A steel plate cutting device with derusting, cleaning and drying functions

A technology for cutting devices and steel plates, which is applied to used abrasive processing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of unclean removal of stains, long drying time and cannot be used in time, and achieves good practicability, Avoid the effect of re-rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with the following examples.

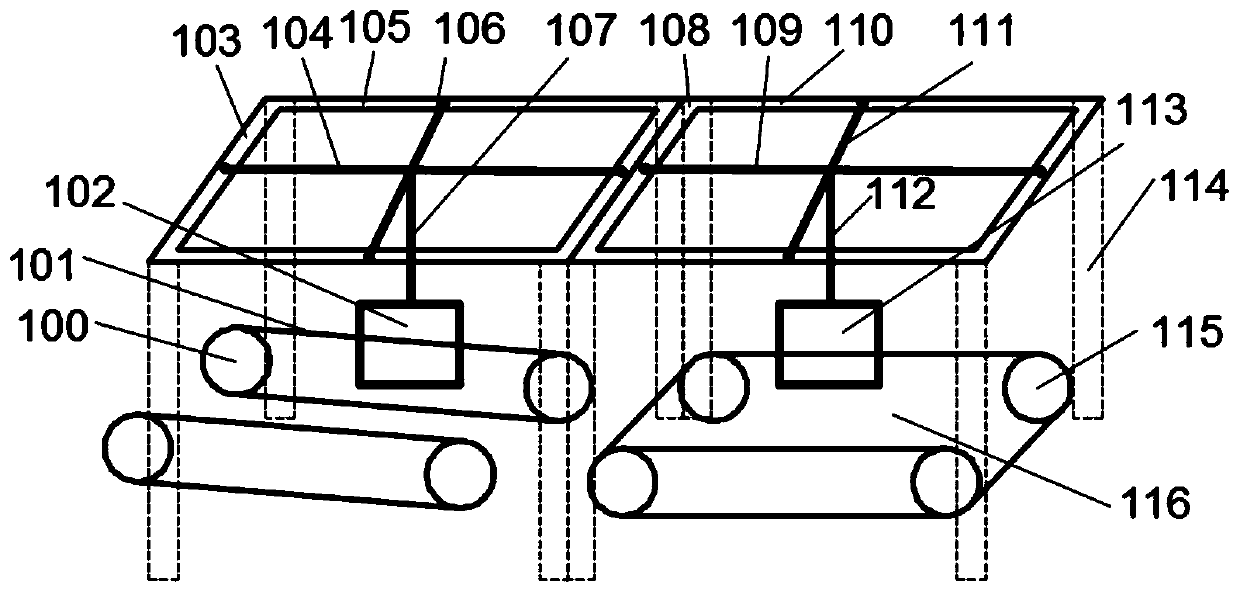

[0017] Such as figure 1 Shown is a steel plate cutting device with rust removal, cleaning and drying functions. The steel plate processing device includes a sprocket 100, a chain 101, a cutting machine 102, a first vertical slideway 103, a first horizontal slide bar 104, a first Horizontal slideway 105, first vertical slide bar 106, cutting machine telescopic bar 107, second vertical slideway 108, second horizontal slide bar 109, second horizontal slideway 110, second vertical slide bar 111, Decontamination machine telescopic rod 112, decontamination machine 113, slideway support leg 114, roller 115, conveyor belt 116.

[0018] Two first vertical slideways 103 and two first transverse slideways 105 are fixedly connected to form a rectangle, and the slideway supporting legs 114 are connected to the rectangle, and there is a sprocket 100 engaging the chain 101 below the rectangle; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com