Rust removal and prevention agent and preparation method thereof

A rust inhibitor and anti-oxidation technology, applied in metal material coating process, packaging, packaging objects under special gas conditions, etc., can solve the problem that the passivation film is not dense enough, the anti-rust oil cannot be removed, and the rust effect and other problems, to achieve the effect of improving the mixing and stirring effect, preventing rust again, and ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

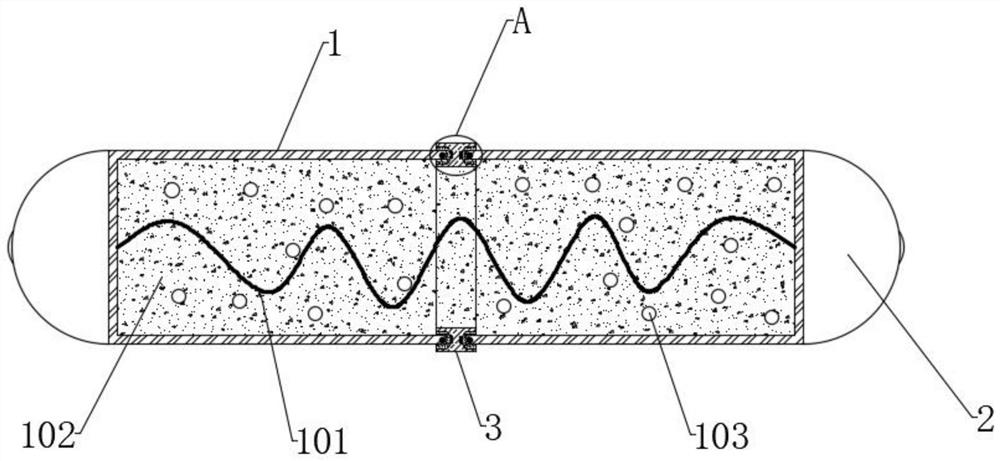

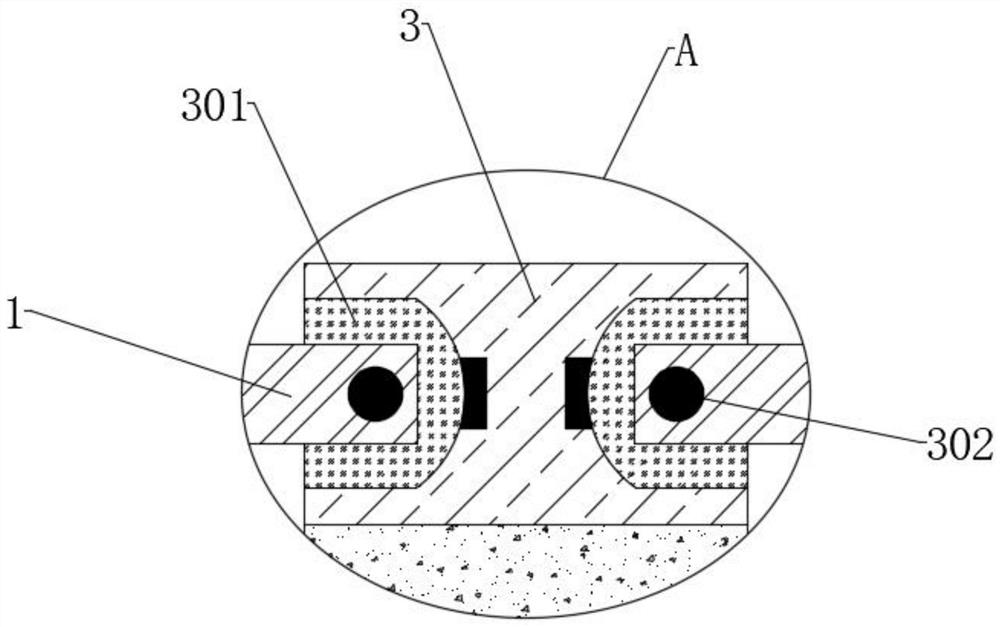

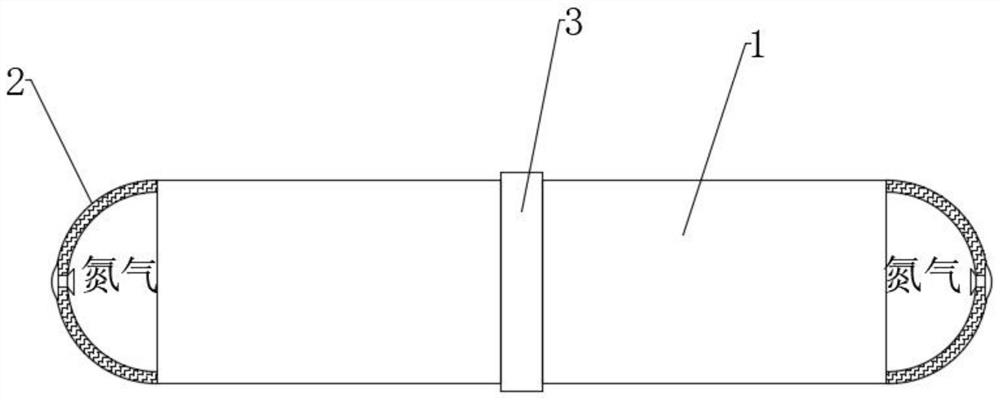

[0049] see Figure 1-8 , a rust-removing and anti-rust agent and preparation method thereof, please refer to Figure 8 , comprising the following components by weight: 300 parts of phosphoric acid, 2 parts of copper powder, 15 parts of aluminum powder, 2 parts of sodium dodecylbenzenesulfonate, 3 parts of barium petroleum sulfonate;

[0050] Its preparation method comprises the following steps:

[0051] S1. Dilute phosphoric acid to 30% first, then mix and stir it with the anti-oxidation capsule wrapped with aluminum powder and copper powder, and make it fully react until the aluminum powder and copper powder are completely dissolved, cool to room temperature, and obtain a spare solution ;

[0052] S2, fully mixing sodium dodecylbenzenesulfonate and barium petroleum sulfonate to obtain the mixture for later use;

[0053] S3. Add the mixed solution in the step S2 to the reserve solution in the step S1, stir well and filter out the solid impurities and the outer shell of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com