Carbon steel wire machining process

A processing technology and carbon steel technology, applied in the field of carbon steel wire processing technology, can solve problems such as a large amount of waste acid and increase costs, and achieve the effect of reducing waste acid recovery costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

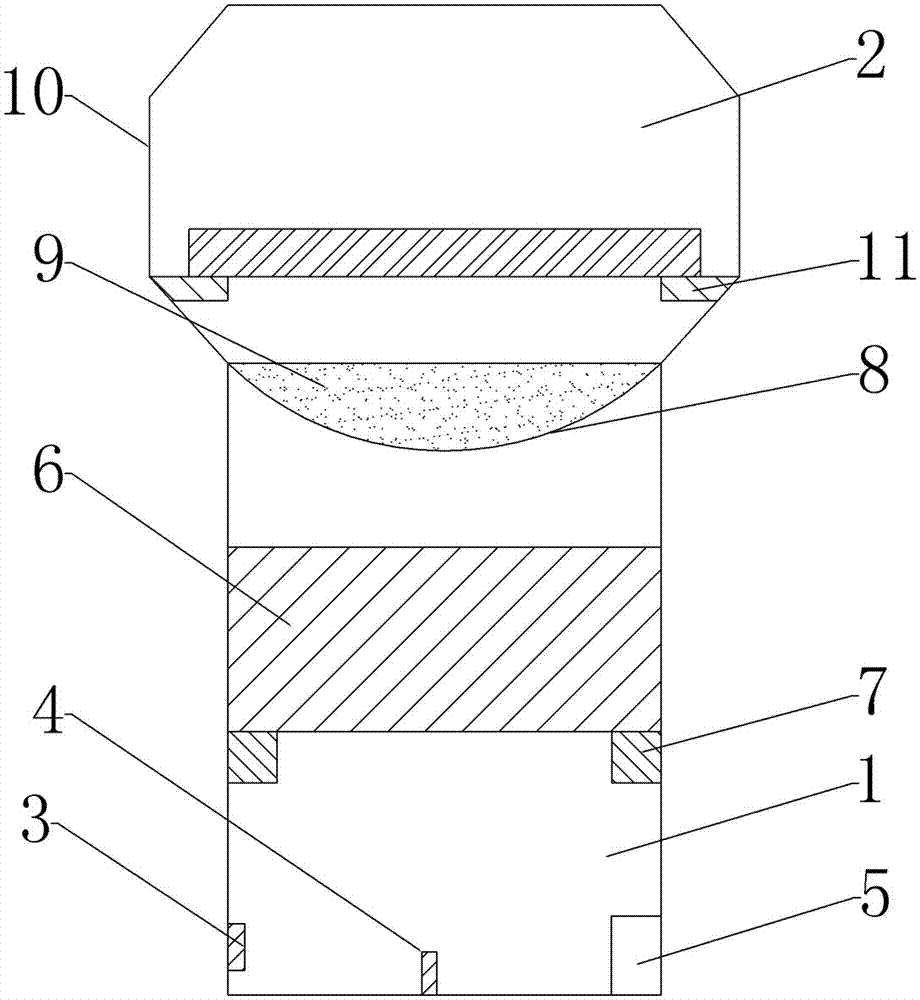

[0029] The reference signs in the drawings of the description include: gas explosion chamber 1, derusting chamber 2, air inlet 3, igniter 4, gas detector 5, sliding area 6, positioning block 7, elastic layer 8, abrasive material 9, inlet Material channel 10, shelf 11.

[0030] The present embodiment is a carbon steel wire processing technology, and its specific processing steps are:

[0031] (1) Select a carbon steel alloy with a hardness less than 85HRB, a weight of 200kg, and a diameter of 9mm as the raw material for carbon steel wire processing;

[0032] (2) Use a hydrogen explosion derusting device to derust carbon steel materials;

[0033] (3) Put the carbon steel material that has been derusted into a phosphate solution with a concentration of 12-20g / L and a temperature of 75-85°C for 8-10 minutes for phosphating, thereby forming a network on the surface of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com