Water-based antirust liquid suitable for steel surface organic composite film formation

A steel surface, anti-rust liquid technology, applied in anti-corrosion coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problems of unenvironmental protection, scratch resistance, low efficiency, etc., and improve corrosion resistance. , The effect of preventing rust again and excellent protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

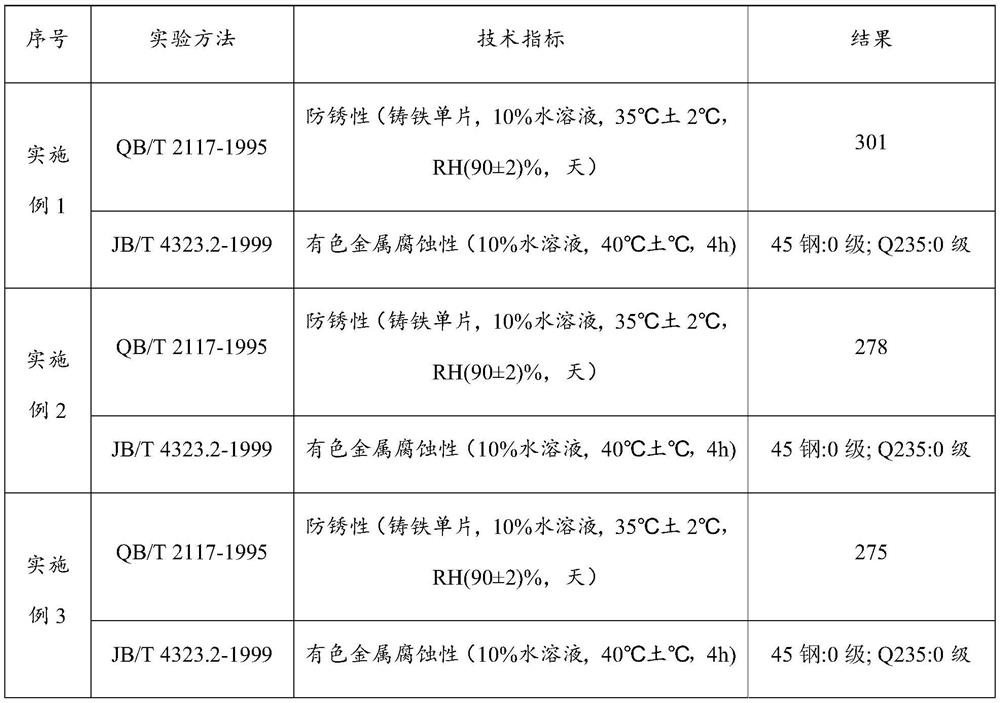

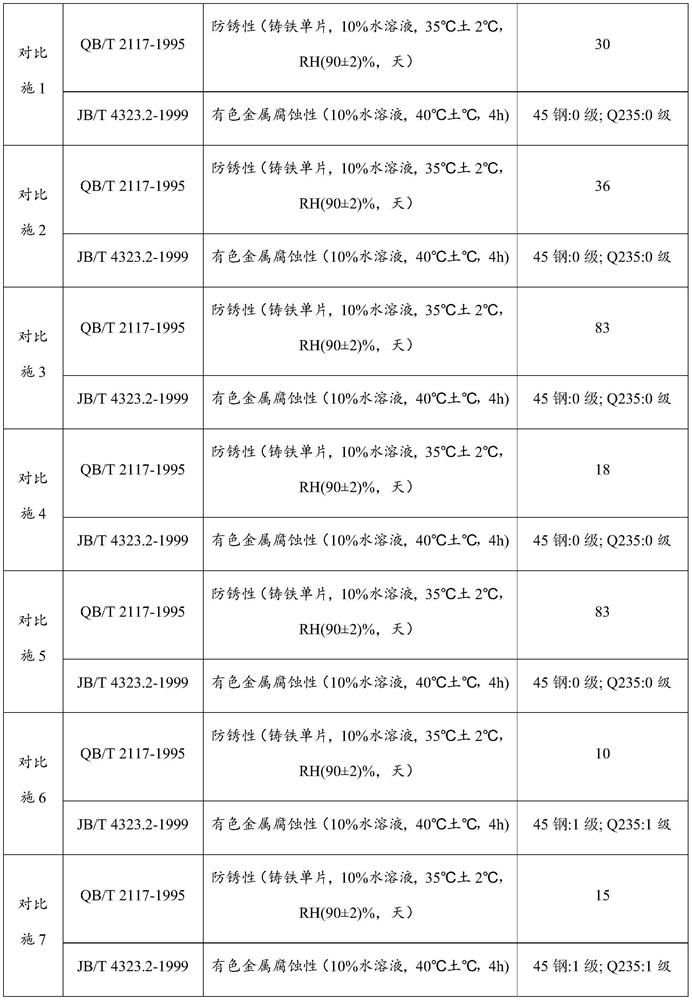

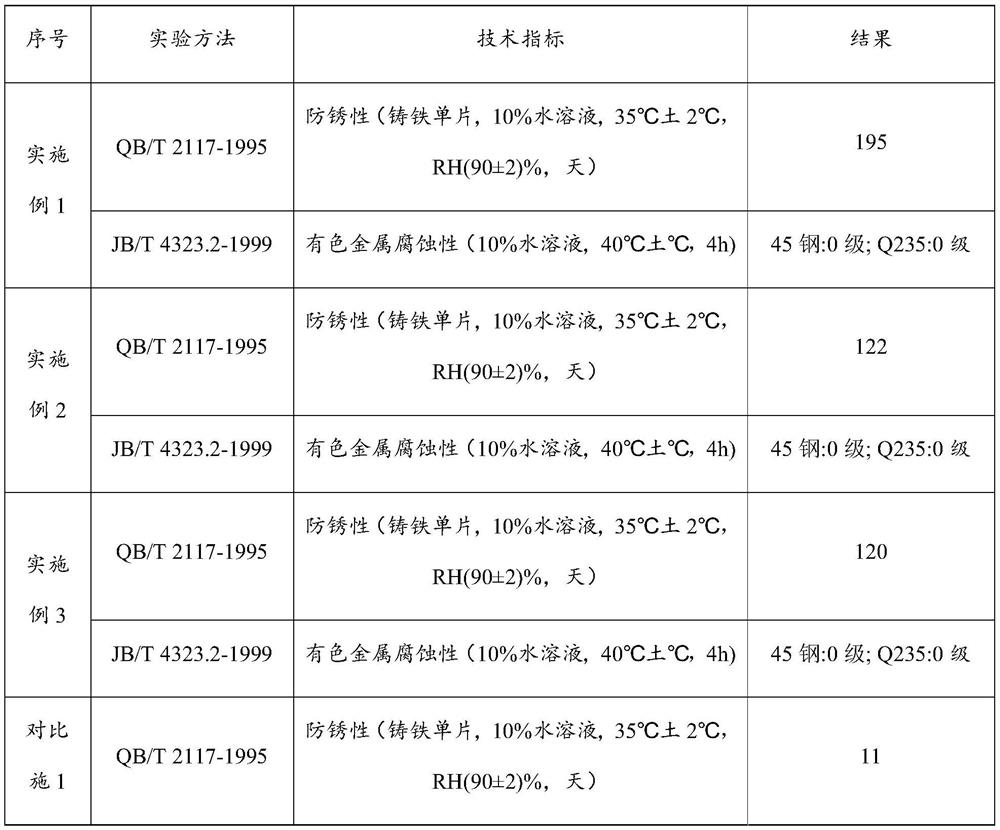

Examples

Embodiment 1

[0047] A water-based anti-rust solution suitable for organic compound film formation on steel surfaces, comprising components at the following concentrations:

[0048] Triisopropanolamine ring borate 2500ppm, ternary polycarboxylic acid 1700ppm, dibutyl sebacate 1000ppm, sodium gluconate 150ppm film-forming aid, rubidium carbonate 50ppm catalyst.

[0049] Stir and dissolve each component in water, adjust the pH value of the solution to 9.5, add pure water until the volume of the film-forming solution is 1000 mL, and obtain the film-forming solution described in this example.

[0050] The method for preparing the multiple organic composite membranes on the steel surface by using the film-forming solution described in this embodiment comprises the following steps:

[0051] (1) Pretreatment: ① Cut out a 50mm×100mm steel sample and punch a hole, and connect the iron wire at the hole; ② Polish the sample with sandpaper or chemically treat it until the original color of the substrat...

Embodiment 2

[0054] A water-based anti-rust solution suitable for organic compound film formation on steel surfaces, comprising components at the following concentrations:

[0055] Triisopropanolamine ring borate 1500ppm, ethyl borate 1000ppm, benzoic acid 1000ppm, dioctyl sebacate 1000ppm, disodium edetate 100ppm film-forming aid, rubidium sulfate 100ppm catalyst.

[0056] Stir and dissolve each component in water, adjust the pH value of the solution to 9.0, add pure water until the volume of the film-forming solution is 1000 mL, and obtain the film-forming solution described in this example.

[0057] The method for preparing the multiple organic composite membranes on the steel surface by using the film-forming solution described in this embodiment comprises the following steps:

[0058] (1) Pretreatment: ① Cut out a 50mm×100mm steel sample and punch a hole, and connect the iron wire at the hole; ② Polish the sample with sandpaper or chemically treat it until the original color of the su...

Embodiment 3

[0061] A water-based anti-rust solution suitable for organic compound film formation on steel surfaces, comprising components at the following concentrations:

[0062] Triphenyl borate 1000ppm, ethyl borate 2000ppm, benzoic acid 500ppm, ternary polycarboxylic acid 1500ppm, diisooctyl sebacate 1000ppm, sodium citrate 200ppm film-forming aid, rubidium nitrate 75ppm catalyst.

[0063] Stir and dissolve each component in water, adjust the pH value of the solution to 9.3, add pure water until the volume of the film-forming solution is 1000 mL, and obtain the film-forming solution described in this example.

[0064] The method for preparing the multiple organic composite membranes on the steel surface by using the film-forming solution described in this embodiment comprises the following steps:

[0065] (1) Pretreatment: ① Cut out a 50mm×100mm steel sample and punch a hole, and connect the iron wire at the hole; ② Polish the sample with sandpaper or chemically treat it until the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com