High-precision automatic sampling and calibrating ultrasonic liquid level monitoring system

An automatic sampling and liquid level monitoring technology, which is applied in the direction of testing/calibration devices, liquid/fluid solid measurement, and measuring devices, can solve problems such as poor compatibility, low measurement accuracy, and difficult calibration methods, so as to solve poor compatibility and realize The effect of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

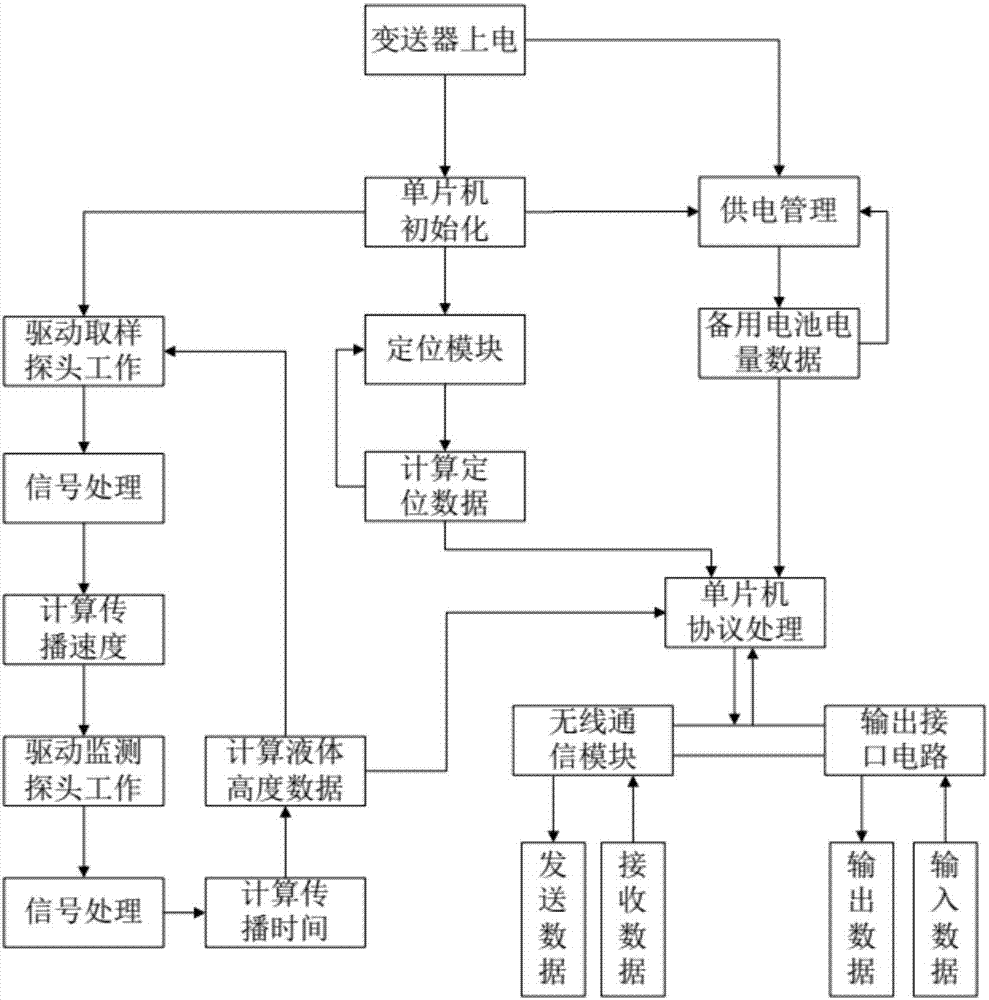

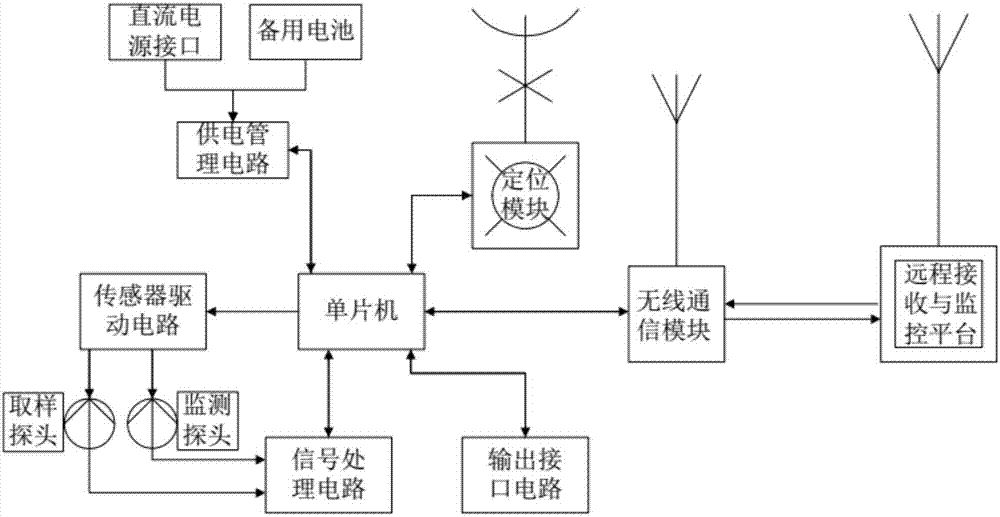

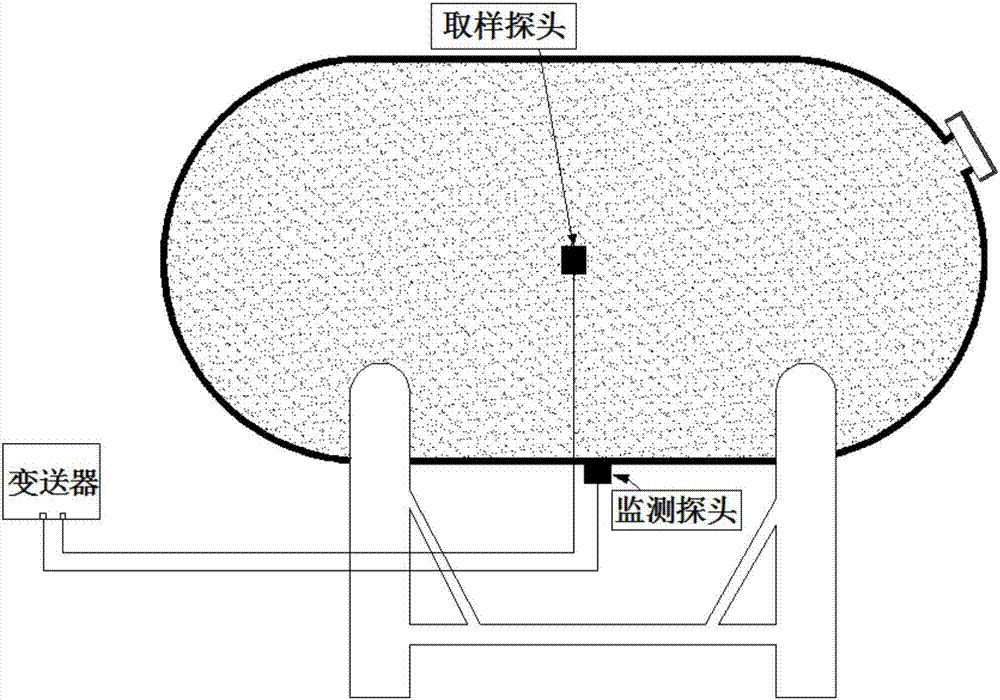

[0025] Such as Figure 1-Figure 6 As shown, a high-precision automatic sampling calibration ultrasonic liquid level monitoring system in this embodiment includes an ultrasonic probe, a transmitter, a power supply device, a container, and a server platform. The ultrasonic probe includes a sampling probe and a monitoring probe. The variable The transmitter is composed of a sensor driving circuit, a signal processing circuit, a wireless communication module, a positioning module, an output interface circuit, a power supply management circuit, and a single-chip microcomputer. The power supply device includes an external DC power supply and a backup battery. The server platform includes a handheld receiving device and Remote monitoring cloud platform.

[0026] The interface of the output interface circuit includes RS232, RS485, 4-20mA, and analog voltage output; the container is a variety of metal, plastic, glass and other containers for storing liquids, as well as high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com