Bracket type carrier cable holder

A tension-bearing cable seat and bracket-type technology, applied in power lines, transportation and packaging, vehicle parts, etc., can solve the problems of increasing catenary load, low productivity, cumbersome manufacturing, etc., to improve production efficiency, reduce weight, The effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

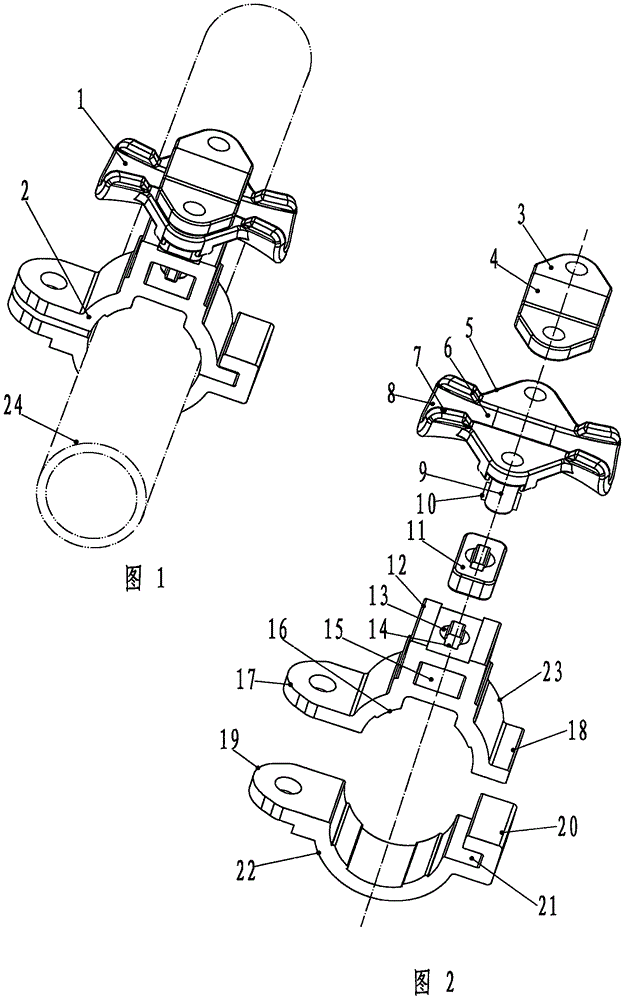

[0018] Below in conjunction with the accompanying drawings and specific embodiments, the bracket type load-bearing cable seat of the present invention will be further described:

[0019] figure 1 It is a schematic diagram of the three-dimensional structure of the bracket-type load-bearing cable seat of the present invention, figure 2 Yes figure 1 Schematic diagram of the assembly relationship of each part. In the figure, the bracket-type load-bearing cable seat includes a base 2 fixed on the flat wrist arm and a saddle-shaped support 1 on the base. The base 2 is composed of a semicircular main hoop 23 and a secondary hoop 22 up and down. , the main hoop 23 and the two semicircular rings of the secondary hoop 22 are combined to form a ring that is tightly hugged on the round tube type flat wrist arm 24 that needs to be installed.

[0020] One ring end of the semicircular ring on the main hoop 23 stretches out the clasp 18 in parallel to the outside, and the other ring end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com