Storage tank bottom plate corrosion noncontact ultrasonic detection method based on dynamic wavelet fingerprint technology

A non-contact, ultrasonic testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc., can solve the hidden dangers of safe and economical operation of storage tanks, high cost, leakage To avoid corrosion measurement errors, improve inspection efficiency, and reduce inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with concrete experiment the present invention will be further described:

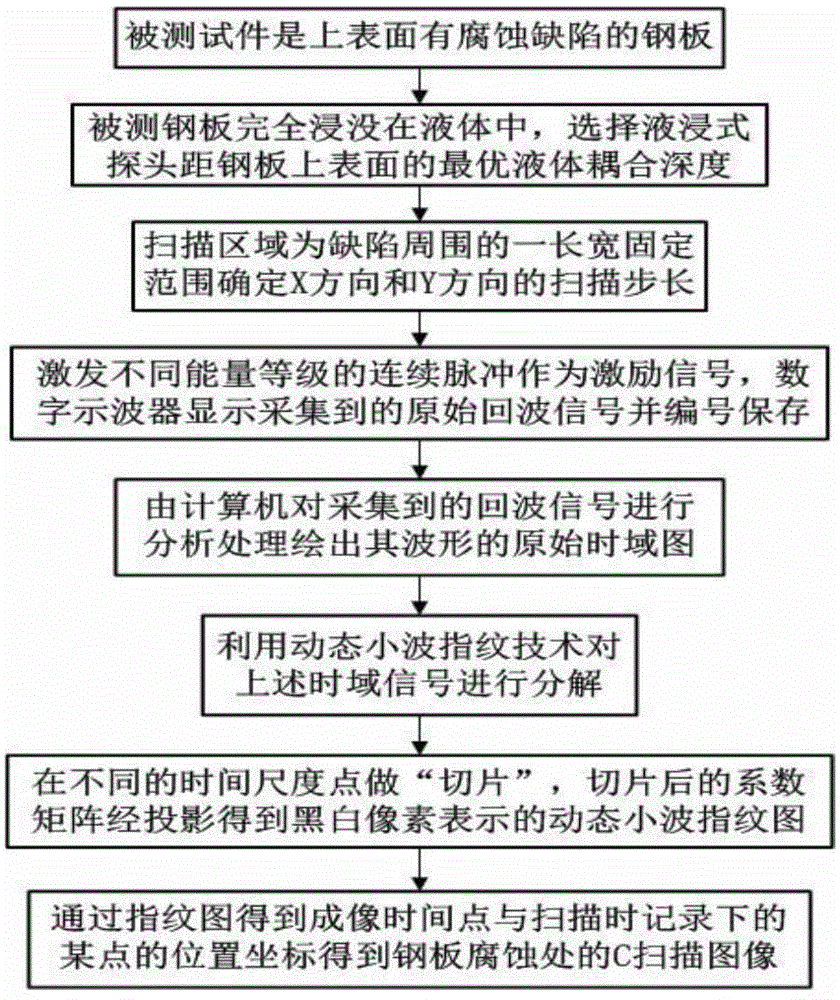

[0043] The implementation process of this experiment includes the following steps:

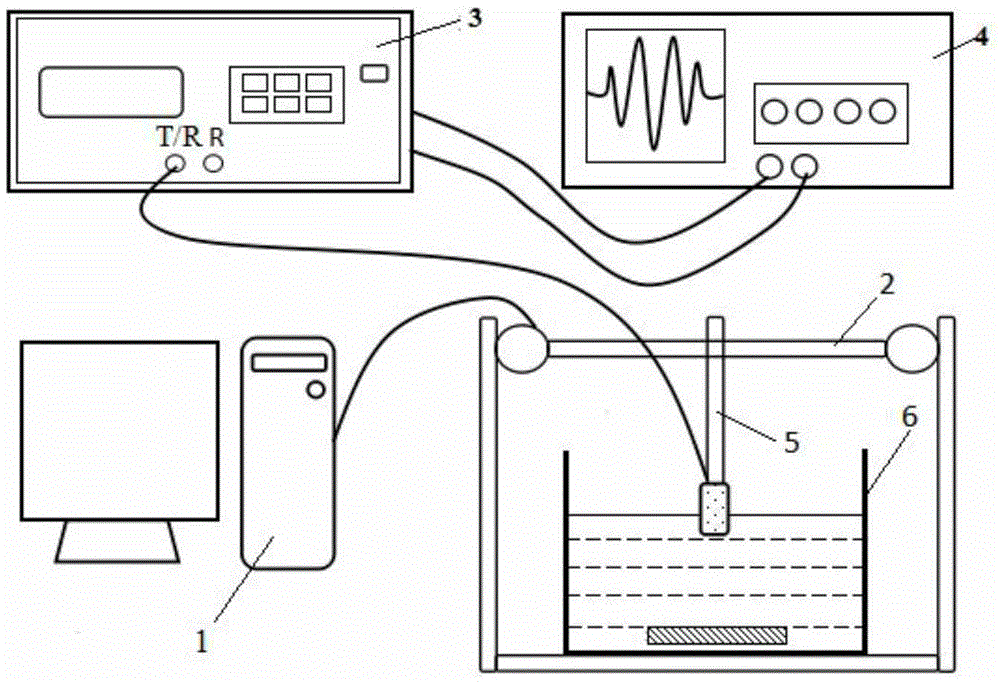

[0044] 1. Experimental system construction: according to figure 2 The system diagram of the detection device shown in the installation test system includes a computer 1, a four-axis linkage scanning platform 2, an ultrasonic pulse transmitter receiver 3, a digital oscilloscope 4, a water immersion non-focus probe with a center frequency of 5MHz 5, 45cm×35cm× 25cm transparent glass sink6. The four-axis linkage scanning platform 2 is connected with the computer 1, and the water immersion non-focus probe 5 with a center frequency of 5 MHz is fixed on the four-axis linkage scanning platform 2, and the optimal position in the Z direction is selected to remain unchanged, and the probe can be changed by a stepping motor The position in the X and Y directions. The T / R port of the ultrasonic puls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com