Water jet rust removal cleaning gun capable of forming gradient coating

A technology for cleaning guns and water jets, applied in the direction of spraying devices, spraying devices with movable outlets, etc., can solve the problems of partial destruction of good paint in the outer layer area, poor coating adhesion, and increased secondary coating costs, etc. Achieve the effect of reducing the cost of secondary coating, improving the bonding force of the coating, and increasing the area of jet cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

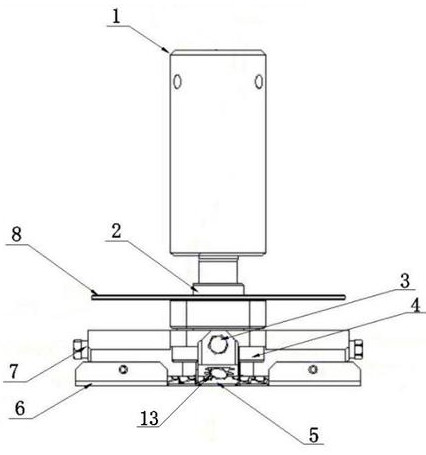

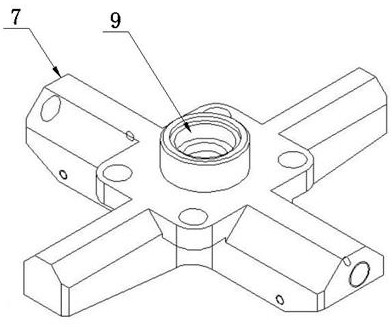

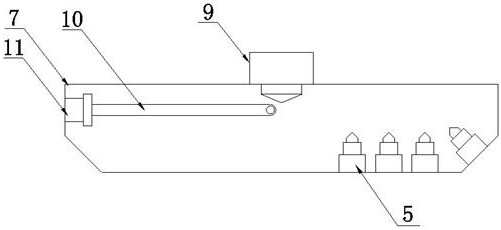

[0024] The cleaning gun 12 is provided with a central rotating body 1. The central rotating body 1 is provided with a cross spray bar 7 near the bottom. A nozzle 5 is provided in the center below the cross spray bar 7. A hexagonal bolt is arranged between the nozzle 5 and the cross spray bar 7. 4. The two sides of the nozzle 5 are symmetrically provided with a protective cover 6, and the protective cover 6 is installed in cooperation with the cross spray bar 7 and the nozzle 5.

Embodiment 2

[0026] The cleaning gun 12 is provided with a central rotating body 1. The central rotating body 1 is provided with a cross spray bar 7 near the bottom. A nozzle 5 is provided in the center below the cross spray bar 7. A hexagonal bolt is arranged between the nozzle 5 and the cross spray bar 7. 4. Both sides of the nozzle 5 are symmetrically provided with a protective cover 6, and the protective cover 6 is installed with the cross spray bar 7 and the nozzle 5. The inside of the cleaning gun 12 is provided with a rotary nine-way 13, and the inner center of the rotary nine-way 13 is provided There is a nozzle connector 14, the outside of the nozzle connector 14 is provided with a central rotating body 15, the central rotating body 15 is a regular octagon, and the inside of the central rotating body 15 is equiangularly provided with a flow channel 18, and the flow channel 18 is in the vertical direction. The angle adjustment range is 0-10°, and the spray range of the nozzle 5 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com