrasound materials systems and measurement techniques

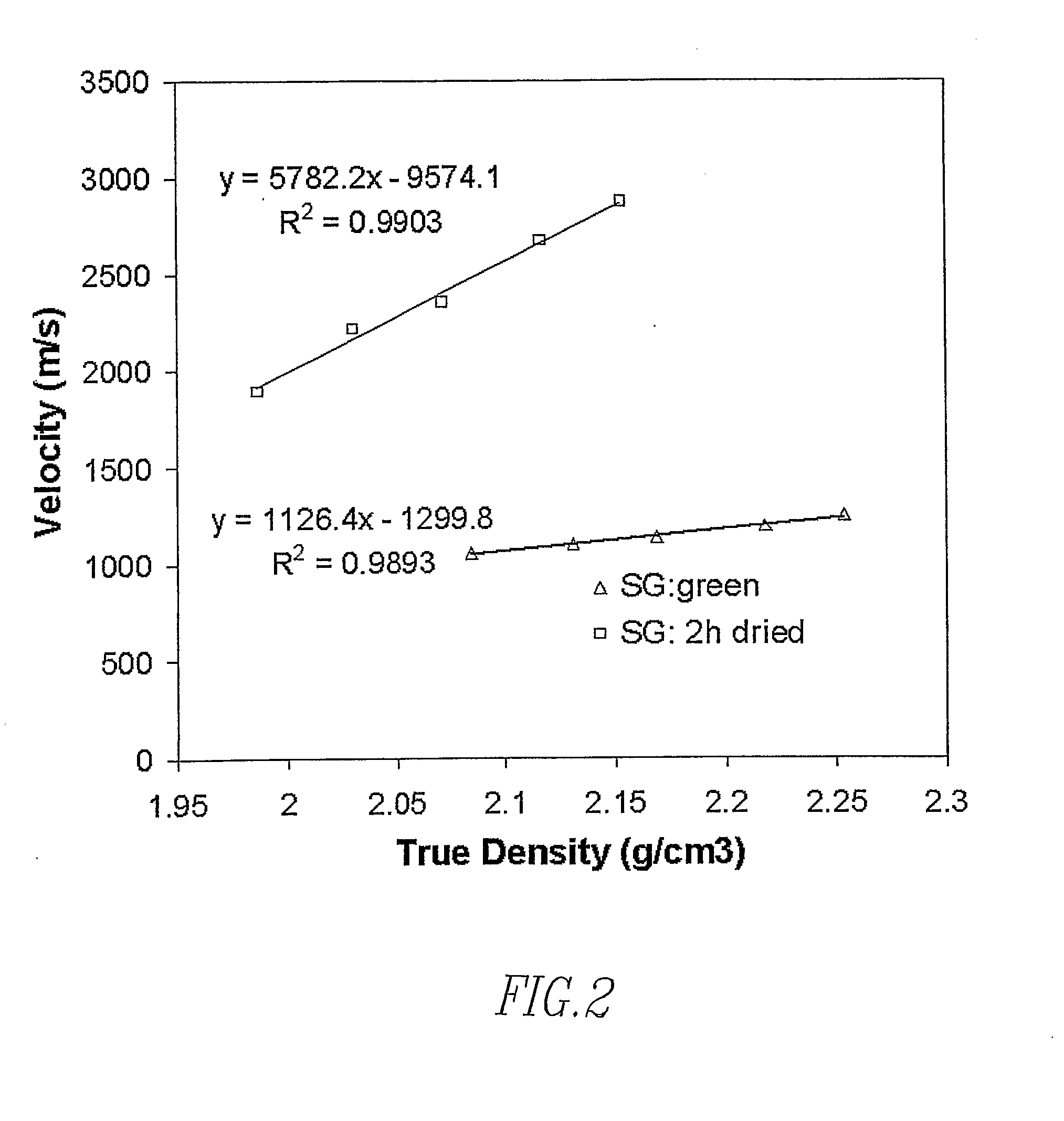

ActiveUS20090199641A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationNon-contact ultrasound

Apparatus for determining the speed of sound through a specimen comprises an ultrasound sending transducer, an ultrasound receiving transducer, a pair of laser distance sensors, a display device, a controller in communication with the ultrasound sending transducer, the ultrasound receiving transducer and the pair of laser distance sensors and the display device. The ultrasound sending transducer and one laser distance sensor are supported with a transducer surface in a first plane. The ultrasound receiving transducer and one last distance sensor are supported with a transducer surface in a second plane parallel with the first plane. A support for a specimen is provided between the first and second planes. The controller is programmed for gathering data from the ultrasound transducers and the laser distance sensors for calculating the speed of ultrasound in the specimen and displaying the results.

Owner:THE ULTRAN GRP INC

Non-contact ultrasonic tonometer

A non-contact ultrasonic tonometer for measuring intraocular pressure of an examinee's eye in non-contact manner by use of an ultrasonic wave comprises: a probe including a vibrator for making the ultrasonic wave incident on the examinee's eye and a sensor for detecting the ultrasonic wave reflected from the examinee's eye; and an observation optical system for observing an anterior segment of theeye, wherein the probe is placed in an optical path of the observation optical system, and the observation optical system forms an image of the anterior segment through a surrounding region of the pr obe.

Owner:NIDEK CO LTD

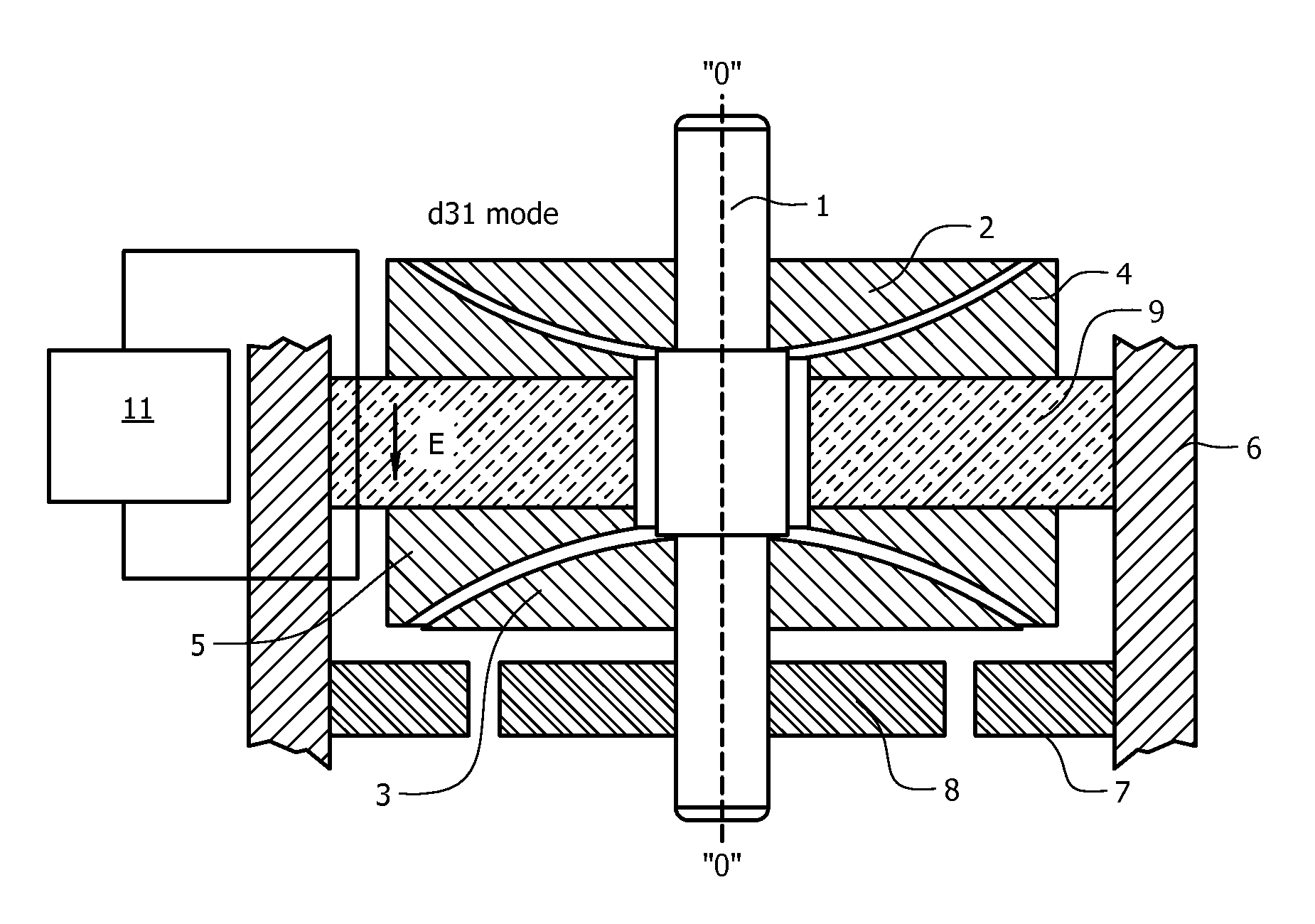

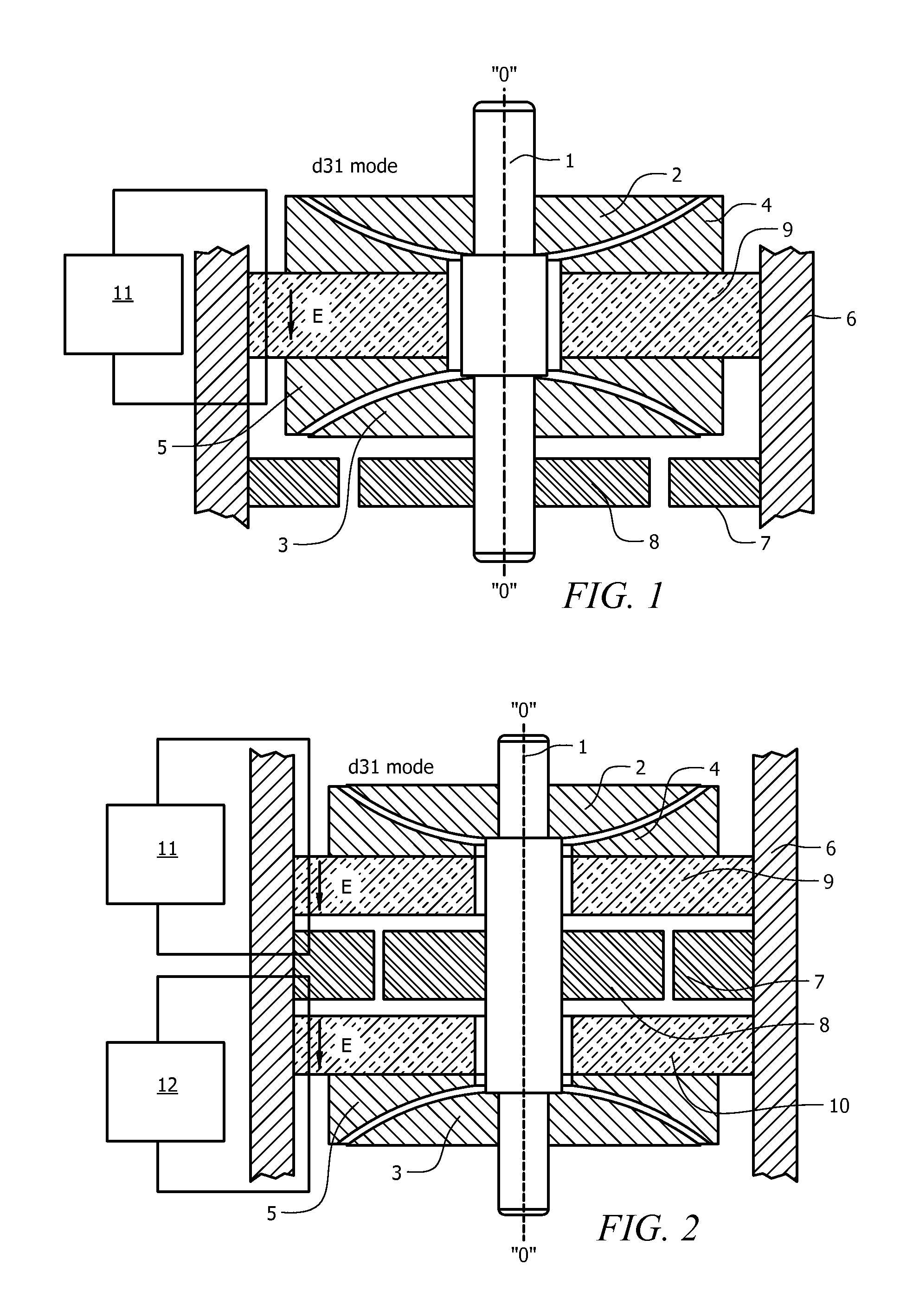

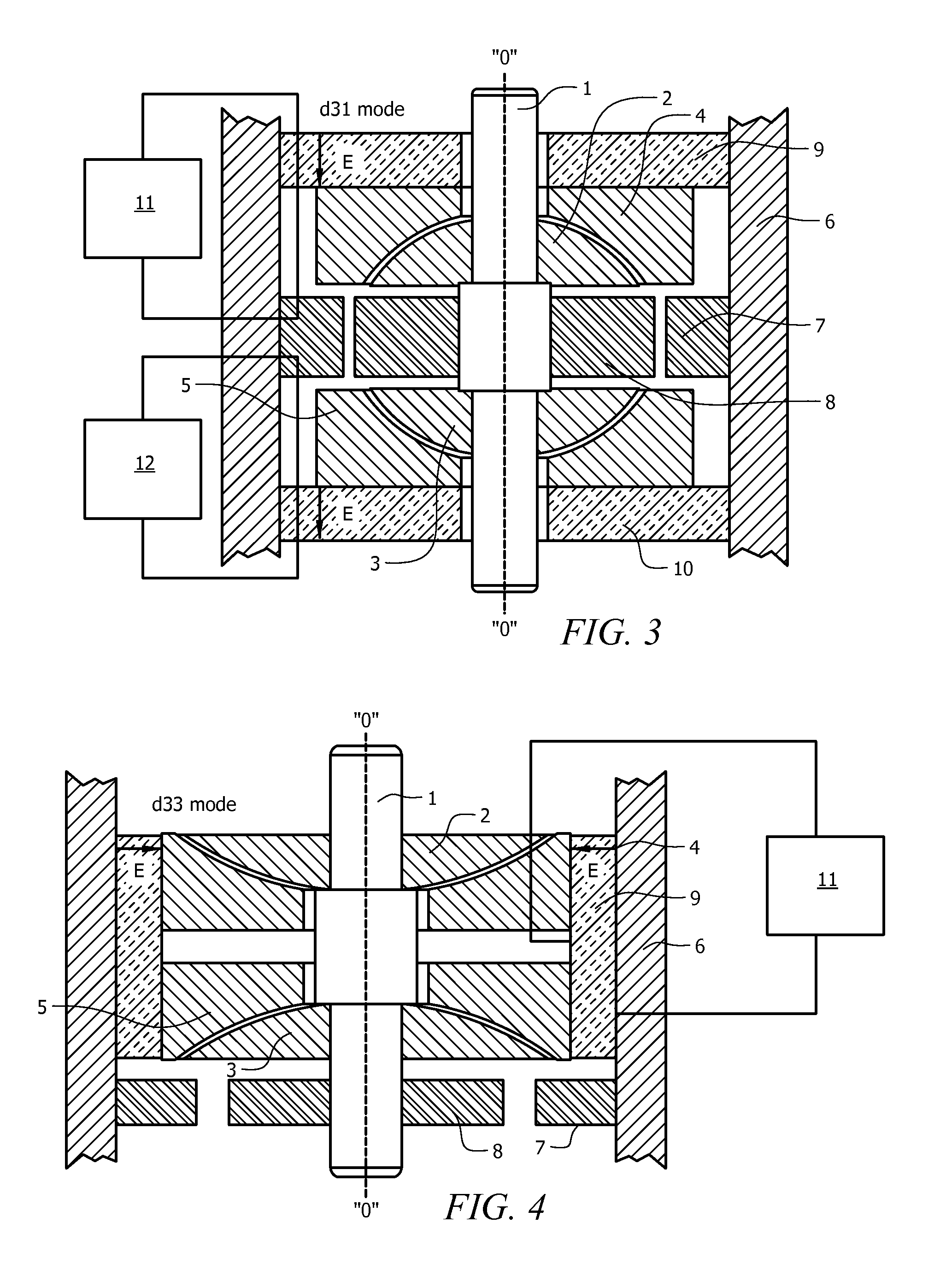

Electric motors and generators with opposing non-contact piezoelectric bearing supports

InactiveUS20120049679A1Improved technical characteristicReduce power consumptionGas cushion bearingsSliding contact bearingsNon-contact ultrasoundUltrasonic levitation

Electric motors and generators, in which a non-contact ultrasonic suspension of the rotor of the electric motor, are provided. The non-contact ultrasonic suspension is achieved by the formation of an elevated-pressure gaseous microfilm between conjugated surfaces of saddle-resonators and trunnions of a bearing system.

Owner:DTI MOTION CORP

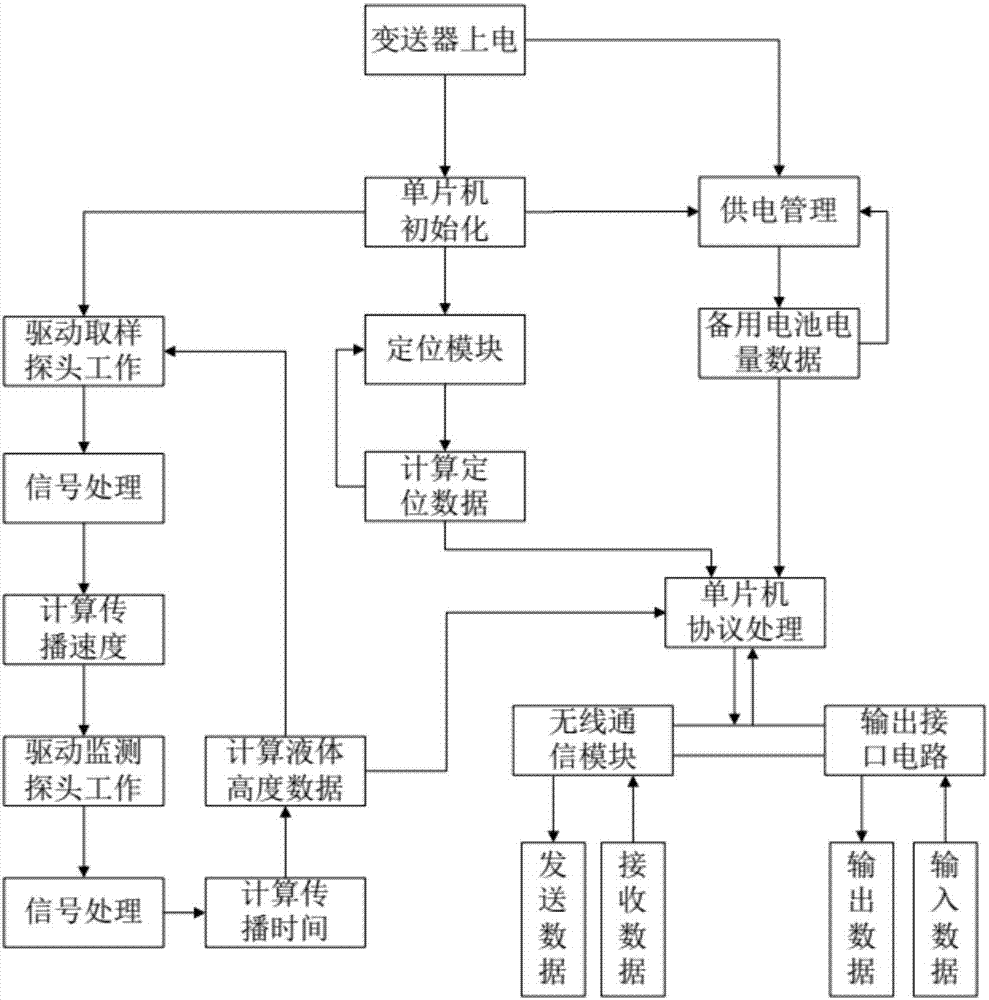

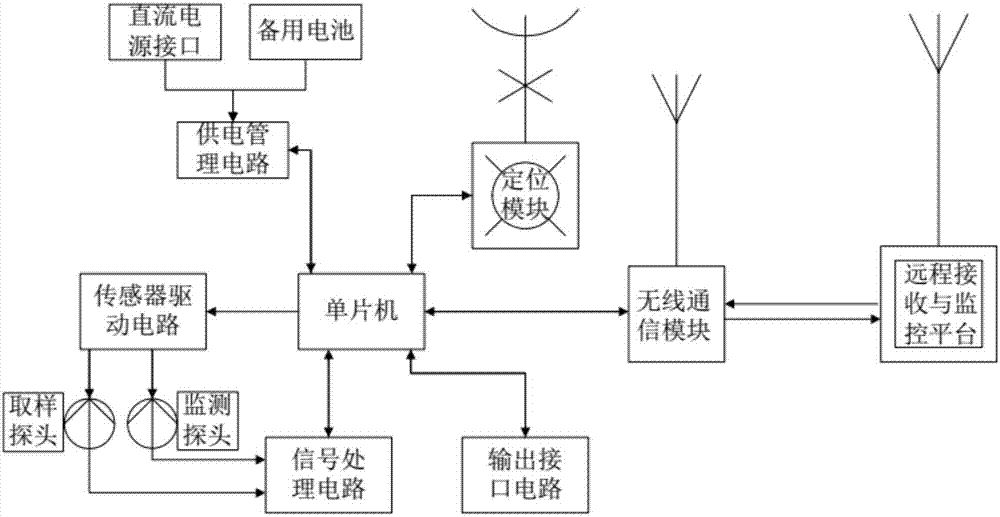

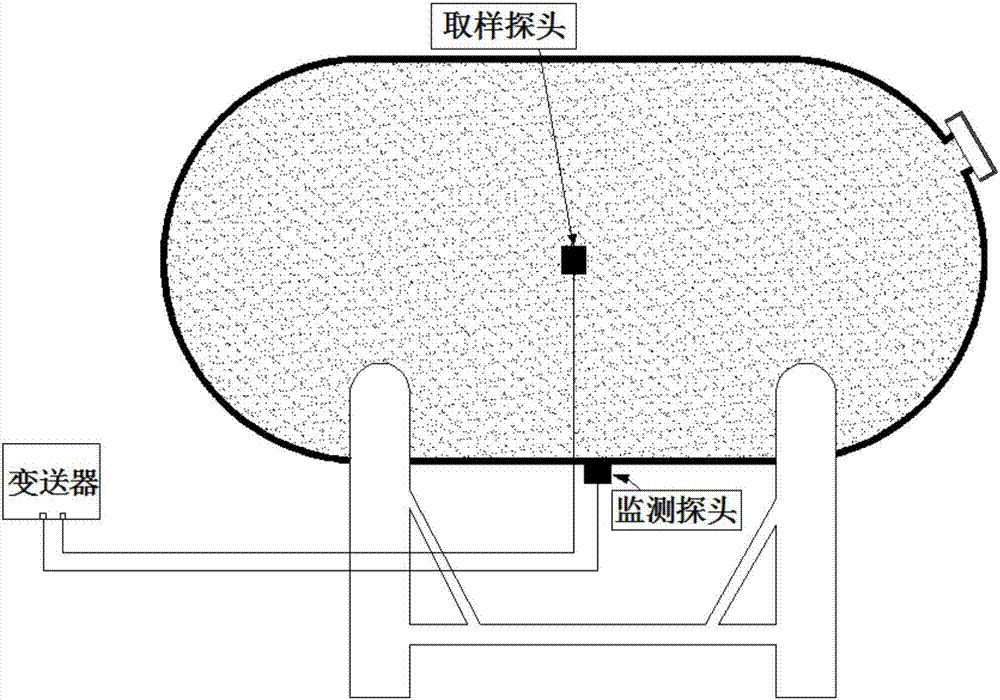

High-precision automatic sampling and calibrating ultrasonic liquid level monitoring system

PendingCN106932055AGuaranteed high precision measurementSolve the problems of poor compatibility, difficult calibration methods, and low measurement accuracyTesting/calibration apparatusMachines/enginesLiquid ChangeSignal processing circuits

The invention discloses a high-precision automatic sampling and calibrating ultrasonic liquid level monitoring system, which comprises an ultrasonic probe, a transmitter, power supply equipment, a container and a server platform, wherein the ultrasonic probe comprises a sampling probe and a monitoring probe; the transmitter comprises a sensor drive circuit, a signal processing circuit, a wireless communication module, a locating module, an output interface circuit, a power supply management circuit and a single chip microcomputer; the power supply equipment comprises an external DC power supply and a standby battery. According to the high-precision automatic sampling and calibrating ultrasonic liquid level monitoring system, by adopting an externally bonded non-contact ultrasonic measurement technology, when the liquid changes under different factors such as a temperature, air pressure and a container, high-precision measurement of the liquid level can be ensured through automatic calibration; when liquids of different density are measured, the problems of poor compatibility, difficulty in calibration method and low measurement accuracy are solved; and meanwhile, by using a wireless technology and a locating technology, wireless fixed-point real-time monitoring of liquid level data is achieved.

Owner:SHENZHEN DIANYINGPU TECH

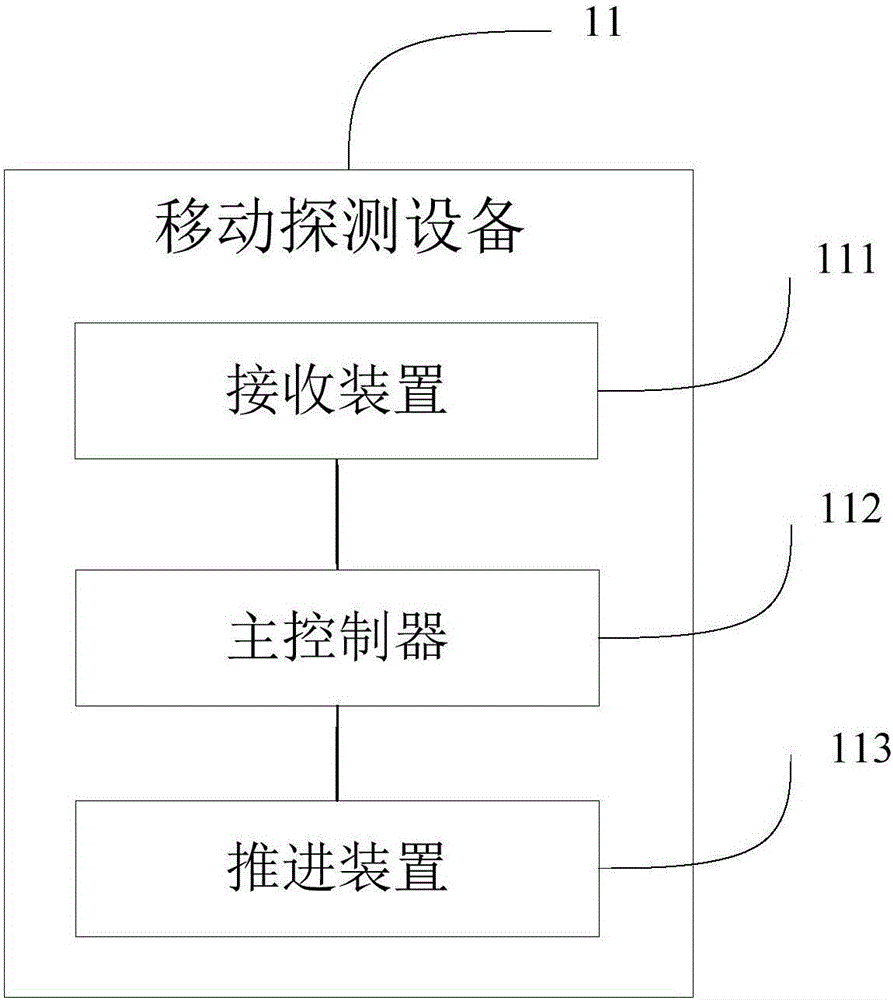

Storage tank bottom plate detection system

InactiveCN105973987AIncrease lossIncrease construction costsAnalysing solids using sonic/ultrasonic/infrasonic wavesTransmission systemsWireless controlNon-contact ultrasound

The invention relates to the technical field of equipment detection, in particular to a storage tank bottom plate detection system. The system comprises mobile detection equipment and terminal equipment. The mobile detection equipment and the terminal equipment are arranged on the liquid level of a storage tank containing liquid. The mobile detection equipment is used for receiving wireless control signals, being controlled to move to the preset position of the liquid level according to the wireless control signals, transmitting ultrasonic waves to a storage tank bottom plate at the preset position and receiving the ultrasonic waves reflected by the storage tank bottom plate. The terminal equipment is used for analyzing and processing the reflected ultrasonic waves, and analyzed and processed detection data of the storage tank bottom plate is obtained. The detection data at least comprises the corrosion position data and corresponding corrosion degree data. The online detection efficiency and accuracy of the system are high, through the non-contact type ultrasonic detection technology, the operation complexity and the construction cost are low, and therefore good practicality is achieved.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Ultrasonic detecting system and method

PendingCN106645414AHigh degree of automationOvercoming Detection EfficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesNon-contact ultrasoundContact type

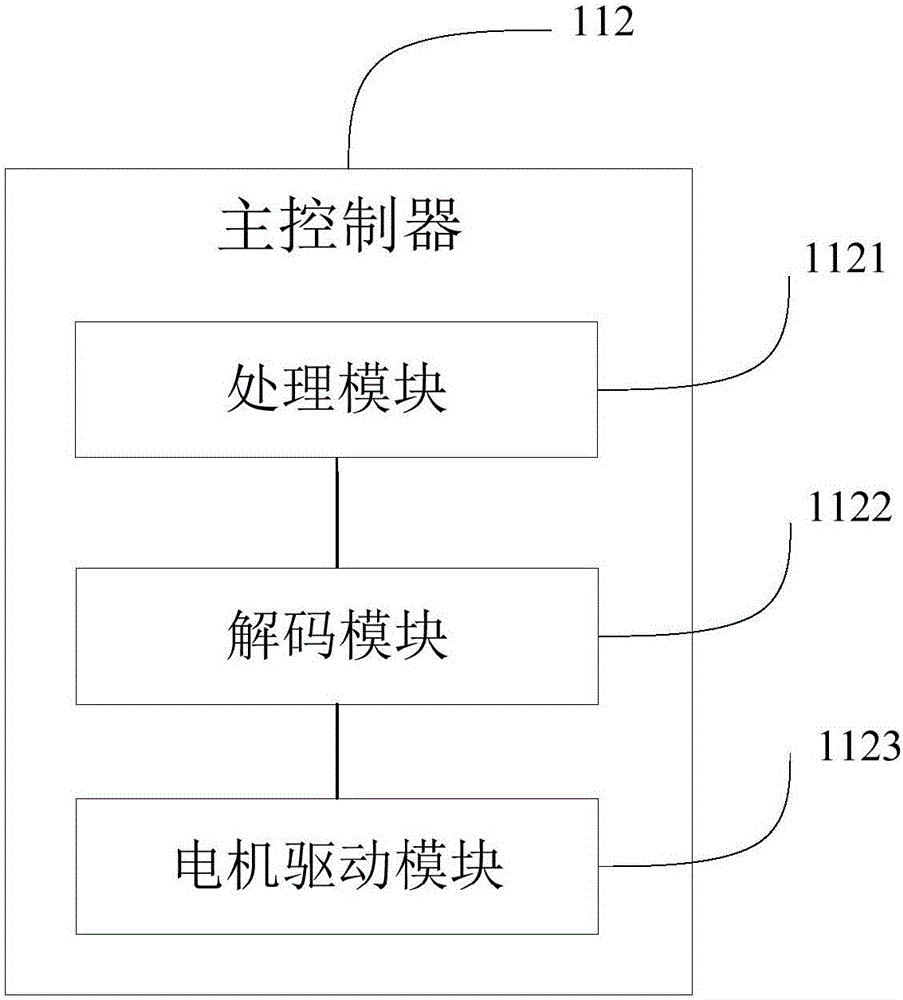

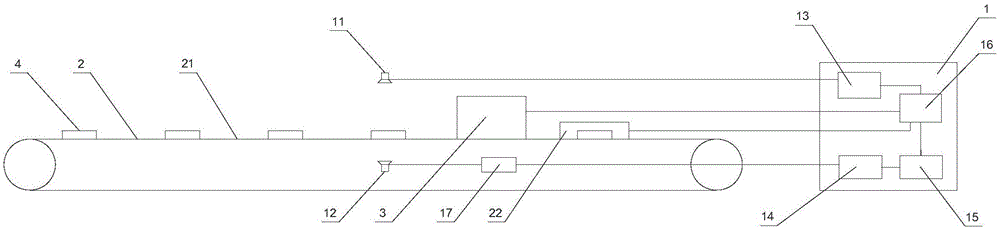

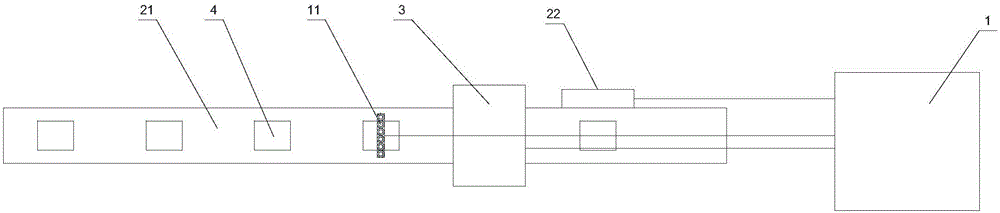

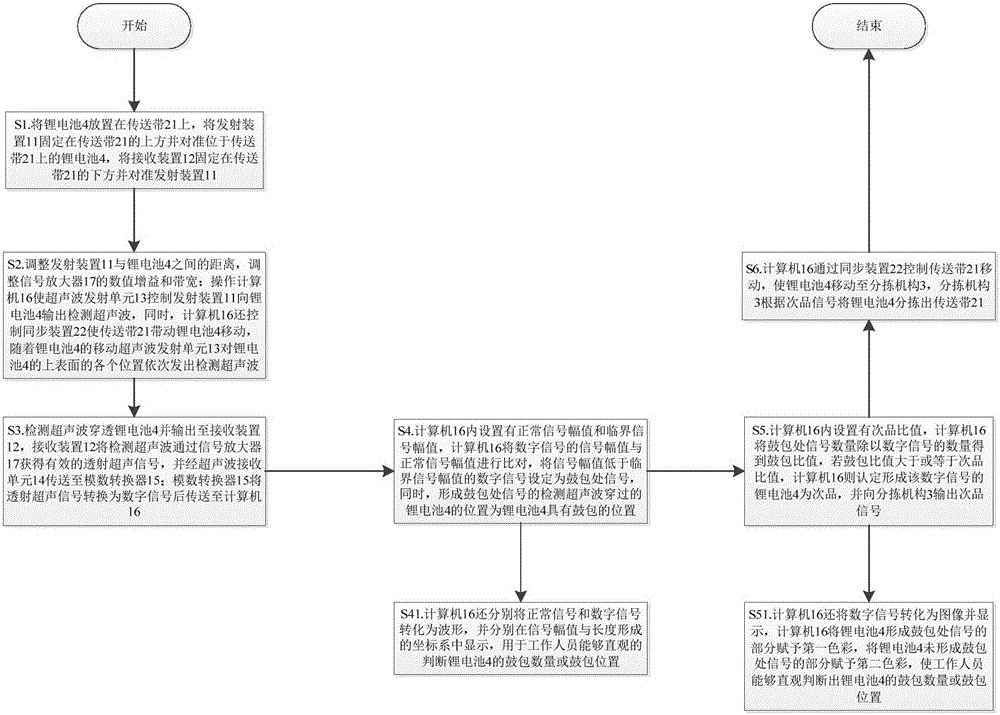

The invention discloses an ultrasonic detecting system and method. The ultrasonic detecting system is used for detecting lithium batteries and comprises a detecting portion, a transmitting portion, a sorting mechanism, wherein the detecting portion is used for detecting swelling of the lithium batteries, the transmitting portion is used for bearing and moving the lithium batteries, the transmitting portion is further connected with the detecting portion, and the sorting mechanism is arranged above the transmitting portion, connected with the detecting portion and used for sorting the lithium batteries with the swelling. The ultrasonic detecting system has the advantages and the beneficial effects of achieving a non-contact type ultrasonic detecting effect and having high flexibility, strong penetrating power, good directivity, quick detecting speed, low cost, relatively simple equipment and no harm to a human body. The ultrasonic detecting system also has the advantages of avoiding coupling agent, keeping longer distance with an object to be detected, having a simple and convenient detection process, improving the automation degree of lithium battery detection, greatly saving labor consumption of a battery swelling detecting process, reducing production cost, being beneficial to solving the problem that the efficiency and the accuracy are not high in manual product detection and greatly improving the production efficiency.

Owner:NONGTAIKE SHANGHAI DETECTION TECH CO LTD

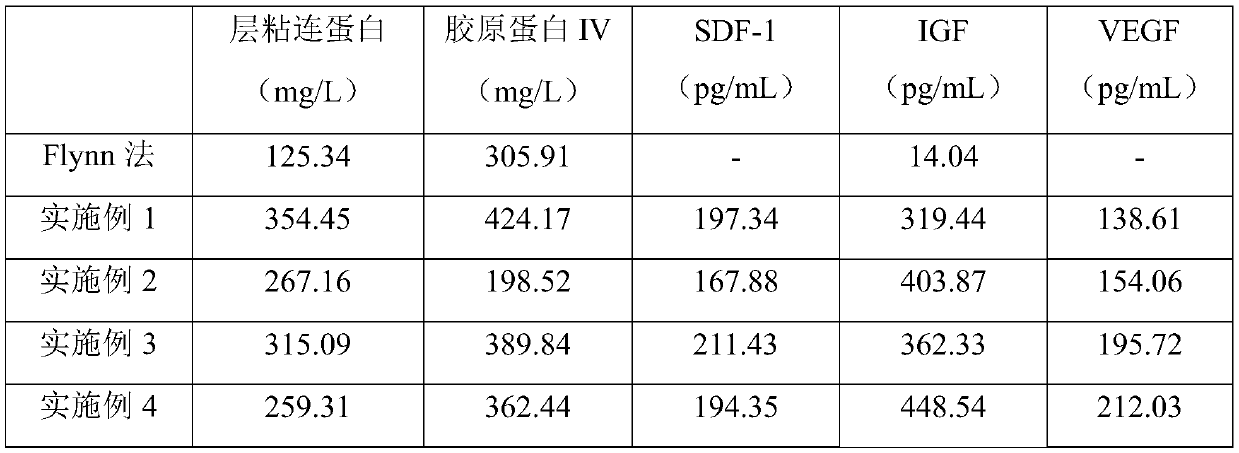

Method for efficiently preparing fat source biomaterial by using ultrasonic wave

ActiveCN109876189ATo achieve the purpose of enriching SVFsNo securityUnknown materialsDermatological disorderCellular componentFat grafting

The invention discloses a method for efficiently preparing a fat source biomaterial by using ultrasonic wave. The method comprises the steps of centrifugation, ultrasonic wave breaking (including contact type and non-contact type ultrasonic wave), centrifugal collection and the like. According to the method, the ultrasonic wave is utilized to break most mature fat cells in fat tissues, and the flocculation centrifugal sedimentation technology is applied to collect oil droplets generated by breaking the mature fat cells to achieve the purpose of enriching SVFs; high-speed centrifuging is utilized to remove cellular components to obtain ECM. After ultrasonic treatment, the cell activity is greatly improved, and the apoptosis rate is greatly reduced, so that the effectiveness of the transplantation is greatly improved. At the same time, an ECM biomacromolecule material can be obtained, and the low ECM content and the cytokine loss caused by the cumbersome operation are avoided. The biomaterial obtained by the method can be used for the autologous transplantation biological therapy, reduces the complications of fat transplantation and improves the survival rate of transplanted fat.

Owner:聂云飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com