Non-contact ultrasonic flow velocity meter and non-contact flow velocity detection method

A non-contact, ultrasonic technology, used in fluid velocity measurement, velocity/acceleration/impact measurement, measurement devices, etc., can solve the problems of difficult manufacturing and transportation, low installation position accuracy, inconvenient debugging and maintenance, etc., to improve stability. The effect of stability and accuracy, low relative position accuracy, convenient debugging and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

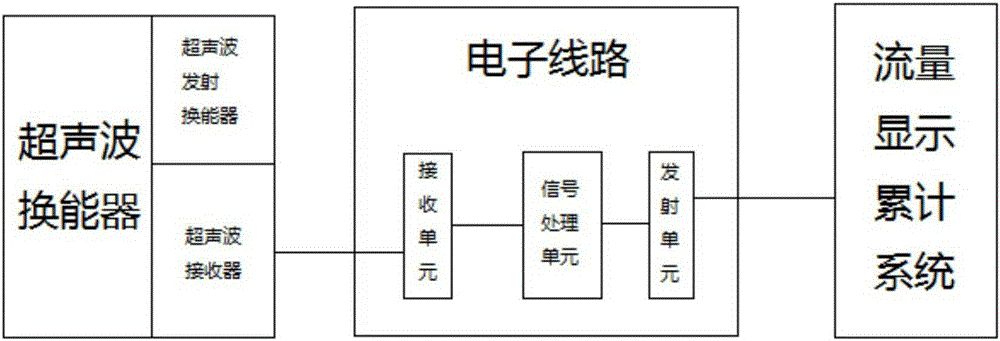

[0039] In this embodiment, preferably, the ultrasonic transducer is a piezoelectric transducer, the ultrasonic transmitting transducer adopts the inverse piezoelectric effect, and the ultrasonic receiver adopts the piezoelectric effect. The piezoelectric transducer utilizes the piezoelectric effect of the piezoelectric material, and uses a suitable transmitting circuit to add electric energy to the piezoelectric element of the ultrasonic transmitting transducer to generate ultrasonic vibration. Ultrasonic waves are injected into the fluid at a certain angle, then received by the ultrasonic receiver, and converted into electrical energy by piezoelectric elements for detection.

[0040] Preferably, in this embodiment, the piezoelectric transducer is made of lead zirconate titanate.

[0041] In order to ensure the directionality of the vibration, in this embodiment, the ultrasonic transducer is a circular sheet that vibrates along its thickness.

[0042] Further preferably, the ...

Embodiment 2

[0047] The invention also discloses a non-contact flow velocity detection method, comprising the following steps:

[0048] S1: Calculate the average velocity of the water flow: using the velocity area method, the radar water velocity meter detects the velocity of the water surface and transmits it to the host computer, calculates the velocity correction coefficient K, measures the horizontal average velocity, and obtains the water flow section through the data provided by the liquid level gauge area, and finally calculate the flow rate and send it to the signal processing unit;

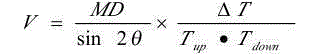

[0049]S2: Install the ultrasonic transducer: attach the ultrasonic transmitting transducer and the ultrasonic receiver to the outer wall of the pipeline to be tested at a certain distance, using the V method of two sound paths, the W method of four sound paths, or the use of sound waves Directly pass through the relative installation Z method of the pipeline under test, record the propagation time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com