Non-contact type ultrasonic flaw-detecting machine for hollow car axle

A hollow axle, non-contact technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices, etc., can solve the problem of affecting the efficiency of hollow axle flaw detection and the wear of probe carriers Serious, time-consuming and other problems, to achieve the effect of reducing labor intensity, long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

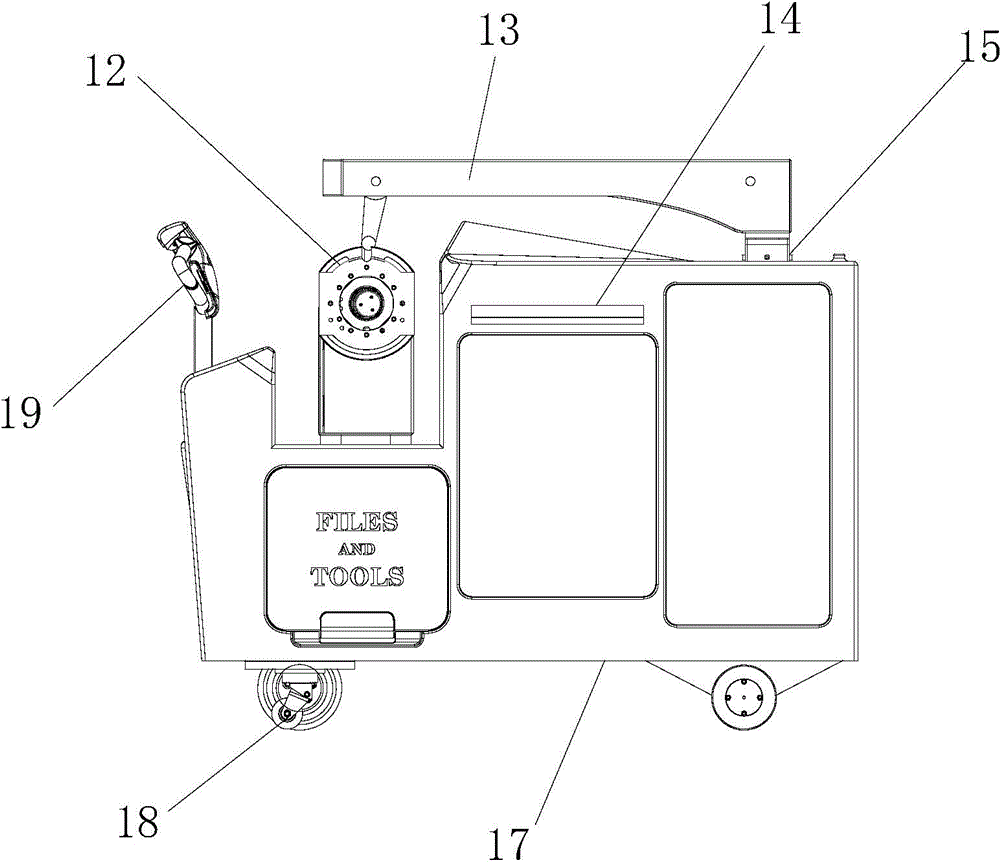

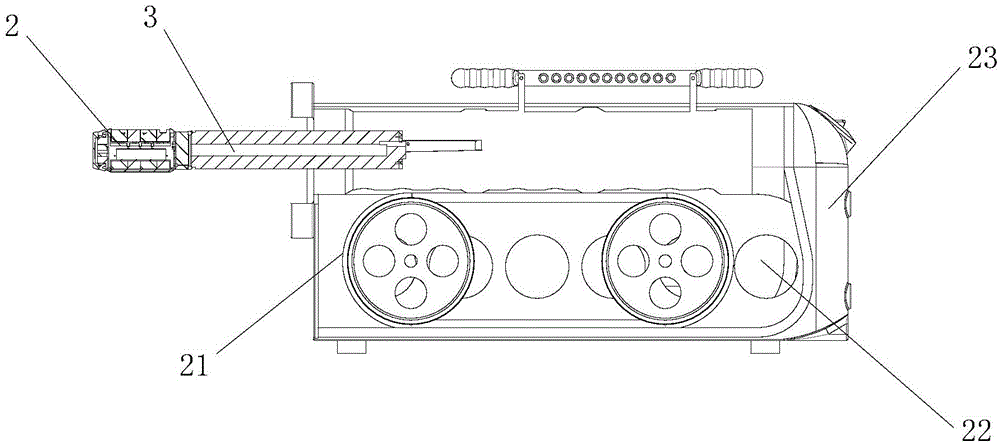

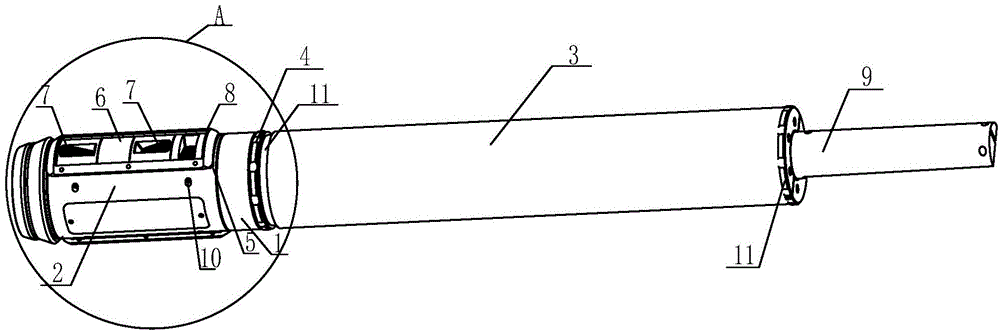

[0024] This embodiment provides a non-contact hollow axle ultrasonic flaw detector, the structure is as follows Figure 1 to Figure 6 As shown, it includes a chassis 17, a body 14, a feed mechanism 12, a detection control system and a lifting mechanism. The bottom of the chassis 17 is provided with a universal traveling wheel 18, and a control handle 19 is provided on one side of the chassis. On the upper surface of the chassis on the opposite side of the handle installation side, the feeding mechanism is arranged on the body 14 between the control handle and the lifting mechanism. Feed the motor 22, one side of the housing is provided with a plug that cooperates with the feed mechanism, the feed mechanism connection cable is installed on the plug, the probe rod is installed on the feed mechanism, and the installation end of the probe rod passes through the chain through the transmission assembly It is connected with the feed motor, and the detection end of the probe rod is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com