Building steel bar rust removal and prevention device

A technology for construction and steel bars, which is applied to spray devices, grinding drive devices, liquid spray devices, etc., can solve the problems of easy rust again, difficult to remove rust and dust on the surface of steel bars, and easy to get wet with water, etc. The effect of rusting and increasing the efficiency of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

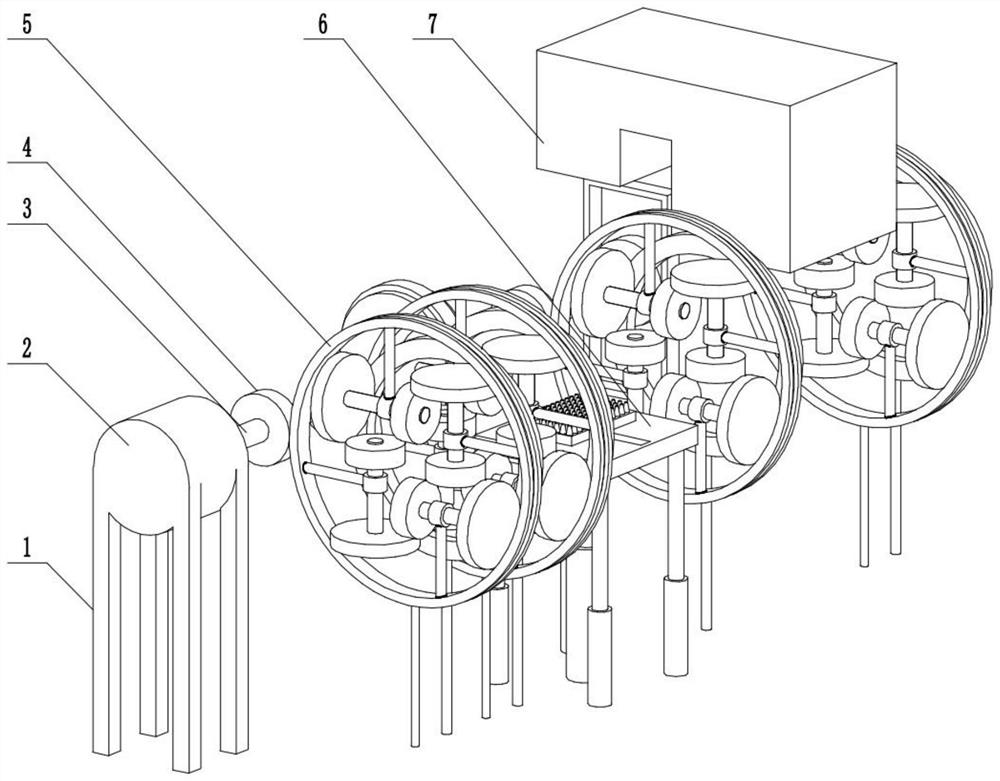

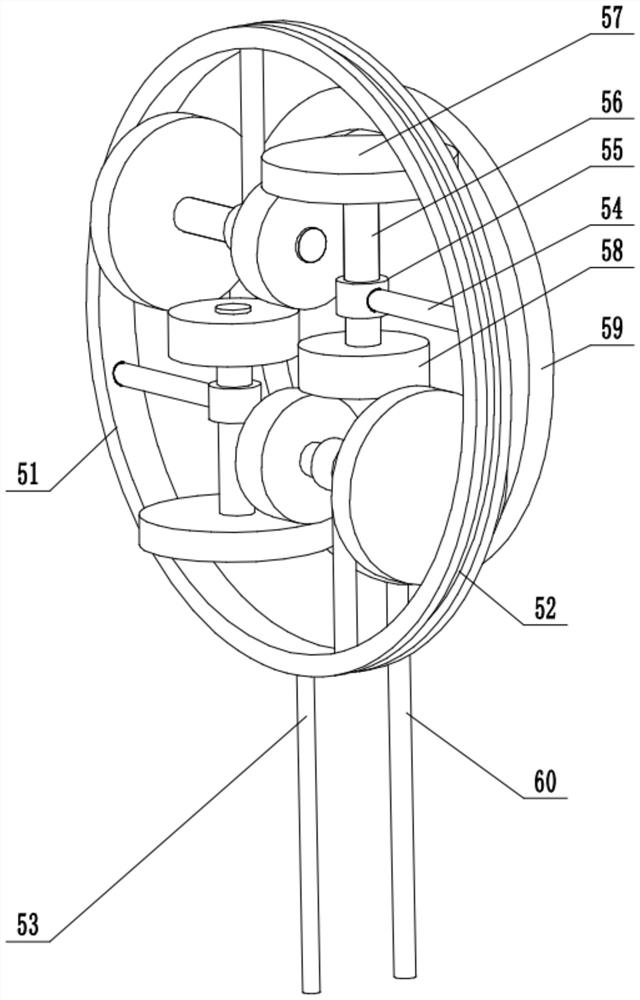

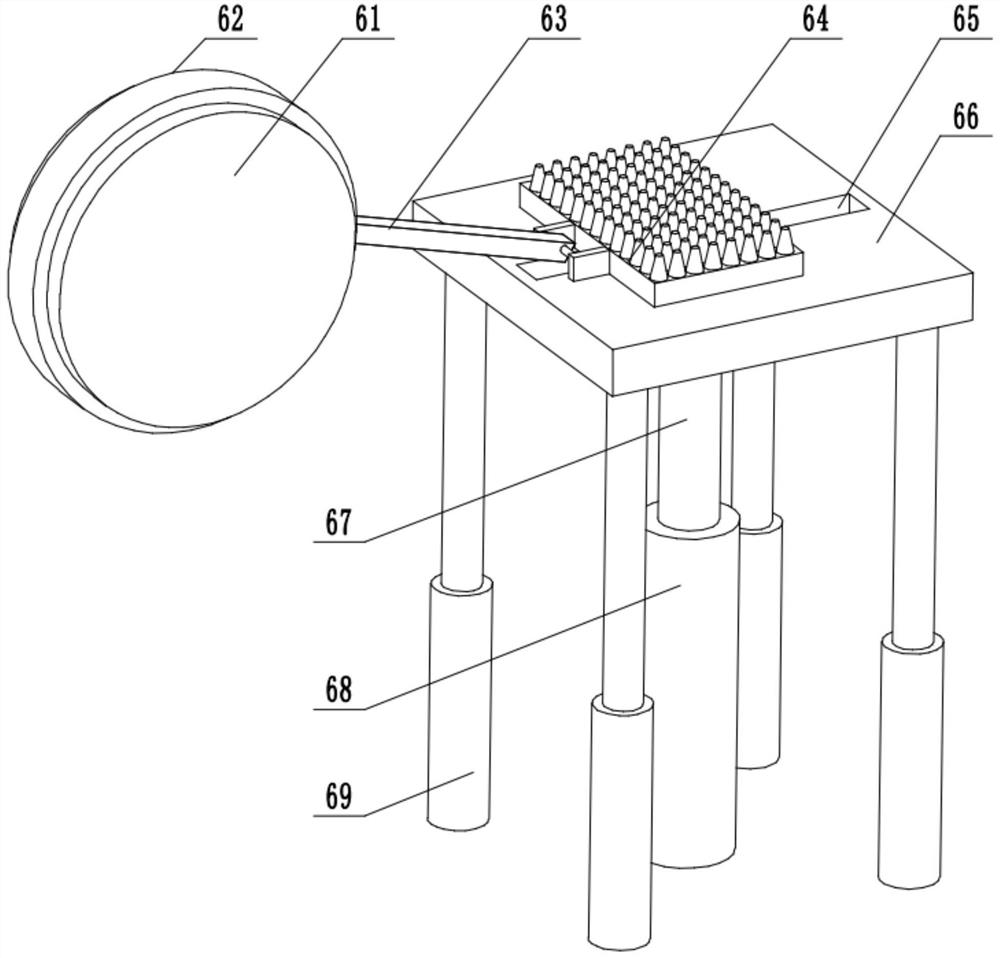

Embodiment 1

[0027] refer to Figure 1~4 , in an embodiment of the present invention, a rust removal and antirust device for steel bars for construction includes a motor 2, an output shaft 3 is installed at one end of the motor 2, and 4 groups of first gears 4 are installed on the outside of the output shaft 3, and the first gear 4 is meshed with Screw pushing device 5, said screw pushing device 5 includes a second ring gear 51 meshed with the first gear 4, 4 groups of first rods 54 evenly distributed are installed inside the second ring gear 51, and the other end of the first rod 54 is equipped with The first bearing seat 55, the first bearing seat 55, the second rod body 56 is installed in the middle, the transmission roller 58 is installed at one end of the second rod body 56, and the bevel gear 57 is installed at the other end of the second rod body 56, the cones described in 4 groups The gear 57 is meshed by the bevel gear 59, the derusting device 6 is arranged between the second grou...

Embodiment 2

[0030]In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a thickened fastening tape is pasted on the outside of the conveying roller 58 for adapting to steel bars of different thicknesses.

[0031] The working principle of the present invention is: the motor 2 drives the output shaft 3 to rotate, the output shaft 3 drives the first gear 4 to rotate, the first gear 4 drives the second ring gear 51 to rotate, and the second ring gear 51 drives the bevel gear 57 to rotate around the second gear The center line of the ring 51 revolves, and meshes with the bevel gear ring 59 at the same time to realize the self-rotation, and then realizes the self-rotation while the transmission roller 58 revolves, and realizes the spiral transmission of the steel bar. The output shaft 3 drives the eccentric disc 61 to rotate at the same time, and the eccentric disc 61 drives the circular sleeve 62 to move, the circular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com