Patents

Literature

35results about How to "Prevent re-rusting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

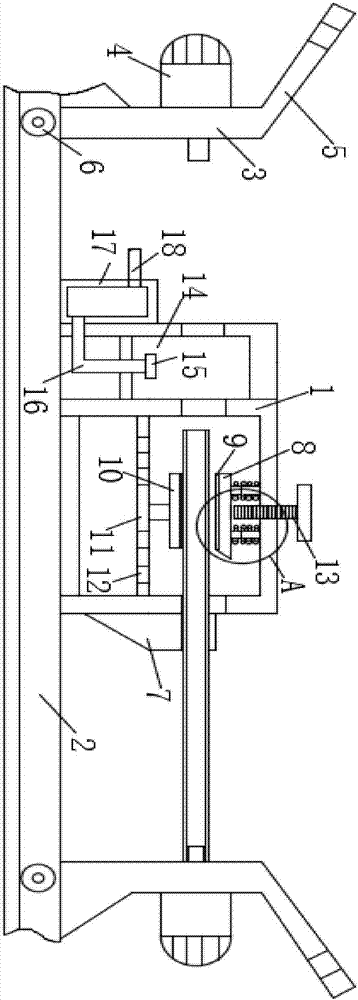

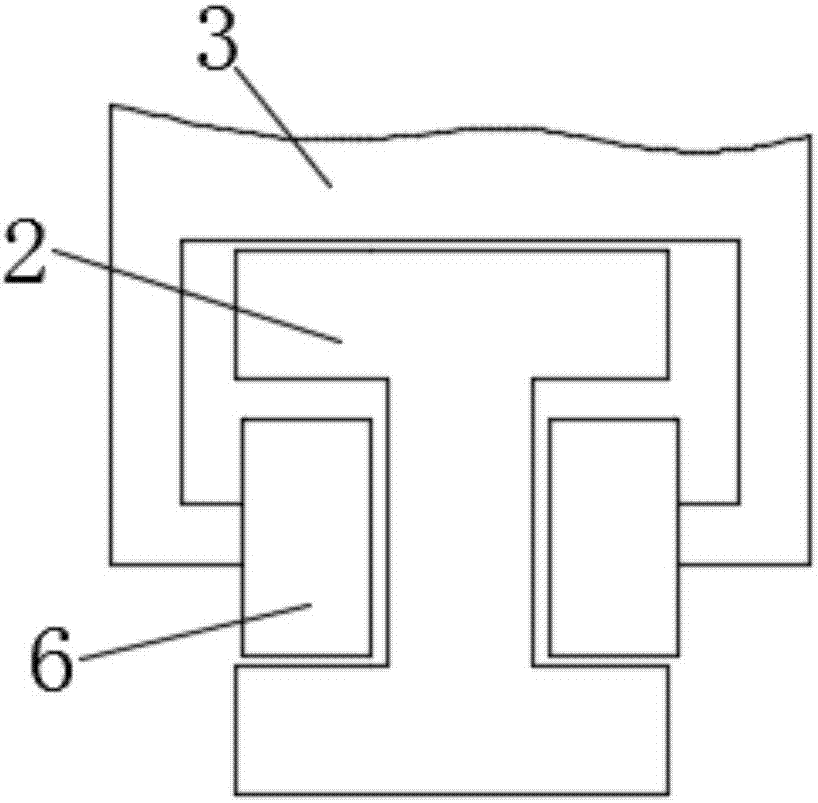

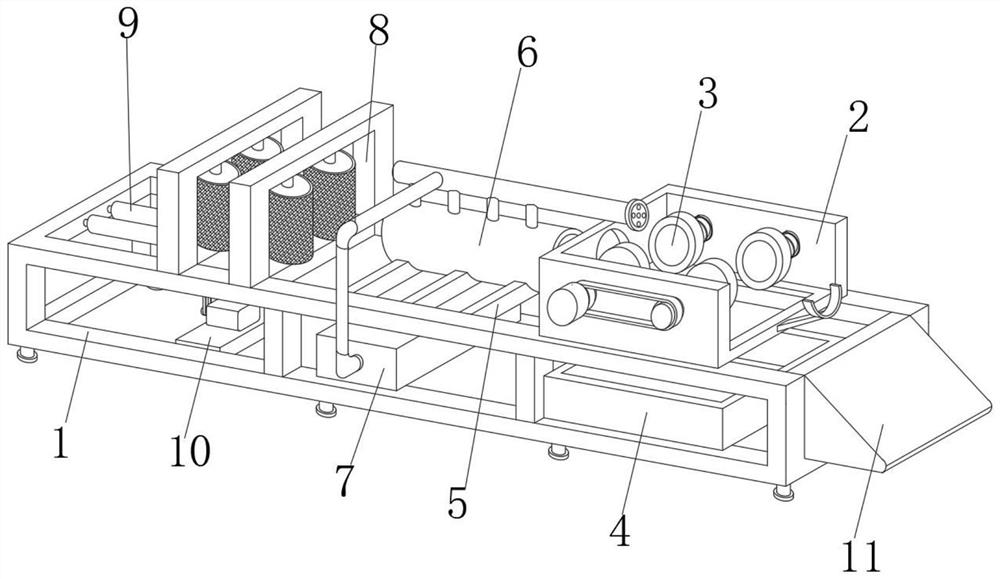

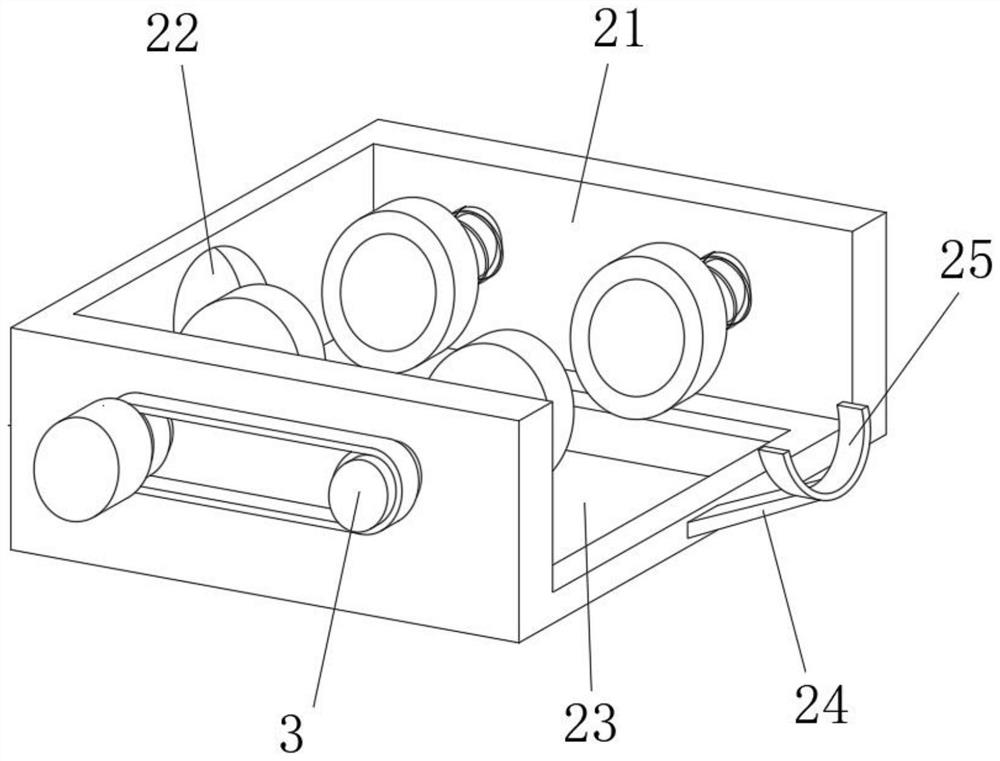

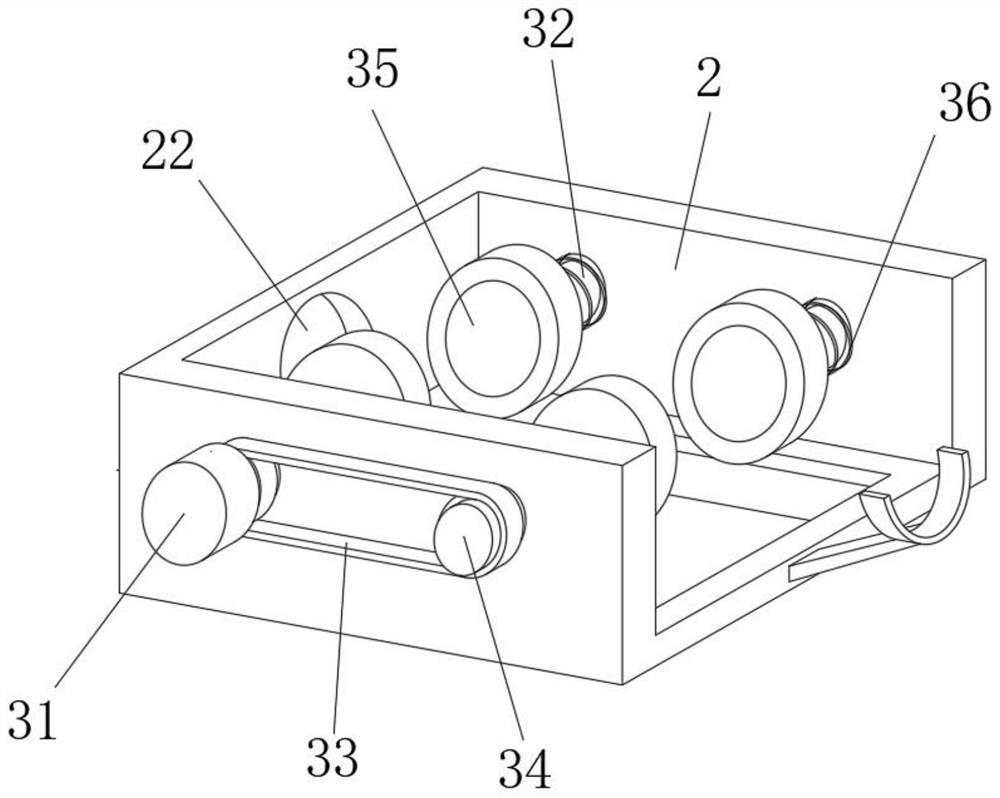

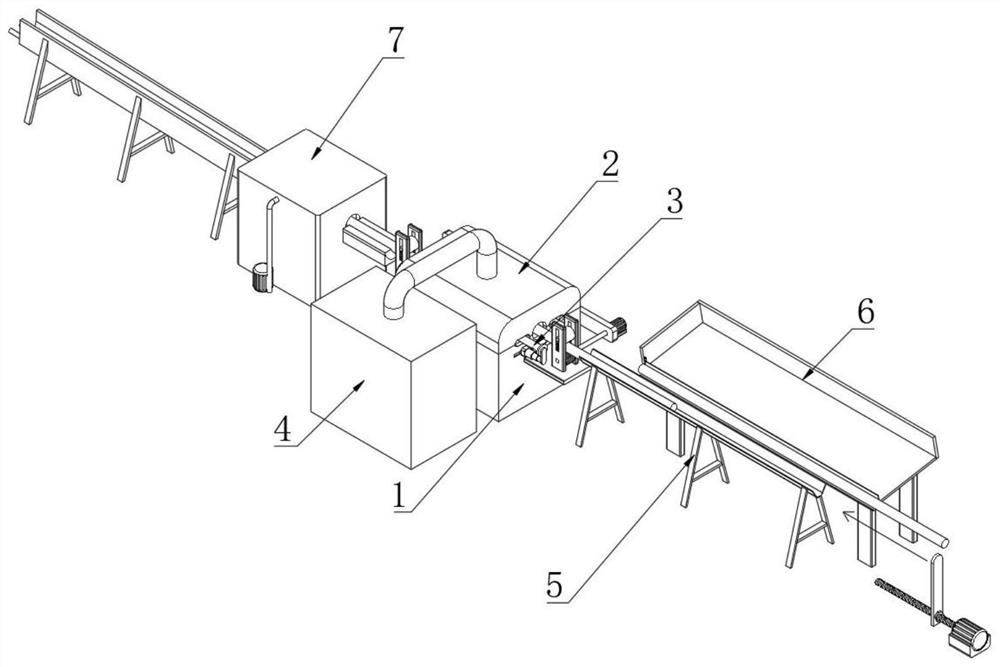

Rust removing and paint spraying device for outer wall of steel pipe

InactiveCN107185748AEasy to operateImprove rust removal efficiencyPretreated surfacesLiquid spraying apparatusSteel tubeEngineering

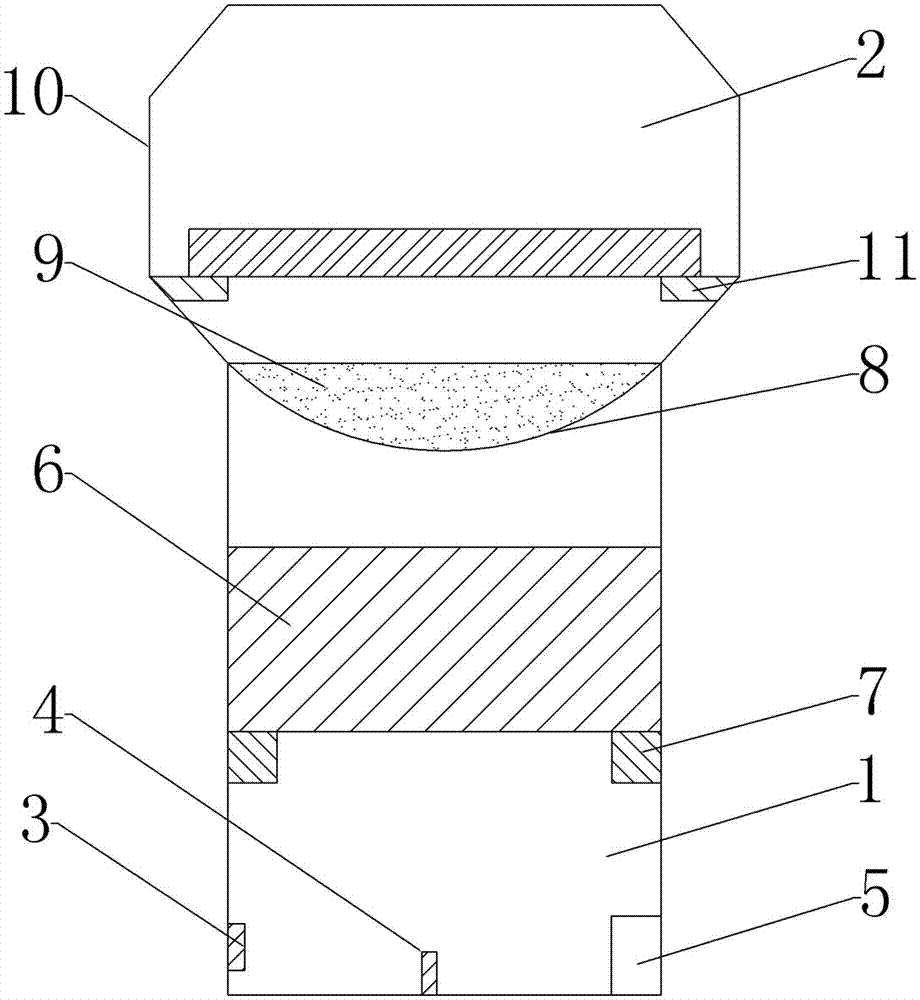

The invention discloses a rust removal and painting device for the outer wall of a steel pipe. The center of the upper surface of the main body is connected with a knob bolt through a threaded hole. A movable pressure plate is arranged above the main body of the derusting device, a fixed plate is arranged under the main body of the derusting device, and a spray booth is provided on the left surface of the main body of the derusting device. The invention pushes the steel pipe into the body of the derusting device, the steel pipe is closely attached to the movable plate between the fixed plates, the rotation of the steel pipe enables the derusting frosted sheet to derust the steel pipe, and when the left end of the steel pipe moves into the paint spraying room, the compressed gas will The paint in the paint tube is sprayed onto the surface of the steel pipe through the nozzle to complete the steel pipe painting work, which improves the rust removal efficiency of the steel pipe, and can also spray the steel pipe to prevent the steel pipe from rusting again.

Owner:桐乡市锦格家纺有限公司

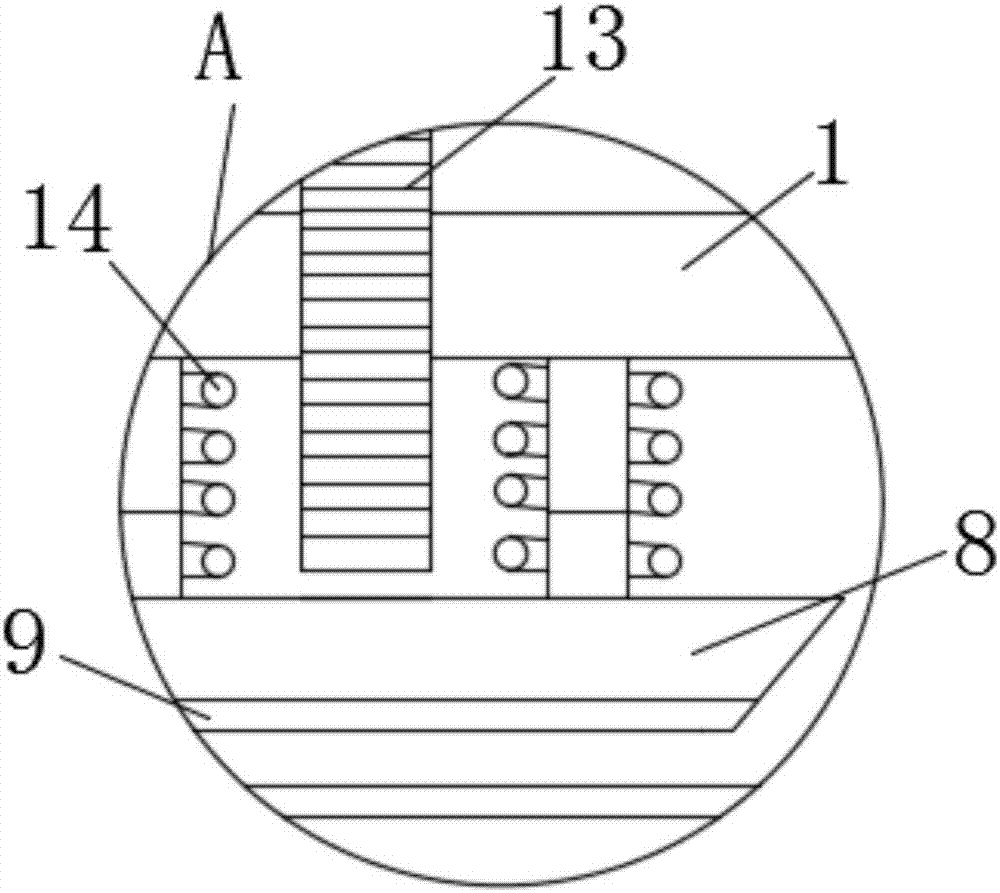

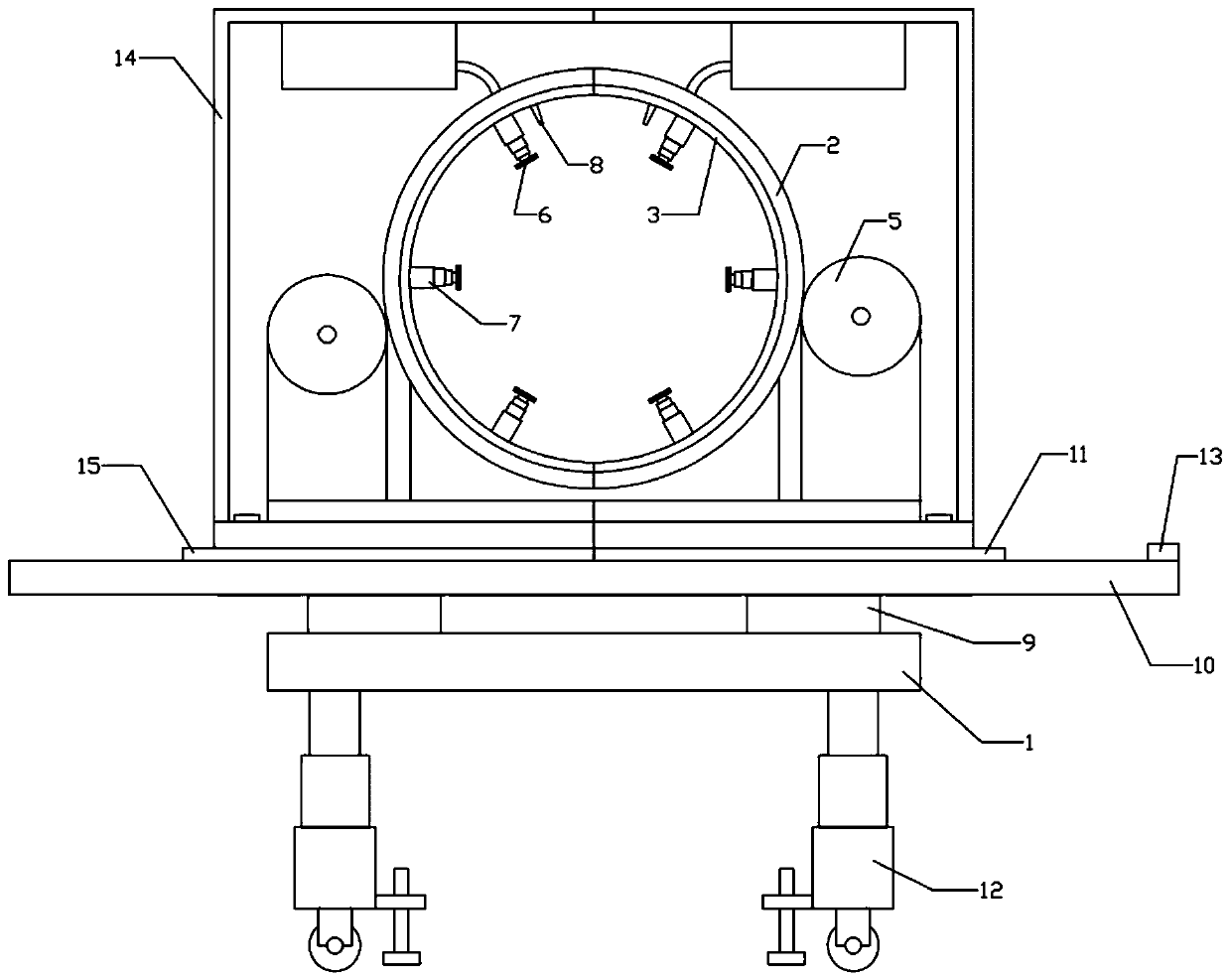

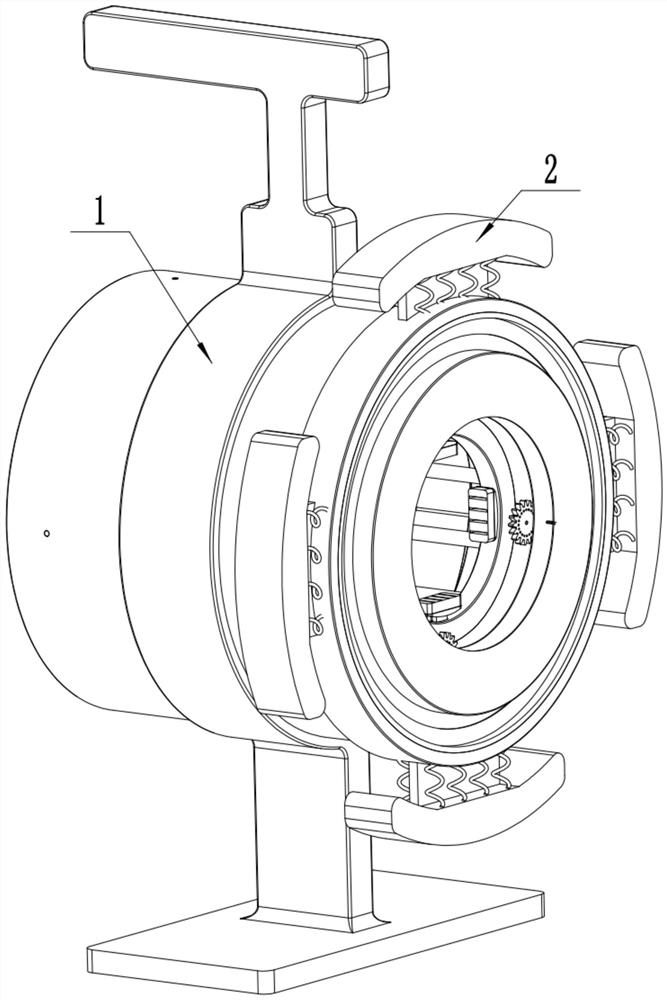

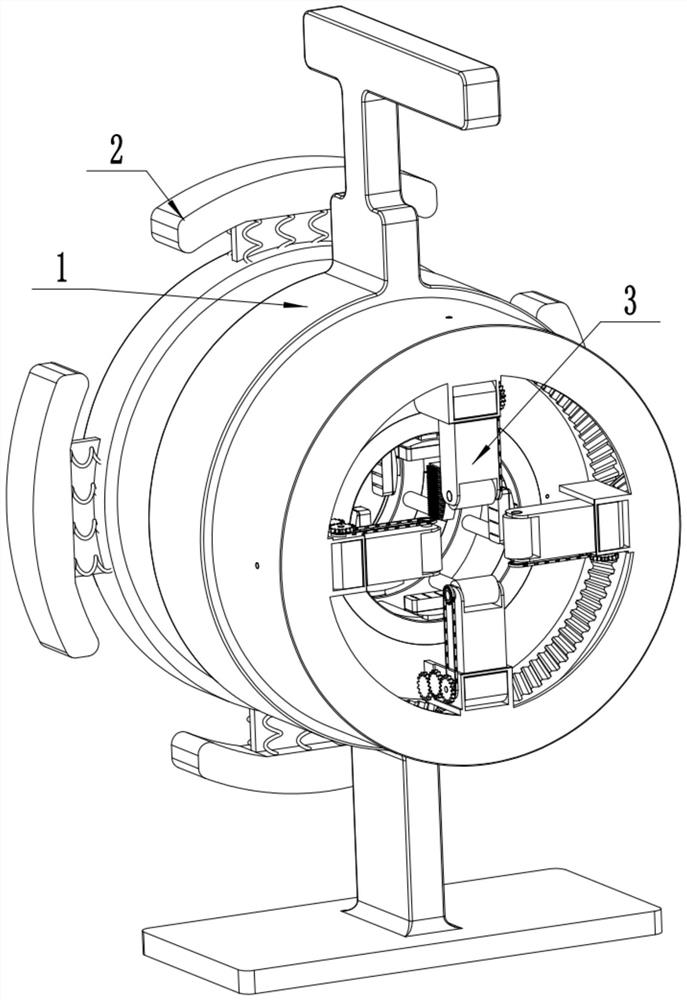

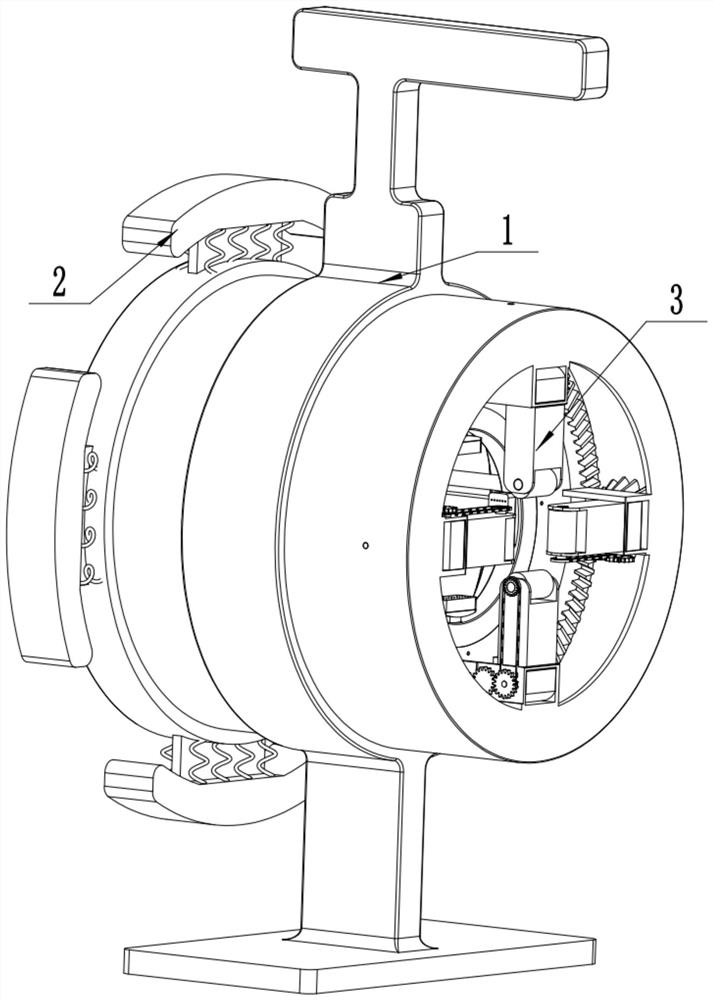

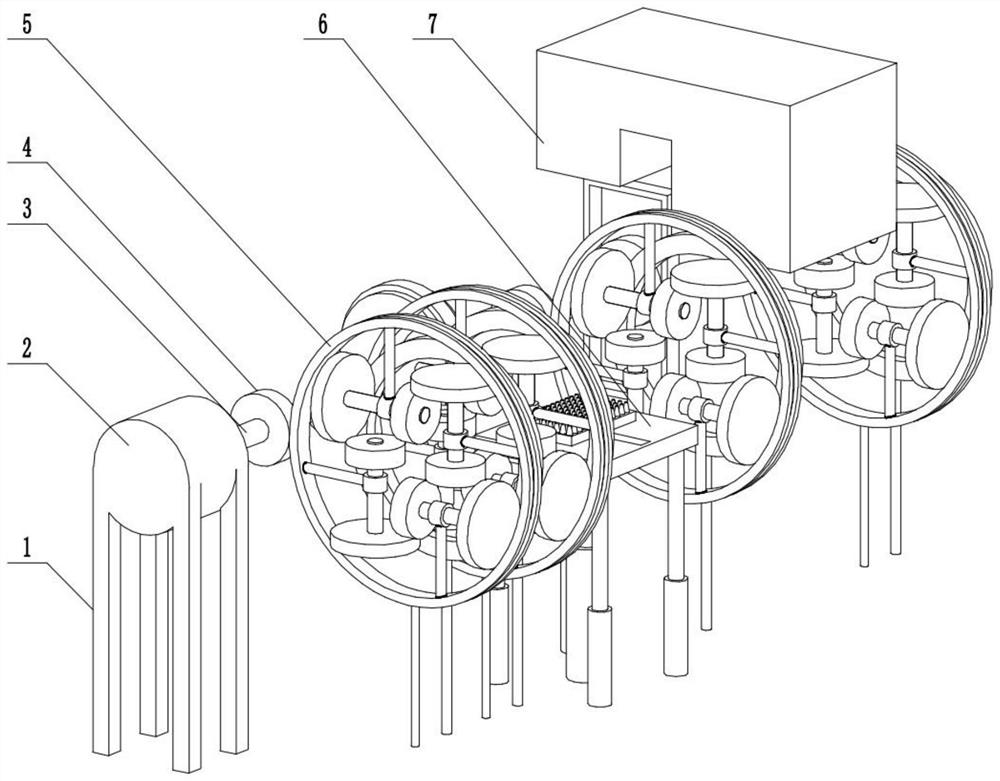

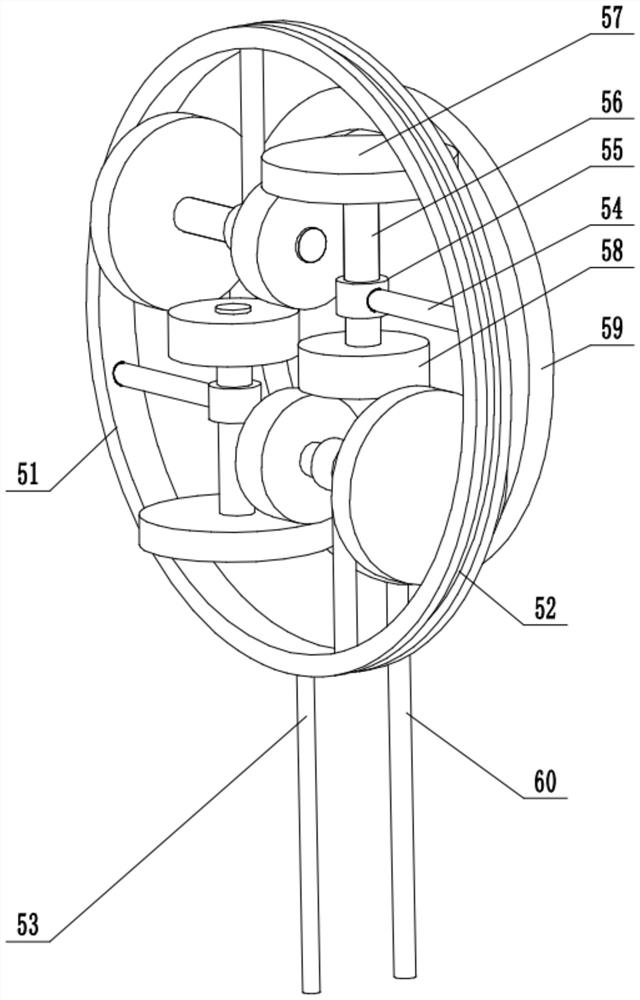

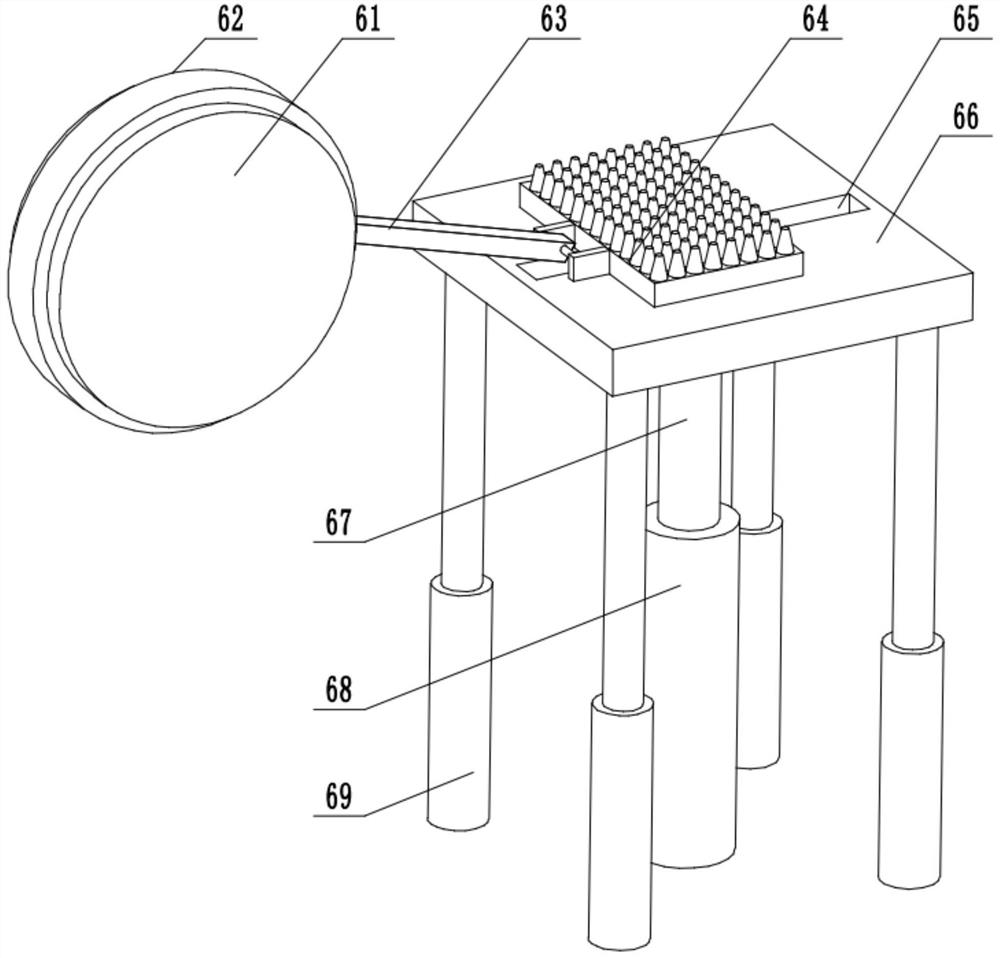

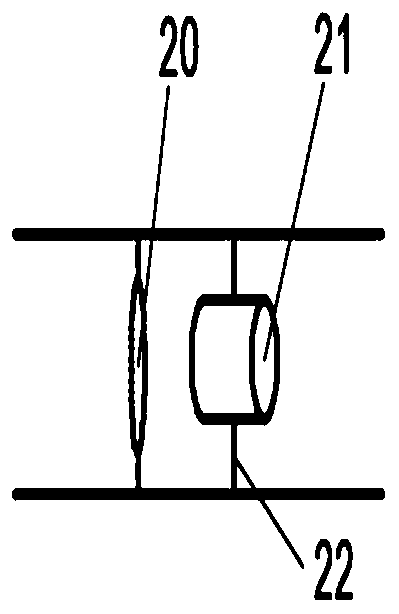

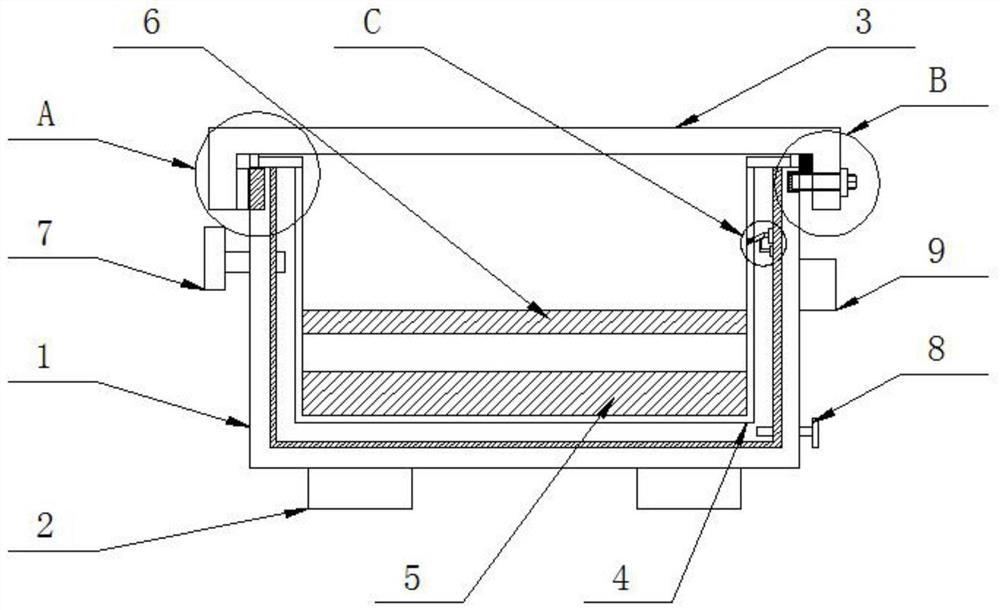

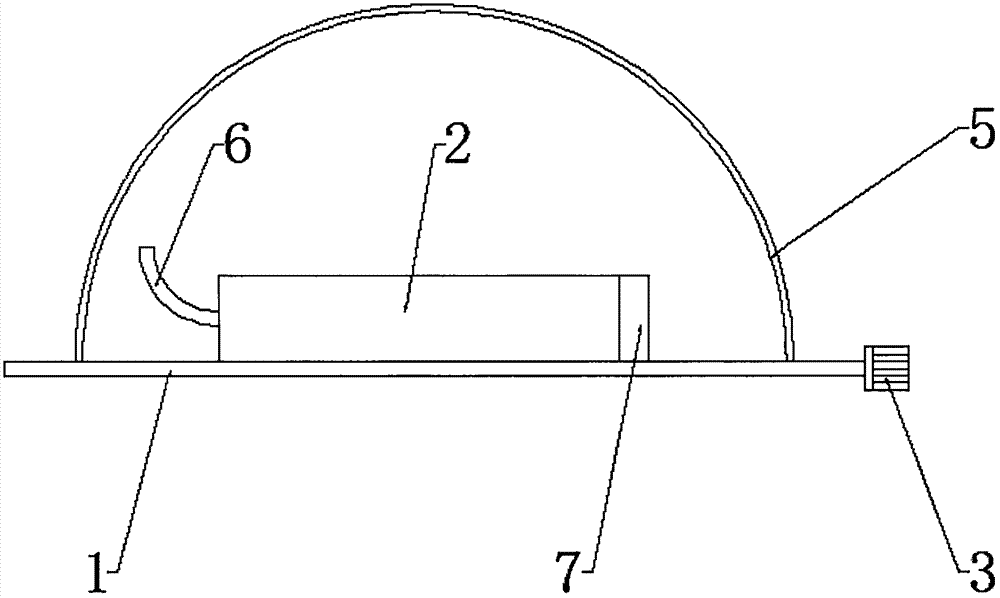

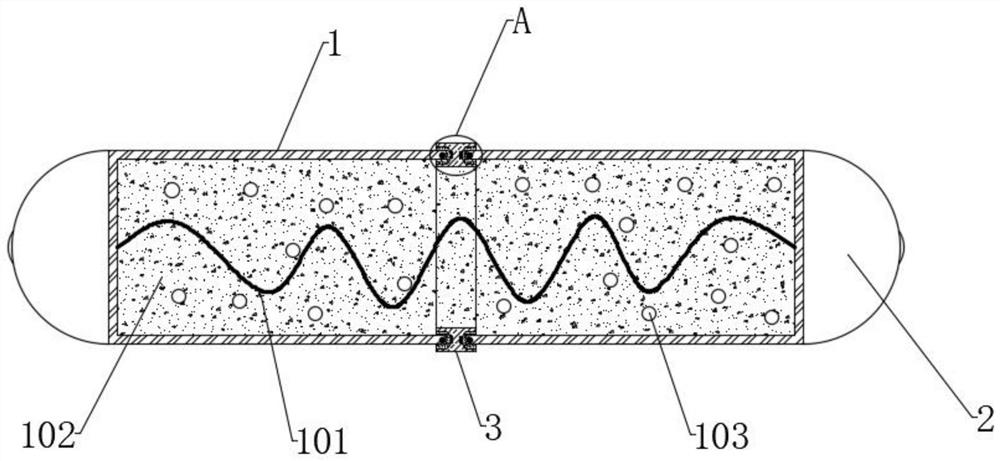

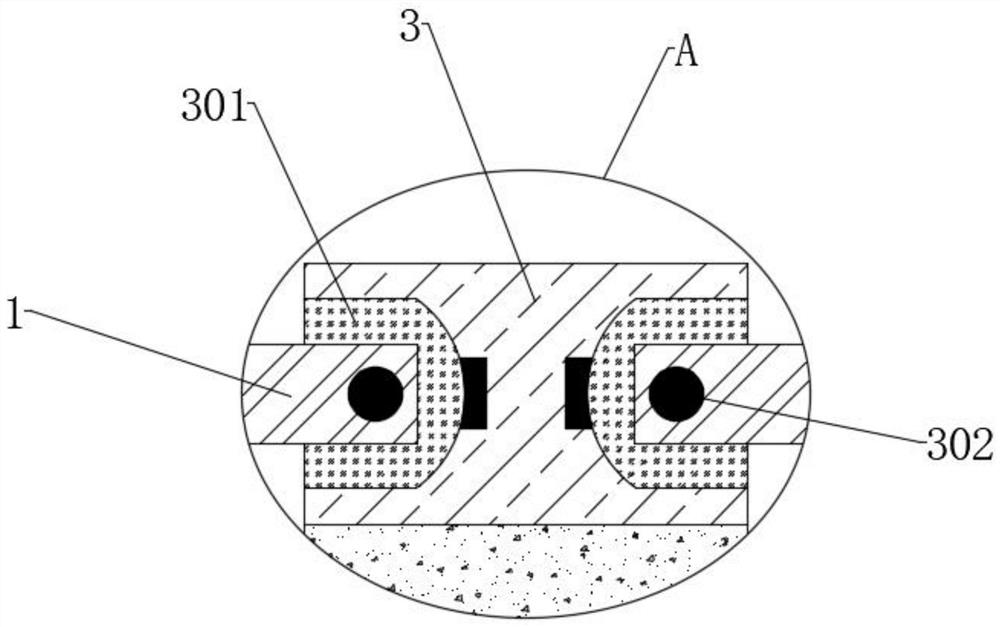

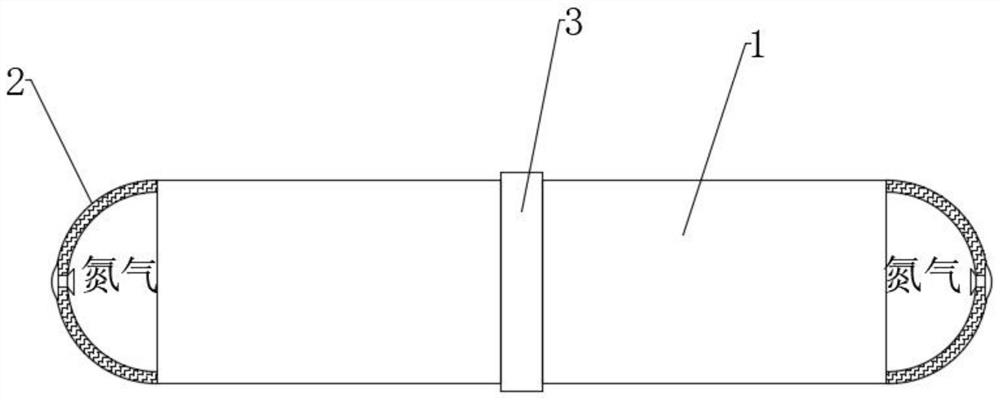

Derusting device for outer surface of water conservancy construction pipeline and using method thereof

ActiveCN111266979APrevent re-rustingProblems Affecting Structural StrengthGrinding carriagesGrinding drivesGear wheelElectric machinery

The invention relates to a derusting device for the outer surface of a water conservancy construction pipeline and a using method thereof. The problem that an existing derusting device is not prone toderusting a pipeline in use is solved. The derusting device for the outer surface of the water conservancy construction pipeline comprises a supporting frame, the derusting device is arranged on thesupporting frame and comprises annular sliding rails arranged at the front end and the rear end of the supporting frame, a ring body is arranged between the annular sliding rails at the front end andthe rear end, and the ring body is clamped between the annular sliding rails through sliding blocks on the front end face and the rear end face, toothed blocks are arranged on outer wall of the left side and the right side of the ring body and engaged with gears on output shafts of rust removal motors on the left side and the right side of the ring body, six rust removal heads are evenly distributed on the inner ring face of the ring body and detachably fixed to spring supporting columns on the ring body, and a cleaning spray head and an anti-rust liquid spray head are further arranged on theinner ring face of the ring body and connected with a cleaning liquid and an anti-rust liquid through hoses respectively.

Owner:郭宗超

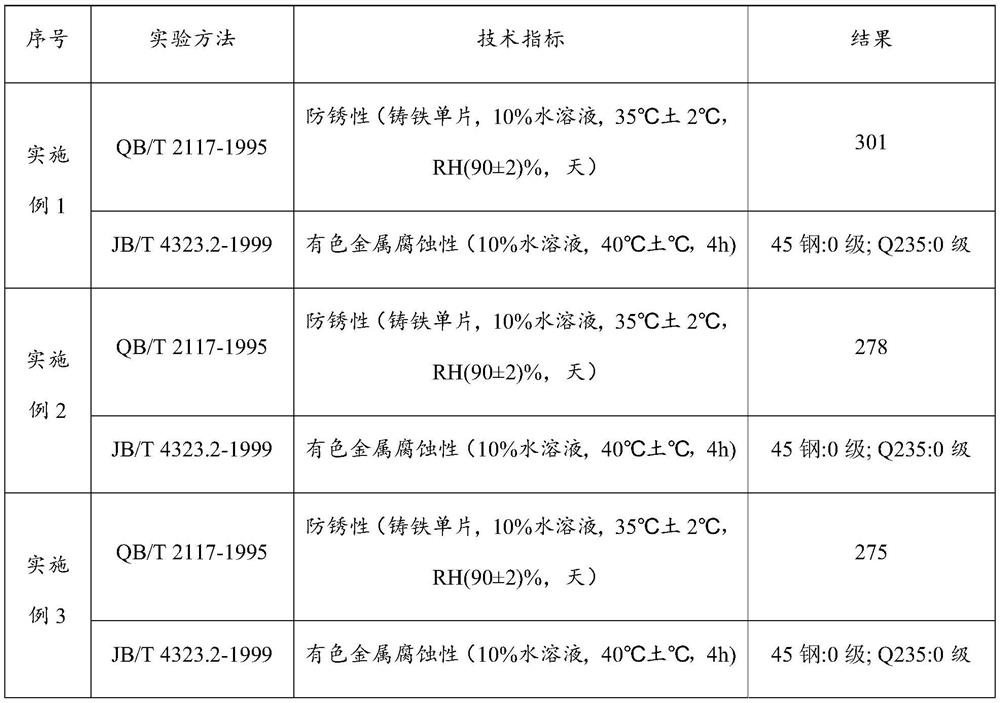

Efficient metal corrosion inhibitor and preparation method thereof

The invention relates to an efficient metal corrosion inhibitor, which is prepared from the following raw materials in parts by weight: 15 to 25 parts of sodium tungstate, 40 to 60 parts of ethylene glycol, 7 to 15 parts of ethyl alcohol, 20 to 30 parts of monoethanolamine, 4 to 9 parts of ammonium citrate, 40 to 60 parts of zirconium carbonate, and 250 to 350 parts of water. A preparation method comprises the following steps of adding the water in a glass container, adding the sodium tungstate, and stirring for dissolving; and then sequentially adding the ethylene glycol, the ethyl alcohol, the monoethanolamine, the ammonium citrate and the zirconium carbonate, and stirring for dissolving to obtain the efficient metal corrosion inhibitor provided by the invention. The efficient metal corrosion inhibitor provided by the invention has no need to be water-washed after being used, and can be directly sprayed with oil paint, the oil paint cannot be bubbled or fallen off, and the painting film adhering capacity achieves 0 degree.

Owner:HUNAN JINYU CHEM

Domestic rust remover

The invention discloses a domestic rust remover. The domestic rust remover is prepared from the following materials including, by weight, 100-200 parts of citric acid, 50-100 parts of acetic acid, 100-200 parts of gluconic acid, 20-30 parts of tea seed powder, 20-45 parts of borax, 20-35 parts of wool fat, 10-30 parts of cellulose, 15-20 parts of sapindus mukorossi gaertn, 5-10 parts of rice, 15-25 parts of table salt, 400-800 parts of deionized water and 100-200 parts of coconut oil. In the domestic rust remover, the rice is rich in starch and amino acid, and the starch, the amino acid and tea saponin in the tea seed powder can be combined with iron on the surface of an appliance to form a layer of compact protecting film, so that the iron appliance is prevented from being rusted again.

Owner:广西钱隆投资管理有限公司

Method for recycling boned neodymium iron boron permanent magnet defective product

InactiveCN102101120APrevent re-rustingPrevent oxidationSolid waste disposalBall millNeodymium iron boron

The invention provides a method for recycling a boned neodymium iron boron permanent magnet defective product, which comprises the following steps of: putting the boned neodymium iron boron permanent magnet defective product into a ball milling tank, adding deionized water and antirust liquid into the ball milling tank, and tumbling the boned neodymium iron boron permanent magnet defective product by using a centrifugal tumbling mill; putting the tumbled defective product into the mixed solution of the deionized water and the antirust liquid for cleaning; putting the cleaned defective product into a drying furnace, charging protective gas into the drying furnace, and drying the cleaned defective product; and putting the dried defective product into the ball milling tank, crushing the dried defective product by using a ball mill, and then screening the crushed defective product by using a screen to obtain powder with proper particle size. The powder can become a raw material for producing a boned neodymium iron boron permanent magnet, so recycle is realized, and the purpose of reducing the production cost of an enterprise is fulfilled.

Owner:上海三环磁性材料有限公司 +1

Electromechanical product rust removing device

InactiveCN109176273AEmbody inventivenessGood rust removal effectGrinding carriagesGrinding drivesEngineeringRust

The invention discloses an electromechanical product rust removing device which comprises a rust removing device body, a dust removing bin and a bearing plate, wherein the dust removing bin is fixedlyconnected with the top of the dust removing device body; the bearing plate is fixedly connected with the bottom of the dust removing device body; a first grinding knife is fixedly connected with themiddle part of one side of the interior of the dust removing bin; a second grinding knife is fixedly connected with the top of one side of the interior of the dust removing bin; spray heads are fixedly connected with the interior of the dust removing bin; and a clamping device is movably connected with the bottom of the interior of the dust removing bin. The grinding knives can be driven by the clamping device to clean up rust on the surface of a product more rapidly, so that the high efficiency of the rust removing device body can be reflected; through the strong control capability of an NS16032 control chip, the convenience and the rapidness of the dust removing device body can be reflected; through a plating liquid, the product of which the rust is removed can have the anti-rust function after being treated, and then the multifunctionality of the dust removing device body can be reflected; and the electromechanical product rust removing device is convenient to use, is high in safety, is applicable to the technical field of dust removing devices, and has broad development prospects in the future.

Owner:含山县人和铸造有限公司

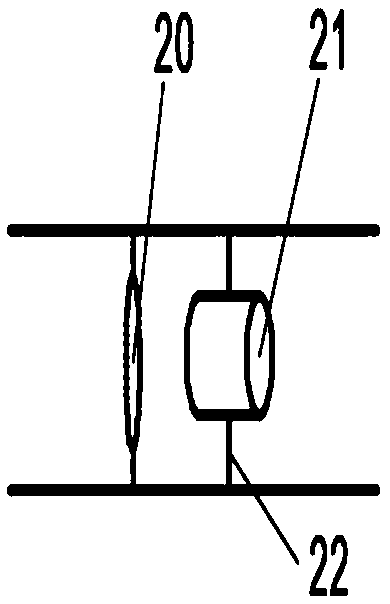

Portable steel bar rust removal device

InactiveCN114770328AApply evenlyAutomatic derusting operationLiquid surface applicatorsGrinding machinesEngineeringRebar

A portable steel bar rust removal device comprises a shell part, a rotating part and an adjusting part. When the rust on the reinforcing steel bar needs to be removed, the equipment is used, and the equipment is placed on the ground or taken up. And the half gear is meshed with the gear A, so that the rust removal brush, the sliding column A and the sliding column B move, and after movement is completed, the rust removal brush, the sliding column A and the sliding column B are fixed. And a rust remover is added into the rust remover containing barrel, anti-rust paint is added into the anti-rust paint containing barrel, the rust remover is conveyed to the designated position, and the anti-rust paint is conveyed to the designated position. A steel bar is inserted into the supporting column, and the steel bar moves to drive the rust remover brush and the antirust paint brush to rotate. When the steel bars move to the designated positions, the rust remover flows to the steel bars and is evenly smeared, the rust removal brush removes rust, and the rust-proof paint flows to the steel bars and is evenly smeared. And after the rust removal operation is completed, the equipment restores under the action of the spring.

Owner:田密峰

Surface cleaning agent for sensor zinc-plating shell

The invention discloses a surface cleaning agent for a sensor zinc-plating shell. The surface cleaning agent mainly comprises XP-80, TX-10, phenanthroline, phytic acid, sodium salicylate, a citric acid corrosion inhibitor, hydrochloric acid, a hydrochloric acid fog inhibitor and water, wherein the hydrochloric acid fog inhibitor comprises the following components in percentage by weight: 8-18% of a corrosion inhibitor, 4-8% of a fog inhibitor, 8-15% of a surfactant and the balance of water. By adopting the surface cleaning agent for the sensor zinc-plating shell disclosed by the invention, over-corrosion and acid fog formation can be inhibited, the consumption of materials and hydrochloric acid can be saved, the service life of hydrochloric acid can be prolonged, and environmental protection can be achieved. In addition, the invention also provides a surface cleaning agent for a sensor zinc-plating shell. By adopting the surface cleaning agent for the sensor zinc-plating shell, the cleaning time can be shortened, and the corrosion can be reduced. Meanwhile, by adopting the surface cleaning agent for the sensor zinc-plating shell, an anti-rust layer can also be formed on the cleaned metal surface so as to prevent the cleaned metal surface from rusting again.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Carbon steel wire machining process

ActiveCN107058690ARust removal achievedReduce recycling costsMetallic material coating processesProcess efficiency improvementHydrogenAlloy

The invention relates to the technical field of carbon steel wire machining, in particular to a carbon steel wire machining process. Compared with the prior art, in the scheme, a hydrogen explosion rust removal device is adopted for removing rust of carbon steel alloy materials, hydrogen is inflated into the device, shake generated by hydrogen explosion is used for achieving mutual friction of abrasive materials and carbon steel in the device, rust removal of the carbon steel is achieved, matter generated after hydrogen explosion only contains water, and therefore direct discharging can be achieved without retreatment. In this way, the problem that a large amount of waste acid will be generated in the existing process, special equipment and method are needed for recycling, and enterprise cost generated by treating waste is increased can be solved.

Owner:重庆方略精控金属制品有限公司

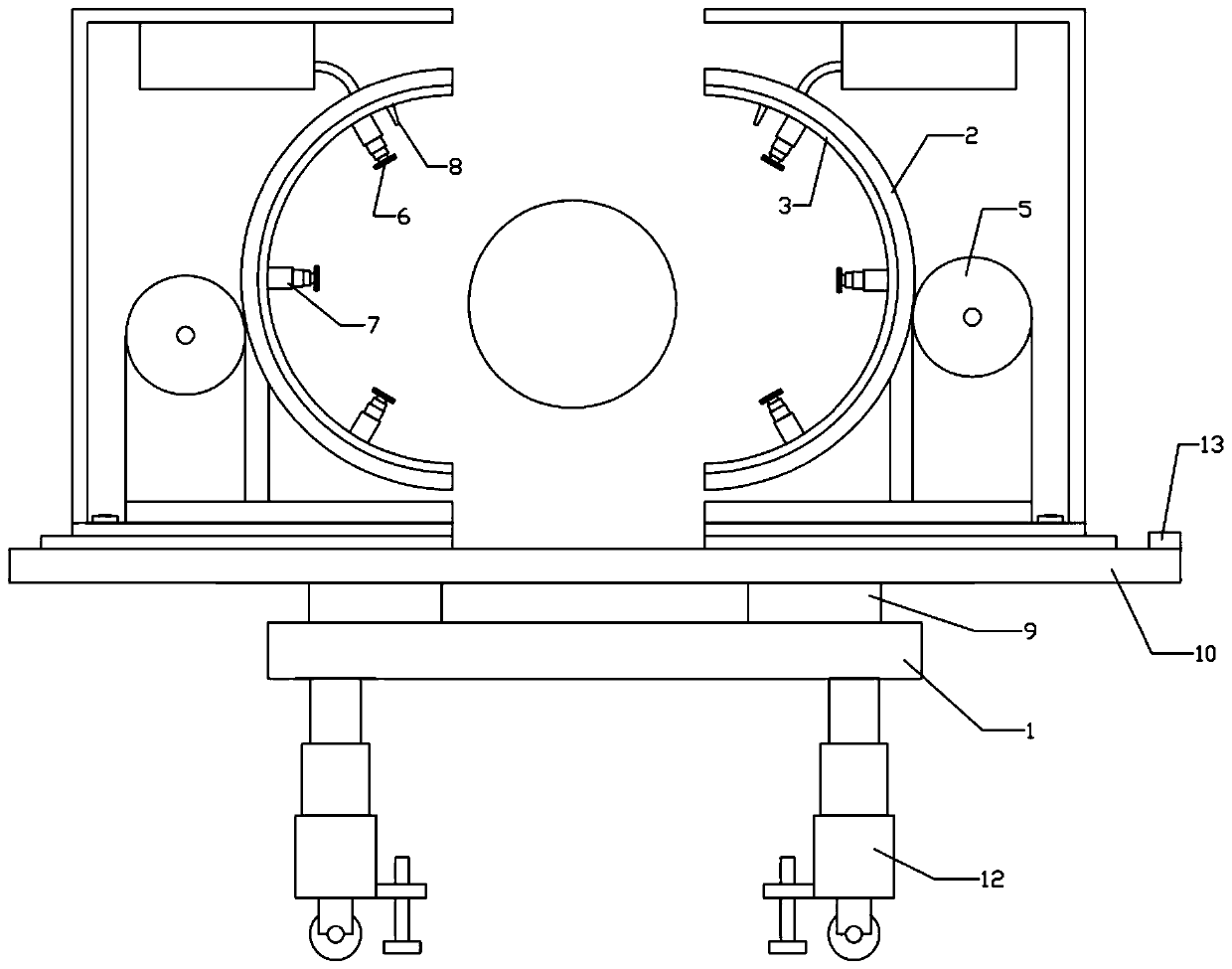

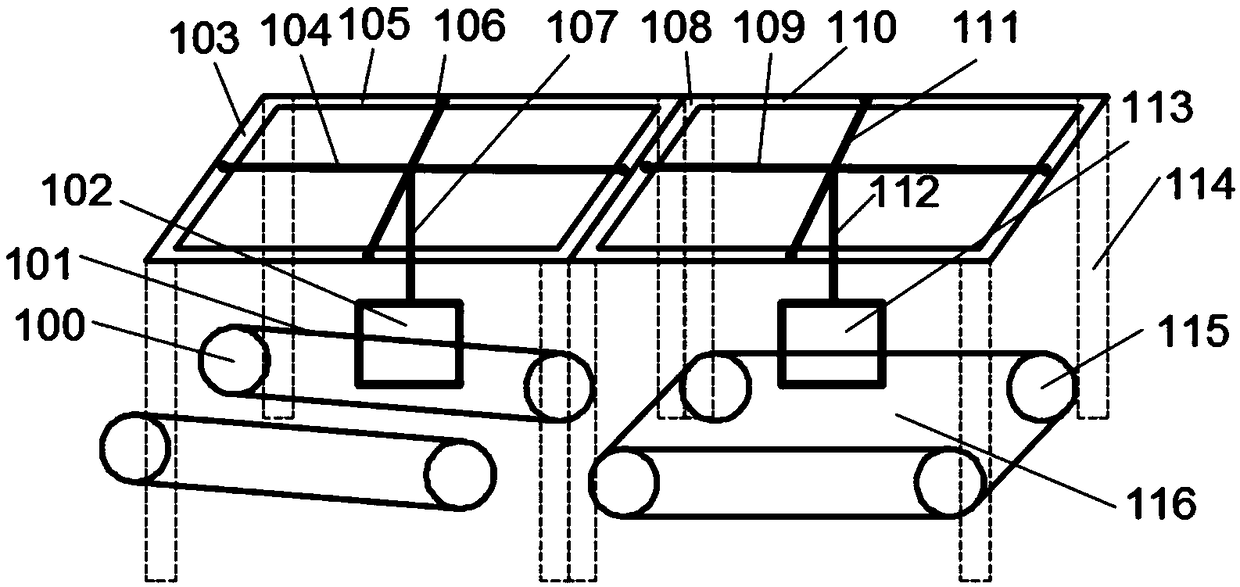

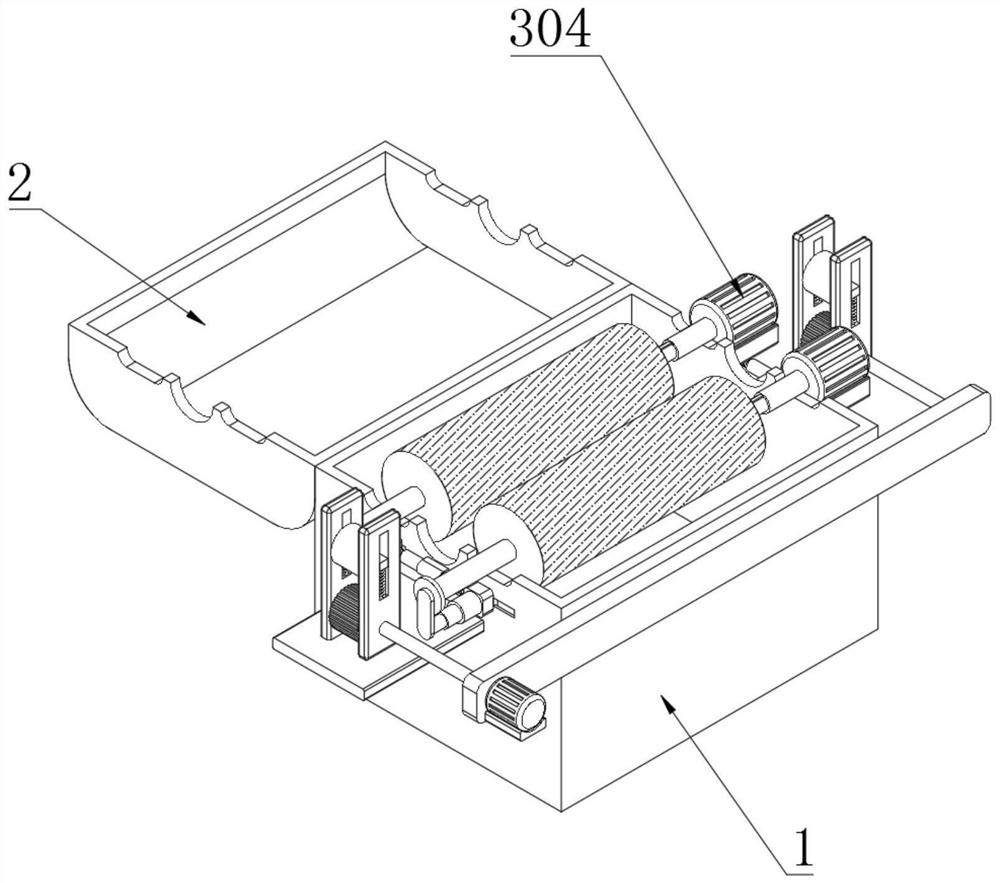

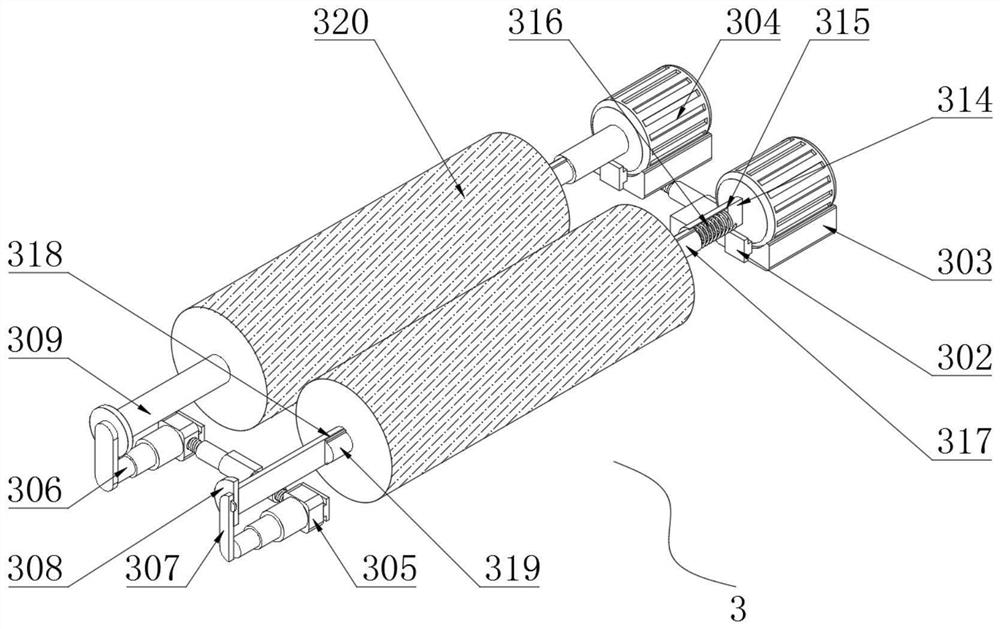

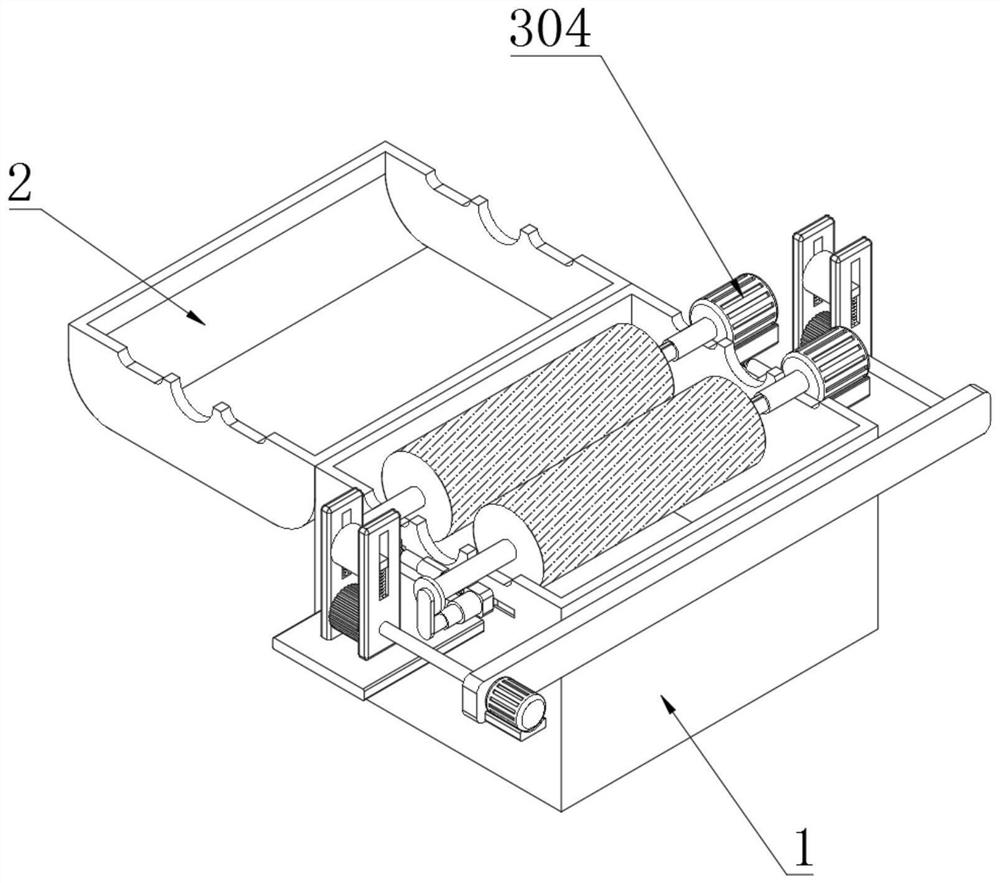

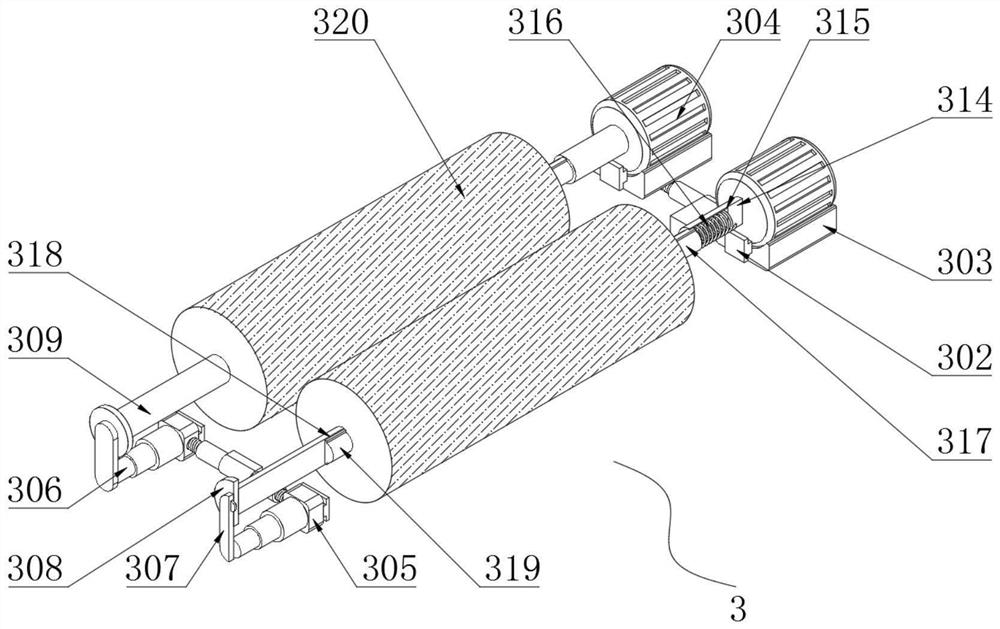

Building steel bar rust removal and prevention device

ActiveCN112536698ANo need for frequent installation and removalImprove rust removal efficiencyGrinding drivesGrinding machinesGear wheelElectric machinery

The invention relates to the field of buildings, in particular to a building steel bar rust removal and prevention device. The device comprises a motor, wherein an output shaft is installed at one endof the motor, four first gears are installed on the outer side of the output shaft, and the first gears are in engagement with a spiral pushing device which comprises a second gear ring in engagementwith the first gears. Four first rod bodies are uniformly distributed on the inner side of the second gear ring, a first bearing pedestal is arranged at the other end of each first rod body, a secondrod body is installed in the middle of each first bearing pedestal, and a conveyer roller is installed at one end of each second rod body. Through arrangement of the first gears, the second gear ring, the first rod bodies, the first bearing pedestals, the conveyer rollers, a bevel gear, a bevel gear ring, a rust removal device and a rust-proof spraying device, when the device is used for removingrust on steel bars, the steel bars only need to be inserted into the space between the conveyer rollers from the left side without frequent mounting, fixing and dismounting, and the rust removal efficiency of the device is improved; and meanwhile, after rust on the steel bars are completely removed, and rust-proof liquid is sprayed on the steel bars immediately to prevent the steel bars from rusting again.

Owner:深圳市中贺工程检测有限公司

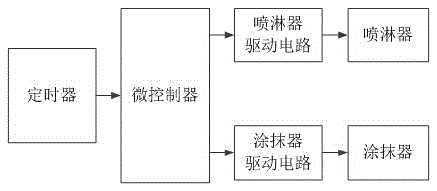

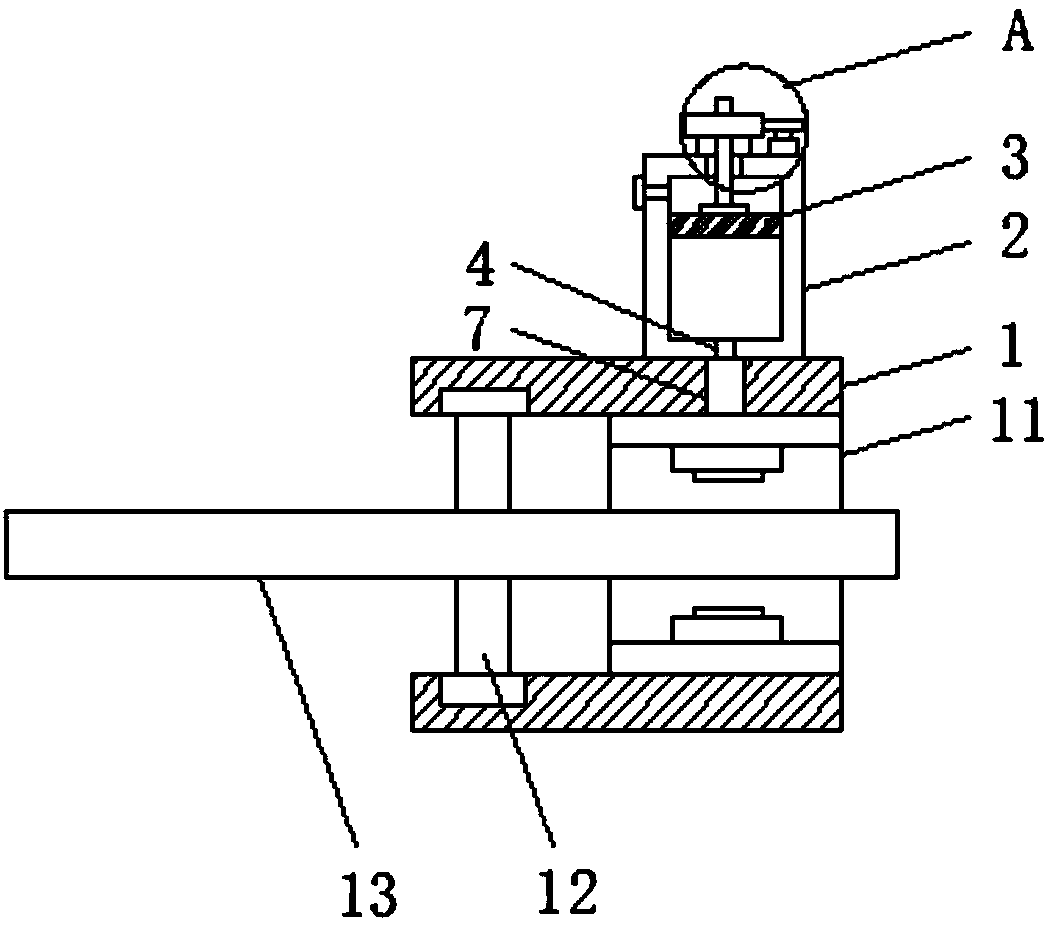

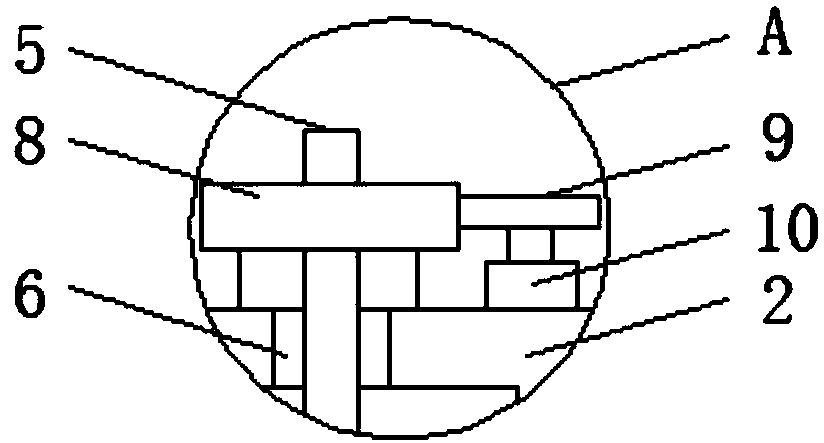

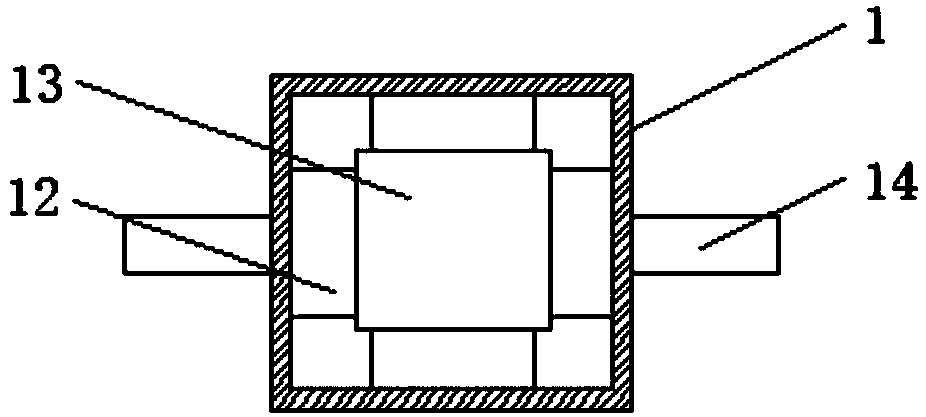

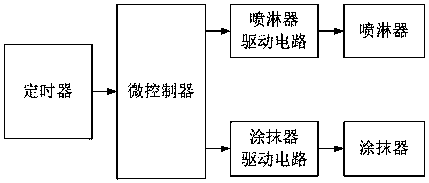

Regular rust removal device for photoelectric direct-reading long-pass valve control water meter valve

The invention discloses a regular rust removal device for a photoelectric direct-reading long-pass valve control water meter valve. The regular rust removal device for the photoelectric direct-reading long-pass valve control water meter valve comprises a timer, a microcontroller, a sprayer used for spraying a rust removal agent, and an applicator used for applying lubricating grease. The sampling signal input end of the microcontroller is connected with the timer. One control signal output end of the microcontroller is connected with the sprayer through a sprayer drive circuit, and the other control signal output end of the microcontroller is connected with the applicator through an applicator drive circuit. Rust removal is regularly conducted on the valve, rust removal is stopped after rust removal is conducted for a period of time, the applicator is started to apply a layer of lubricating grease to the valve, and the intelligence degree is high. On the rust removal basis, the valve can be effectively prevented from being rusted again through the lubricating grease, meanwhile, a very good lubricating function can be achieved, and the flexibility of the valve is guaranteed. The valve cannot be corroded or damaged through the rust removal agent, the rust on the valve can be effectively removed, meanwhile, a certain lubricating property is achieved, and the lubrication of the valve can be kept on the rust removal basis.

Owner:天津市金凤来仪科技有限公司

Metal rust remover

InactiveCN106567098ANo pollution in the processRaw materials are easy to getPhosphoric acidStearic acid

The invention relates to a metal rust remover which is prepared from, by weight, 20-35 parts of magnesium sulfate, 10-15 parts of calcium sulfate, 2-15 parts of mahogany petroleum sulfonate, 3-18 parts of an amides vapor phase inhibitor, 15-25 parts of phosphoric acid zinc oxide, 3-15 parts of potassium chlorate, 5-15 parts of phosphoric acid dihydro iron red powder, 5-10 parts of stearic acid, 2-6 parts of white wax and 10-15 parts of gasoline. After the metal rust remover is used, the metal surface is bright and new, pollution to the environment is avoided, and harms to the human body are avoided.

Owner:WEIHAI XINSHENG POWER MACHINERY MFG

Steel with rust removal device

InactiveCN108326709ASimple structureEasy to useSpraying apparatusGrinding machinesGear wheelLiquid storage tank

The invention discloses a steel with a rust removal device in the technical field of steel. The steel with the rust removal device comprises a square moving block, a liquid storage tank is installed at the top of the square moving block, a piston is slidably arranged in an inner cavity of the liquid storage tank, and a rotating rod is installed at the top of the piston through a bearing. The rotating rod is provided with a driven gear, the bottom of the driven gear is mounted at the top of the liquid storage tank through a bearing, the right side of the driven gear meshes with a driving gear,and a motor is mounted at the bottom of the driving gear. A coating device is installed on the inner wall of the right side of the square moving block, four sets of rust removal knives with the same structure are uniformly installed on the inner wall of the left side of the square moving block, and a steel body is arranged among the four sets of rust removal knives. The steel with the rust removaldevice is simple in structure and easy to use, the square moving block is moved by holding a handle, rust or impurities on the steel body can be removed by the removal knives, the operation is simpleand quick, the speed of rust removal is accelerated, and the problem that manual rust removal is time-consuming and laborious is avoided.

Owner:扬州八方冷拉型钢有限公司

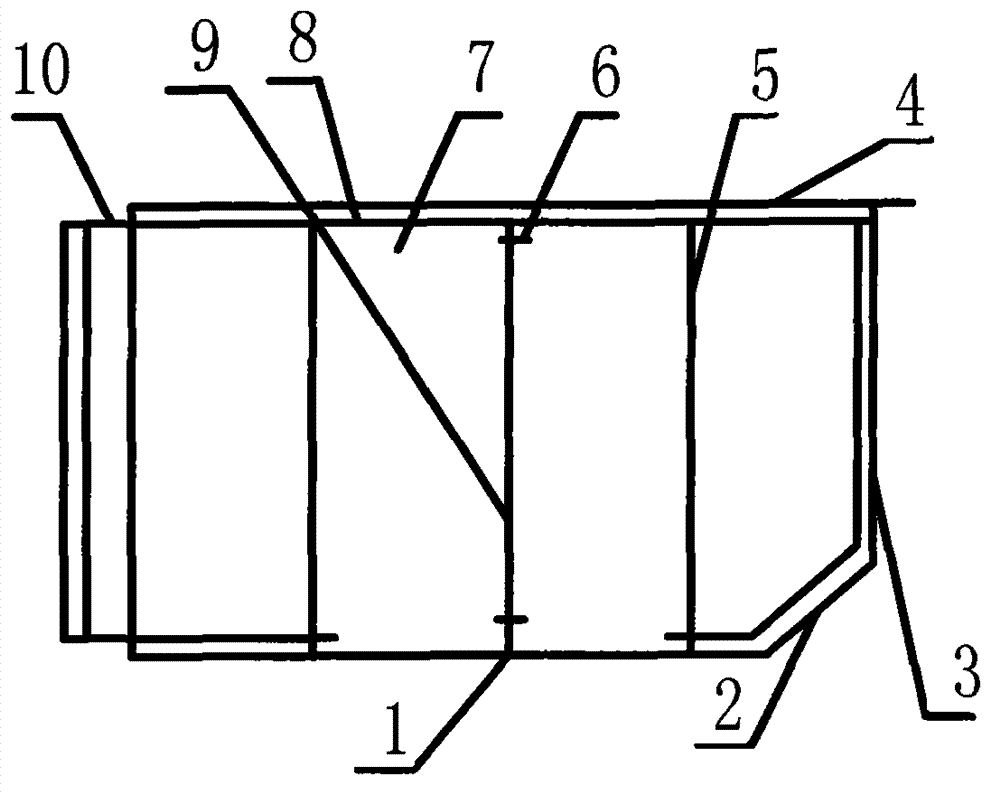

Modularized wharf boat body

The invention discloses a modularized wharf boat body which comprises a baseboard, a bilge strake, a side plate, a deck, a transverse bulkhead, a middle keel, a rib plate, a web frame, a support and a connection channel beam. The wharf boat body is totally processed in a factory instead of a construction site, the steel plate can be prevented from getting rust after pretreatment, simultaneously the processing and installation period is shortened, the problem of transportation of the wharf boat body in highways can be thoroughly solved, and the modularized wharf boat body fills the blank in modularized design of the wharf boat body of inboard and abroad mobile water intake pumping stations, well solves the problem that the existing wharf boat body is irregular in structure, complicated in manufacture process and high in production coat and cannot ensure the quality, additionally is simple in structure, convenient to operate, fast and convenient to assemble and has good application value.

Owner:江苏中兴水务有限公司

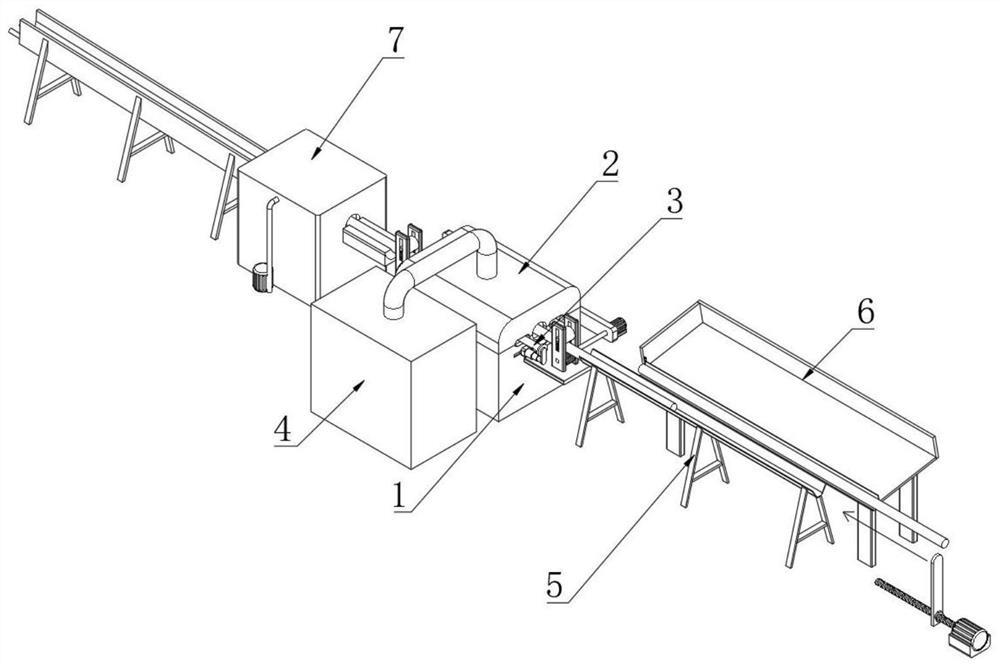

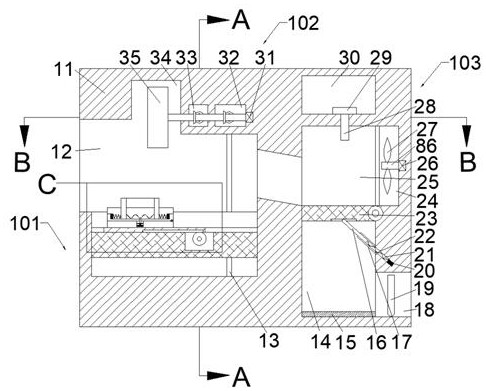

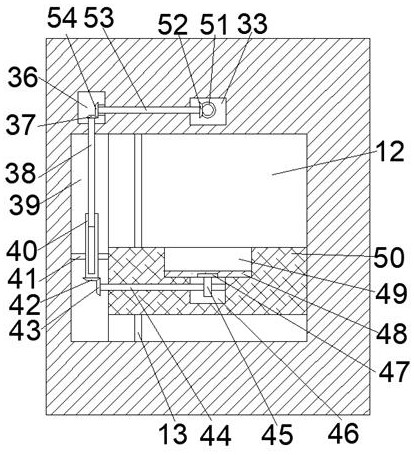

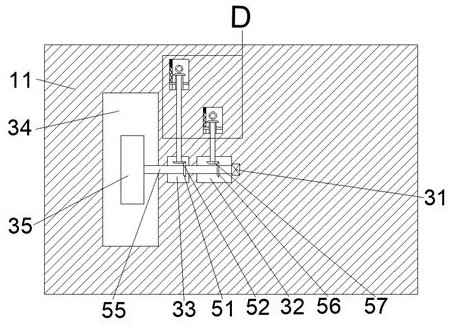

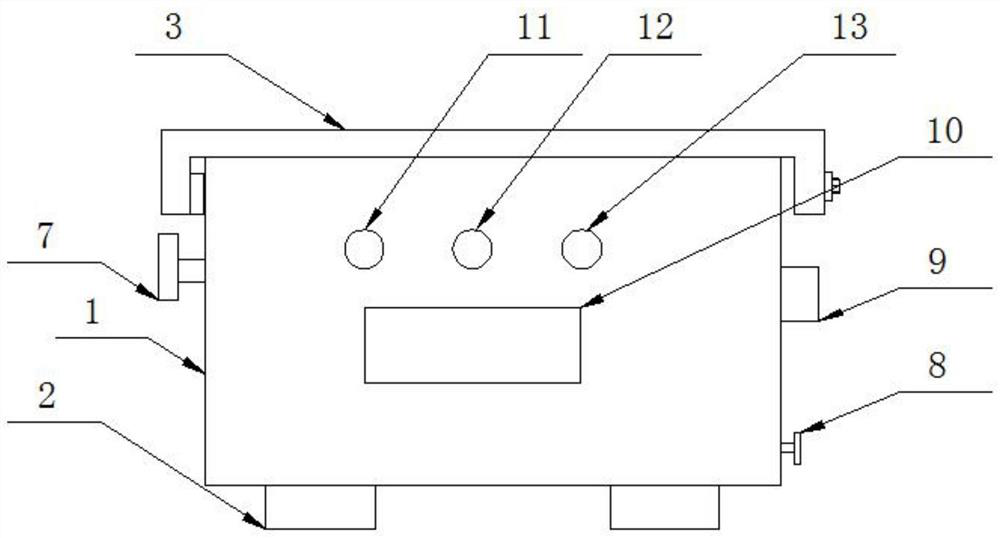

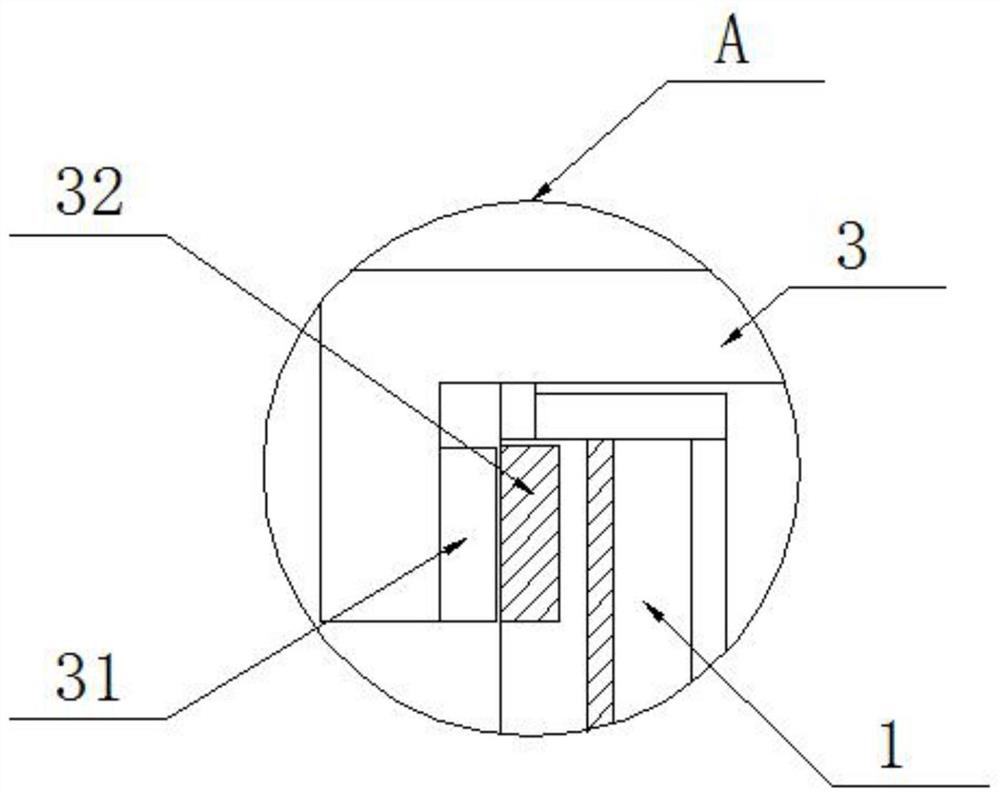

A kind of high-efficiency rust removal equipment for iron rods for hardware processing

ActiveCN112847087BUniform removalPrevent splashGrinding drivesGrinding machinesEngineeringStructural engineering

The invention discloses a high-efficiency derusting equipment for iron rods for hardware processing. Both the front end and the rear end are fixedly interspersed with a grinding device, the right part of the inner lower wall of the processing frame is fixedly connected with a collection box, and the middle part of the upper end of the processing frame is fixedly connected with three support rods, and the upper ends of the three support rods are fixedly connected together There is an acid liquid soaking device, the middle part of the inner lower wall of the processing frame is fixedly connected with a liquid supply device, the upper left part of the processing frame is fixedly connected with a brush device, and the left part of the inner lower wall of the processing frame is fixedly connected with a fixing plate, The lower part of the left end of the brush device is movably interspersed with a rotating device, and the lower end of the rotating device is fixedly connected to the upper middle part of the fixing plate. The high-efficiency derusting equipment for iron rods for hardware processing according to the invention has high derusting efficiency and high speed, and saves derusting time.

Owner:深圳市宝易升精密五金有限公司

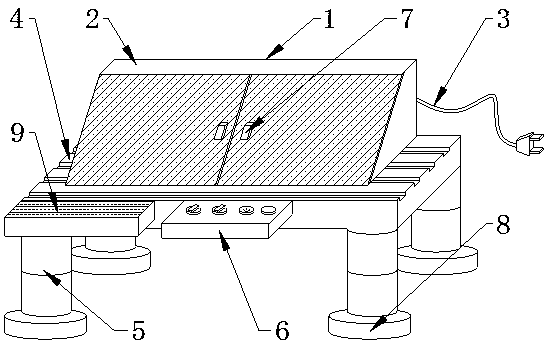

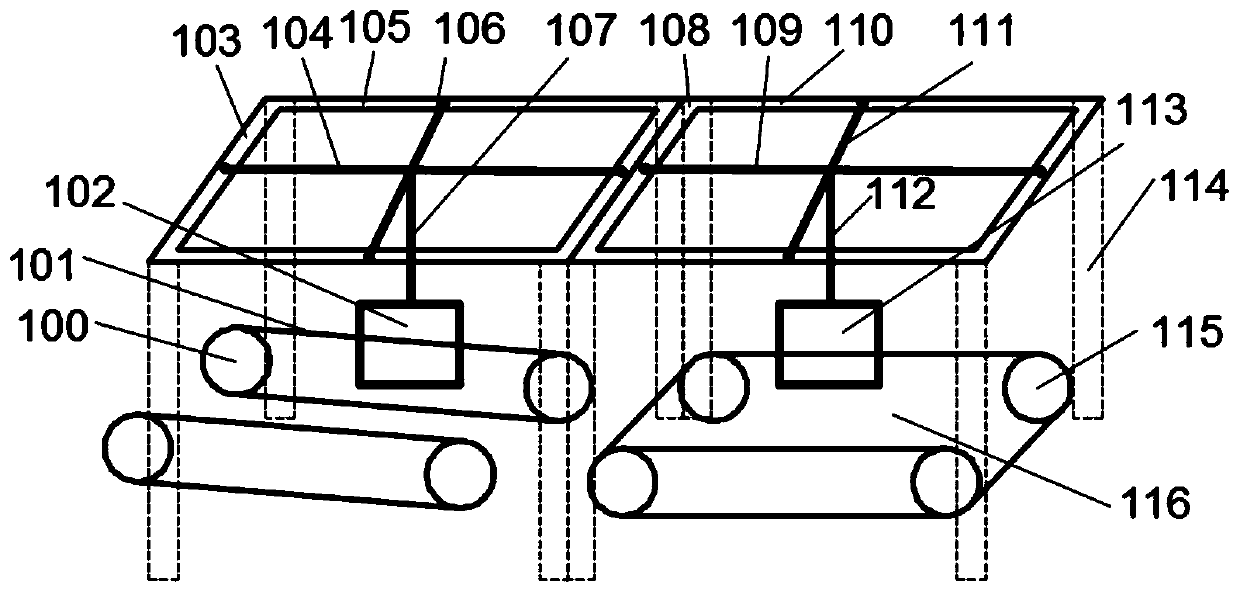

Steel plate cutting device with rust removal cleaning and drying function

ActiveCN109226892APrevent re-rustingEfficient removalAbrasive machine appurtenancesEngineeringConveyor belt

The invention discloses a steel plate cutting device with a rust removal cleaning and drying function. The device comprises a chain wheel, a chain, a cutter, a first vertical sliding way, a first transverse sliding rod, a first transverse sliding way, a first vertical sliding rod, a stretchable rod for a cutter, a second vertical sliding way, a second transverse sliding rod, a second transverse sliding way, a second vertical sliding rod, a cleaner stretchable rod, a cleaner, sliding way supporting legs, rollers and a conveyor belt. The chain wheel and the chain can convey steel plates, the rollers and the conveyor belt can convey the steel plates, the cutter and the cleaner can transport the steel plates; the sliding rods and the sliding ways can drive the cleaner and the cutter to move, the cleaner can clean the steel plates, and the cutting machine can cut the steel plates; the cleaner comprises an energy transduction gas liquid conveying pump and a stubborn stain cleaning device. The steel plate cutting device with the rust removal cleaning and drying function can effectively remove steel plate stains, and is simple in structure and convenient to assemble and disassemble.

Owner:嘉兴云切在线科技有限公司

Steel bar rust removal treatment device based on construction site

ActiveCN111843778AScientific and reasonable structureEasy to useGrinding carriagesGrinding drivesElectric machineryEngineering

The invention discloses a steel bar rust removal treatment device based on a construction site. The steel bar rust removal treatment device comprises a grinding box, wherein moving grooves are formedin two ends of two sides of the grinding box; a moving block is connected to the inside of each moving groove in a sliding manner; a grinding motor is mounted at the top end of a motor base; screws are movably mounted at one end of a driving block and one end of a mounting block; every two adjacent screws are connected through a threaded cylinder; the outer side of each threaded cylinder is fixedly connected with a fixed sleeve in a sleeving manner; and one end of each fixed sleeve is mounted at one end of the grinding box through a screw. Compared with the prior art, the steel bar rust removal treatment device has the beneficial effects that a worker can conveniently move a steel wire roller and can directly move the steel wire roller from the outside of the grinding box, the problem thatthe worker needs to open a box cover to move the steel wire roller in the prior art is solved, meanwhile, the steel wire roller can be directly moved without closing a machine in the grinding process, the steel bar rust removal treatment device can adapt to steel bars with different specifications in the grinding process, different steel bars are ground, and the grinding efficiency is improved.

Owner:安徽恒星建设工程有限公司

A steel plate cutting device with derusting, cleaning and drying functions

ActiveCN109226892BPrevent re-rustingEfficient removalAbrasive machine appurtenancesSprocketConveyor belt

The invention discloses a steel plate cutting device with a rust removal cleaning and drying function. The device comprises a chain wheel, a chain, a cutter, a first vertical sliding way, a first transverse sliding rod, a first transverse sliding way, a first vertical sliding rod, a stretchable rod for a cutter, a second vertical sliding way, a second transverse sliding rod, a second transverse sliding way, a second vertical sliding rod, a cleaner stretchable rod, a cleaner, sliding way supporting legs, rollers and a conveyor belt. The chain wheel and the chain can convey steel plates, the rollers and the conveyor belt can convey the steel plates, the cutter and the cleaner can transport the steel plates; the sliding rods and the sliding ways can drive the cleaner and the cutter to move, the cleaner can clean the steel plates, and the cutting machine can cut the steel plates; the cleaner comprises an energy transduction gas liquid conveying pump and a stubborn stain cleaning device. The steel plate cutting device with the rust removal cleaning and drying function can effectively remove steel plate stains, and is simple in structure and convenient to assemble and disassemble.

Owner:嘉兴云切在线科技有限公司

Storage equipment capable of cleaning hardware

The invention discloses storage equipment capable of cleaning hardware. The storage equipment comprises a cleaning machine, a cleaning cavity with a leftward opening is formed in the left side of theinner part of the cleaning machine, a polishing device is arranged on the upper side of the inner part of the cleaning cavity, and the polishing device comprises a rotating wheel cavity formed in theupper side of the cleaning cavity in a communicating mode. A manner that rust removal is carried out on hardware firstly and then cleaning is carried out is adopted, rust removal is carried out on thehardware through a rust removal device, then cleaning and disinfection are carried out through a cleaning device, then the hardware is kept in a dry state through an air drying device, so that the used hardware is prevented from rusting again, and then the hardware is dried and stored; and generally, manual rust removal wastes time and labor, the effect is poor, cleaning and disinfecting cannot be effectively carried out on the hardware, the manual operation efficiency is low when the hardware is cleaned and subjected to rust removal on a large scale, and the hardware cannot be quickly treated, and meanwhile, the device can further store the hardware and prevent the hardware from rusting again.

Owner:广州杰威锁具有限公司

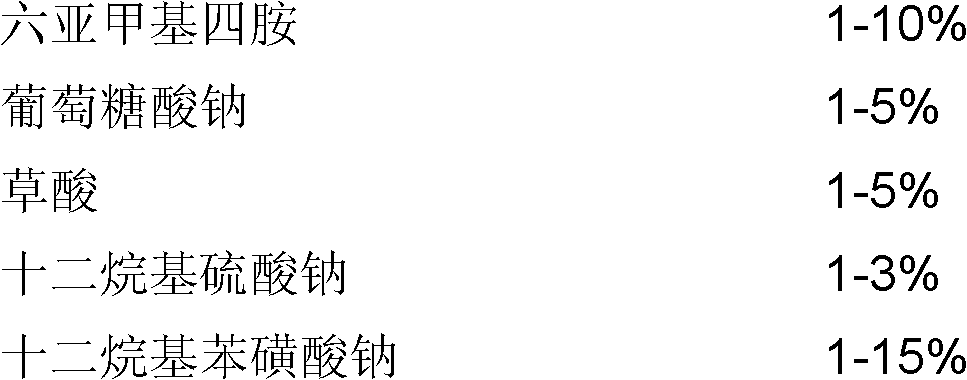

Acid-washing corrosion-inhibition fog inhibitor

The invention relates to an acid-washing corrosion-inhibition fog inhibitor, which achieves an effect of corrosion inhibition by using combination of methenamine, sodium gluconate and oxalic acid, prevents a steel base body from being subjected to acid corrosion and avoids an over-pickling phenomenon. In the acid-washing corrosion-inhibition fog inhibitor provided by the invention, foam can be generated by combination of dodecyl sodium sulfate, sodium dodecyl benzene sulfonate and AES (Sodium Alcohol Ether Sulphate) in the ingredients; and by using octadecyl polyoxyethylene ether, alkylphenolpolyoxyethylene ether, a penetrant, a leveling agent, fatty alcohol-polyoxyethylene ether, cocoanut fatty acid diethanolamide and a foam stabilizer in the ingredients, the form is promoted to be formed and time for forming the foam can be stabilized. The fog inhibitor prepared by the invention has the advantage of obvious acid fog inhibition effects with a fog inhibition rate of more than 80%, thereby obviously improving work condition of a production workshop and reducing damages to plants, equipment, workers and surrounding conditions of the acid fog.

Owner:TIANJIN JUNYITAI TECH DEV CO LTD

a rust removal paste

The invention relates to derusting slurry which contains 10-30wt% of aluminum oxide polishing powder, 1-3wt% of octadecyl triethoxy silane, 0.1-3wt% of stearic acid, 1-2wt% of glycerol, 0.1-1wt% of phosphoric acid, 0.1-1wt% of manganese dioxide, 0.1-0.5wt% of surfactant and the balance of water. According to the invention, the derusting slurry can remove iron rust on surfaces of iron devices, and can simultaneously form a protective film, thereby preventing the iron devices from rusting again.

Owner:江苏意迪驱动设备有限公司

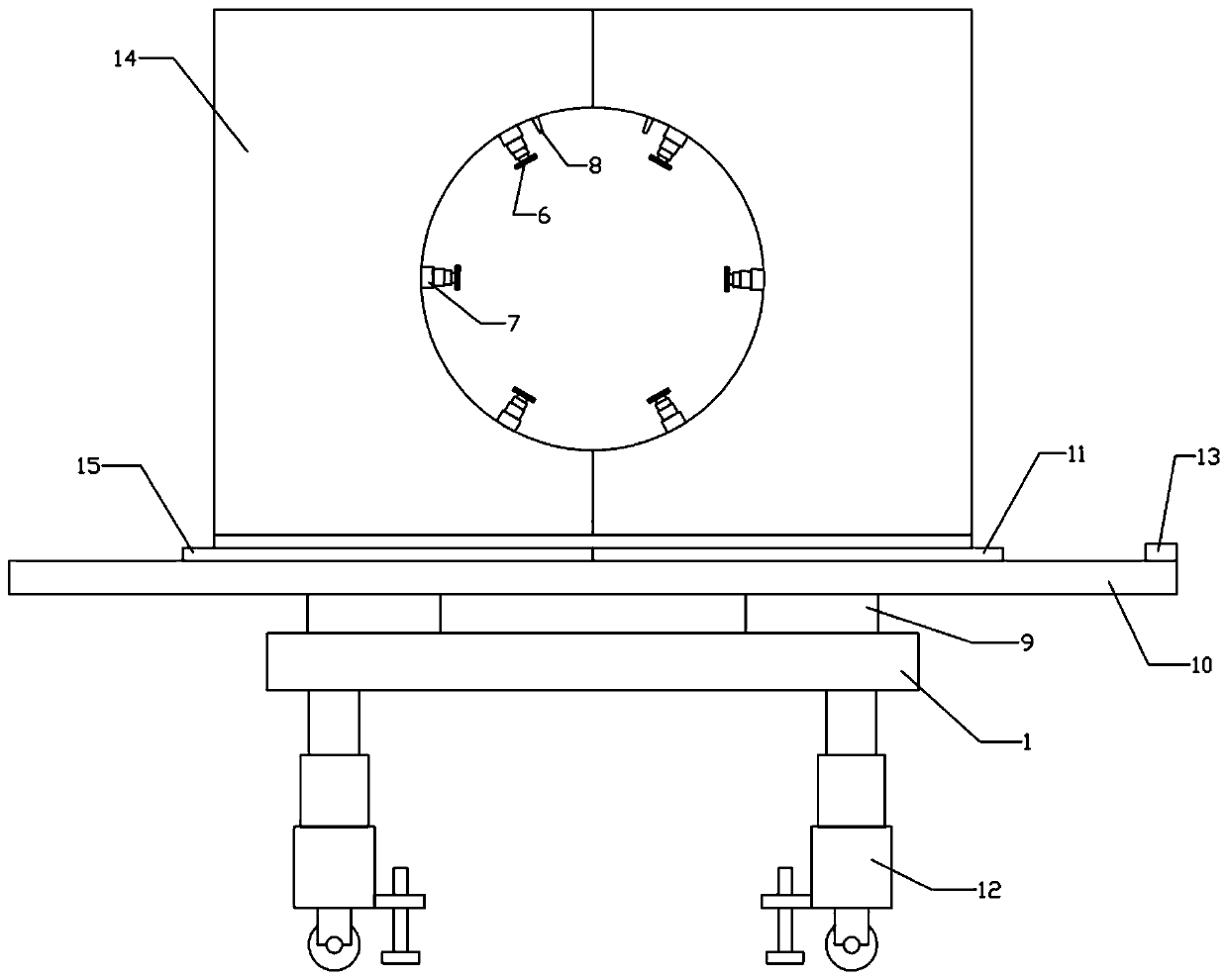

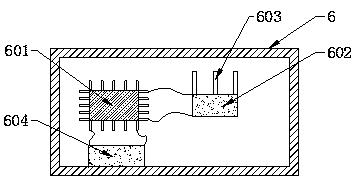

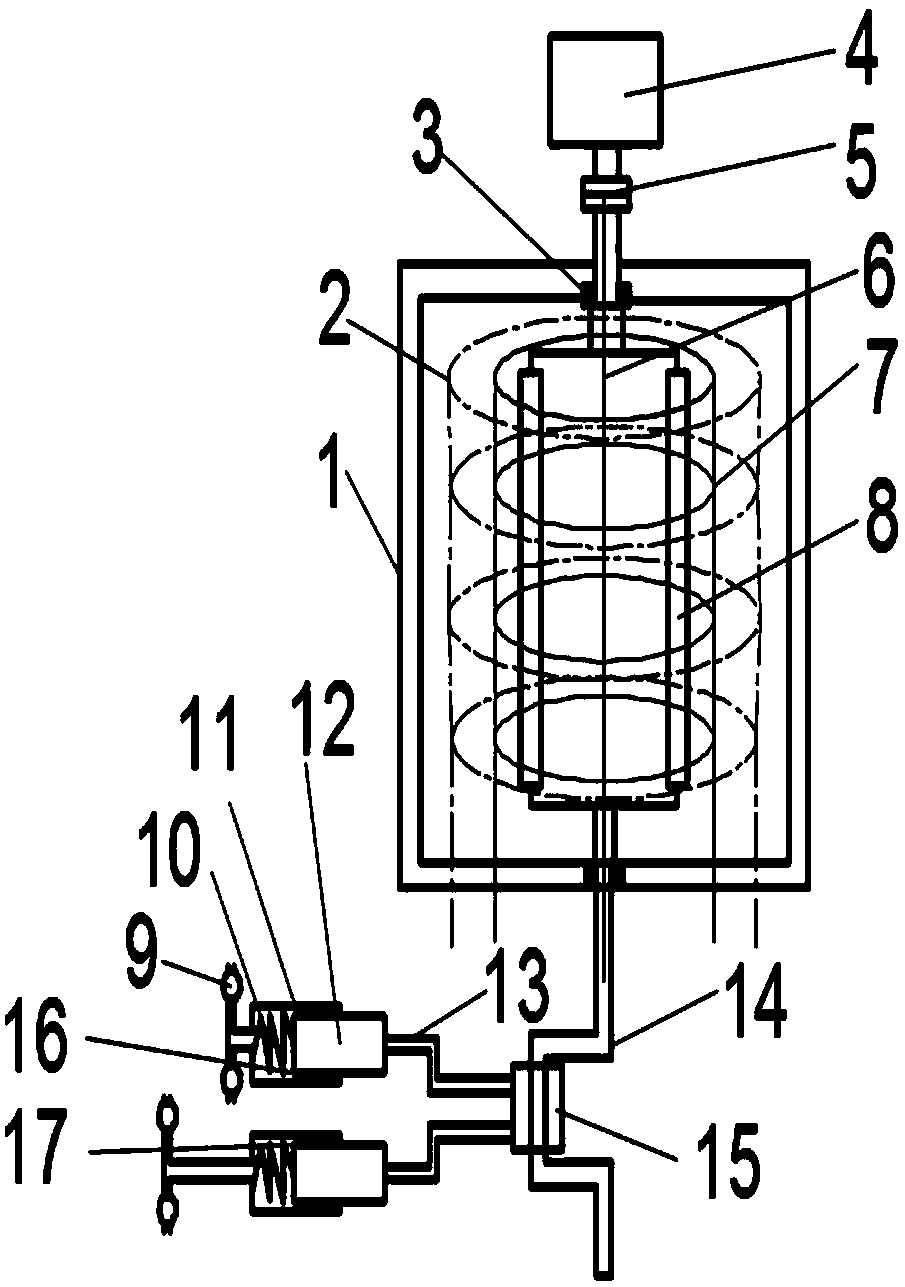

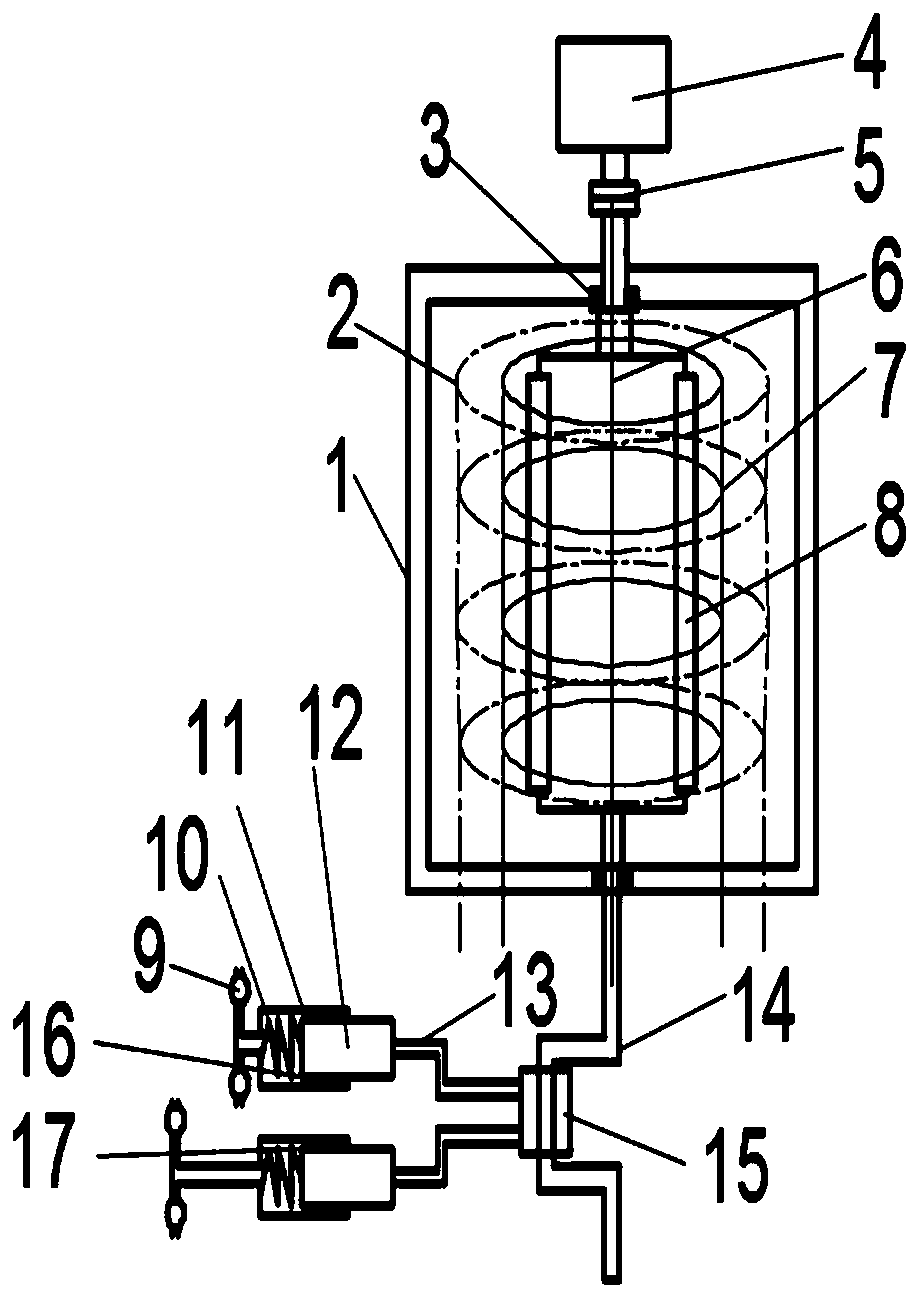

Full-automatic rotary ultrasonic cleaning device

InactiveCN112474575AReduce workloadPrevent re-rustingDrying gas arrangementsDirt cleaningMegasonic cleaningProcess engineering

The invention discloses a full-automatic rotary ultrasonic cleaning device, and particularly relates to the field of cleaning devices. The full-automatic rotary ultrasonic cleaning device comprises abox body; a base is fixedly installed at the bottom of the box body; an upper cover plate is detachably installed at the top end of the box body, and an inner frame body is detachably installed at thebottom of an inner cavity of the box body; and a waste scrap collecting box is placed at the bottom of an inner cavity of the inner frame body, and grid layers are fixedly installed at the positions,located on the two sides of the inner cavity of the inner frame body, of the top end of the waste scrap collecting box. According to the full-automatic rotary ultrasonic cleaning device provided by the invention, the scrap collecting box is arranged at the bottom of the cleaning device, removed rust can fall into the collecting box after rust of iron products is removed, so that the workload of workers for cleaning garbage is reduced, a water outlet is formed in the bottom of the device, used water can be discharged, clear water is introduced through a water inlet to clean workpieces, and then the cleaner workpieces can be obtained, the workpieces are dried through a draught fan, and therefore the possibility that the workpieces rust again is avoided.

Owner:无锡德工机械制造有限公司

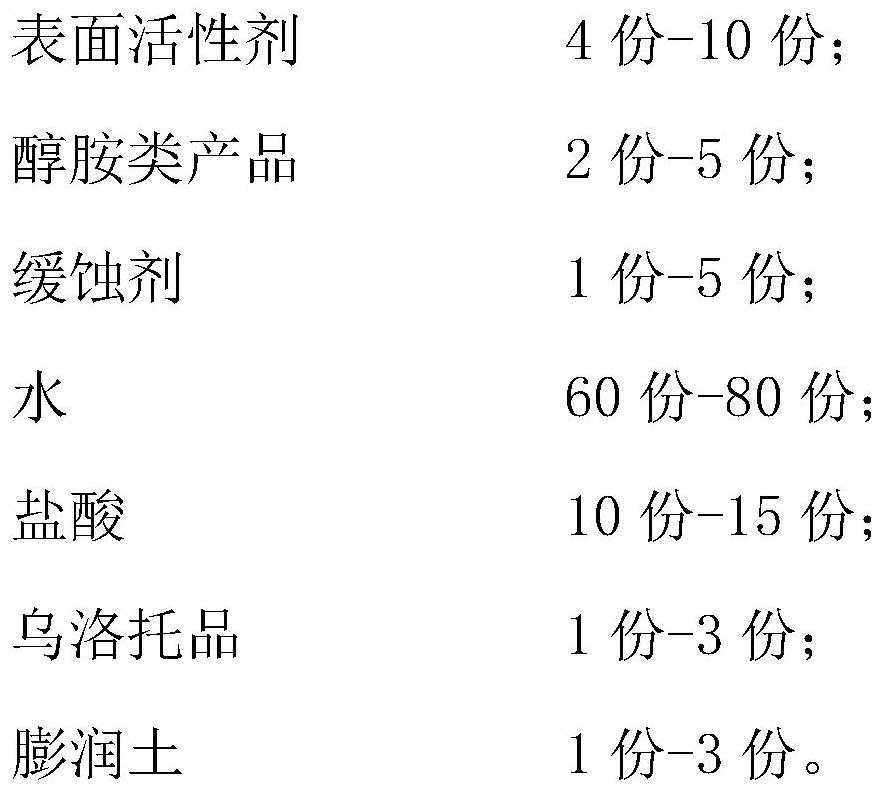

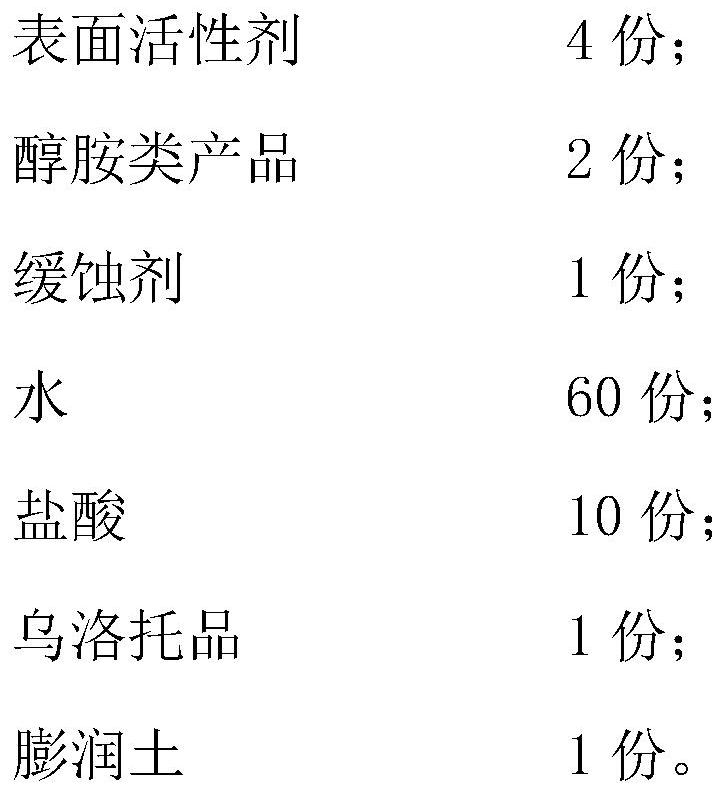

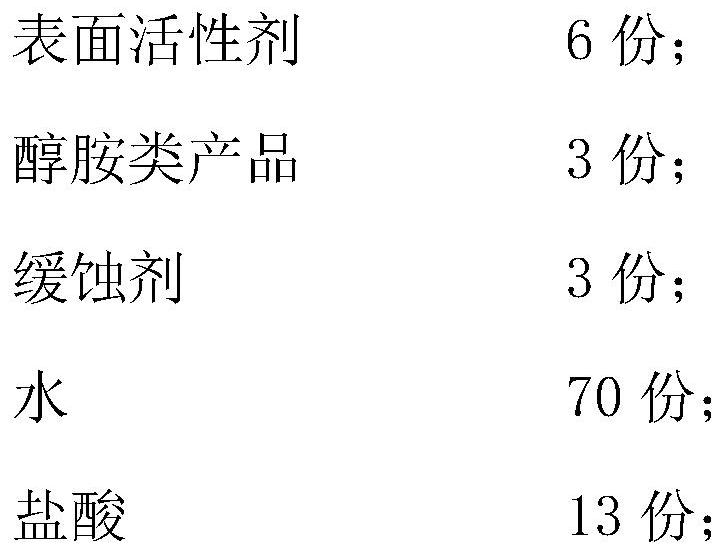

Mist-inhibiting rust remover and preparation method thereof

The invention discloses a mist-inhibiting rust remover and a preparation method thereof. The mist-inhibiting rust remover comprises the following raw materials in parts by weight: 4 to 10 parts of surfactant; 2 to 5 parts of amine product; 1 to 5 parts of corrosion inhibitor; and 60 to 80 parts of water. The invention relates to the technical field of chemical engineering. According to the mist-inhibiting rust remover and the preparation method thereof, 4 to 10 parts of the surfactant is arranged, the surfactant can foam and remove dirt on the metal surface, generated foam can play a role in blocking acid mist; 2 to 5 parts of alcohol amine product is arranged, so that the surfactant can be attached to the metal surface to avoid rusting after rust removal is finished; 1 to 5 parts of corrosion inhibitor is arranged, rust removal of hydrochloric acid can be assisted, the rust removal efficiency is improved; 60 to 80 parts of water is arranged to serve as a carrier solution; and 10 to 15parts of hydrochloric acid is arranged, the hydrochloric acid can be subjected to a chemical reaction with rust and metal oxide to generate soluble salt, so that the rust removal purpose is achieved.

Owner:仙桃市环美化工有限公司

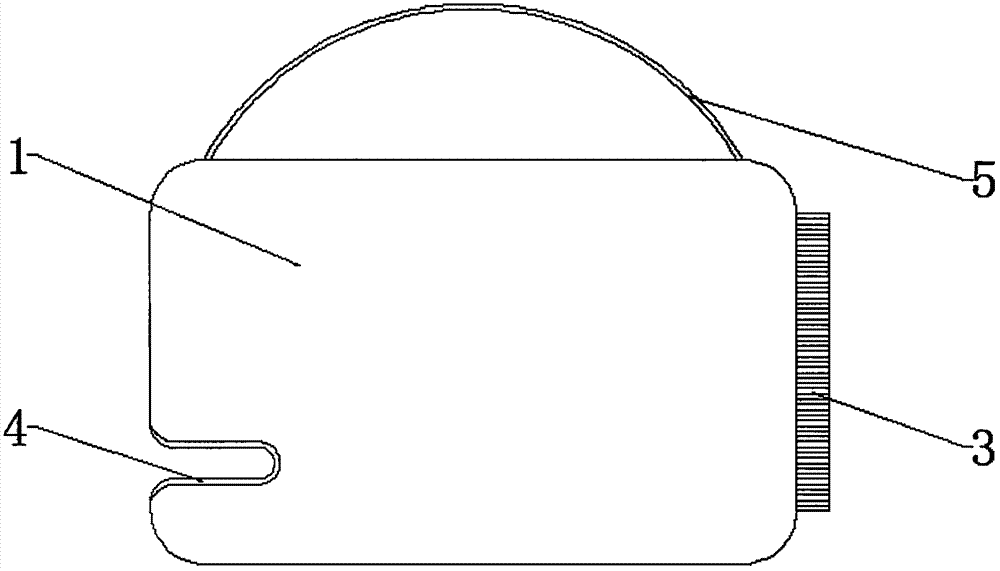

Electric safety warning sign

The invention discloses an electrical safety warning sign, which relates to the field of safety warning devices. A steel brush is provided on one side of the warning sign body of the electrical safety warning sign, and a scraping groove is opened on the other side of the warning sign body, and a blade is opened on the inner wall of the scraping groove. There is a sling on the top of the warning sign body, and a cylindrical drug cartridge is fixed on the back of the warning sign body, and the cartridge is filled with neutral vaseline. Warning slogans for electrical equipment are printed on the front of the warning sign body, and the warning sign body can be hung on the electrical equipment through a sling to serve as a warning. When the metal parts in the electrical equipment are rusted, you can take off the warning sign body, use a steel brush to remove the rusted parts of the thick metal parts, or use a scraper to remove the rusted parts of the small metal parts, and then squeeze the medicine Apply neutral petroleum jelly from the syringe to the metal parts to prevent rerusting. The electrical safety warning sign has various functions, is convenient to use and has strong practicability.

Owner:韩锟

A kind of steel bar derusting treatment device based on the construction site

ActiveCN111843778BEasy to moveSolve mobileGrinding carriagesGrinding drivesArchitectural engineeringElectric machinery

The invention discloses a steel bar derusting treatment device based on a construction site, which includes a grinding box, two ends of the grinding box are provided with moving grooves, a moving block is slidably connected to the inside of the moving groove, and a grinding motor is installed on the top of the motor base to drive One end of both the block and the installation block is movably installed with a screw rod, and the two adjacent screw rods are connected through a threaded cylinder. Compared with the technology, the beneficial effect of the present invention is convenient for the staff to move the steel wire roll, and the staff can directly move the steel wire roll from the outside of the grinding box, which solves the problem in the prior art that the staff needs to open the box cover to move the steel wire roll, and at the same time During the grinding process, the steel wire roller can be moved directly without shutting down the machine. It can adapt to different specifications of steel bars during the grinding process, and can grind different steel bars to improve the grinding efficiency.

Owner:安徽恒星建设工程有限公司

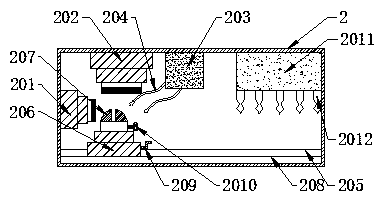

Photoelectric direct reading remote transmission valve control water meter valve timing derusting device

ActiveCN105648459BPrevent re-rustingGuaranteed flexibilityAdditivesProgramme control in sequence/logic controllersMicrocontrollerControl signal

The invention discloses a regular rust removal device for a photoelectric direct-reading long-pass valve control water meter valve. The regular rust removal device for the photoelectric direct-reading long-pass valve control water meter valve comprises a timer, a microcontroller, a sprayer used for spraying a rust removal agent, and an applicator used for applying lubricating grease. The sampling signal input end of the microcontroller is connected with the timer. One control signal output end of the microcontroller is connected with the sprayer through a sprayer drive circuit, and the other control signal output end of the microcontroller is connected with the applicator through an applicator drive circuit. Rust removal is regularly conducted on the valve, rust removal is stopped after rust removal is conducted for a period of time, the applicator is started to apply a layer of lubricating grease to the valve, and the intelligence degree is high. On the rust removal basis, the valve can be effectively prevented from being rusted again through the lubricating grease, meanwhile, a very good lubricating function can be achieved, and the flexibility of the valve is guaranteed. The valve cannot be corroded or damaged through the rust removal agent, the rust on the valve can be effectively removed, meanwhile, a certain lubricating property is achieved, and the lubrication of the valve can be kept on the rust removal basis.

Owner:天津市金凤来仪科技有限公司

Water-based antirust liquid suitable for steel surface organic composite film formation

InactiveCN111621209APrevent re-rustingHigh bonding strengthAntifouling/underwater paintsPaints with biocidesOrganic acidPtru catalyst

The invention discloses a water-based antirust liquid suitable for steel surface organic composite film formation, which can form a layer of organic composite protective film on the surface of steel to prevent rusting again. The water-based antirust liquid comprises the following components in concentration: 1000 to 5000 ppm of a boron-containing copolymer, 600 to 3000 ppm of an organic acid containing an annular structure, 500 to 1000 ppm of a compound containing polycarboxyl, 50 to 300 ppm of a coalescing agent, 50 to 100 ppm of a catalyst, and the balance of pure water; the coalescing agentis an oxyacid alkali metal salt compound; and the pH value of the water-based antirust liquid is 8.5-9.5. The antirust liquid does not contain strong alkali, phosphorus or any toxic heavy metal, canadapt to impregnation or spraying, has the treatment temperature of normal temperature, the treatment time of soaking for 60-180s and the treatment time of spraying for 10-30s, has high bonding strength with a matrix and subsequent organic polymer coatings (such as paint and powder), and ahs obviously enhanced corrosion resistance.

Owner:GUANGZHOU HONGSHUO ENVIRONMENTAL TECH

Metal corrosion inhibitor and preparation method thereof

The invention relates to a metal corrosion inhibitor. The metal corrosion inhibitor is prepared from the following raw materials in parts by weight: 15 to 25 parts of sodium tungstate, 40 to 60 parts of ethylene glycol, 7 to 15 parts of ethyl alcohol, 4 to 9 parts of ammonium citrate, 40 to 60 parts of zirconium carbonate, and 250 to 350 parts of water. A preparation method comprises the following steps of adding water into a glass container, adding the sodium tungstate to stir for dissolving, sequentially adding the ethylene glycol, the ethyl alcohol, the ammonium citrate and the zirconium carbonate, stirring, and dissolving, so as to obtain the metal corrosion inhibitor. The metal corrosion inhibitor has the advantages that water washing after use is not needed, paint can be directly painted, the foaming, falling and the like of the paint are avoided, and the adhesion force of a paint film reaches level 0.

Owner:HUNAN JINYU CHEM

Rust removal and prevention agent and preparation method thereof

ActiveCN113549910APrevent re-rustingImprove the mixing effectPackaging under vacuum/special atmosphereMetallic material coating processesO-Phosphoric AcidAluminium powder

The invention discloses a rust removal and prevention agent and a preparation method thereof, and belongs to the field of rust prevention agents. After the rust removal and prevention agent is brushed or soaked on the surface of a metal product, rust can be removed, a passivation protective film can be formed on the surface of the metal product, metal is prevented from rusting again, in the preparation process, an anti-oxidation capsule is adopted to prevent aluminum powder and copper powder from being oxidized before being put into use, the purity of raw material components is effectively improved, the anti-oxidation capsule enables two anti-oxidation coating shells to be opened through the dissolution effect of phosphoric acid, the aluminum powder and the copper powder inside the anti-oxidation capsule are released into the phosphoric acid to directly participate in the reaction, the two anti-oxidation coating shells are connected through an elastic series rope so that the two anti-oxidation coating shells can be mutually pulled and entangled under stirring, the raw material mixing and stirring effect is effectively improved, meanwhile, nitrogen is sprayed out from a gas outlet pipe under the dissolution action of water in a solution, the motion amplitude of the anti-oxidation coating shells is increased through the counter-acting force during gas spraying, and the mixing and stirring effect is further improved.

Owner:NANTONG YONGYU ANTI RUST MATERIALS CO LTD

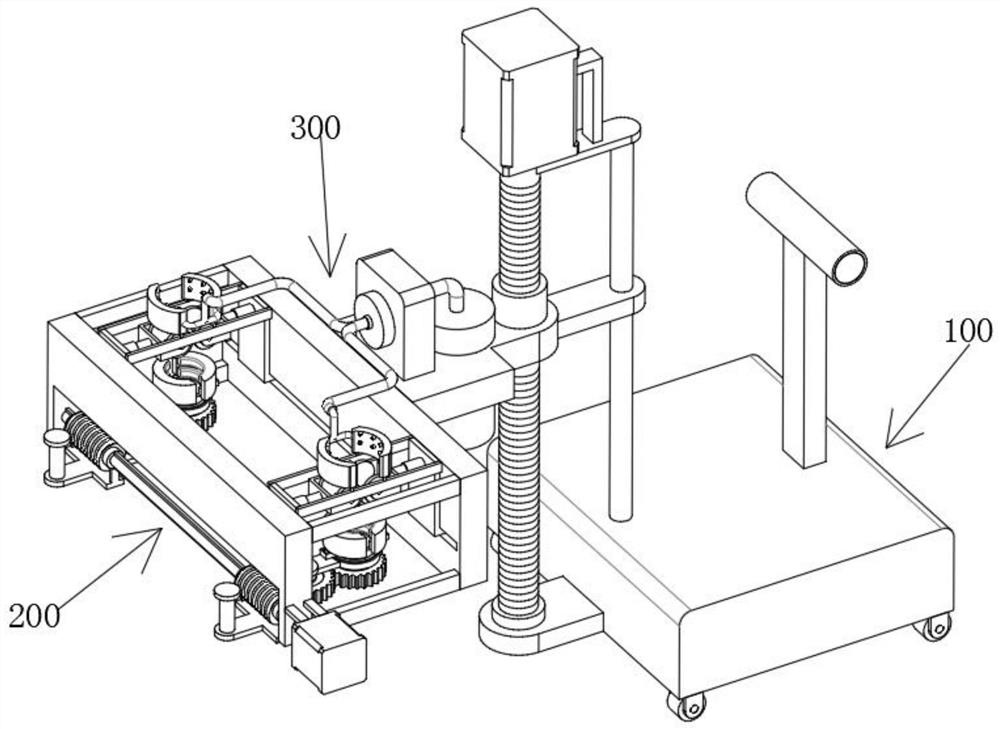

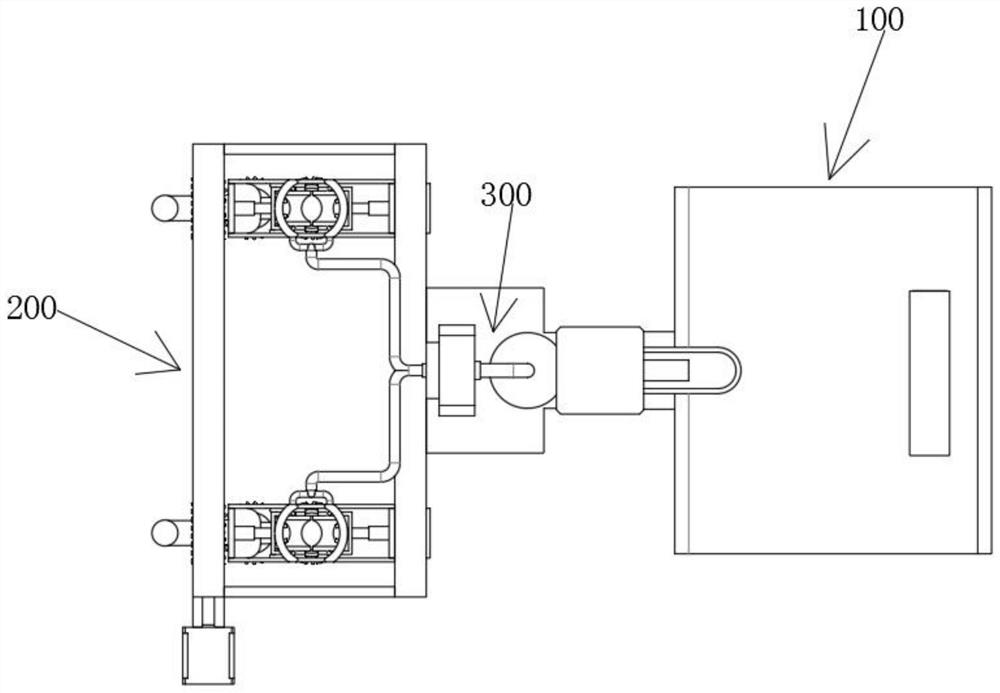

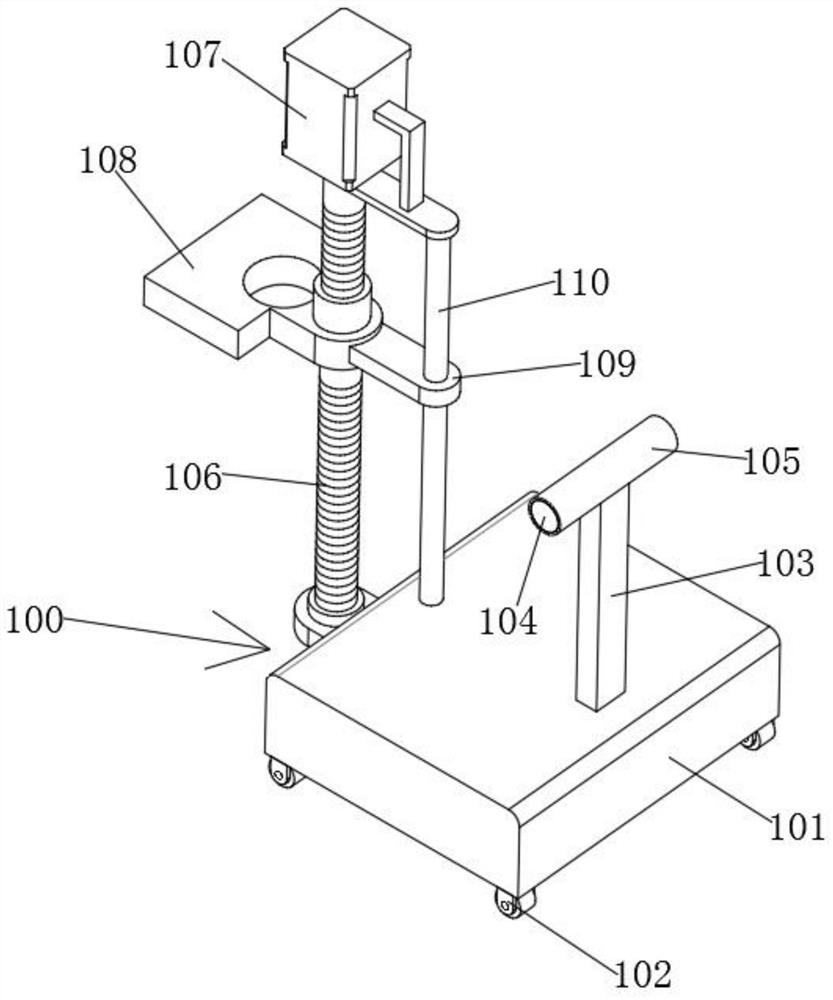

Derusting and polishing device for exposed end of embedded steel bar in constructional engineering and using method thereof

PendingCN113894678AImprove grinding efficiencyEasy to remove rustGrinding machinesLiquid spraying apparatusGrindingElectric machinery

The invention relates to the technical field of grinding equipment, in particular to a derusting and polishing device for an exposed end of an embedded steel bar in constructional engineering and a using method thereof. The device comprises a lifting mechanism, a grinding mechanism is fixedly arranged at one side of a lifting plate, and a paint spraying mechanism is fixedly arranged at the top of the lifting plate. According to the device, the output end of a second driving motor can drive a rotating rod to rotate, so that a fixing column on the rotating rod can drive a worm to rotate, the worm can drive a first gear to rotate, and therefore a second gear can be driven to rotate through the first gear; in this way, the second gear can drive a rotating sleeve to rotate, sliding blocks at the two sides of the rotating sleeve can enable two arc-shaped grinding plates to extrude and attach steel bars under the action of extension springs, and the rotating sleeve can drive the two arc-shaped grinding plates to rotate; and therefore, grinding blocks on the arc-shaped grinding plates can grind the outer walls of the steel bars, and the grinding efficiency of the steel bars can be improved.

Owner:云南银塔电力建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com