Method for measuring existence of powdery materials in specific material position of container and implementation material level switch thereof

A powder material and material level switch technology, which is applied to instruments, measuring devices, liquid level indicators, etc., can solve the problems of short service life of detection devices and unreliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

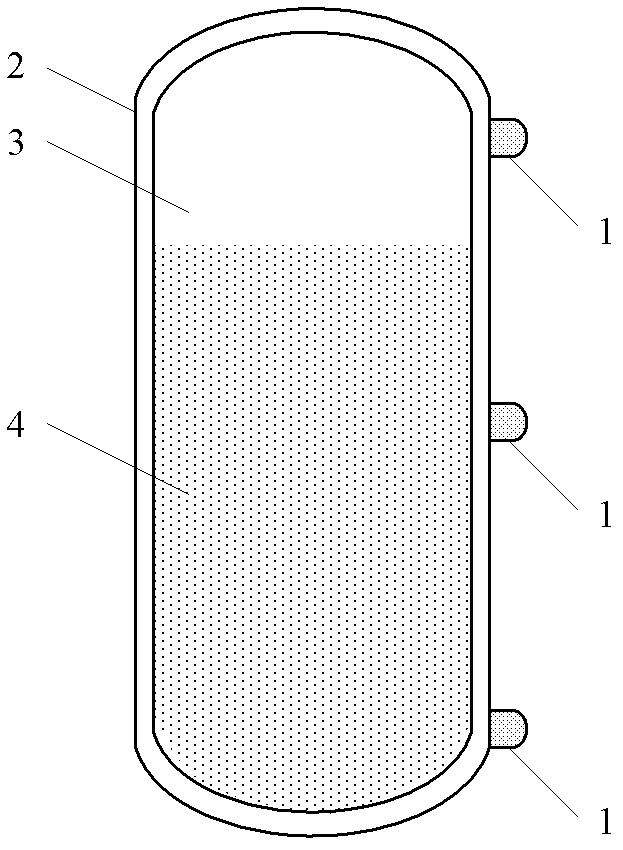

[0052] This embodiment is the application of the method and material level switch of the present invention in the cement silo of the cement mixing station, which is used to detect and control the minimum material level and the maximum material level of the cement silo. Its implementation is to install a non-contact ultrasonic powder material level switch 1 disclosed by the present invention at the lowest material level point and the highest material level point of the cement silo, and the ultrasonic probe 5 of the material level switch 1 is vertically installed in the cement silo Outside the wall 2, the installation method is as attached Figure 5 As shown, the material level switch is fixed outside the wall of the cement silo through the installation structure. The installation structure is mainly composed of pipe joints and flanges. A coupling agent is filled between the ultrasonic probe of the material level switch and the outer wall of the cement silo. In order to ensure T...

Embodiment 2

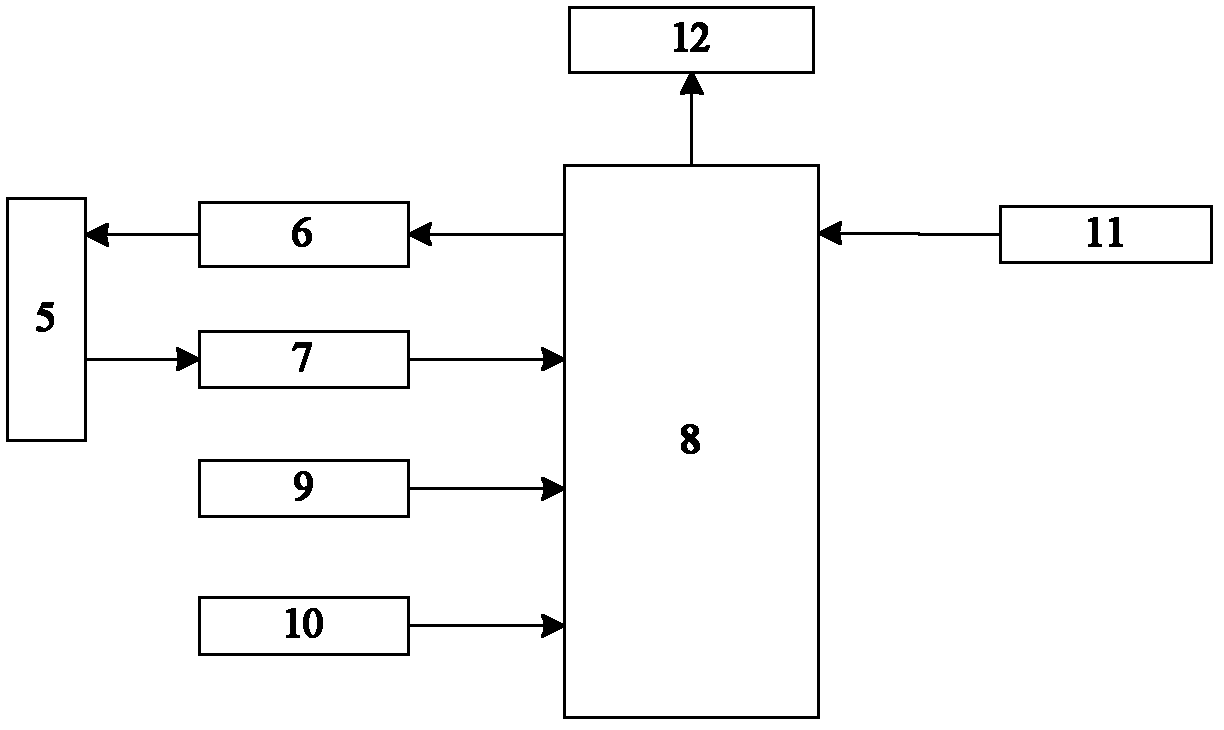

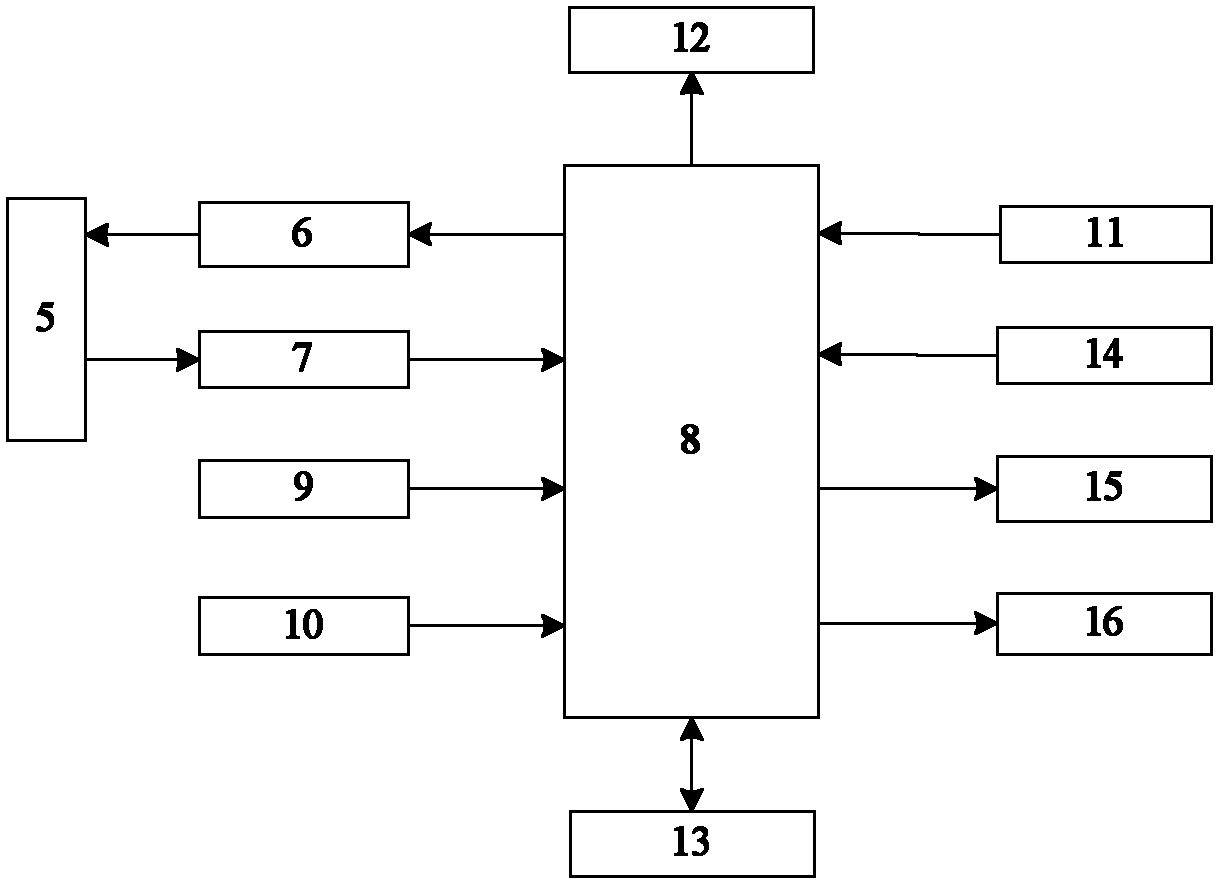

[0057] This embodiment is the application of the method and material level switch of the present invention in the mineral powder silo, which is used to detect and control the minimum material level, the minimum early warning material level, the highest material level and the highest early warning material level in the mineral powder silo. Its implementation is to install a non-contact ultrasonic powder material level switch 1 of the present invention at the lowest material level in the mineral powder silo, the lowest early warning material level, the highest material level and the highest early warning material level. Compared with Embodiment 1, this embodiment is different in addition to the number of the above-mentioned material level detection points, and the composition of the material level switch is different. The composition of the material level switch in this embodiment is as follows: figure 2 As shown, compared with the embodiment 1, several parts such as the serial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com