Large wall plate ultrasonic on-machine non-contact scanning thickness measuring equipment and thickness measuring method

A large-scale panel, non-contact technology, applied in the field of inspection, can solve the problems of difficult to meet the requirements of precise and efficient measurement of wall thickness of large-scale panels, large size of large-scale panels, and complicated control process, etc., and achieves high movement and positioning accuracy and automation. High, functional integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the technical scheme and the accompanying drawings.

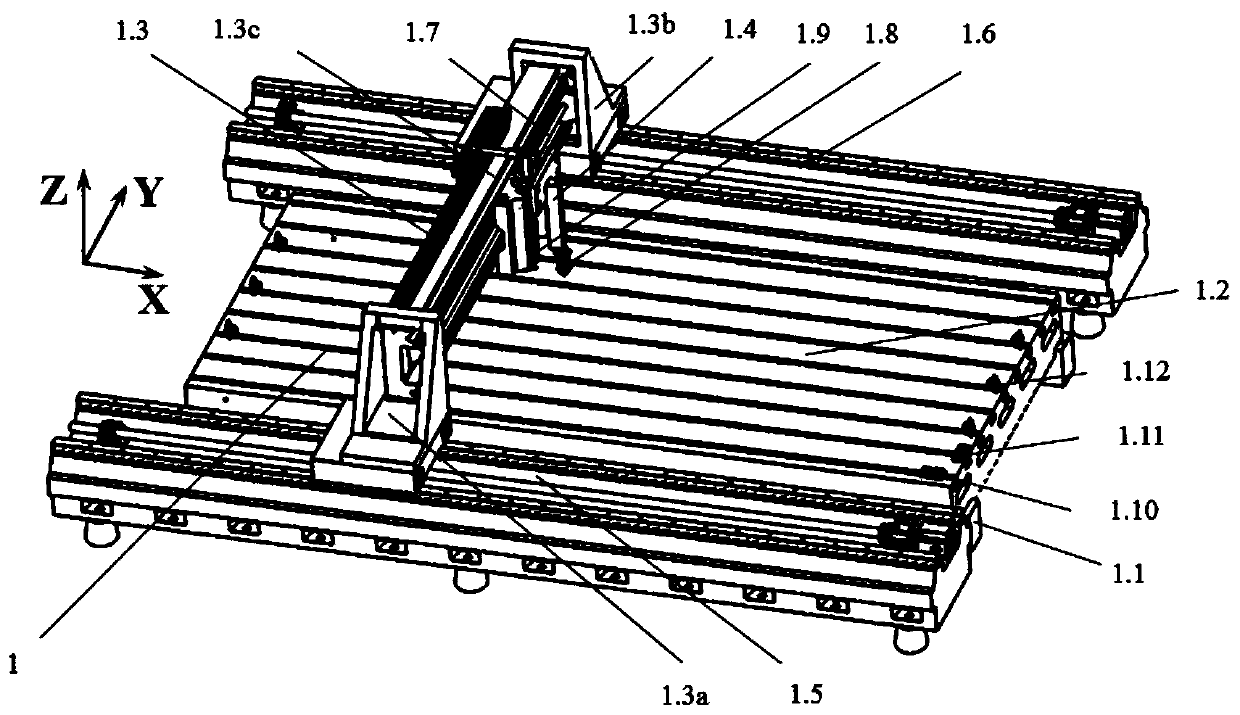

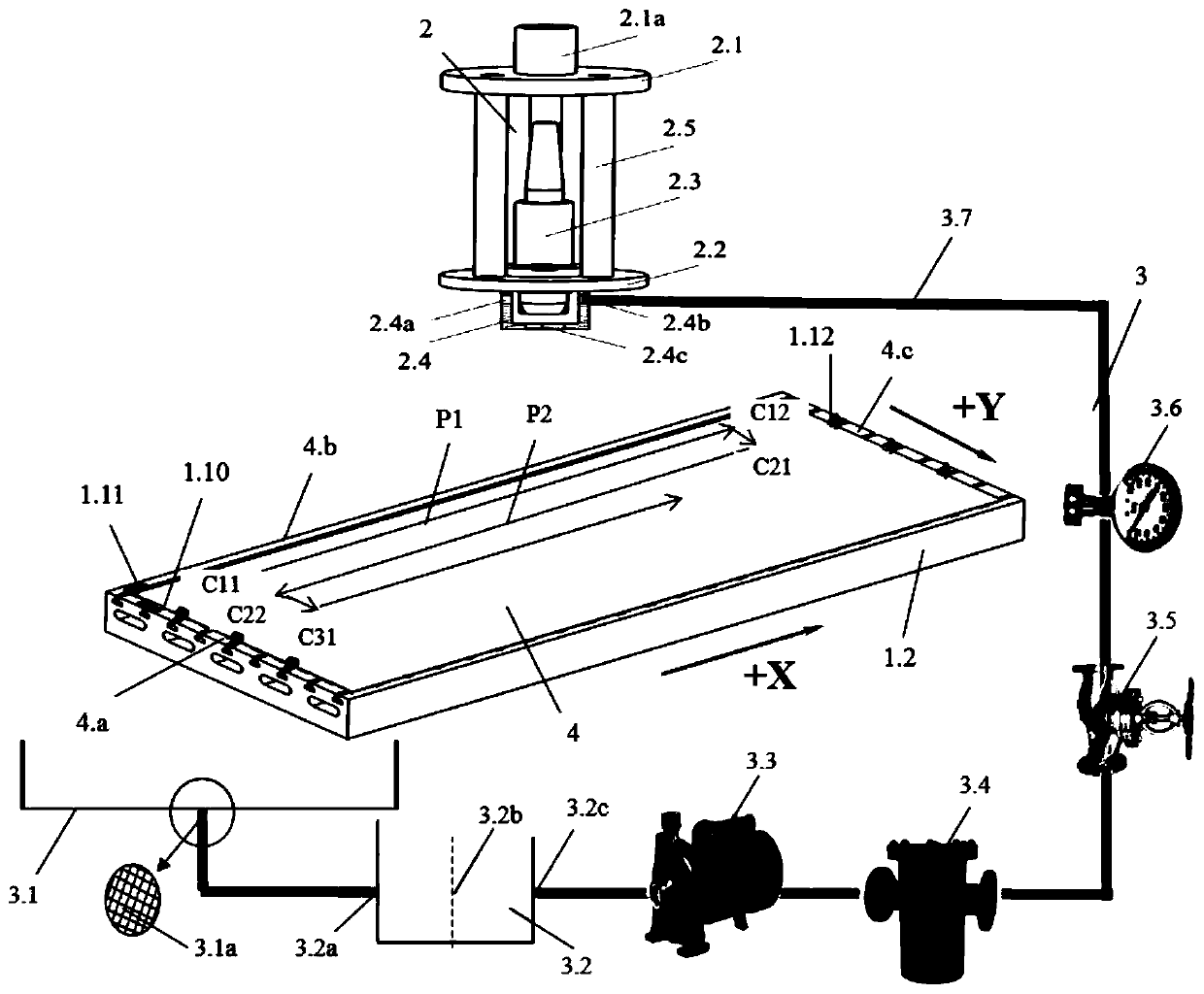

[0022] In the embodiment, attached figure 1 It is a schematic diagram of the structure of the gantry CNC machine tool, with figure 2 It is a schematic diagram of ultrasonic on-machine non-contact scanning thickness measurement of a large wall panel, in which the size of the large wall panel 4 to be tested is 4950mm×2500mm, one side has a diamond-shaped grid feature, and the other side is a plane; measurement requirements: full area measurement of the wall panel , effective measurement point spacing ≤ 10mm, total measurement time ≤ 120min; microemulsion cutting fluid with a volume concentration of 10% is used as the coupling agent, and the jet liquid immersion coupling method is adopted; the center frequency of the ultrasonic probe is 10MHz.

[0023] The equipment consists of a gantry-type CNC machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com