Examination and verification device for noncontact ultrasonic method partial discharge detector and examination and verification method thereof

An ultrasonic method, non-contact technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problem of uneven performance of non-contact ultrasonic partial discharge detectors, affecting the effectiveness and reliability of partial discharge detection results of power equipment, Hidden dangers in the safe operation of power equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

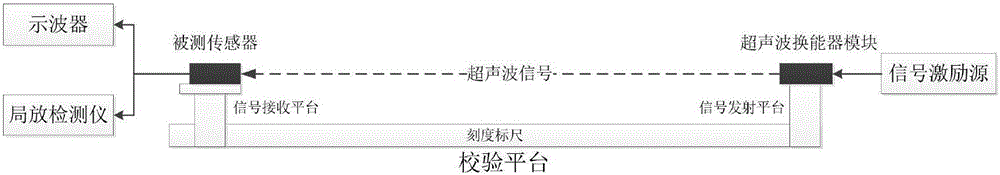

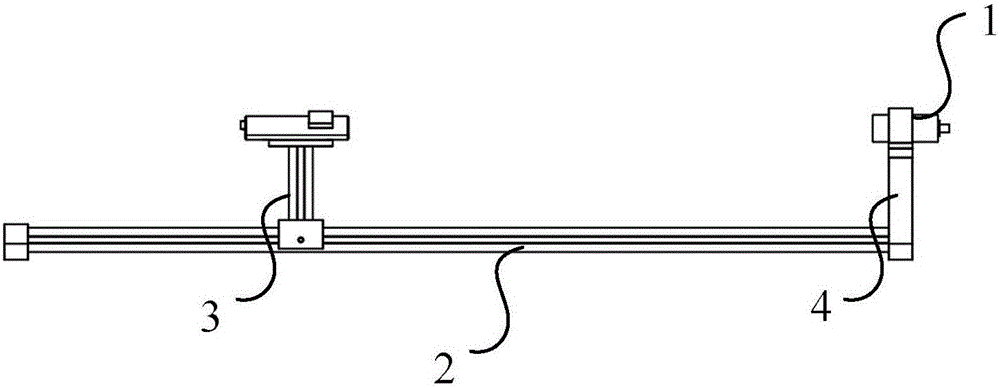

[0042] Such as figure 1 , figure 2 As shown, the present invention proposes an assessment and verification device for a non-contact ultrasonic partial discharge detector, including a signal excitation source, an ultrasonic transducer module 1, a verification platform 2, a reference sensor, an oscilloscope, and a 50Ω coaxial cable , the tested instrument includes the tested sensor and partial discharge detector,

[0043] The signal excitation source is connected to the ultrasonic transducer module by a 50Ω coaxial cable, the signal excitation source is used as a signal source, and the ultrasonic transducer module is used as a signal transmitting device; the calibration platform 2 is provided with a scale The scale, the signal transmitting platform 4 and the signal receiving platform 3 are also respectively arranged on the verification platform, and the signal receiving platform can slide freely on the verification platform; the ultrasonic transducer module 1 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com