Patents

Literature

81results about How to "Simplify the washing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-containing aluminium sol adhesive for catalyst and its prepn

The present invention relates to a phosphorus and aluminum containing sol for petroleum hydrocarbon cracking catalyst and its features are containing Al 2-10 wt%, P 5-20 wt% and no Cl, with its P / Al ratio being 1.2-6 and pH value being 1.0-2.5. The preparation process includes beating aluminium hydroxide or alumina capable of being peptized and deionized water to obtain a slurry with solid content of 15-35 wt%, adding concentrated phosphoric acid according to the required P / Al ratio while stirring, heating to 65-95 deg. and reaction for 15-90 min until becoming transparent colloid. The said phosphorus and aluminum containing sol without C1 may be used together with conventional chlorine-containing aluminum sol.

Owner:CHINA PETROLEUM & CHEM CORP +1

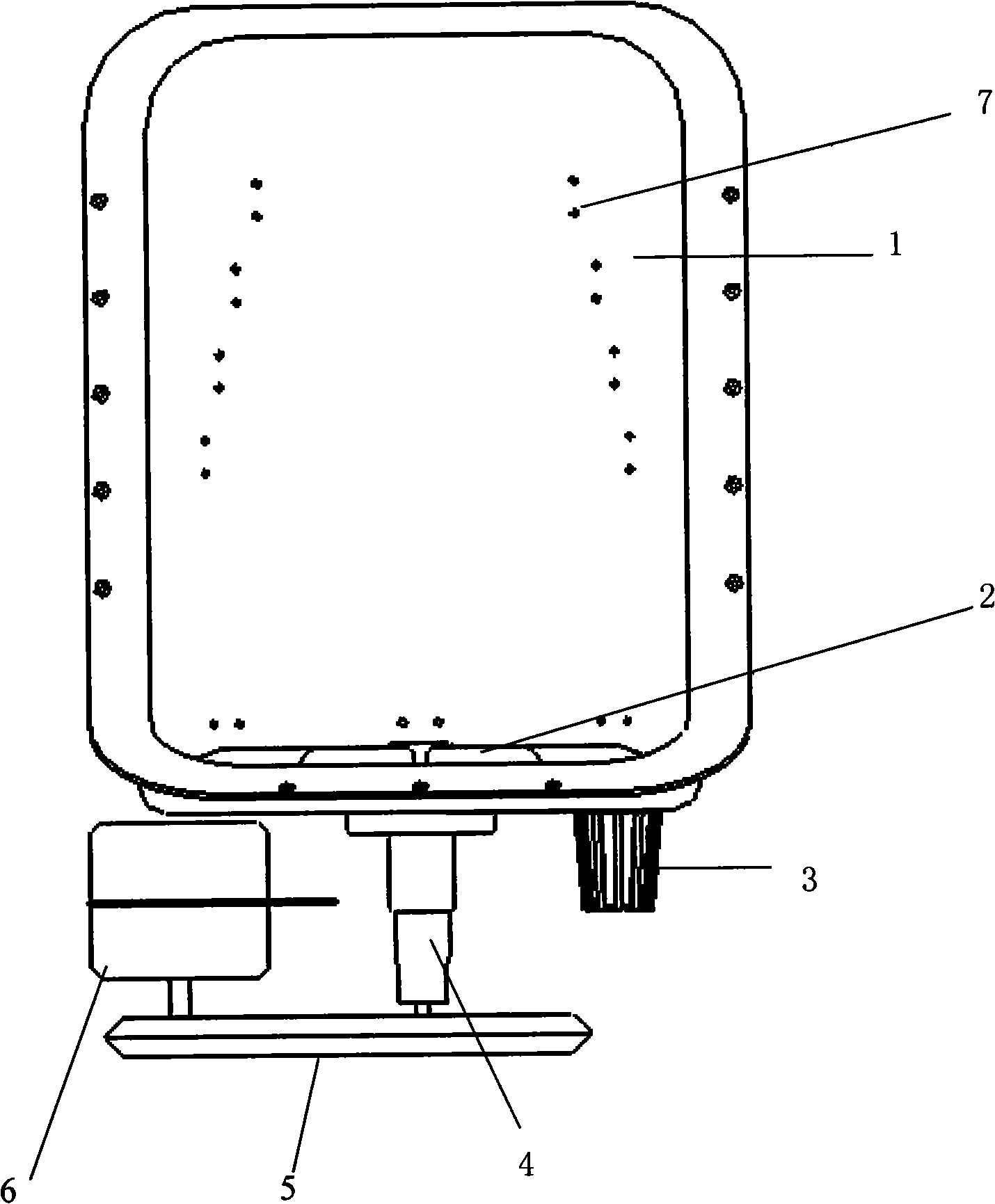

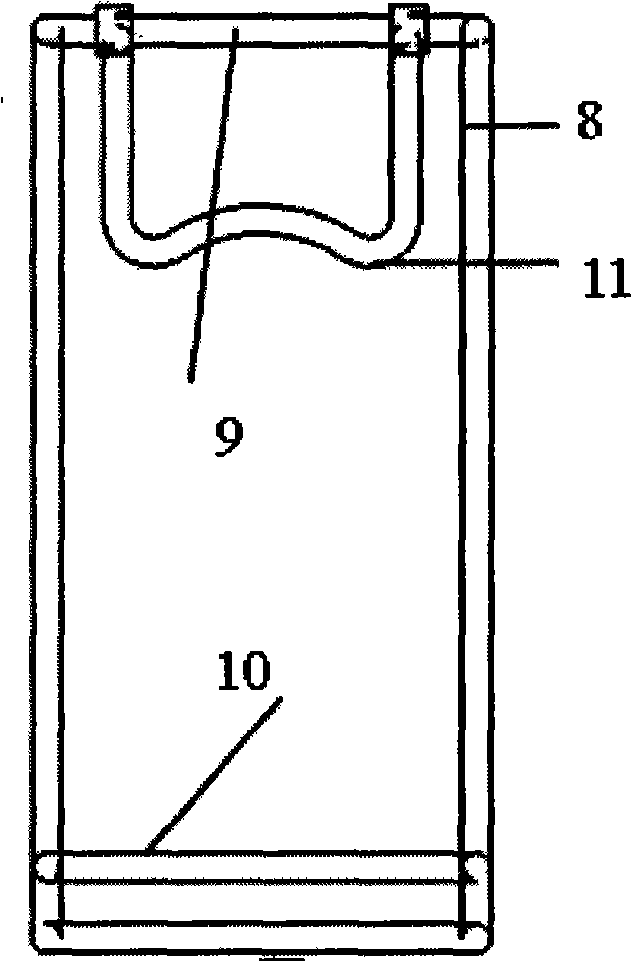

Washing machine and washing method

InactiveCN102953262AReduce material costsReduce manufacturing costOther washing machinesControl devices for washing apparatusProcess engineeringMedia layer

Owner:XEROS LTD

A washing machine and washing method thereof

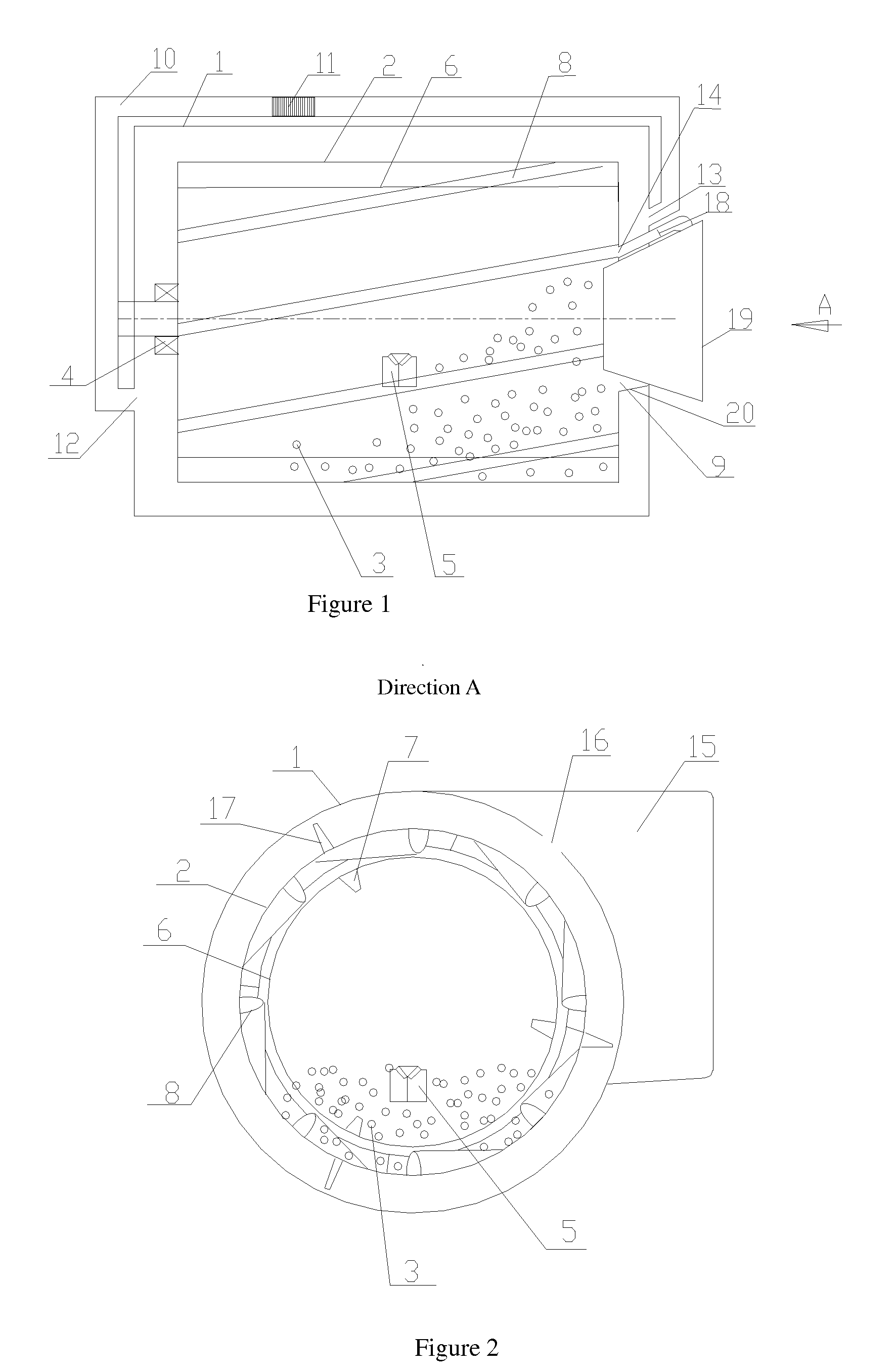

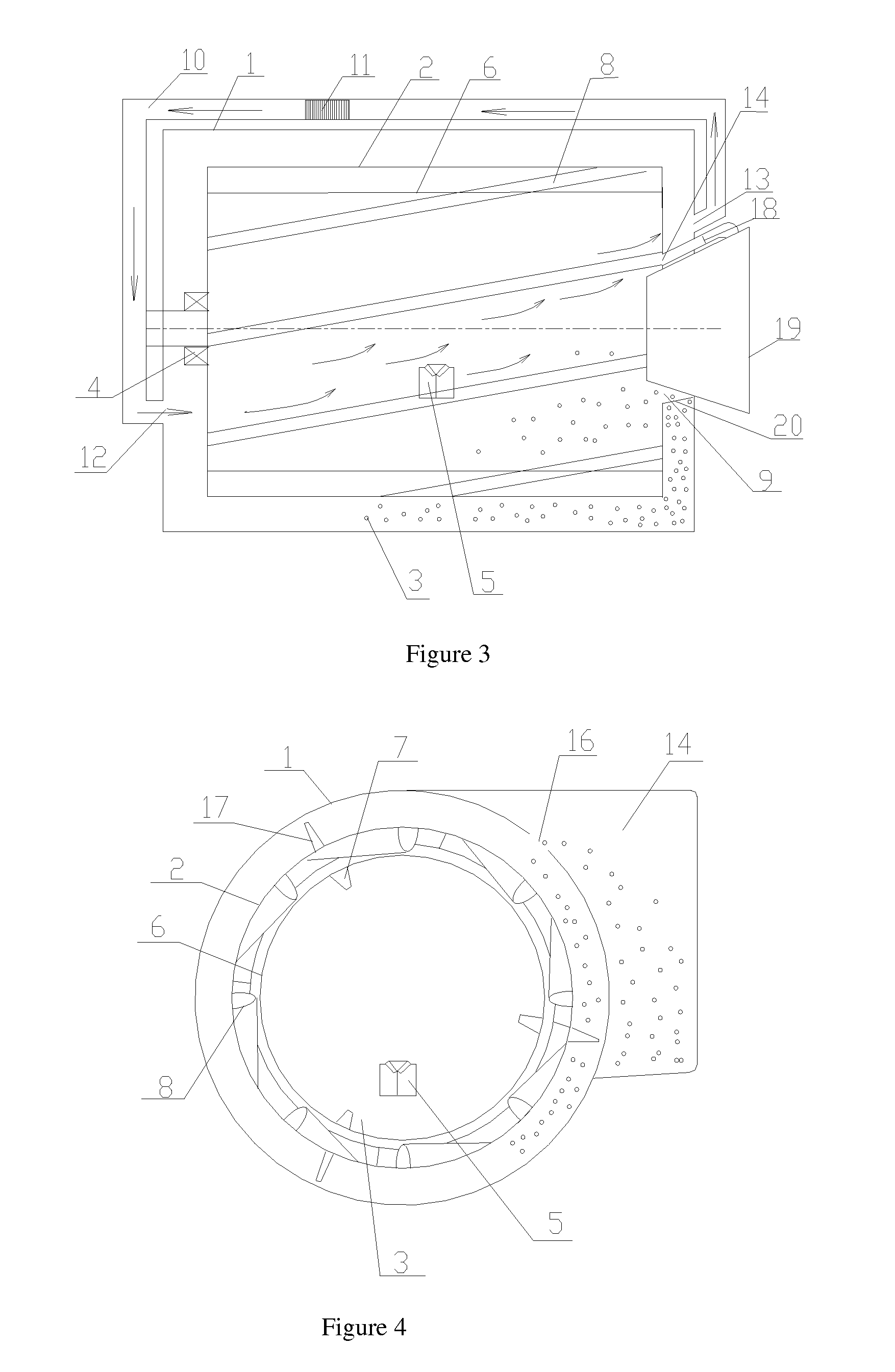

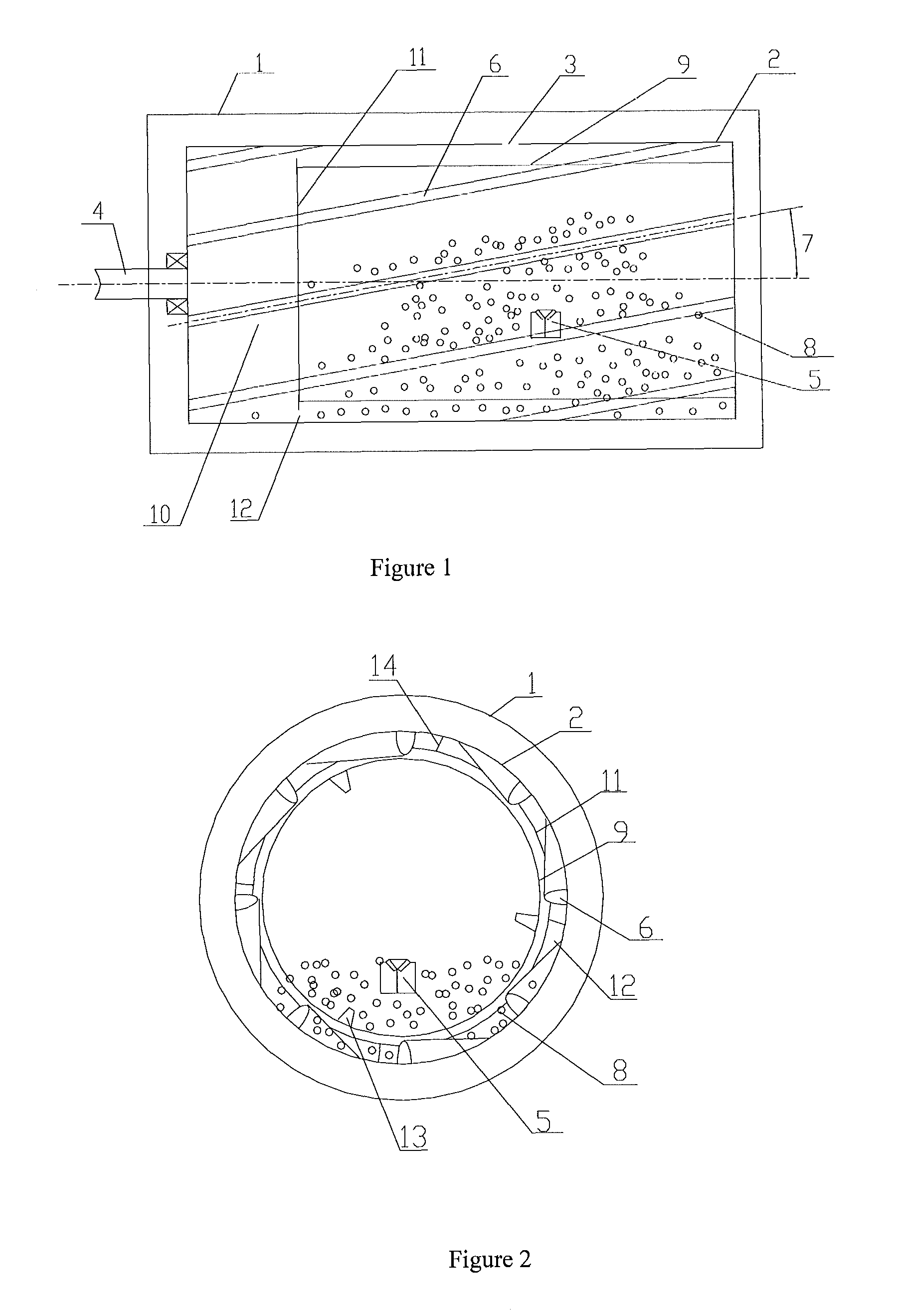

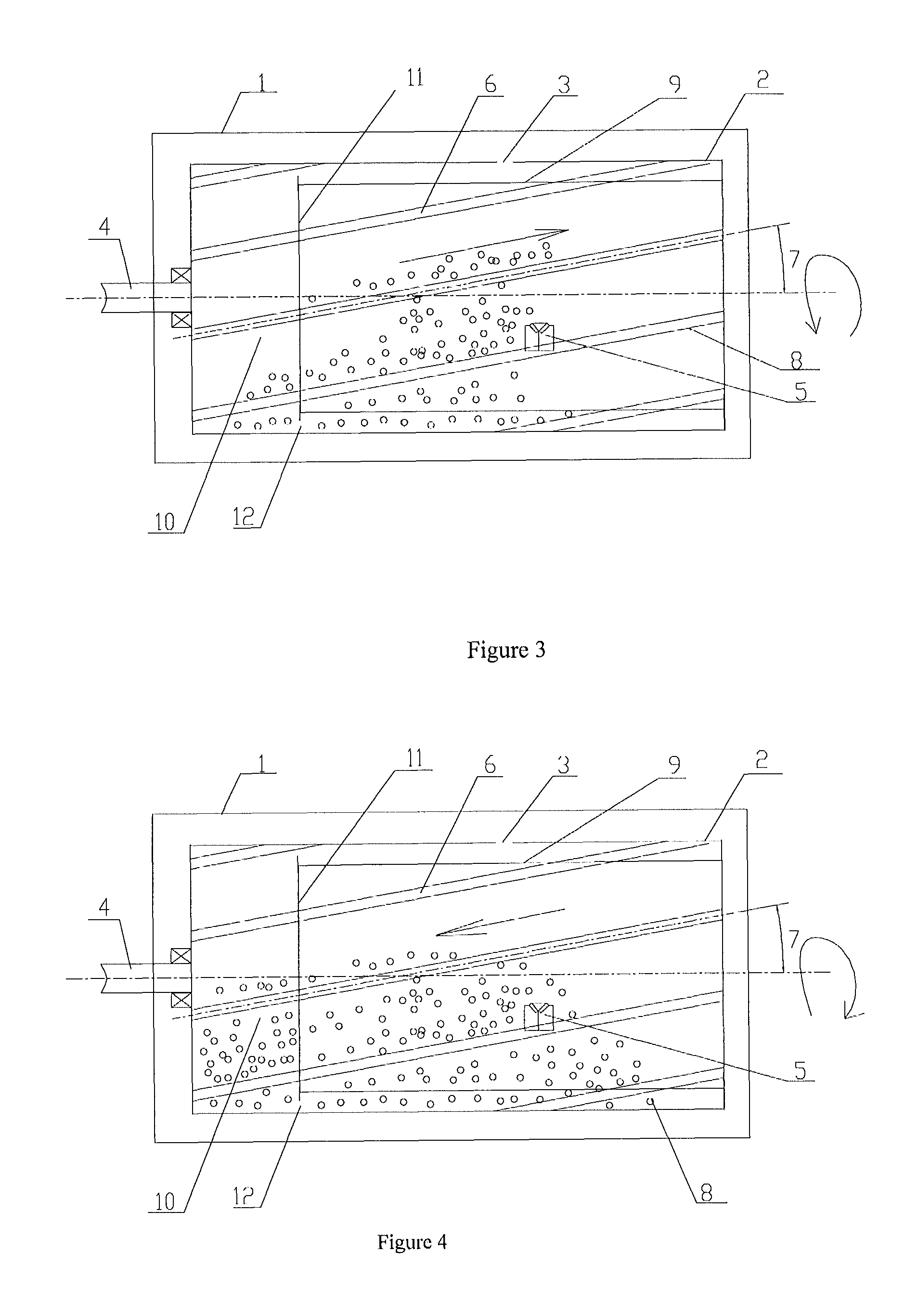

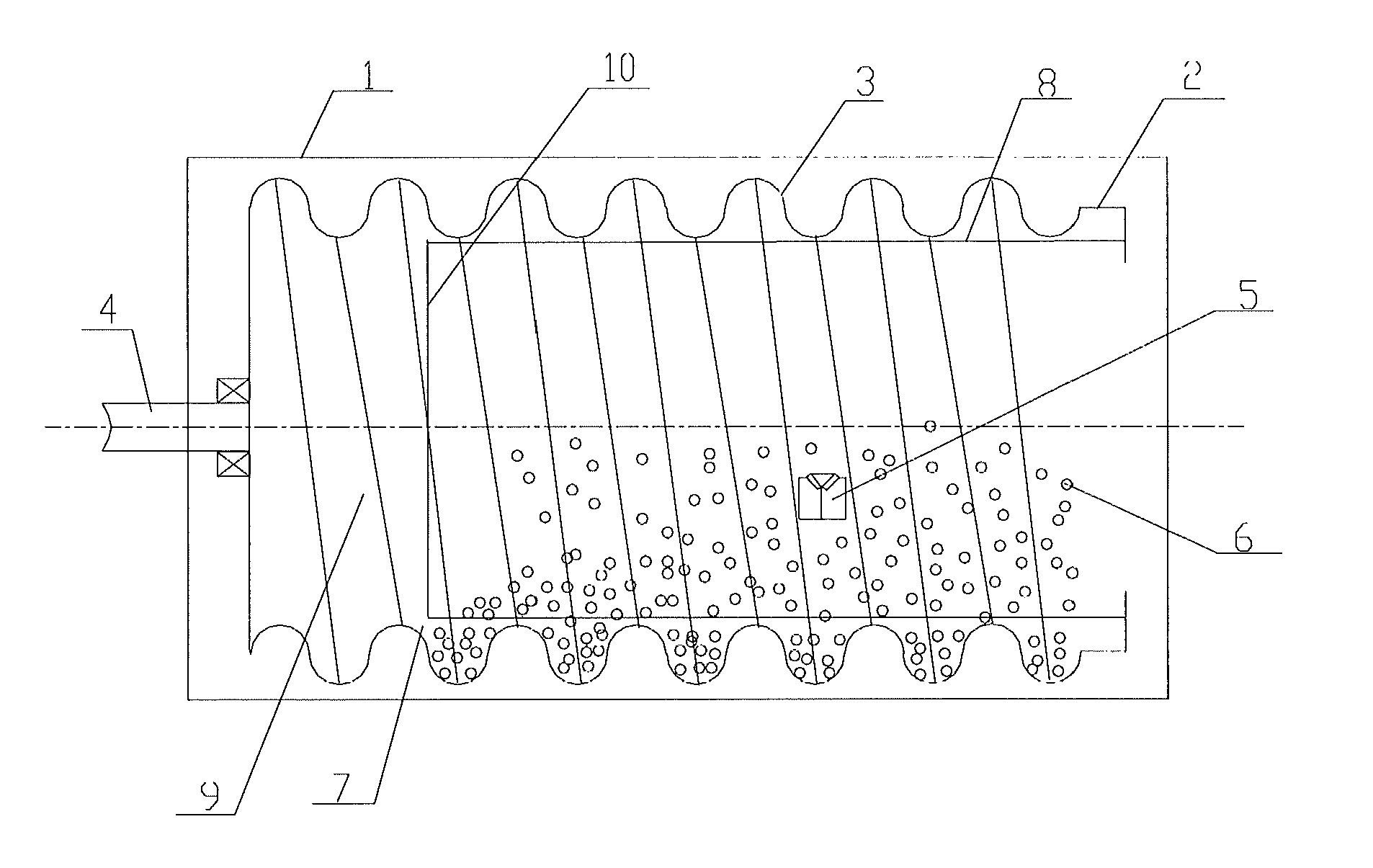

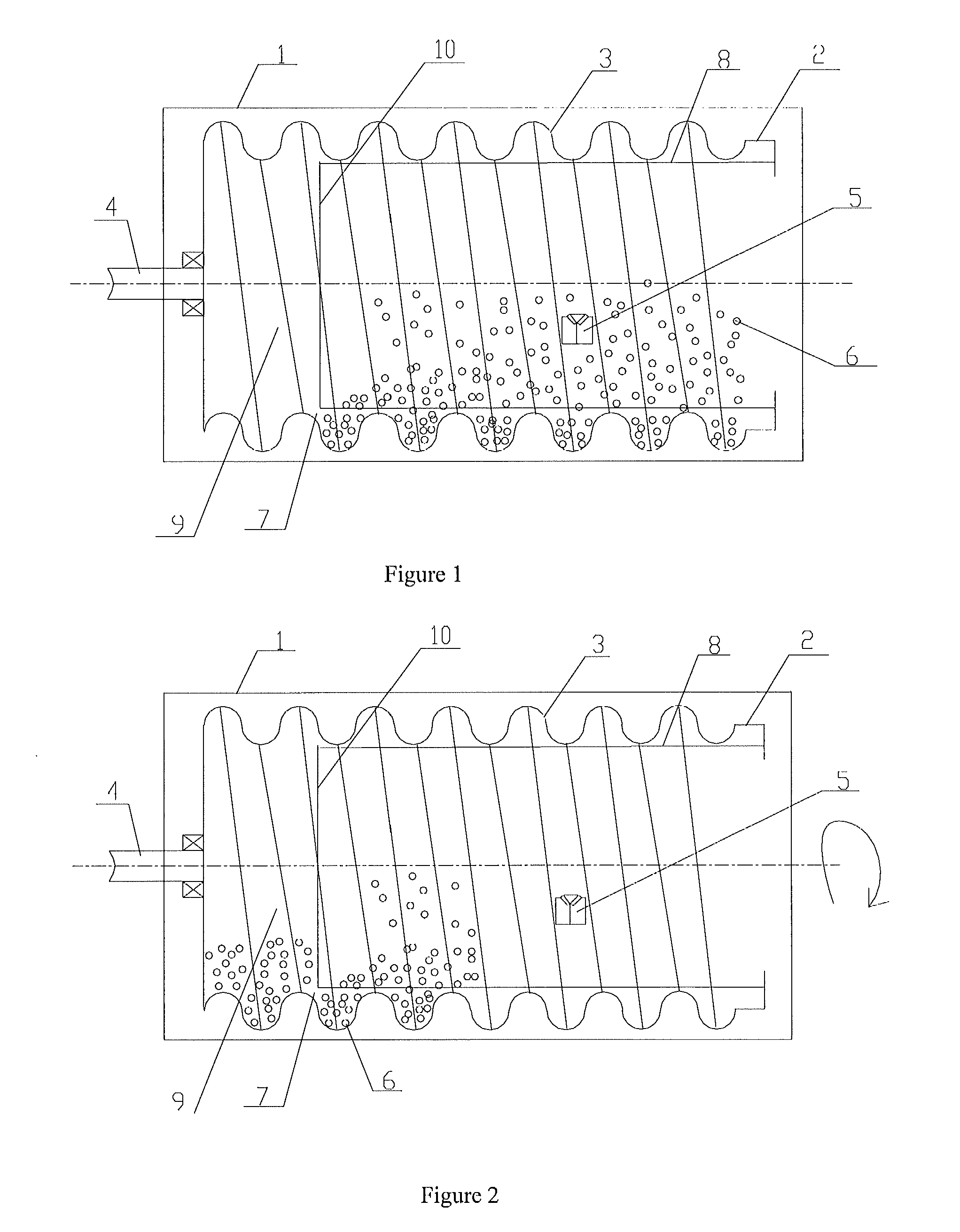

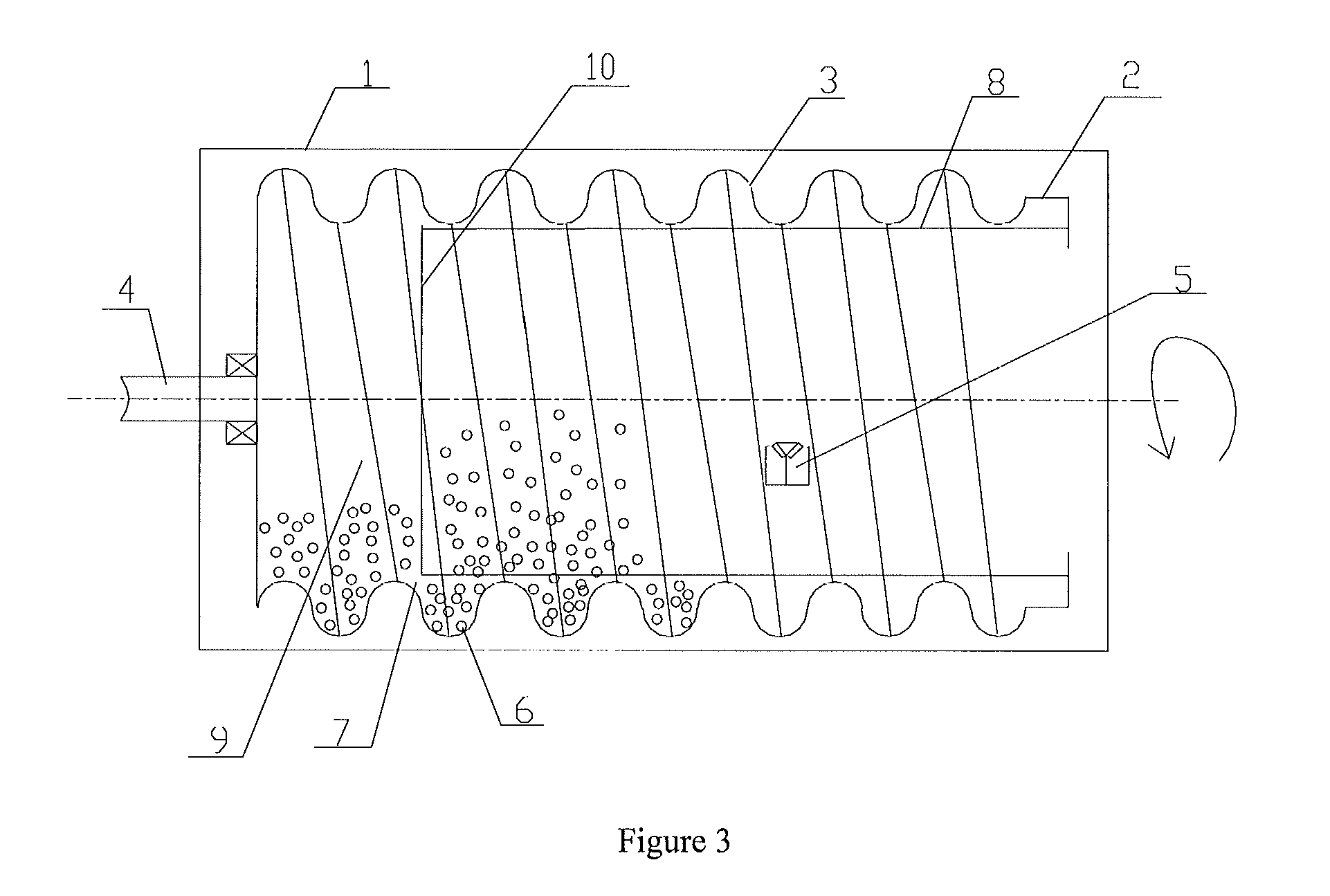

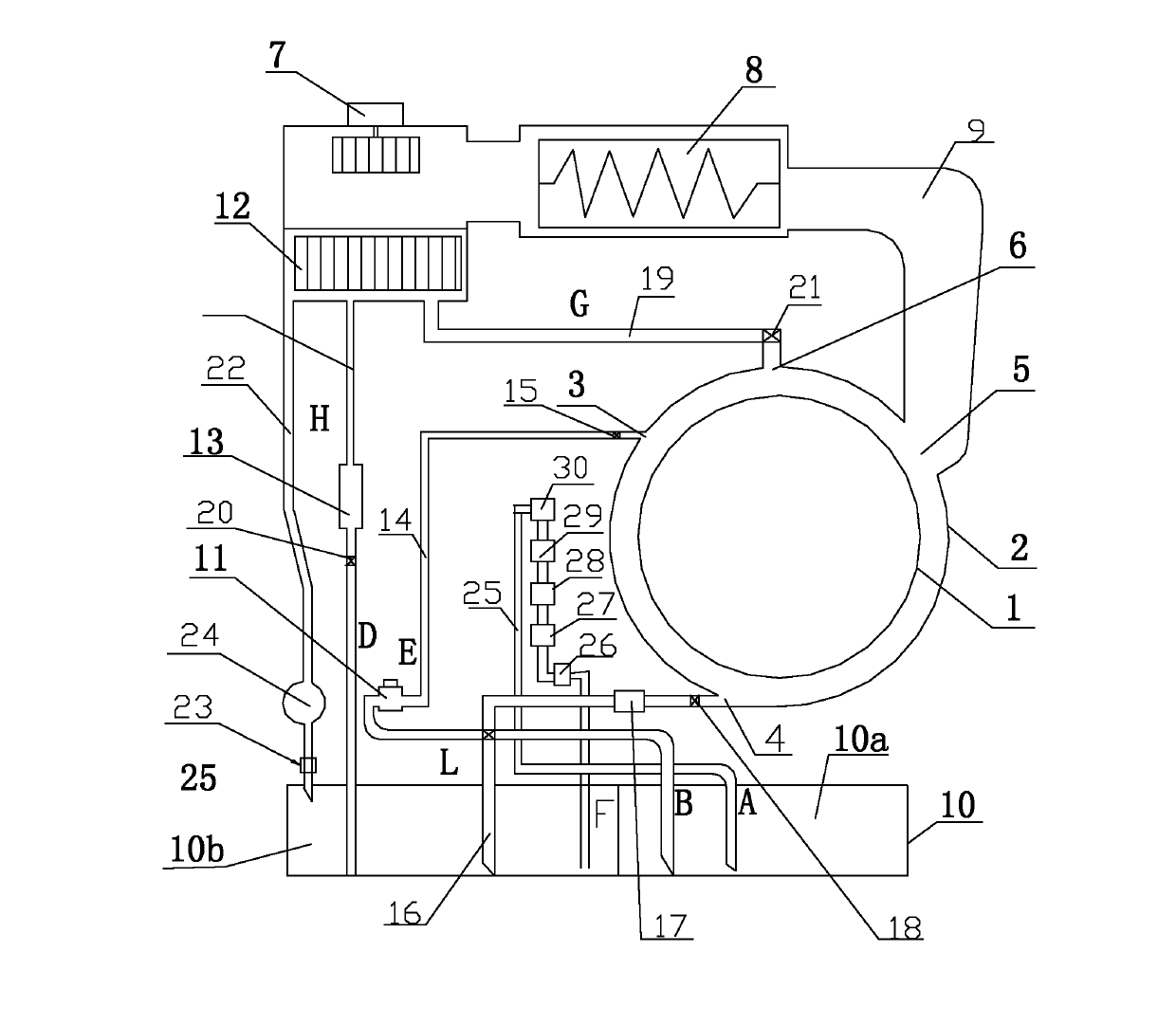

InactiveUS20140317860A1Simplify the washing processImprove cleaning rateOther washing machinesDetergent compounding agentsAir cycleEngineering

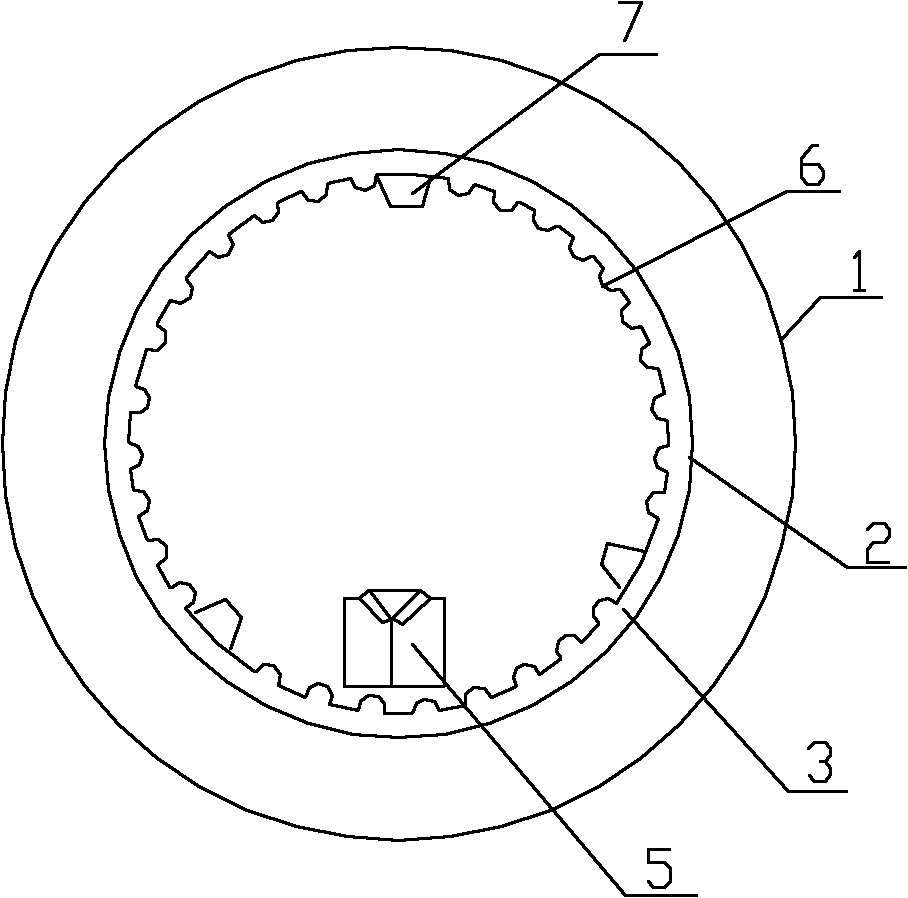

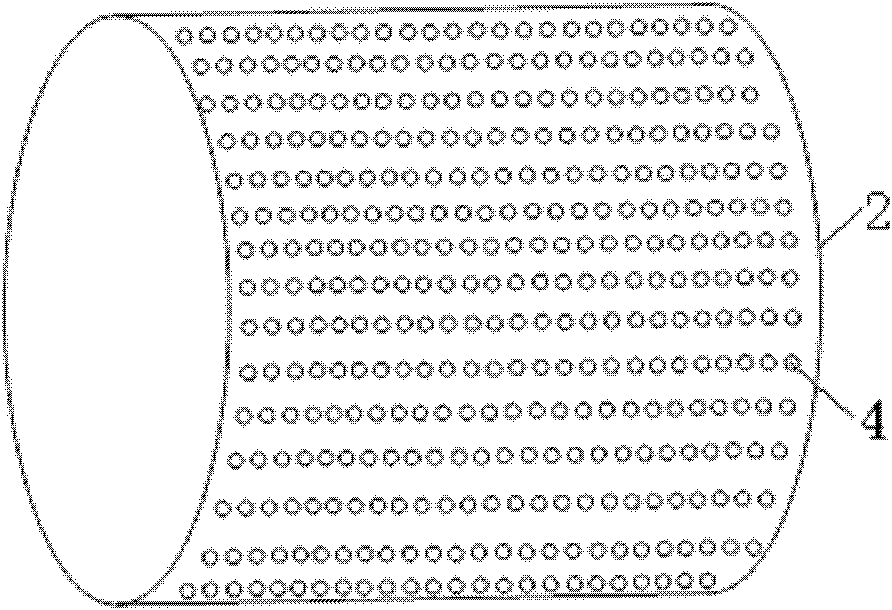

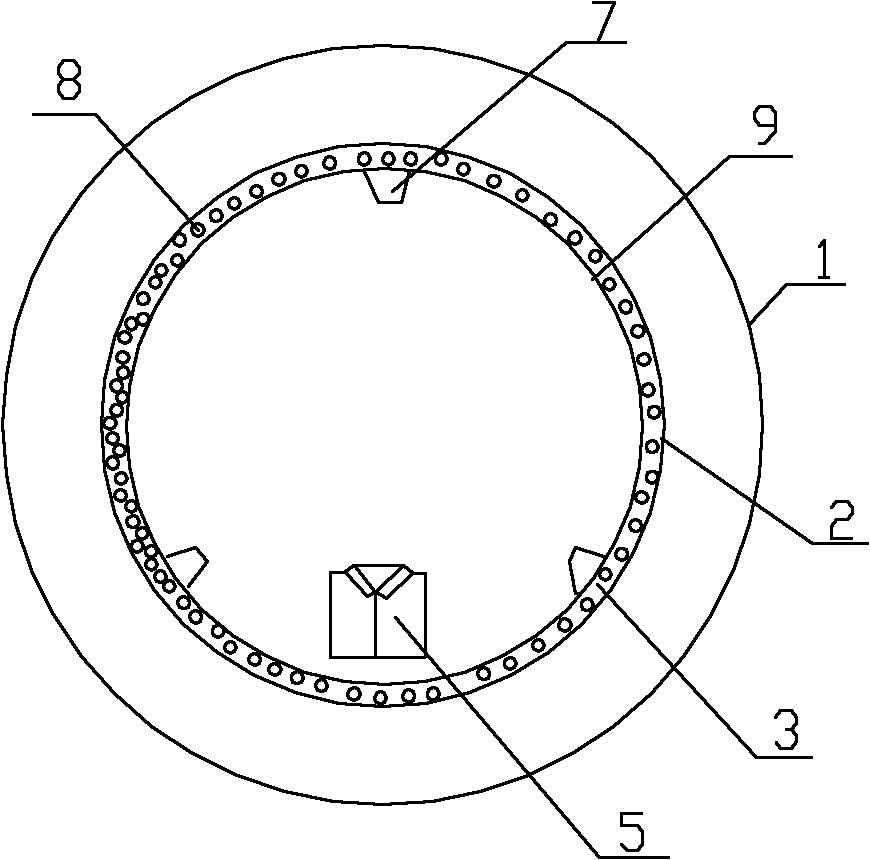

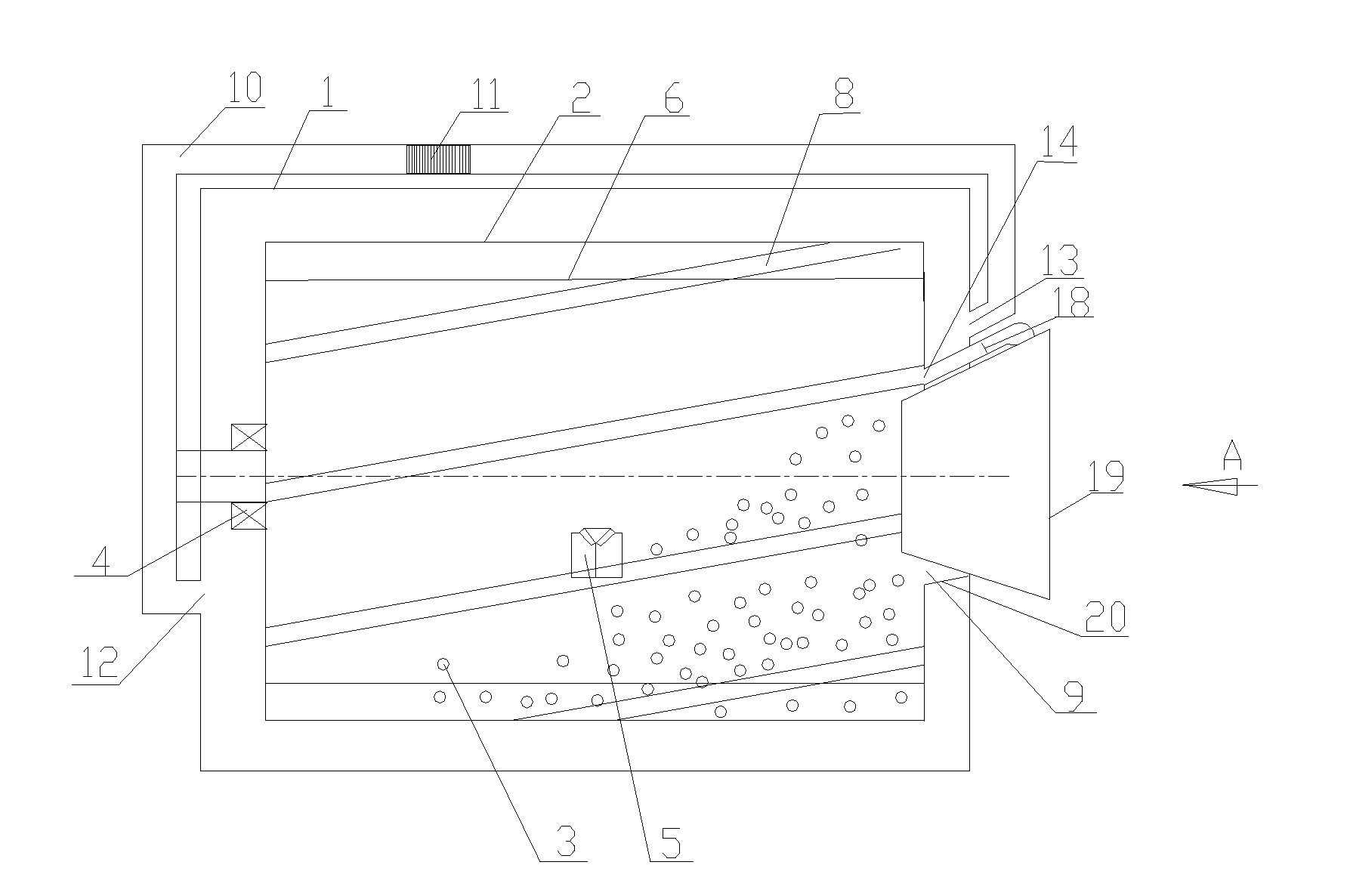

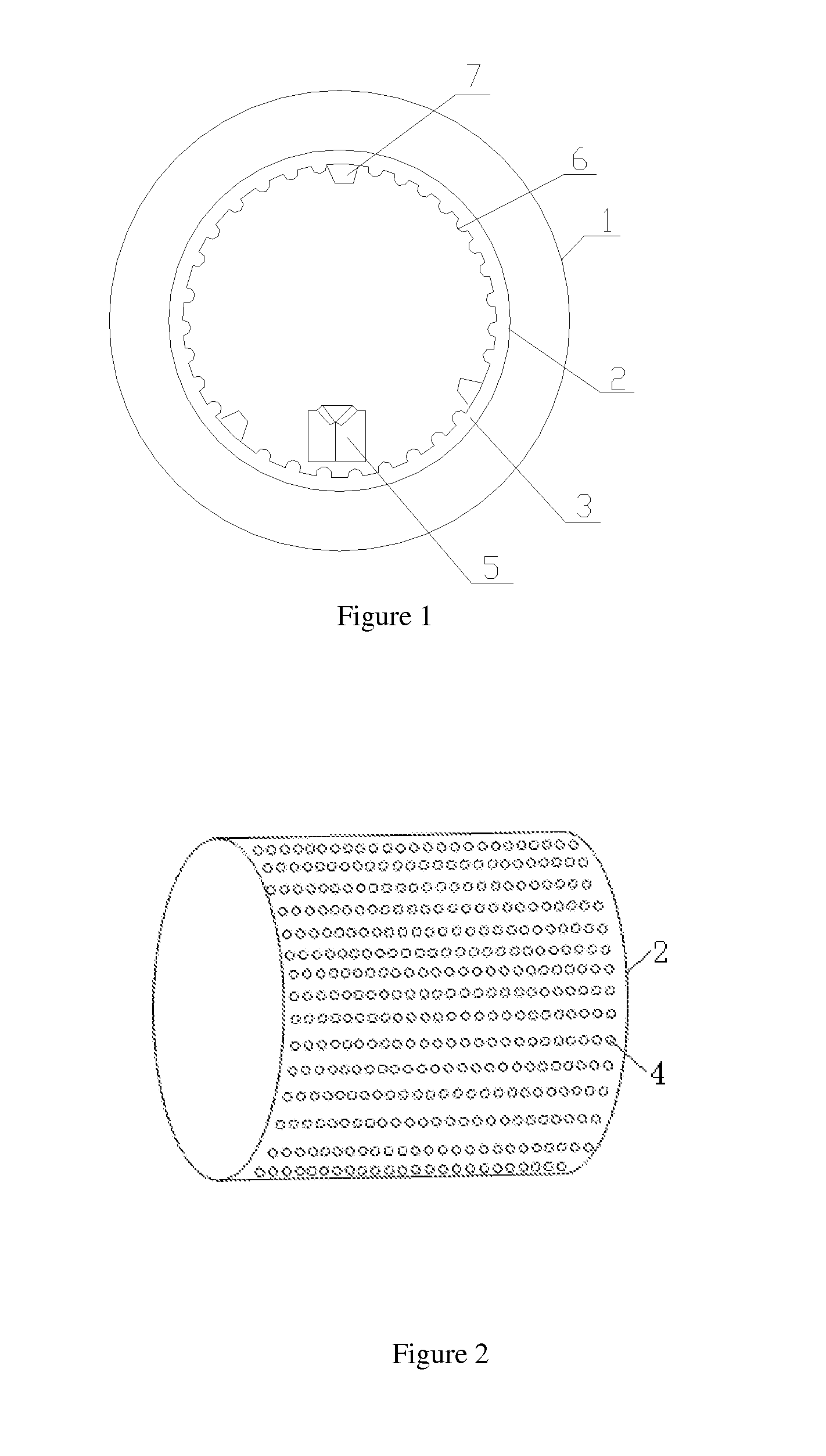

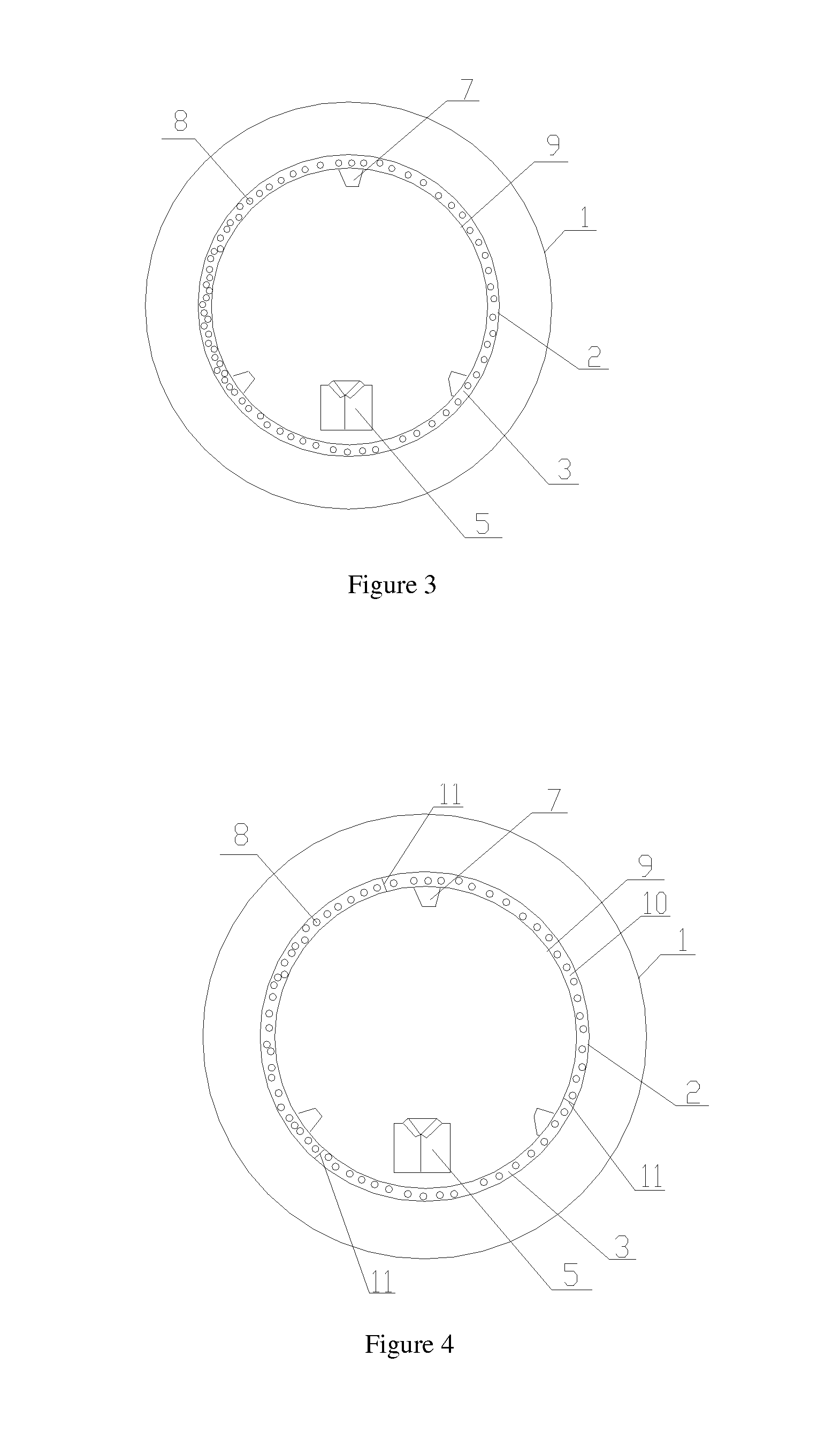

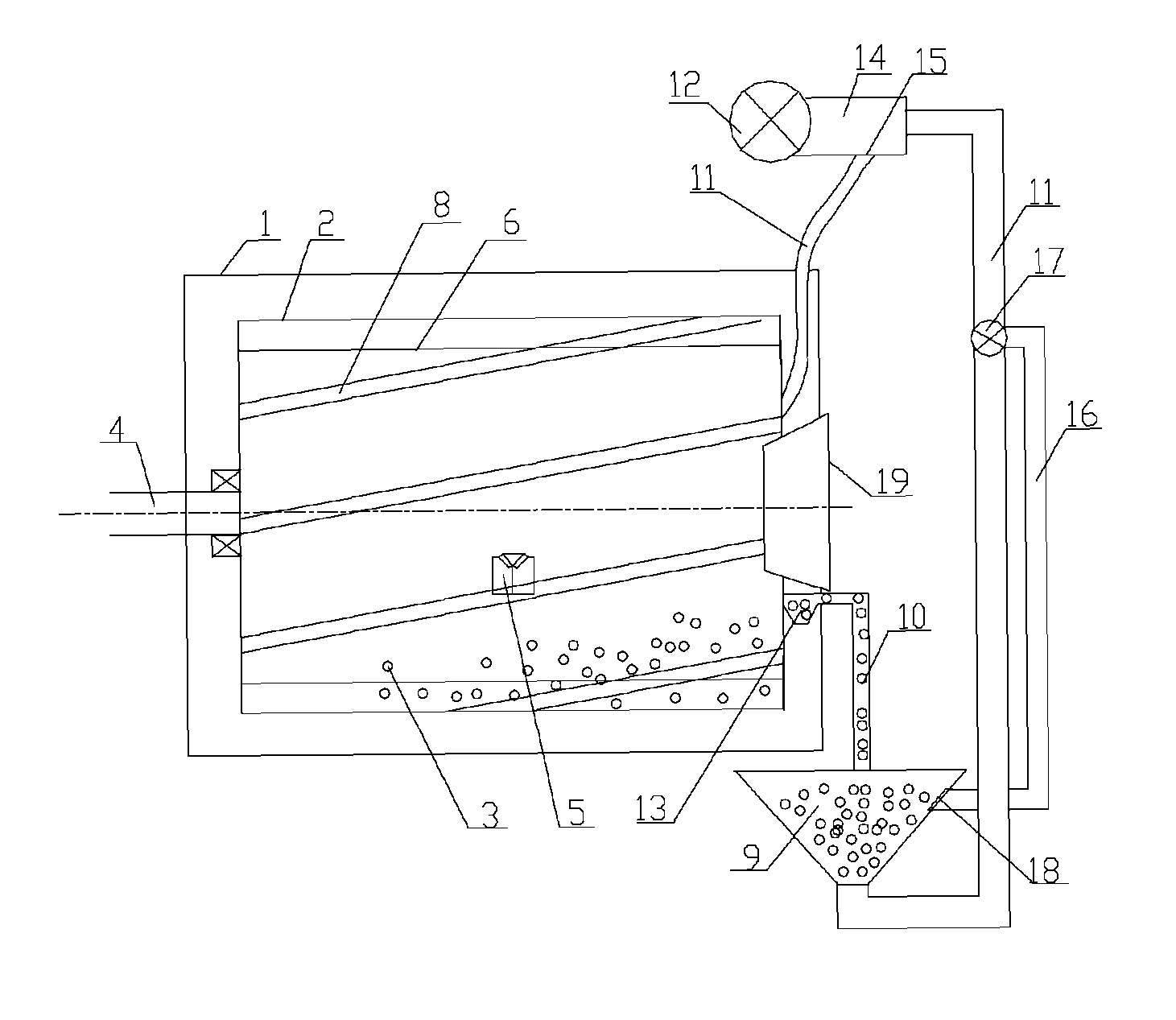

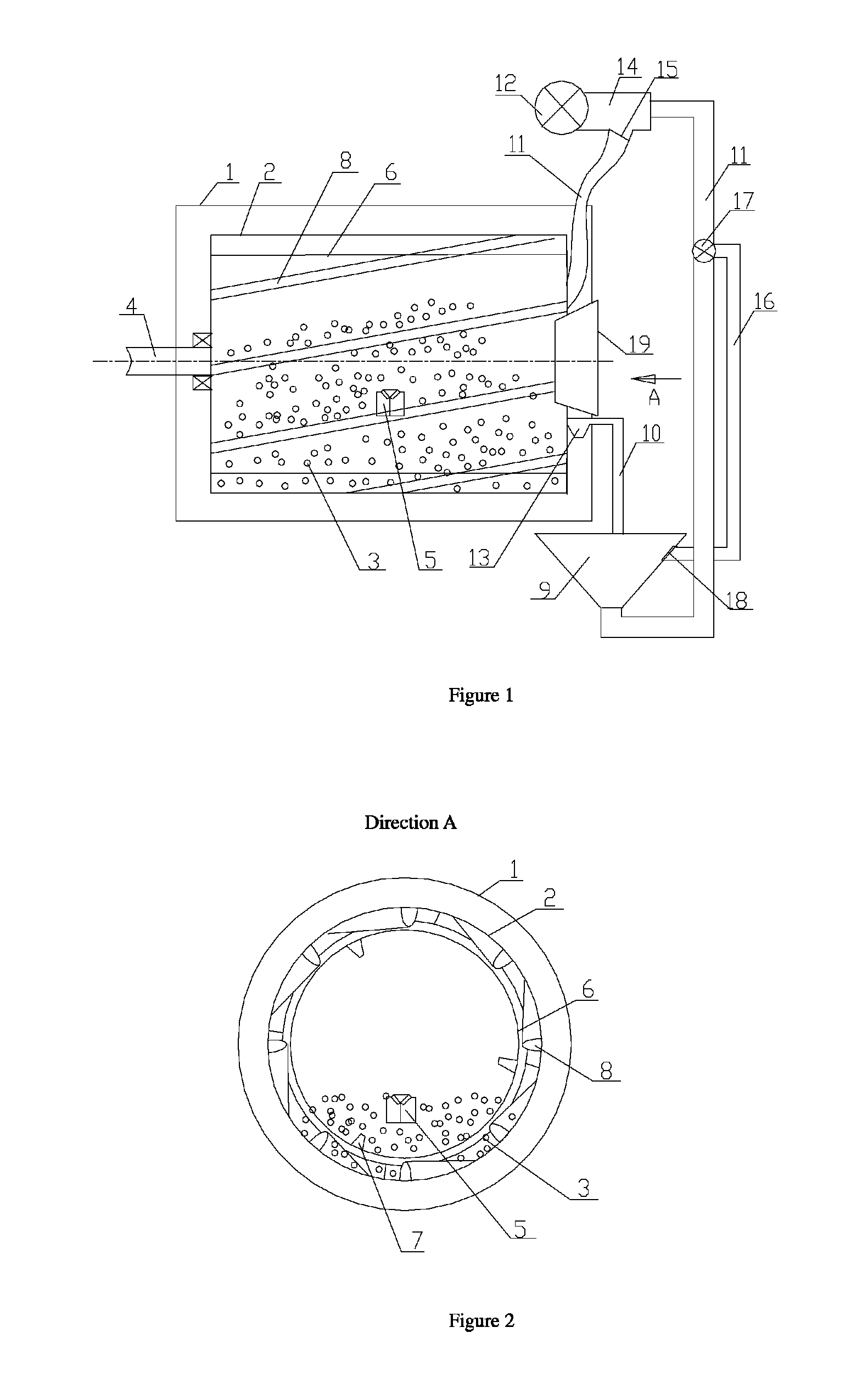

A washing machine and washing method thereof, comprising an inner tub, an outer tub and solid particles as washing medium. The inner tub, whose inner wall is arranged with lifting ribs protruding inward, rotates under the driving power of a driving device. Inside the washing machine, there is an air circulation channel, wherein, a fan is arranged. Both ends of the air circulation channel communicate to the inner tub. A discharge hole for recycling the particles and a feeding hole for putting in the particles are arranged at the front end of the inner tub. When the washing process comes to an end, both the clothes and particles can be dewatered and dehydrated simultaneously, so the washing procedures get simplified. Besides, blowing air towards the inner tub to separate and recycle the particles is conducive to 100% recycling of the particles.

Owner:XEROS LTD

Washing machine and washing method

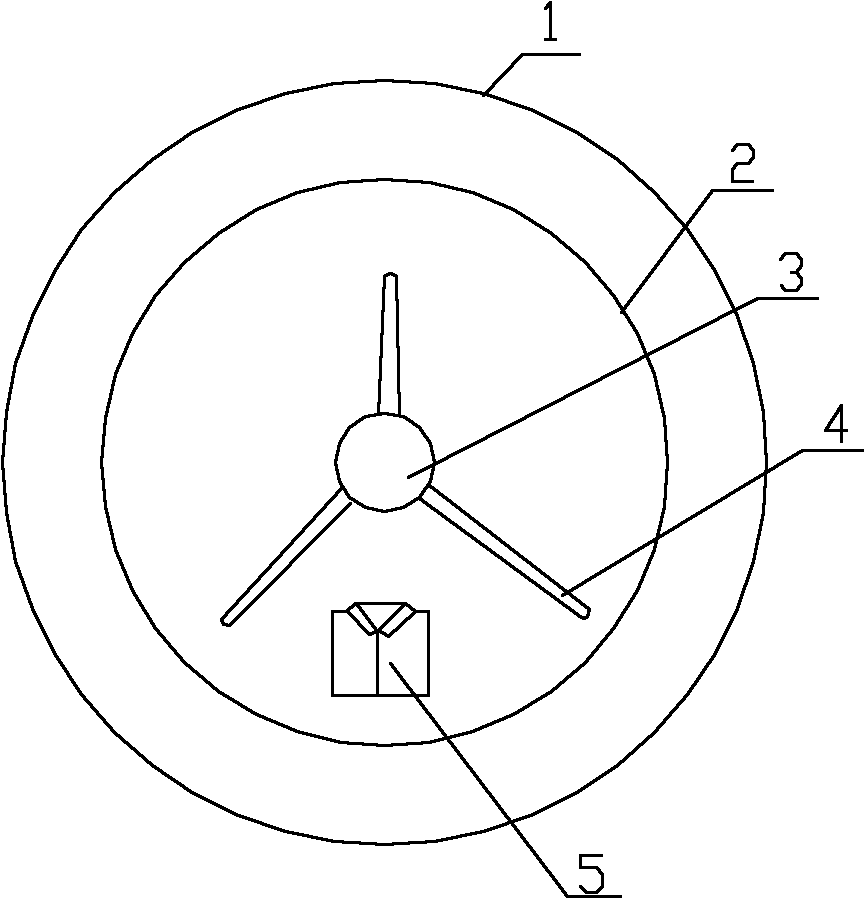

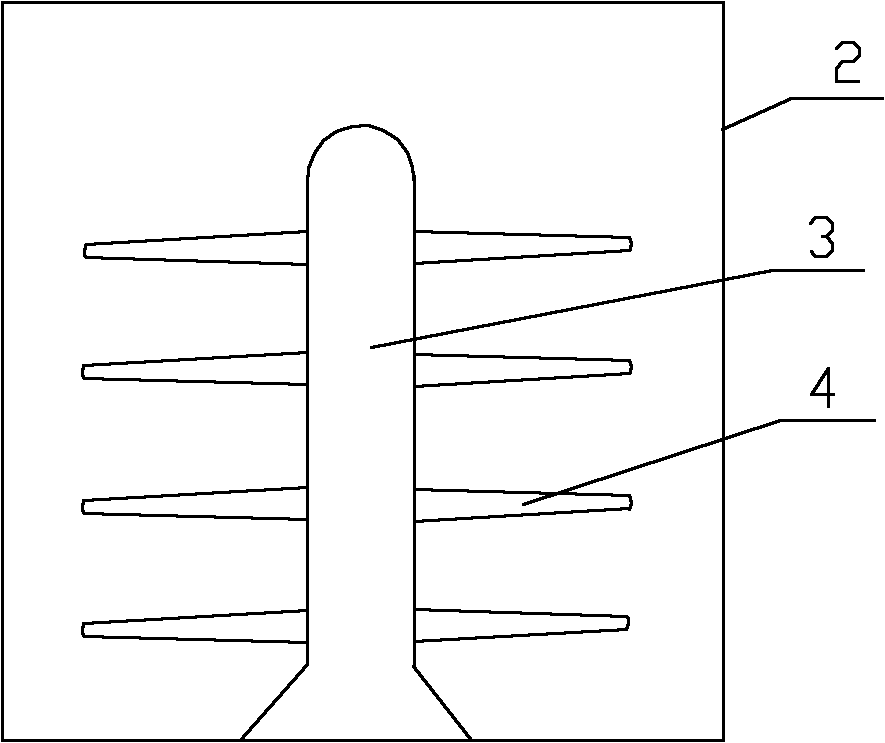

InactiveCN102953250ALittle wearImprove adsorption capacityOther washing machinesWashing machine with receptaclesEngineeringProcess engineering

The invention relates to a washing machine and a washing method. The washing machine comprises a washing drum, a plurality of polymer plastic strips used for washing clothes are radially arranged on a central shaft in the washing drum or on the wall of the washing drum. The radially arranged polymer plastic strips are used for stirring the clothes, and dirt on the clothes and in washing water is washed off by contacting of the polymer plastic strips with the clothes, so that washing of the clothes is completed. Compared with a common washing machine, the washing machine has the advantages that the washing machine is simple in structure, washing process is simplified, and material cost and manufacture cost of the washing machine are lowered greatly. Additionally, when the washing machine is used for washing, contact area of polymer washing media with the clothes is increased, adsorption capacity to the dirt is improved, and the wear degree of the clothes is much lower.

Owner:XEROS LTD

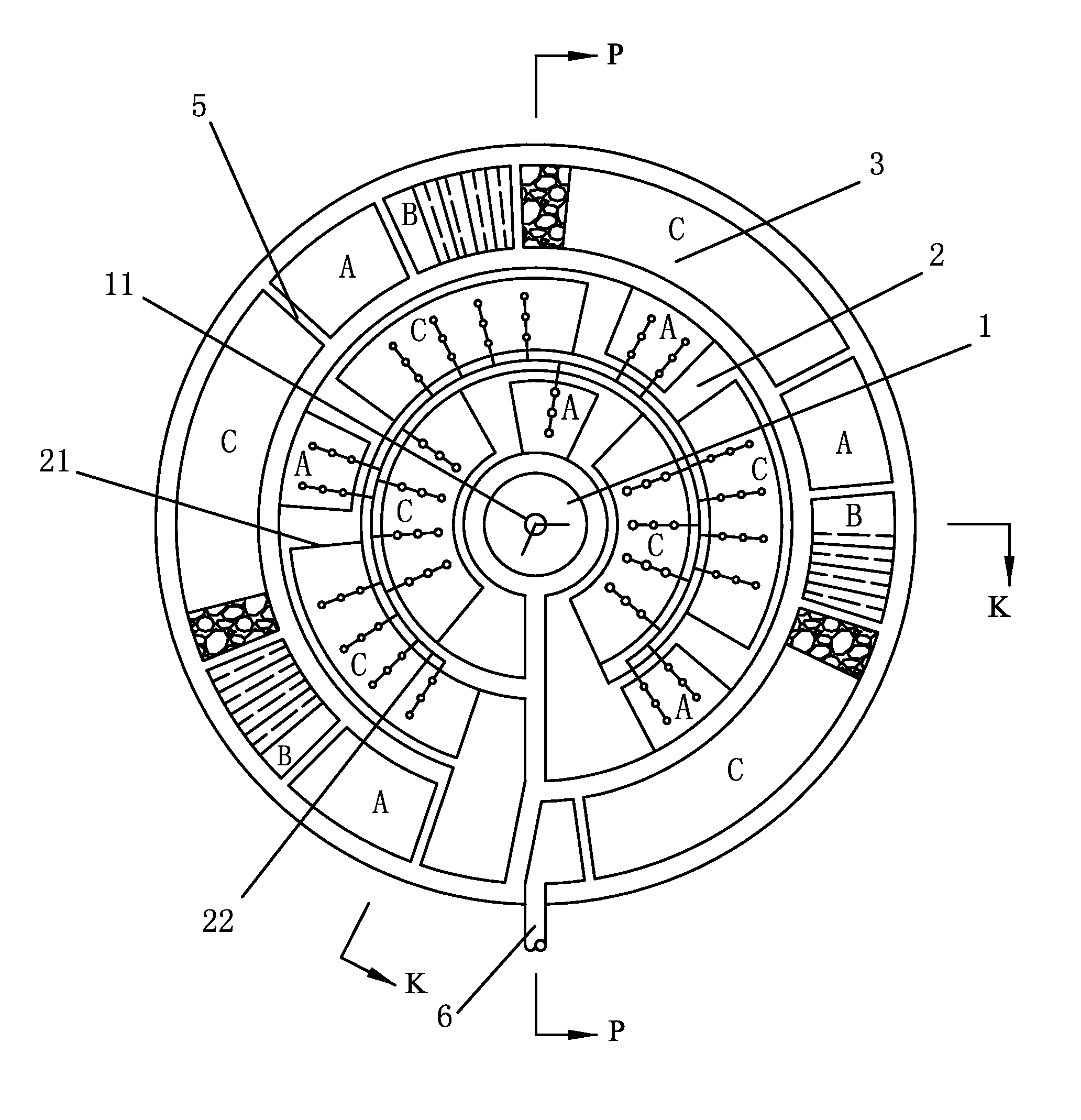

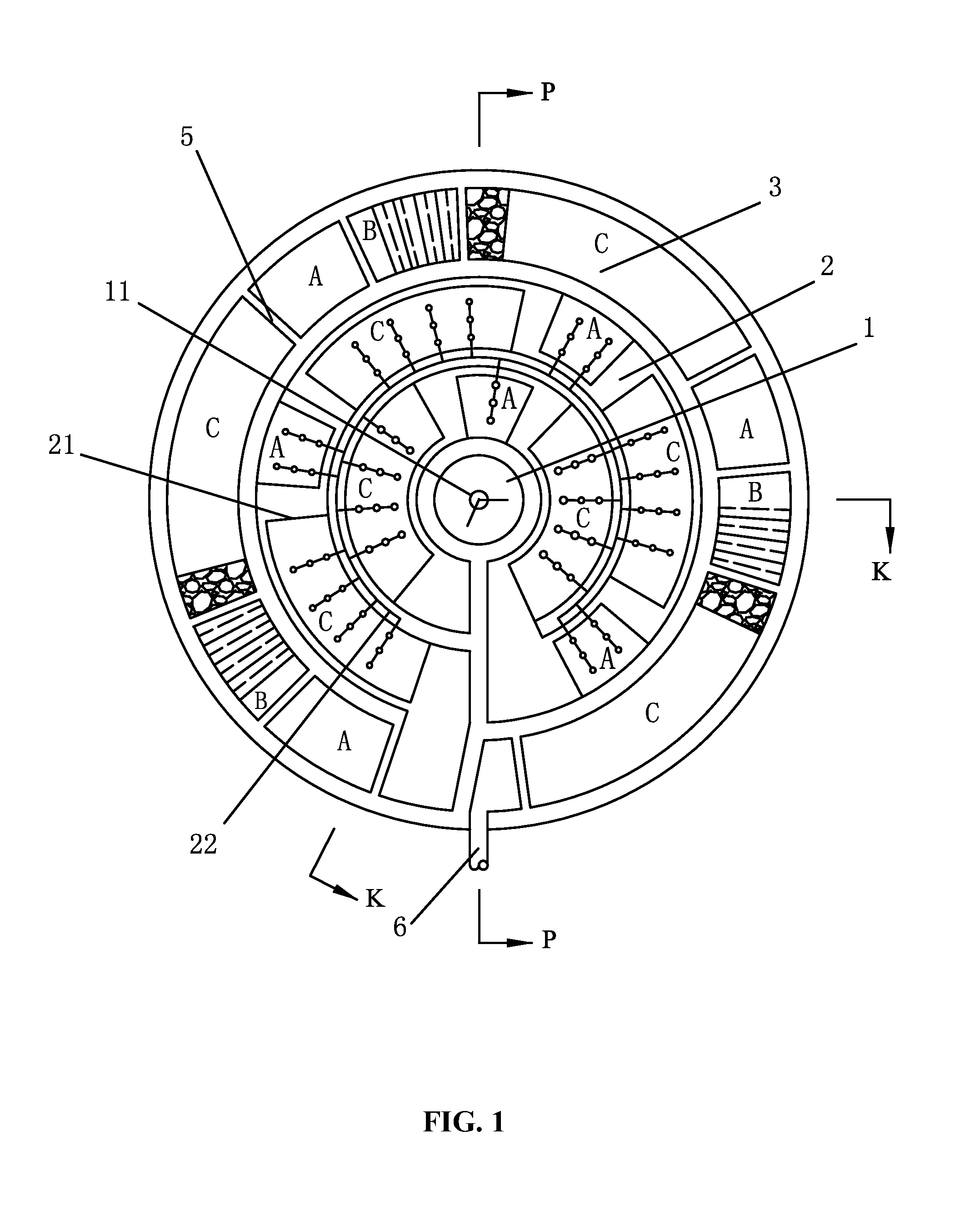

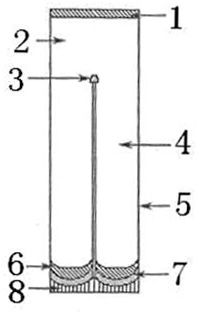

Reactor for sewage treatment

ActiveUS20140262999A1Improve denitrification efficiencyEasy dischargeTreatment using aerobic processesGeneral water supply conservationConstructed wetlandSewage

A reactor for sewage treatment including: an inner layer including a water distribution zone; a middle layer including a biological aerated filter, the biological aerated filer including a wall and a bottom including a water outlet; and an outer layer including an artificial wetland, the artificial wetland including a bottom including a water inlet. The water distribution zone, the biological aerated filter, and the artificial wetland are in the shape of a circle. The sewage is introduced into the water distribution zone via a water inlet pipe. The water distribution zone communicates with the biological aerated filter via a first overflow. The water outlet arranged on the bottom of the biological aerated filer is connected to the water inlet arranged on the bottom of the artificial wetland to allow the biological aerated filter to communicate with the artificial wetland.

Owner:CHONGQING UNIV

Washing machine and washing method thereof

InactiveUS20140201929A1Simplify the washing processSimple structureOther washing machinesDetergent compounding agentsProcess engineeringMedia layer

A washing machine and a washing method thereof comprises at least one washing tub for washing or containing water, and the tub is arranged with a washing medium layer which is a polymer adsorption layer. The present invention, depending on the washing medium layer arranged on the washing tub, is to handle the dirt on the clothes and in the washing water, to achieve the purpose of washing, which not only simplifies the washing procedure like other ordinary washing machines, but also greatly reduces the material cost and the manufacturing cost. In addition, the wearing to clothes is less serious during washing.

Owner:XEROS LTD

Washing machine and washing machine thereof

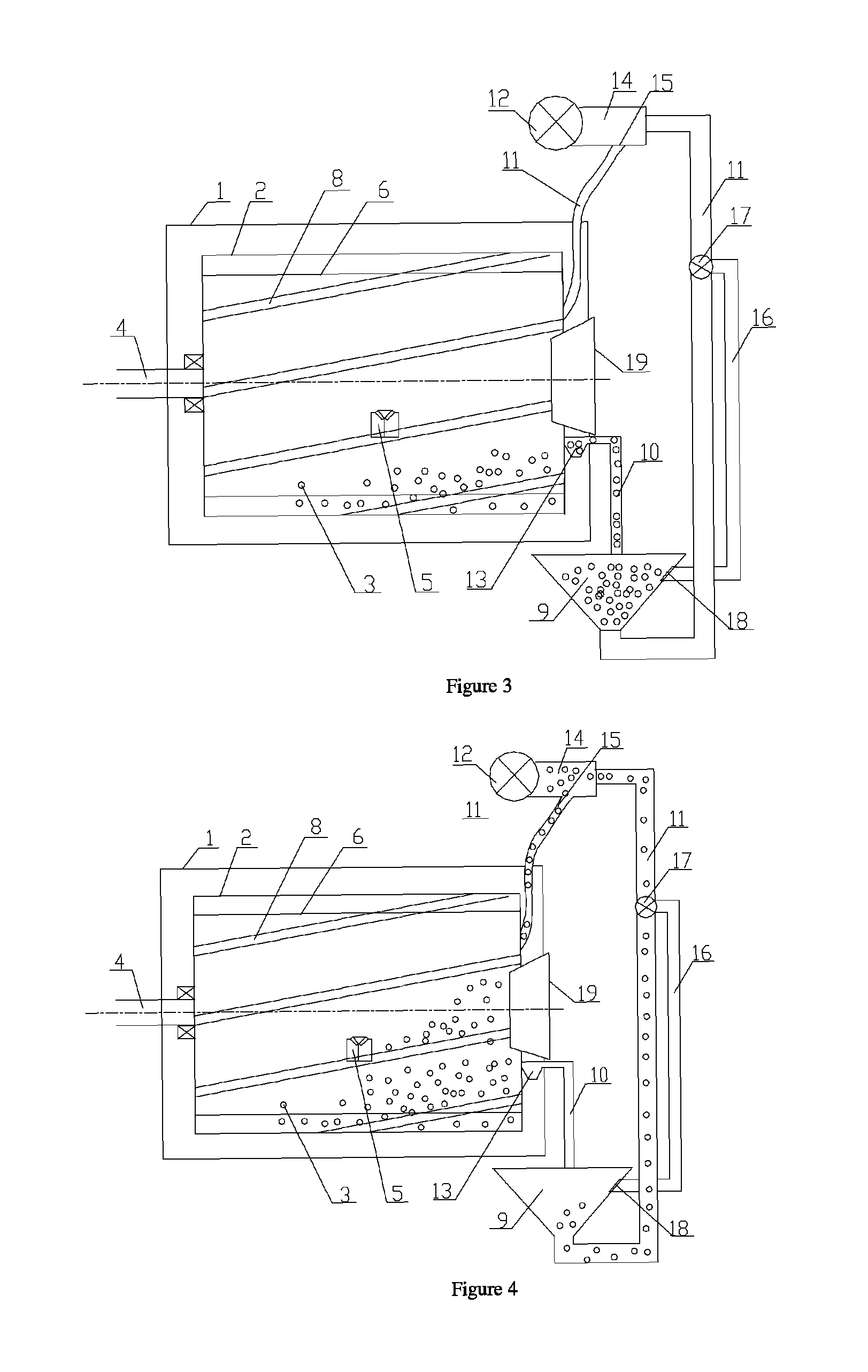

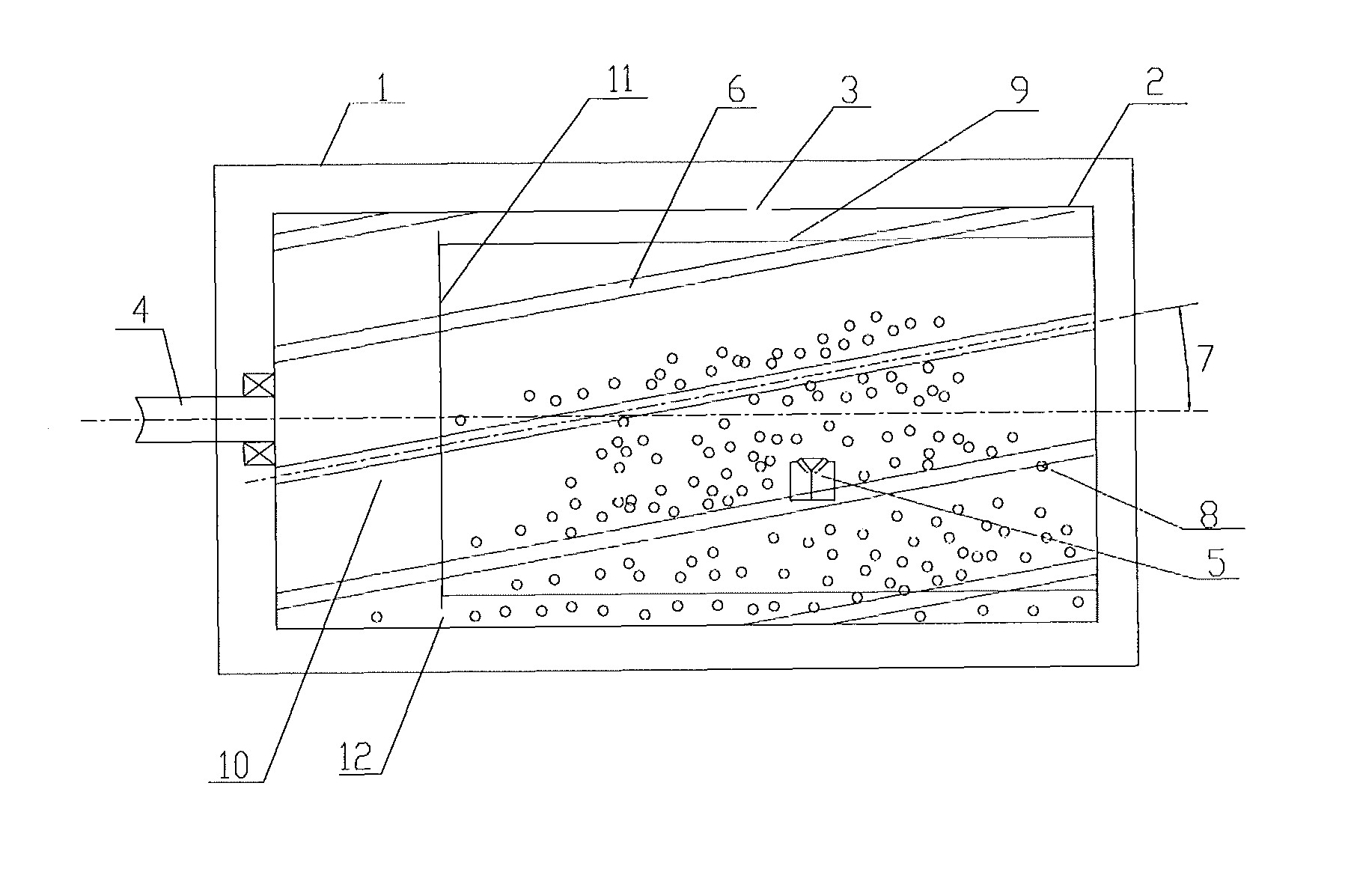

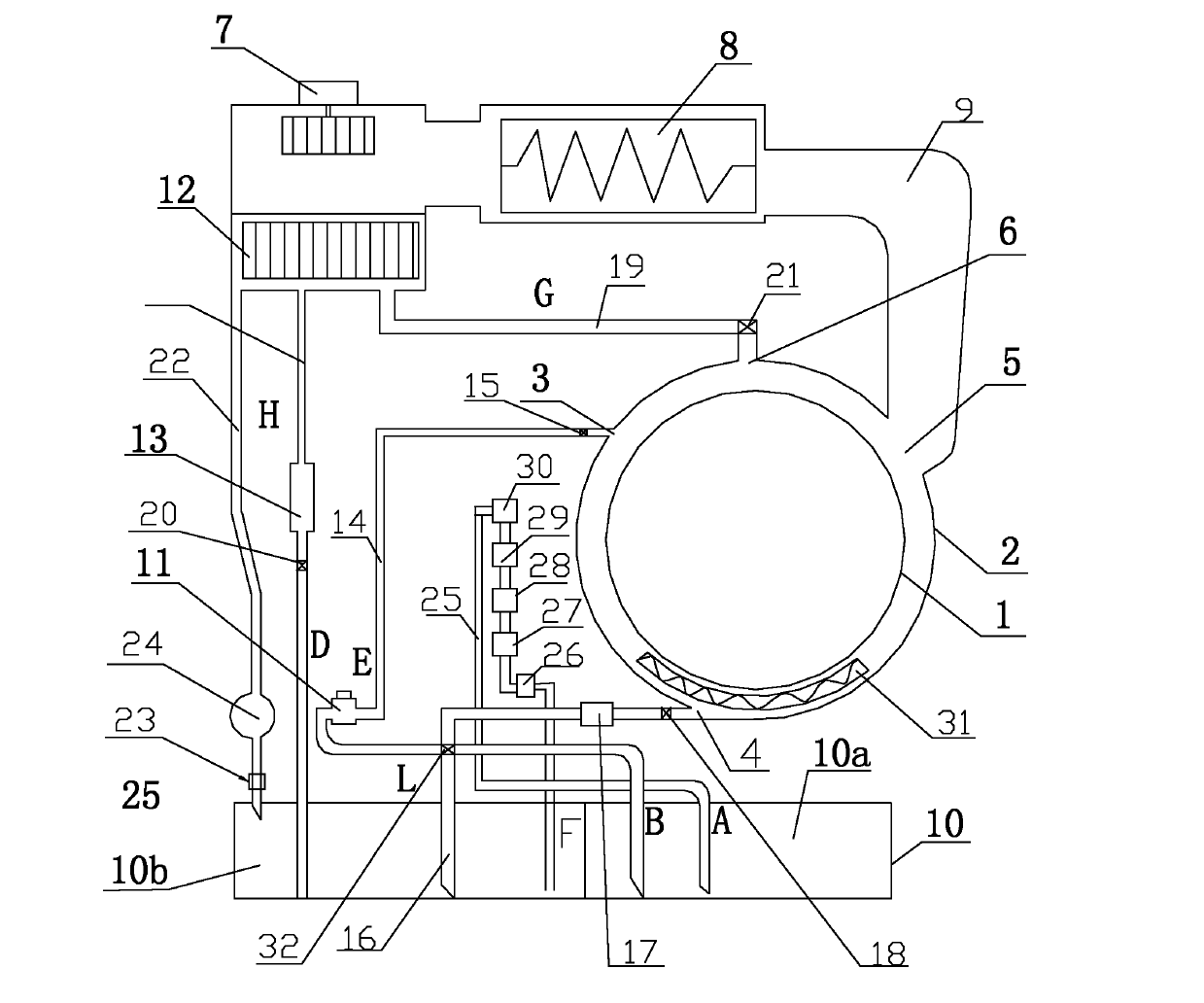

InactiveUS9487898B2Simplify the washing processImprove cleaning rateOther washing machinesWashing machine with receptaclesSolid particleMechanical engineering

A washing machine and washing method thereof comprises an inner tub, an outer tub and solid particles as washing medium. The inner tub, of which the inner wall is provided with lifting ribs protruding inward, rotates under the driving power of a driving device. Inside the washing machine, a storage tank for storing particles connects to the inner tub through a discharge channel for recycling particles and a feeding channel for putting in particles, and an air suction device is arranged on the feeding channel. Through alternate clockwise and counter-clockwise rotates of the inner tub, clothes and particles within are overturned in all directions, thus clothes and particles get better blended, and the cleaning rate gets improved. Meanwhile, putting-in and recycling particles through an air suction device is conducive to 100% recycling of particles.

Owner:XEROS LTD

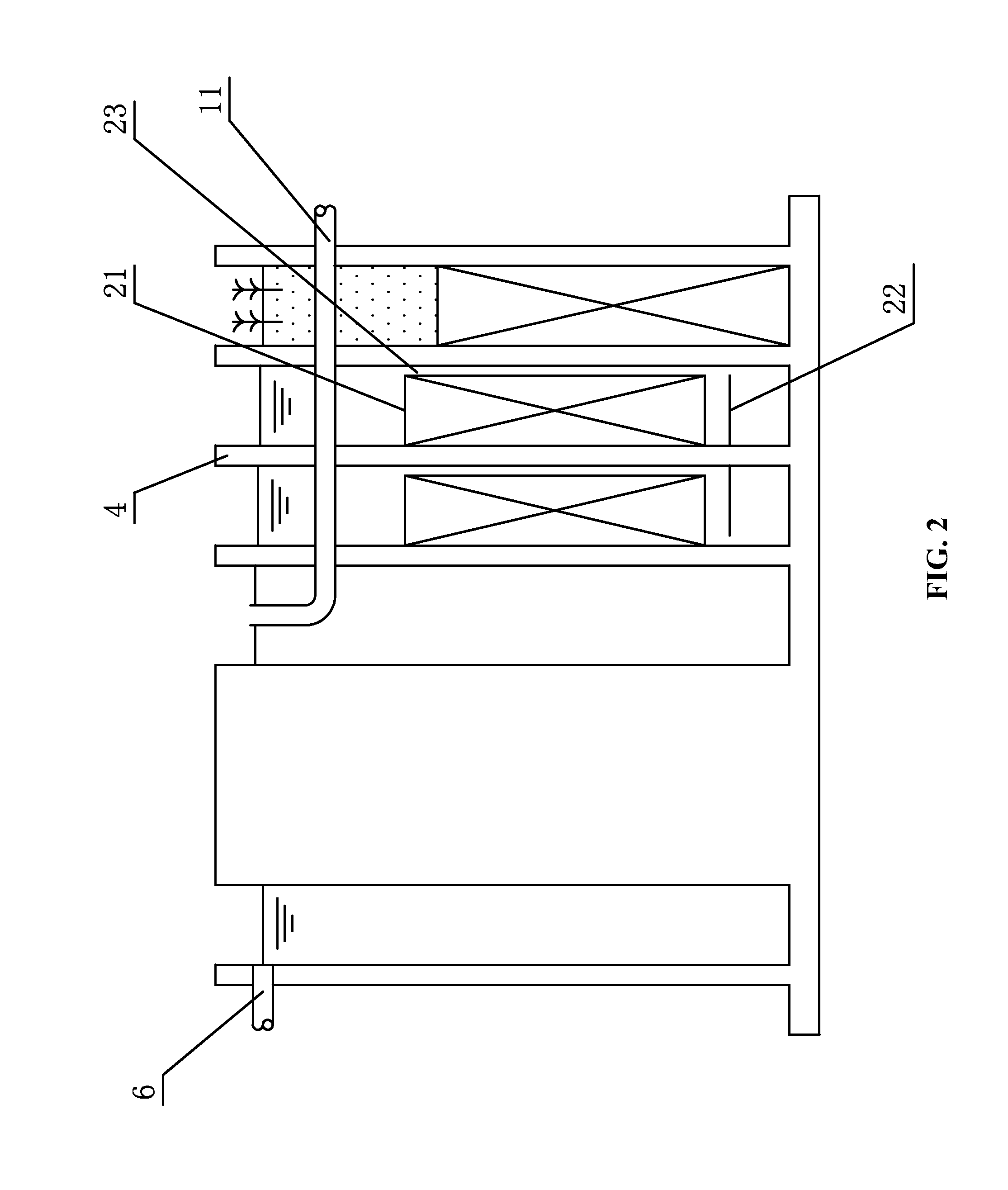

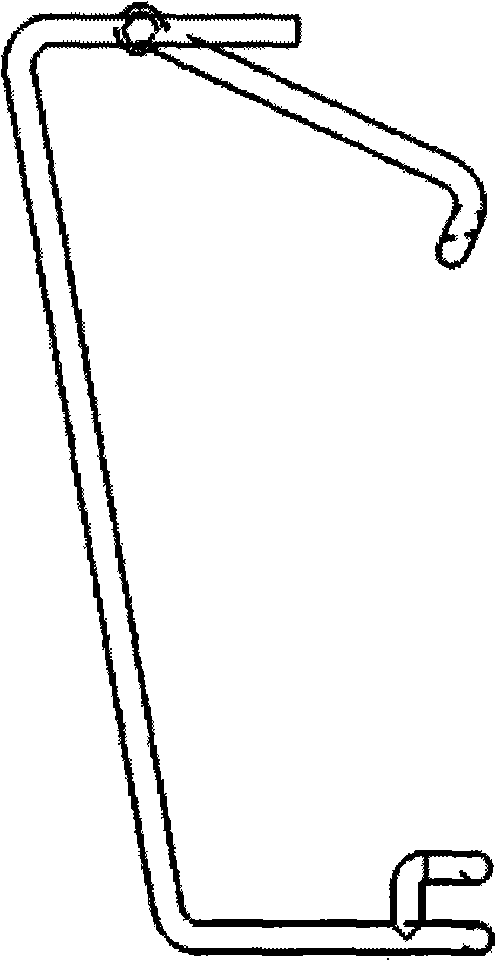

Washing machine and washing method

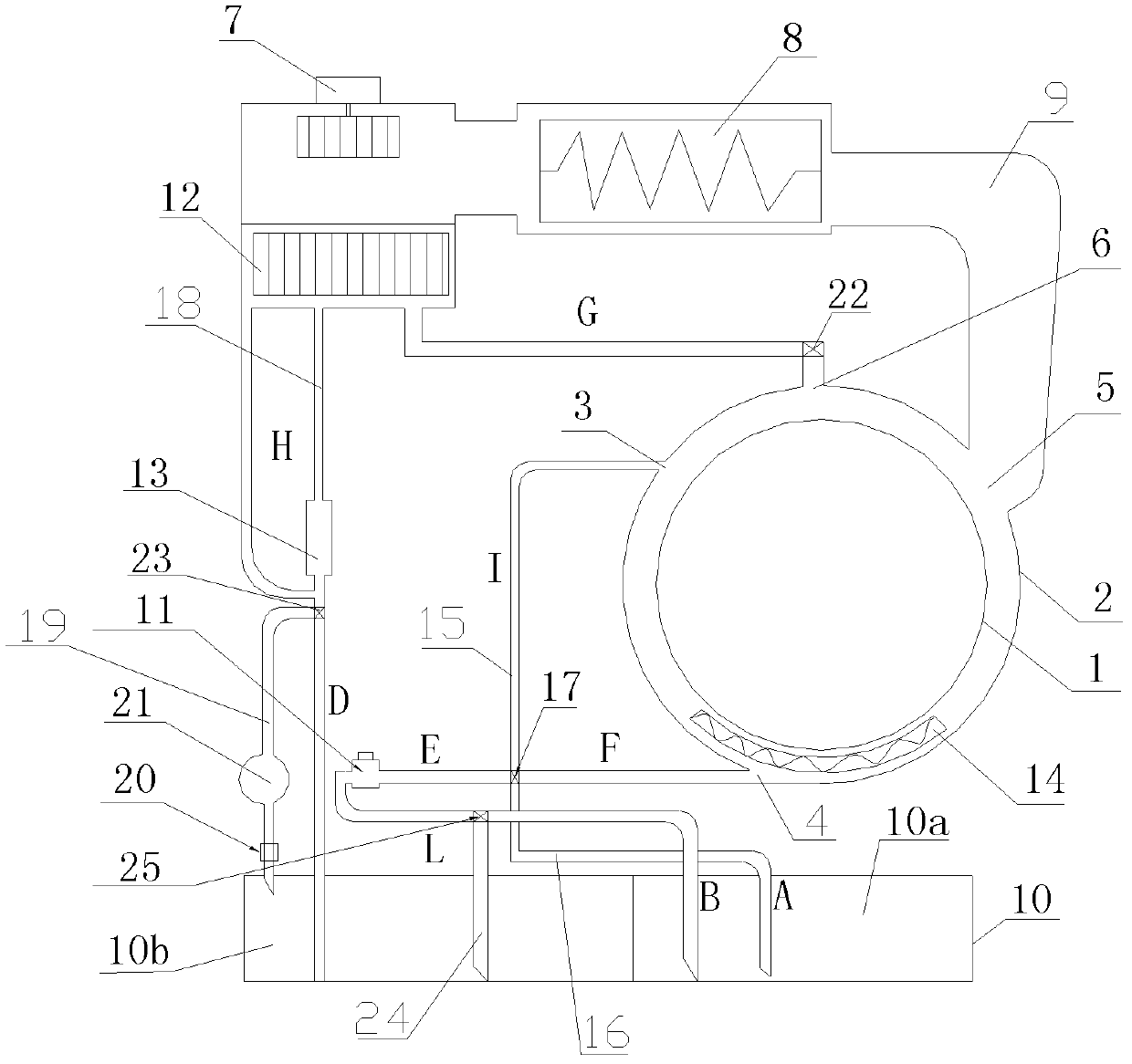

ActiveUS9410278B2Simple structureSimplify the washing processOther washing machinesTextiles and paperEngineeringSolid particle

A washing machine and a washing method, comprises an inner cylinder, an outer cylinder, and solid particles as washing medium. The inner cylinder is driven into rotation by a driver device. The inner cylinder has arranged on the inner wall thereof scraper blades that protrude inwards and are bent along the wall of the inner cylinder. The scraper blades drives the particles into obliquely upward or obliquely downward movements and flipping, thus allowing for more fully mixing clothes with the particles, for simplified washing process, while also for improved cleaning rate, and for facilitated recycling of the particles.

Owner:XEROS LTD

Washing machine and washing method

ActiveUS9404210B2Simple structureSimplify the washing processOther washing machinesTextiles and paperEngineeringSolid particle

A washing machine and a washing method, comprises an inner cylinder, an outer cylinder, and solid particles as a washing medium. The inner cylinder is driven into rotation by a driver unit. A side wall of the inner cylinder is spirally shaped and drives the particles into a spiral movement and flipping within the inner cylinder. When the inner cylinder is spinning, the screw thread drives the particles into flipping in all directions, back-and-forth and up-and-down, within the inner cylinder, thus allowing for increased mixing between clothes and the particles, for simplified washing process while also for improved cleaning rate, and for facilitated recycling of the particles.

Owner:XEROS LTD

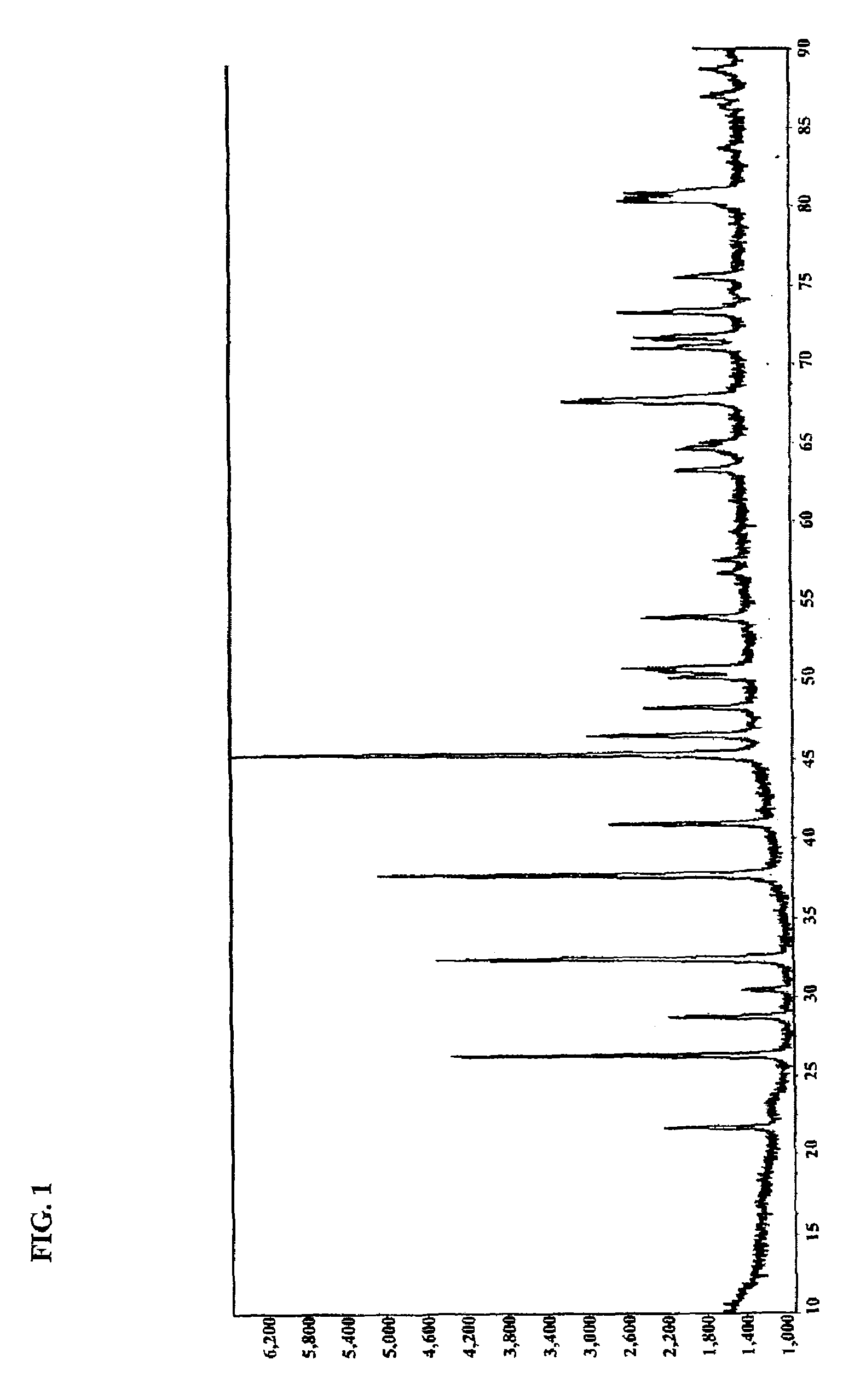

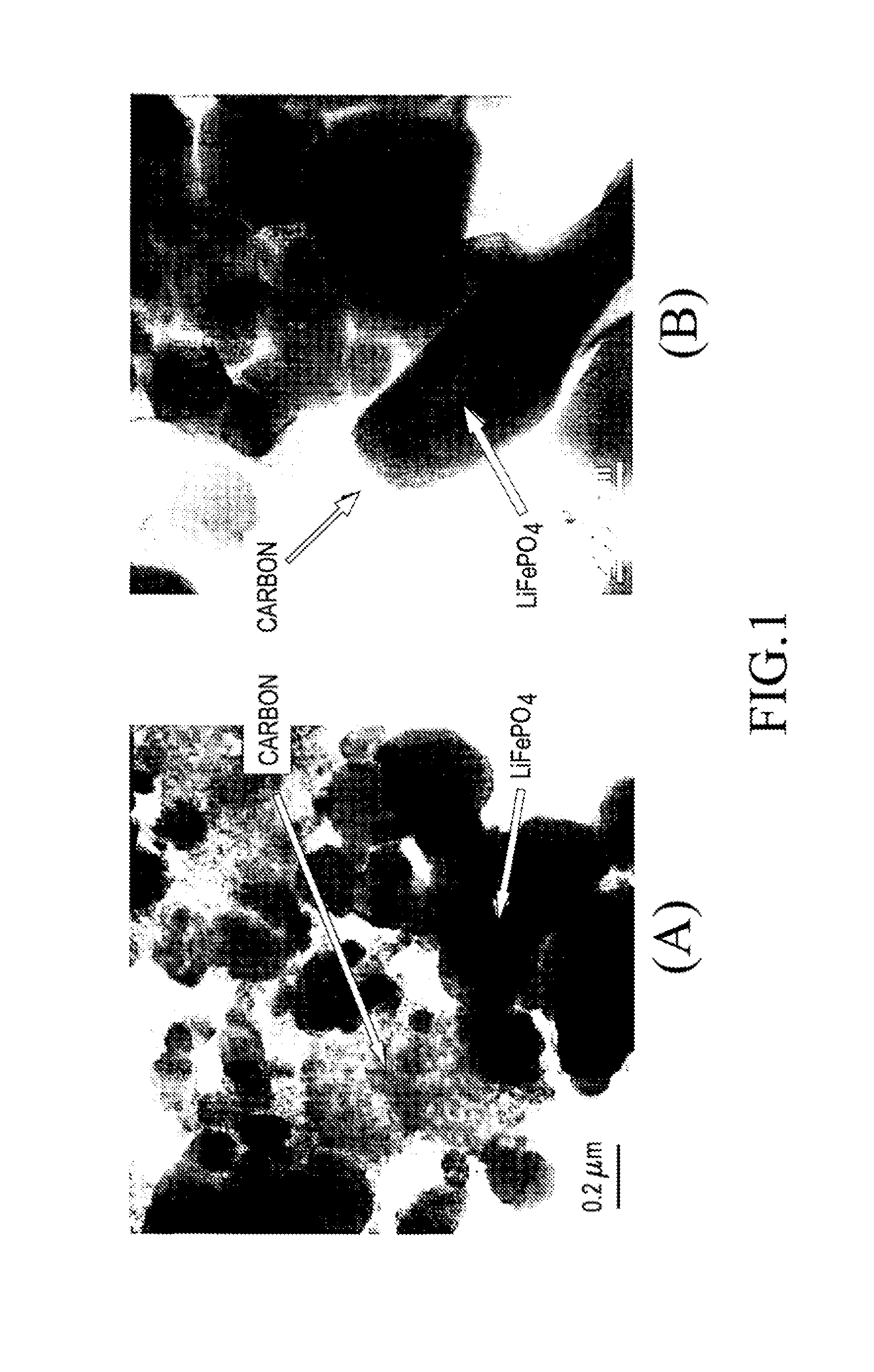

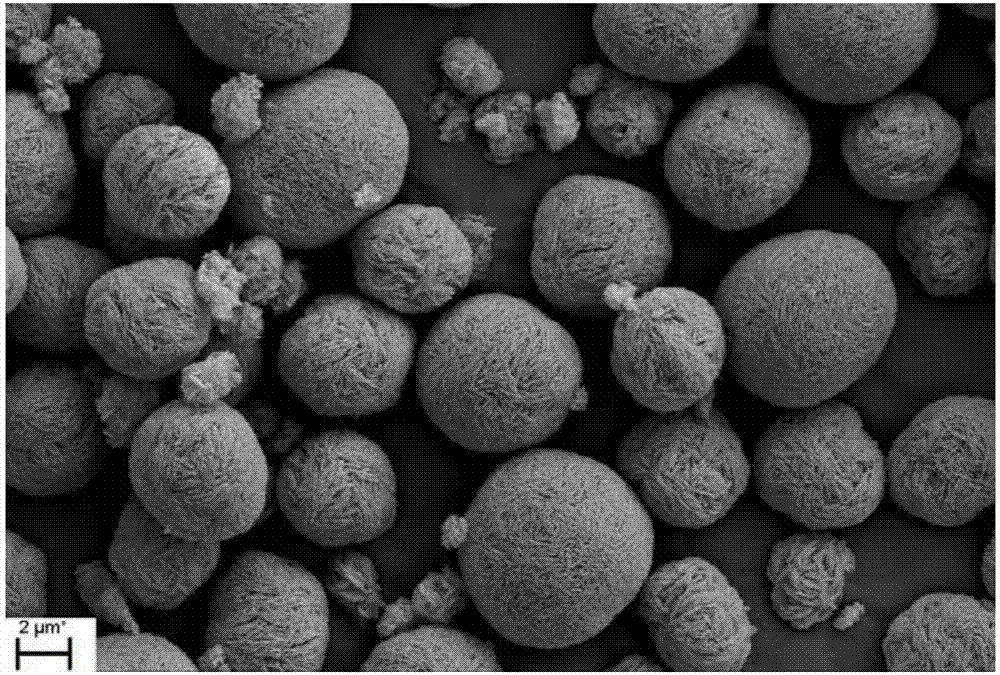

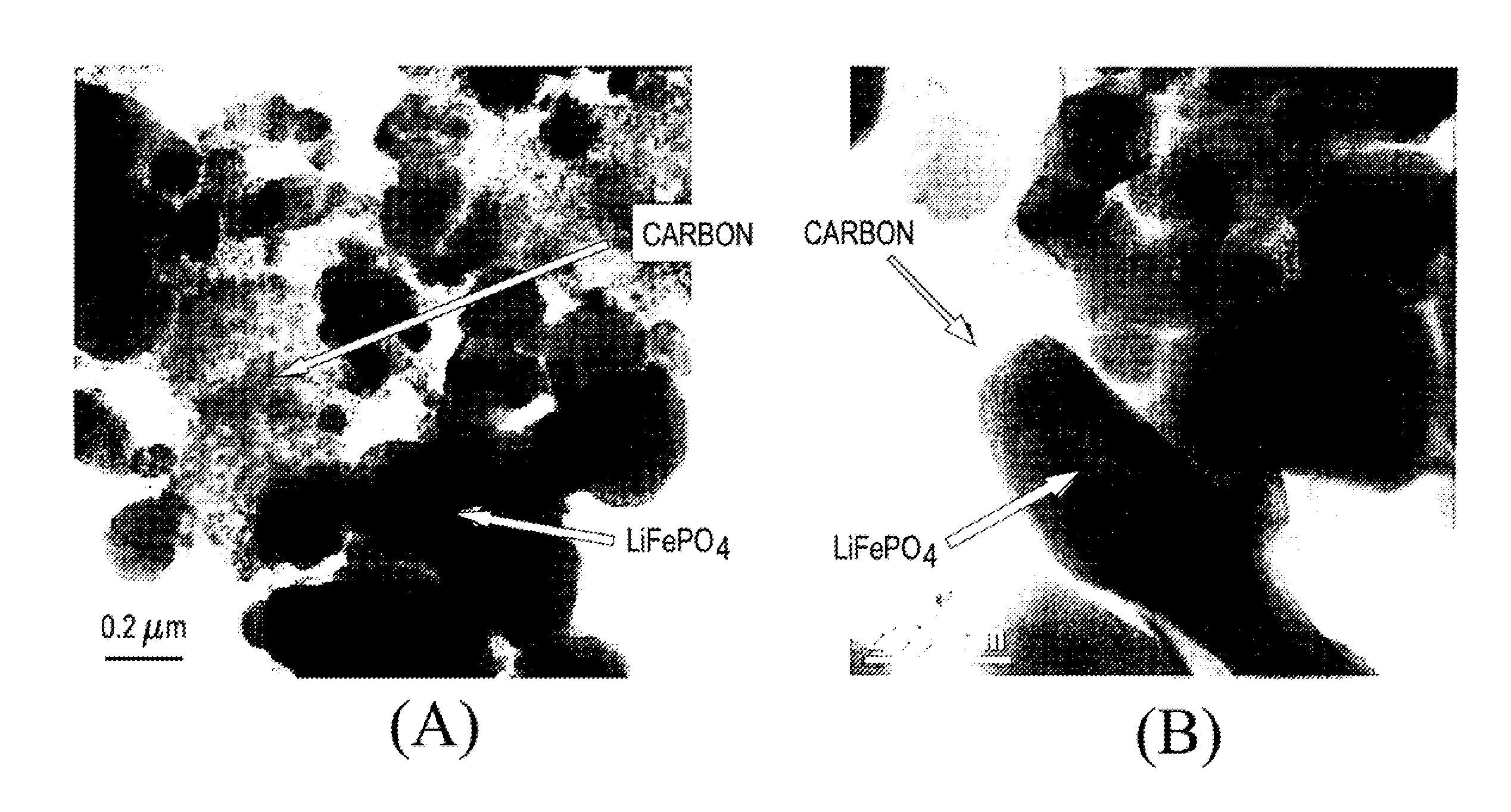

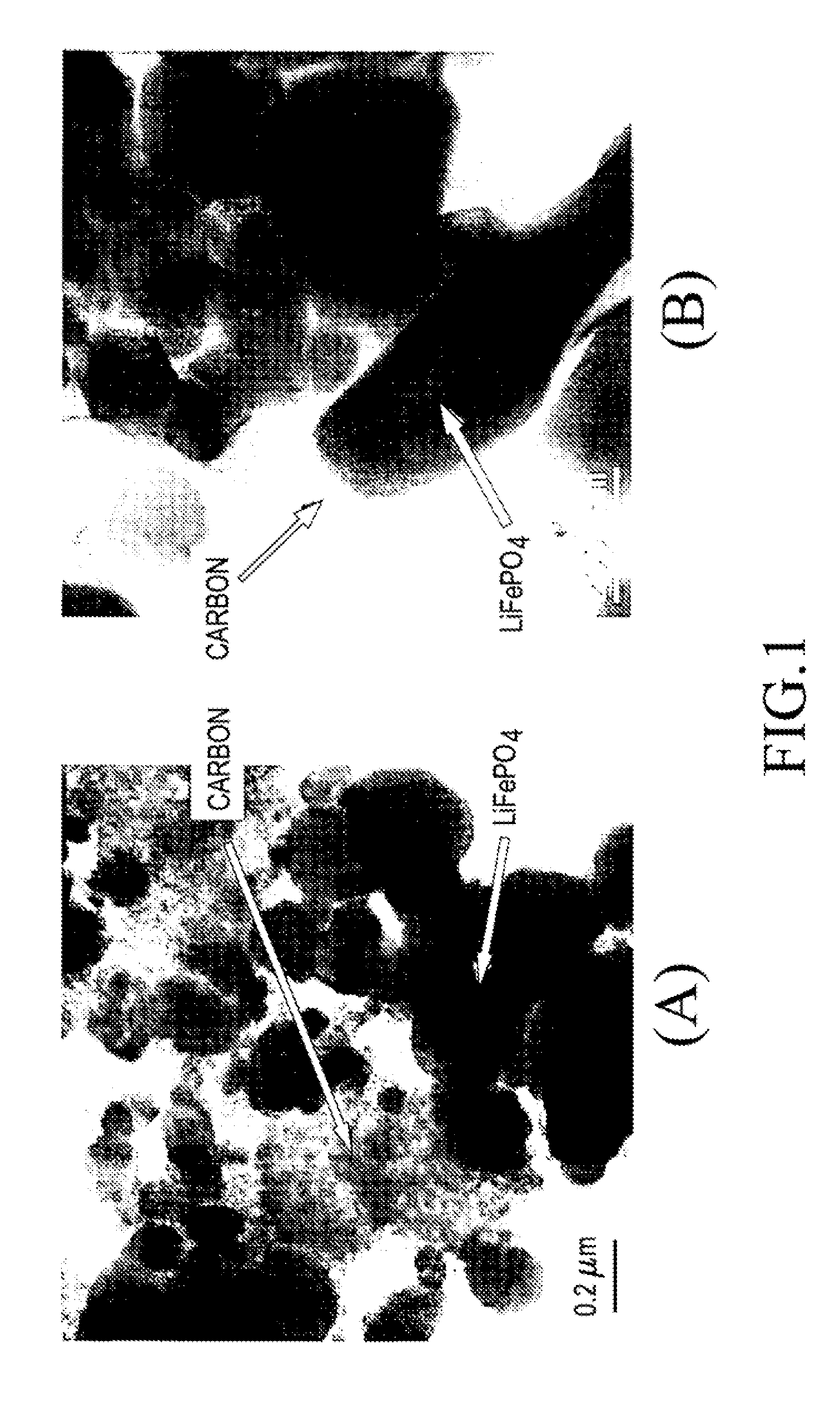

Lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

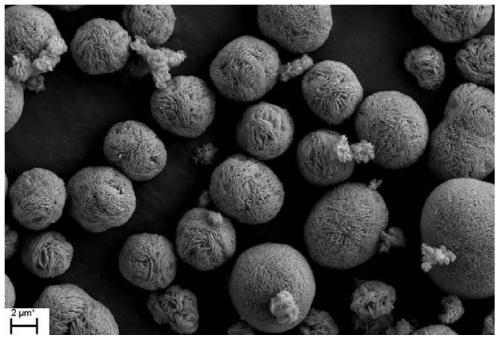

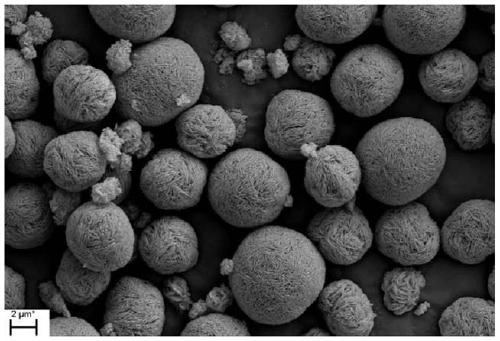

ActiveUS20130029226A1Improve conductivityAvoid separationFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithium iron phosphatePhysical chemistry

Disclosed is lithium iron phosphate having an olivine crystal structure wherein carbon (C) is coated on particle surfaces of the lithium iron phosphate, wherein, when a powder of the lithium iron phosphate is dispersed in water, water is removed from the resulting dispersion and the resulting lithium iron phosphate residue is quantitatively analyzed, a ratio of the carbon-released lithium iron phosphate with respect to the total weight of the carbon-coated lithium iron phosphate is 0.005% by weight or less. Advantageously, the olivine-type lithium iron phosphate is not readily separated through uniform thin film coating on the surface of the lithium iron phosphate and exhibits superior conductivity and density, since carbon is coated on particle surfaces of lithium iron phosphate in a state in which the amount of carbon released in water is considerably small.

Owner:LG ENERGY SOLUTION LTD

Preparation of nano barium titanate powder

InactiveCN101348938APromote crystallizationImprove purityPolycrystalline material growthFrom normal temperature solutionsBarium titanateFiltration

The invention relates to a preparation method for nano barium titanate powder. The method comprises the following steps: nano titanium dioxide (TiO2), tetrabutyl titanate (TiC16H36O4) and barium hydroxide (Ba(OH)2.8H2O) are takes as raw materials, and ammonia water is taken as a precipitating agent; moreover, an appropriate surface-active agent or organic solvent is selected to adjust reaction medium so as to carry out reaction at a temperature between 150 and 300 DEG C for 4 to 24 hours with the filling degree of between 60 and 90 percent and the Ba to Ti molar ratio of between 1.1 and 3.0; and finally, after the reactants are cooled down to room temperature, filtration, washing and drying are carried out so as to prepare the nano barium titanate powder. The technique can simplify technical steps, and has easily controlled technical parameters; moreover, the prepared powder has the characteristics of complete crystallization, controllable grain diameter range of between 50 and 90nm, narrow granule distribution range, high purity, excellent dispersivity, high sintering activity, and the like; because the adopted raw materials do not contain common ions such as Cl-, K+ and N+, the preparation method can simplify washing process and increase the purity of the powder, thereby reducing the adverse influence on material properties caused by impurity ions and ensuring the quality of high-end products.

Owner:UNIV OF JINAN

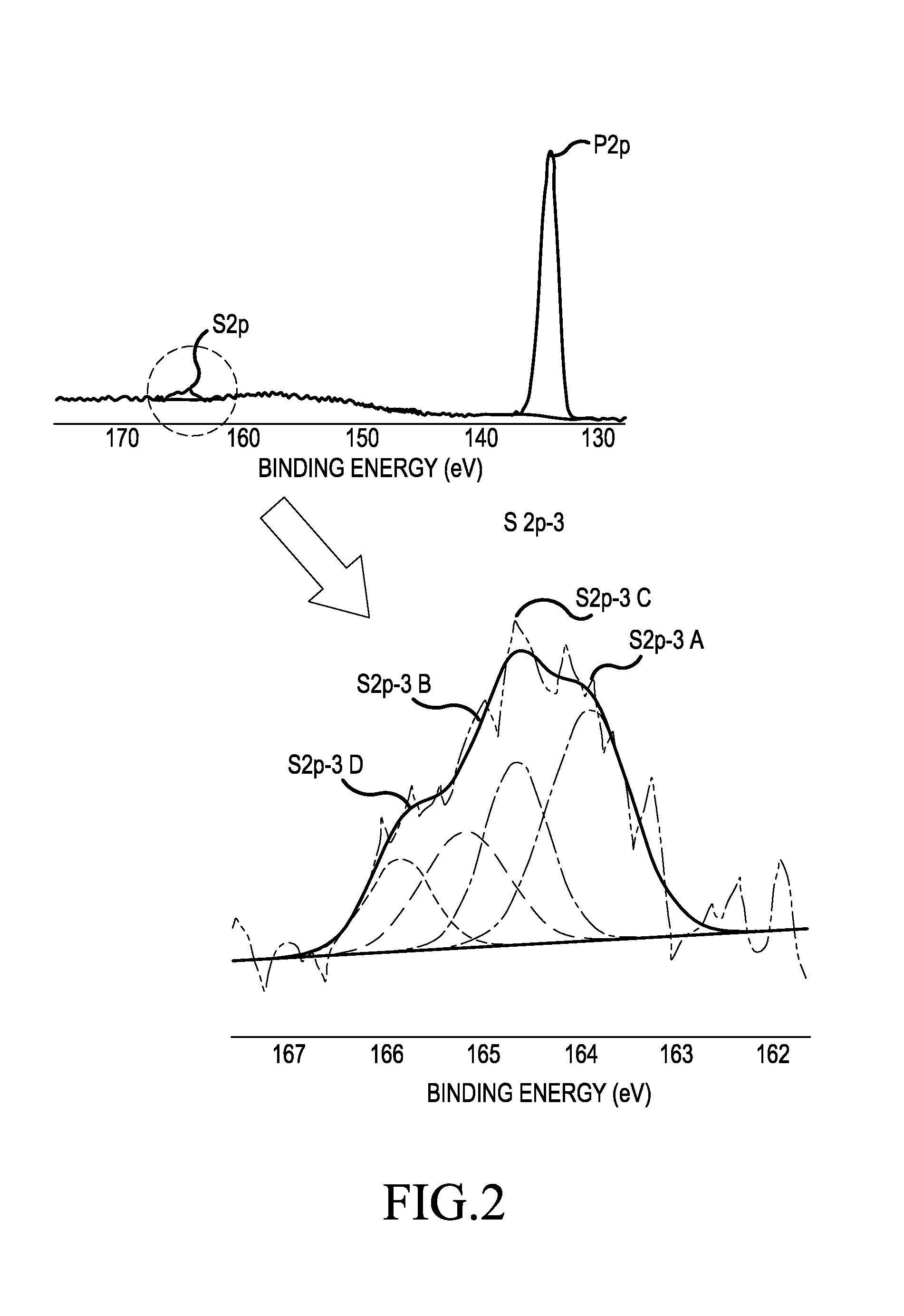

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130216902A1Improve conductivityAvoid separationFinal product manufactureOperating modesChemical LinkageLithium iron phosphate

Disclosed is a lithium iron phosphate with an olivine crystal structure wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the surface of the lithium iron phosphate by chemical bonding via a heterogeneous element other than carbon. Li1+aFe1−xMx(PO4−b)Xb (1) (wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

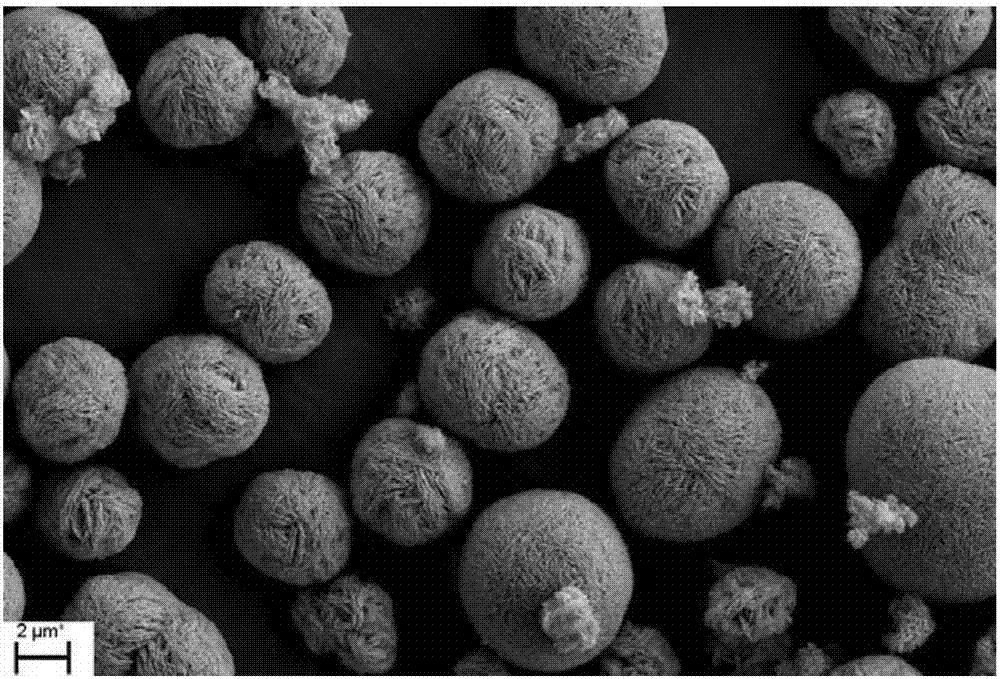

Method for reducing sulfur content of nickel cobalt aluminum precursor

ActiveCN107459069ALow costSimplify the washing processNickel compoundsSulfate radicalsLithium hydroxide

The invention discloses a method for reducing the sulfur content of a nickel cobalt aluminum precursor. Sulfate radicals adsorbed at the surface of the nickel cobalt aluminum precursor can be removed by traditional alkali liquid such as sodium hydroxide and lithium hydrate, but the removal effect on the sulfate radicals in the nickel cobalt aluminum precursor crystalline structure is poor; the requirement of a power battery positive electrode material on the impurity sulfur content is different to meet. The method is characterized in that a nickel cobalt aluminum mixed metal solution, sodium hydroxide and ammonium hydroxide are added into a reaction kettle at the same time; the nickel cobalt aluminum precursor is obtained through controlling the reaction conditions; after the mother liquid removal, the nickel cobalt aluminum precursor is transferred into a washing kettle to be subjected to sizing washing and water washing; then, drying and sieving are performed to obtain the nickel cobalt aluminum precursor with the sulfur content being smaller than or equal to 1000ppm. The method has the advantages that the washing solution is low in cost; the washing process is simple; the operability is high; the efficiency is high; no destroy effect is generated on the microtopography of the nickel cobalt aluminum precursor; the method belongs to a process applicable to industrial production; practical values are realized.

Owner:ZHEJIANG HUAYOU COBALT +1

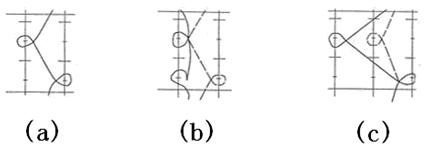

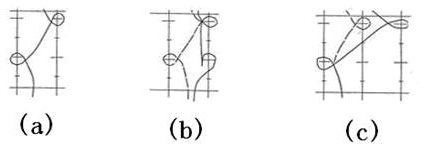

Weaving method for seamless non-snagging warp-knitted panty stockings

InactiveCN102517789AThree-dimensional patternProduce three-dimensional pattern effectWarp knittingEngineeringCrotch

The invention relates to a weaving method for seamless non-snagging warp-knitted panty stockings. The seamless non-snagging warp-knitted panty stockings comprise a panty waist, panty bodies, a stocking crotch, stocking legs, front-rear pieces joints, stocking points, stocking heads and partitions and are formed by weaving elastic yarn materials; the stocking waist, the stocking bodies, the stocking legs, the stocking points and the stocking heads are formed in a way of a circular weaving that the stocking heads are woven to the stocking waist and the stocking waist is woven to the stocking heads by using a unique weaving rule of the warp weaving; front and rear pieces at the stocking crotch and the stocking heads are sewn and organized to form two longitudinal lines and eight columns; the partitions are formed by weaving mutually-clasped chains of the front piece and the rear piece; and the partitions are sheared off after the panty stocking textile is unloaded from the machine and then a pair of complete panty stockings is formed. The panty stockings are formed by weaving on a double needle bar by using a unique weaving rule of the warp weaving. The weaving method is finished by one work procedure without additional sewing; joints which easily scratch or rub the skin are avoided; due to the application of elastic yarns, the panty stockings have ideal fitness; and due to the use of a mesh structure, the panty stockings have favorable permeability.

Owner:王敏其

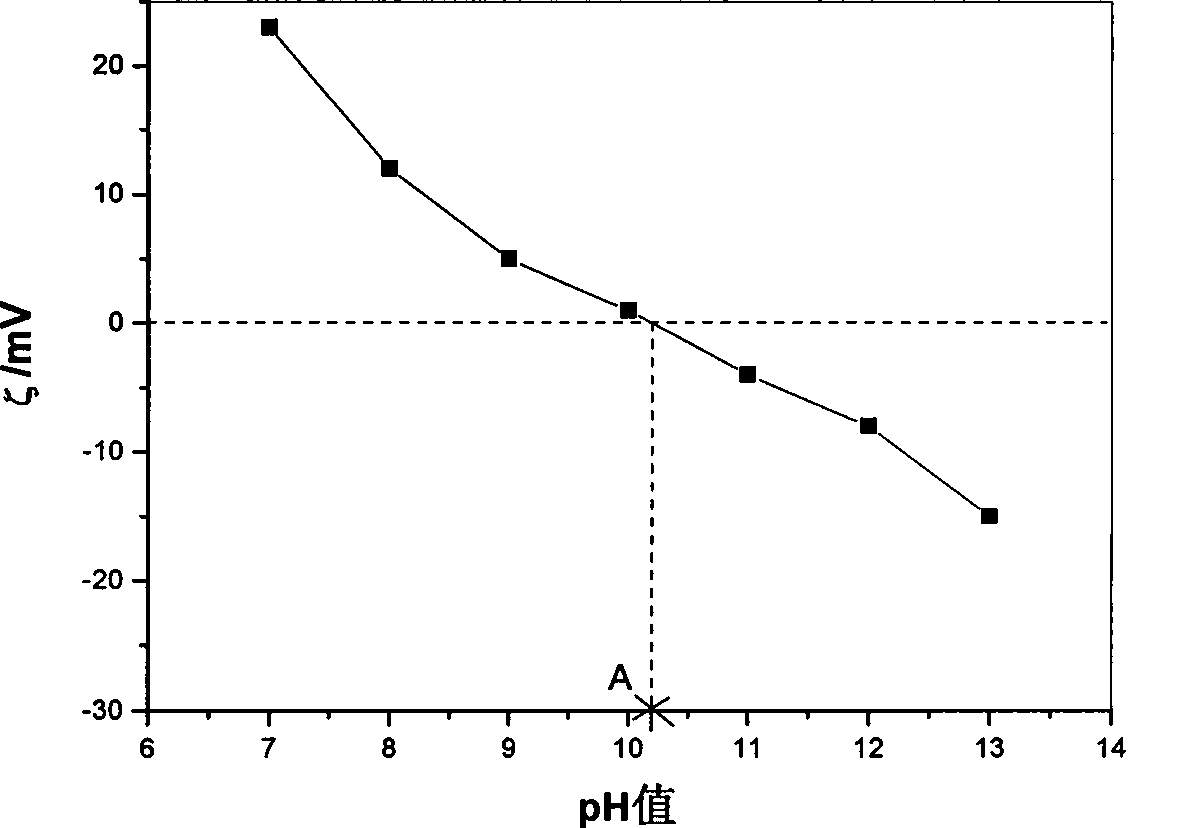

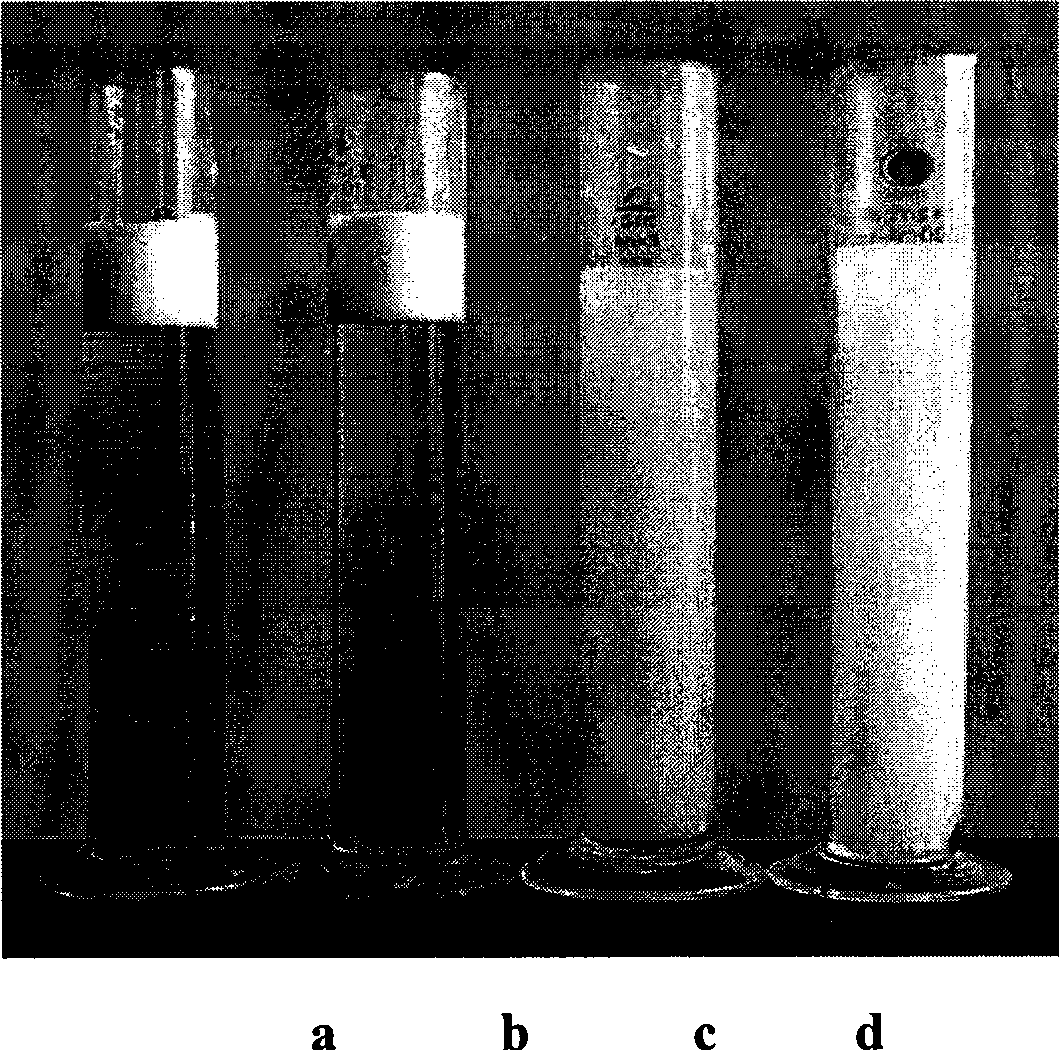

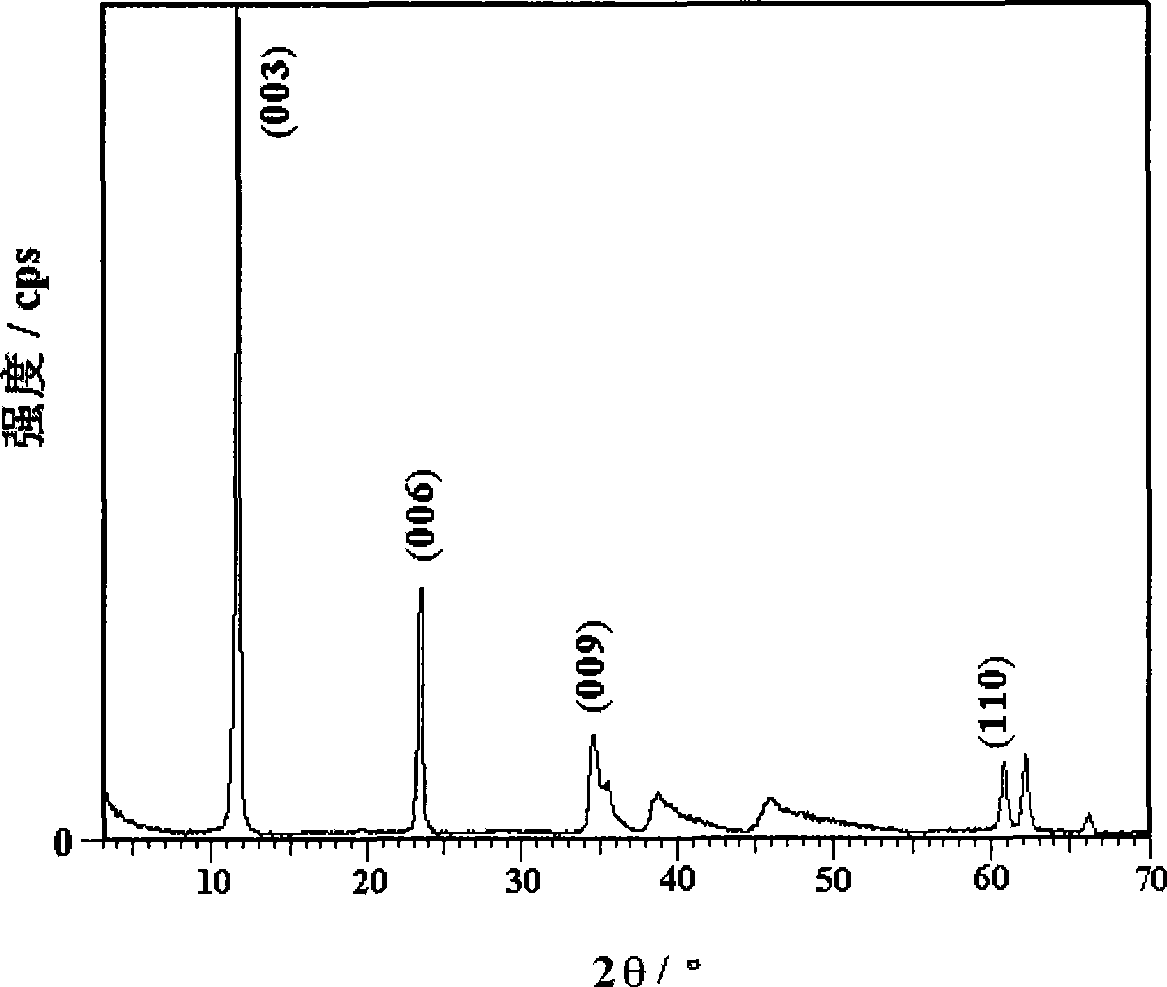

Method for in situ modification by isoelectric point layered composite metal hydroxides

InactiveCN101503182AAvoid reunionEasy to modifyOxide/hydroxide preparationAluminium oxides/hydroxidesInorganic particleFiltration

The invention provides a technology for carrying out surface in situ modification on clad composite metal hydroxid by using isoelectric points. After the clad composite metal hydroxid is prepared for reaction, the system PH value is adjusted to be lower than the isoelectric points of particles before washing, and then modifying agent is directly added for in situ modification so as to lead modifying agent molecules and surface groups of inorganic particles to have physico chemical adsorption and cover on the surface, thus achieving good modification effect. After modification, products can quickly float on the water, so that the process of separation and filtration can be simplified. The method not only effectively avoids ion glomeration, but also greatly simplifies the washing process, thus reducing water consumption when in washing.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for purifying waste water and recovering waste materials on line in electroplating and chemical plating processes

ActiveCN101717136AReduce pollutionQuality assuranceWater/sewage treatment by magnetic/electric fieldsWaste water treatment from metallurgical processCapacitanceProduction line

The invention provides a method for purifying waste water and recovering waste materials on line in electroplating and chemical plating processes. The method comprises the following steps of: directly arranging a capacitance deionizer in a water washing device on a production line to adsorb various negative ions and positive ions in waste water during charging a battery so as to purify the waste water; and then releasing and recovering waste materials through electrode discharge so as to realize zero release of pollutants. The invention ensures that the capacitance deionization method is suitable for the manufacturing processes of various electroplating or chemical plating products through the optimization of process parameters. Through on-line purification and recycle of washing water, the burden of the traditional waste water treatment system is obviously reduced, meanwhile, the quality of plating pieces is guaranteed because the water quality of the washing water is obviously improved, and the classified recovery of waste materials can be achieved. The method can also obviously reduce the COD in the waste water and has wide application prospect in the fields of electroplating and chemical plating.

Owner:TANTZ ENVIRONMENTAL TECH

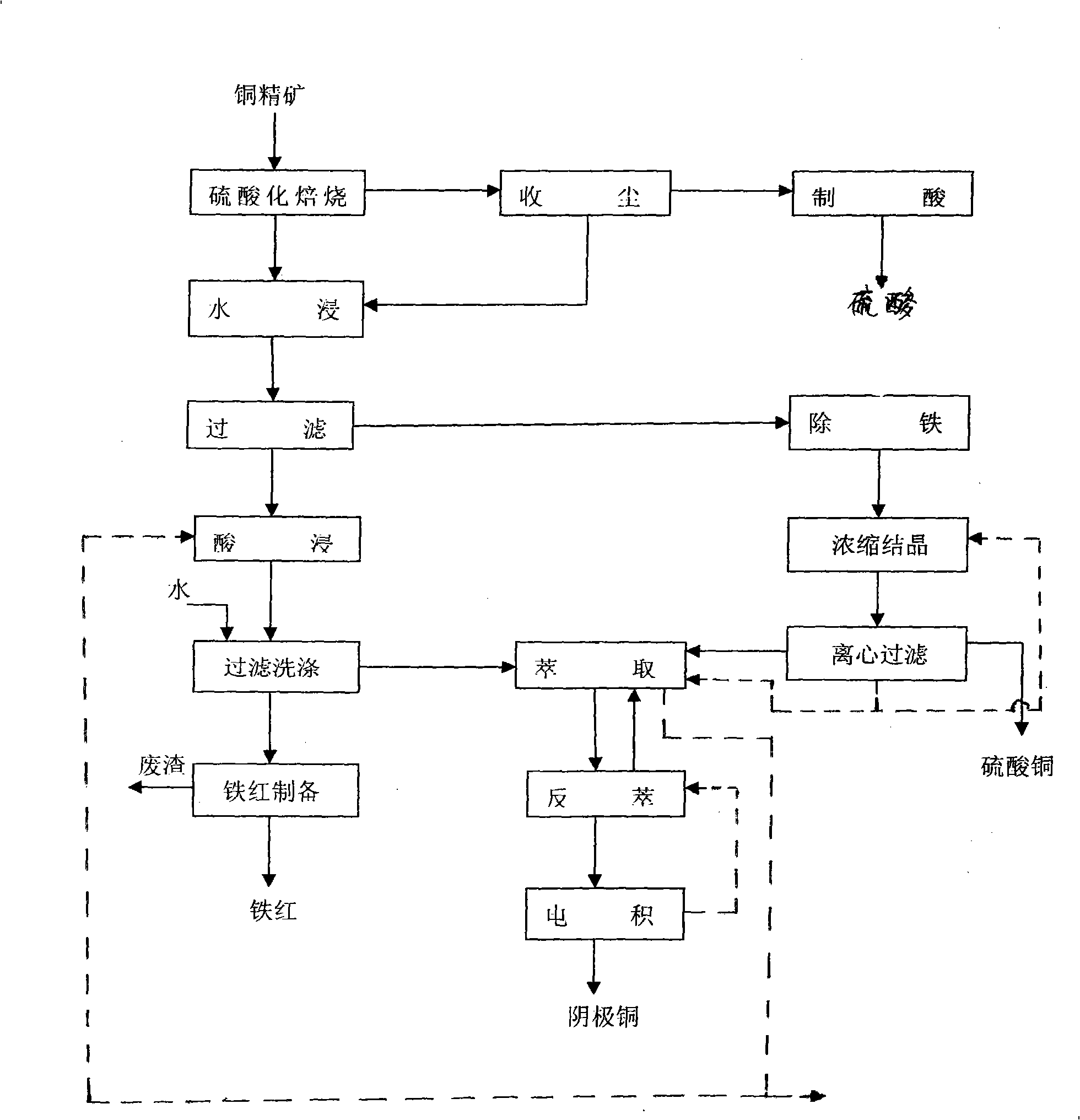

Method for directly preparing copper sulfate and cathode copper from copper ore concentrate

ActiveCN101328542AGuaranteed leaching effectSimplify the washing processRotary drum furnacesCrucible furnacesSide productBrown iron oxide

The invention relates to a method for directly preparing bluestone and cathode copper from copper concentrate. The method orderly comprises the following technological steps: sulphating roasting, water immersion, filtration, acid dipping, filtration washing, extraction, back extraction, electrodeposition and the circular utilization of local working procedures; and when products of bluestone and electrolytic copper with high purity are obtained, side products such as sulphuric acid, iron oxide red and waste residues are simultaneously generated. The method of the invention has the characteristics of low production cost, strong material adaptability, high working efficiency, low investment, simple operation, high utilization rate of copper, diversified products and easy industrialized production, etc., so that the method is suitable to exploit and apply low-grade copper ores.

Owner:ZIJIN MINING GROUP

A kind of method for reducing sulfur content of nickel-cobalt-aluminum precursor

ActiveCN107459069BLow costSimplify the washing processNickel compoundsSulfate radicalsLithium hydroxide

The invention discloses a method for reducing the sulfur content of a nickel cobalt aluminum precursor. Sulfate radicals adsorbed at the surface of the nickel cobalt aluminum precursor can be removed by traditional alkali liquid such as sodium hydroxide and lithium hydrate, but the removal effect on the sulfate radicals in the nickel cobalt aluminum precursor crystalline structure is poor; the requirement of a power battery positive electrode material on the impurity sulfur content is different to meet. The method is characterized in that a nickel cobalt aluminum mixed metal solution, sodium hydroxide and ammonium hydroxide are added into a reaction kettle at the same time; the nickel cobalt aluminum precursor is obtained through controlling the reaction conditions; after the mother liquid removal, the nickel cobalt aluminum precursor is transferred into a washing kettle to be subjected to sizing washing and water washing; then, drying and sieving are performed to obtain the nickel cobalt aluminum precursor with the sulfur content being smaller than or equal to 1000ppm. The method has the advantages that the washing solution is low in cost; the washing process is simple; the operability is high; the efficiency is high; no destroy effect is generated on the microtopography of the nickel cobalt aluminum precursor; the method belongs to a process applicable to industrial production; practical values are realized.

Owner:ZHEJIANG HUAYOU COBALT +1

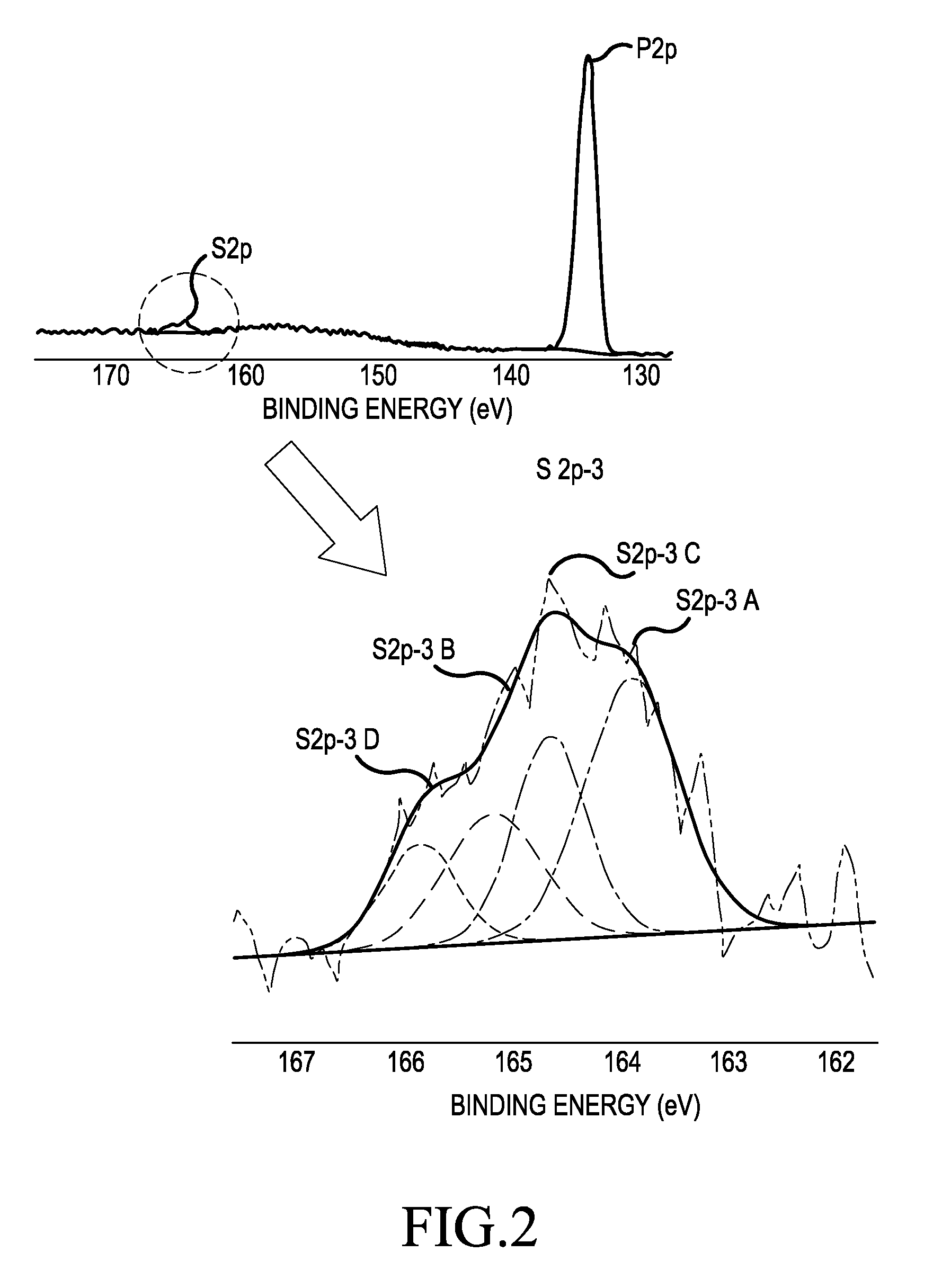

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130022866A1Improve conductivityIncrease electrode densityPhosphatesFinal product manufactureLithium iron phosphateSulfur

Disclosed is lithium iron phosphate having an olivine crystal structure, wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the particle surface of the lithium iron phosphate containing a predetermined amount of sulfur (S).Li1+aFe1−xMx(PO4−b)Xb (1)(wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

Household dry cleaning device, dry cleaning method and dry cleaning solvent recovery method

ActiveCN103306110AEasy and fast recyclingGood for popular useDry-cleaning apparatusTextiles and paperRecovery methodCleaning methods

The invention relates to a household dry cleaning device, a dry cleaning method and a dry cleaning solvent recovery method. A used dry cleaning solvent sequentially passes through a plurality of stages of filtering units, which are connected in series, to be filtered stage by stage so as to reach the standard of cleaning clothes, thereby circularly recovering and recycling the solvent. According to the invention, purification and recovery processing of a distiller on the solvent in the prior art are omitted; and not only can the washing flow be simplified and the solvent is simple, rapid and convenient to recover, but also structures of the distiller and the like in the prior art are omitted, so that the complete machine has a simple structure, equipment volume is reduced and the popularization and application of the dry cleaning machine in families are facilitated.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Hydrocarbon cracking catalyst containing phosphorus and its prepn

The hydrocarbon cracking catalyst contains molecular sieve, binder and clay and its features are the mixed sol of chlorine-containing aluminum sol and phosphorus-containing aluminium sol used as binder. The binder raises the antiwear strength of the catalyst, and decreases the chlorine content in the spray drying slurry and the catalyst. The hydrocarbon cracking catalyst results in lower gas and coke yield and higher diesel oil yield and diesel oil / gasoline ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

Household dry cleaning machine, dry cleaning method thereof and method for purifying and recovering dry cleaning solvent

ActiveCN103306109AGood for popular useEasy and fast recyclingDry-cleaning apparatusTextiles and paperState of artCleaning methods

The invention relates to a household dry cleaning machine, a dry cleaning method thereof and a method for purifying and recovering a dry cleaning solvent. The household dry cleaning machine comprises a solvent purifying and recovering system and a cleaning barrel, wherein the solvent purifying and recovering system comprises a heating device used for evaporating the solvent; and the heating device is arranged in the cleaning barrel. The heating device for purifying and recovering the dry cleaning solvent is arranged in the cleaning barrel used for replacing a distiller in the prior art, and purifying and recovering treatment is performed on the solvent, so that not only can the cleaning process be simplified, but also the solvent recovery can be simple and rapid; and structures such as the distiller in the prior art are omitted, so that the whole structure is simple, the equipment size is reduced, and the dry cleaning machine can be better popularized and used in family.

Owner:HAIER GROUP TECHN R&D CENT +1

One-step leaven washing method

InactiveCN101696546ASimplify the washing processShorten washing timeDry-cleaning apparatus for textilesGramEngineering

The invention relates to a washing process for worn-out finishing of denims, in particular to a one-step leaven washing method. In the one-step leaven washing method, when the bath ratio of 1 weight part of cloth to water is smaller than 1:15, the adding dosage of a washing leaven is 1.0 to 1.8 percent (o.w.f); or, when the bath ratio of 1 weight part of the cloth to the water is between 1:20 and 1:30, the adding dosage of the washing leaven is above 2.5 percent (o.w.f); or, when the bath ratio of 1 weight part of the cloth to the water is between 1:15 and 1:20, the adding dosage of the washing leaven is 1.8 to 2.5 percent (o.w.f); and after finishing the material adding, the method comprises the steps of raising the temperature to between 40 and 60 DEG C, performing constant temperature washing for 40 to 90 minutes, draining, adding clear water, adding an auxiliary agent in a ratio of 1-2 grams per liter, performing washing for 10 to 15 minutes, and performing dewatering and drying. The one-step leaven washing method effectively overcomes various difficulties in the production by a two-step method, can perform desizing and washing in one step, namely finish the desizing and the washing through one step, achieves process innovation, can change the present status of the prior production process, and is favorable for saving energy and water, improving the working efficiency and reducing the cost; besides, the product selling price can be matched with the price of the conventional washing leaven in the prior market, so the method has a good application and popularization prospect.

Owner:南京川平科技开发有限公司

Rotational flow flushing type domestic bowl-washing machine

InactiveCN101278823AAccelerate agencySimple organizationTableware washing/rinsing machinesProcess engineeringRotational flow

The invention provides a rotary flushing type household dishwasher, which comprises a mounting bracket of tableware, a heating system, a disinfecting system, a solid dirt filtering mechanism and a discharging system. The invention is characterized in that the dishwasher also comprises a wave-wheel washing mechanism and a washing container for filling water; the wave-wheel washing mechanism comprises a motor and a wave wheel, the wave wheel is arranged at the bottom of the washing container and the motor is arranged below the washing container; the mounting bracket of tableware is arranged in the washing container; the wave wheel rotates under the driving of the motor and produces rotating flow in the water-filled washing container, thus achieving the flushing type washing of the tableware in the relative movement between the water body and the tableware. The dishwasher has no need of caring the washing of dead-angle, speeds up the washing process, simplifies the operation and the mechanism of the whole dishwasher and reduces the washing time and cost, thus achieving the aim of energy saving and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Hydrocarbon cracking catalyst containing phosphorus and its prepn

The hydrocarbon cracking catalyst contains molecular sieve, binder and clay and its features are the mixed sol of chlorine-containing aluminum sol and phosphorus-containing aluminium sol used as binder. The binder raises the antiwear strength of the catalyst, and decreases the chlorine content in the spray drying slurry and the catalyst. The hydrocarbon cracking catalyst results in lower gas and coke yield and higher diesel oil yield and diesel oil / gasoline ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

Washing and solvent recycling method for paper pulp obtained through organic solvent method

ActiveCN105672016ASimplify the washing processAvoid participationPulp liquor regenerationWashing/displacing pulp-treating liquorsOrganic solventBoiling point

The invention relates to a washing and solvent recycling method for paper pulp obtained through an organic solvent method.The method comprises the following steps that paper pulp obtained by pulping through the organic solvent method is washed with one or more organic solvents, then the organic solvents in the paper pulp are evaporated out through evaporation drying, dry paper pulp is obtained, and organic solvent steam is recycled through condensation.The method is suitable for washing paper pulp obtained through the organic solvent method, the organic solvents are used in the whole washing process, involvement of water is avoided, clean dry paper pulp is directly obtained through evaporation drying after washing, and the washing process of paper pulp is simplified.According to the method, due to the fact that water involvement is avoided in the whole process, energy consumption in organic solvent recycling is reduced due to the low boiling point of the organic solvents when the organic solvents are separated and recycled; in addition, azeotrope is not generated, and the trouble brought by azeotropy on organic solvent recycling is saved.

Owner:QILU UNIV OF TECH +1

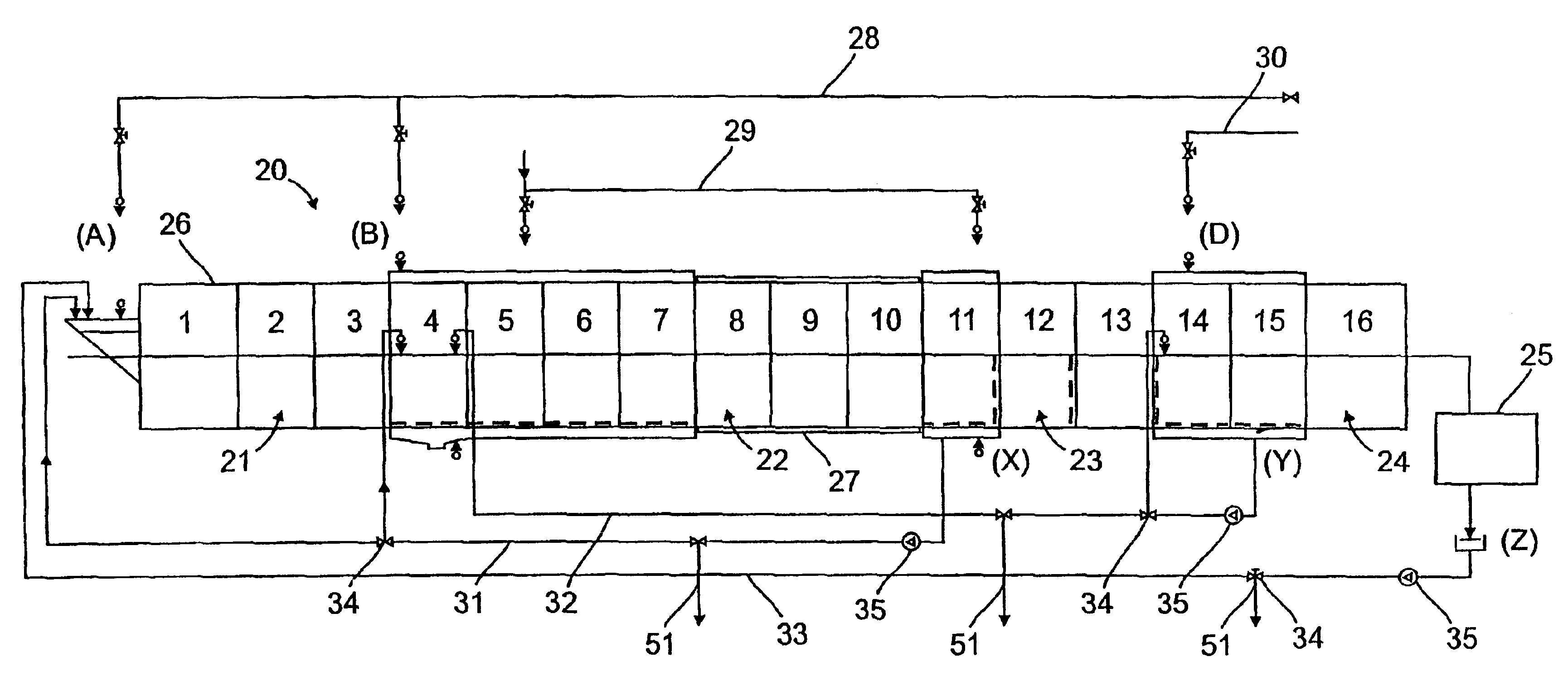

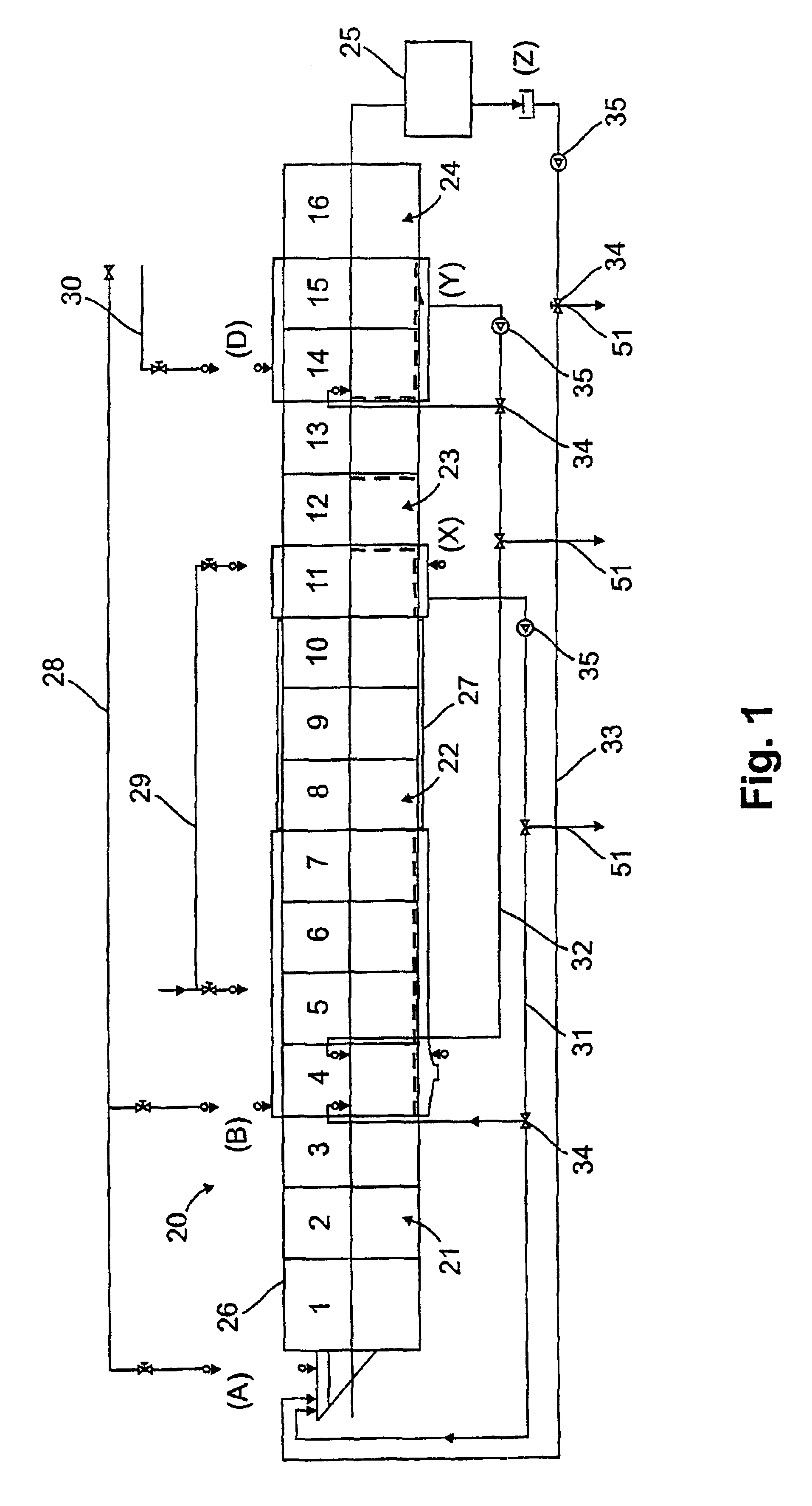

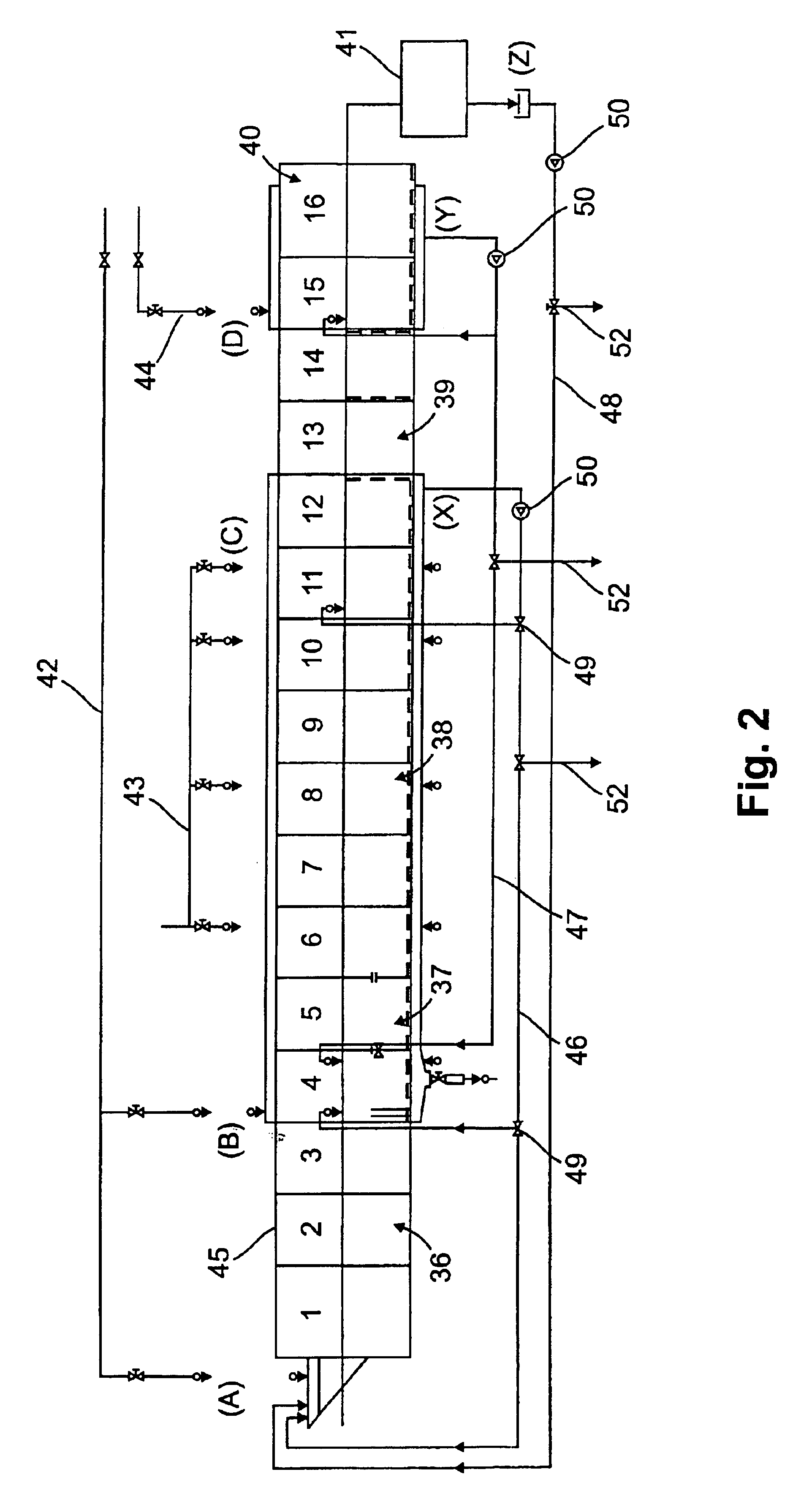

Method for washing laundry in a tank-free wash path as well as wash path for carrying out the method

InactiveUS7089620B2Improve planting efficiencyImprove washabilityTextile treatmentOther washing machinesWastewaterWater circulation

A method for washing laundry and a wash path for laundry in bath change and / or counterflow operation, in which the laundry to be washed when passing through said wash path moves through different treatment zones with chambers 1 to 16, wherein the individual baths are composed of fresh water and waste water of other baths, wherein the waste water of at least one bath without intermediate storage and directly is at least partly supplied to another bath, and wherein no waste water is intermediately stored in the water circulation during washing.

Owner:SENKINGWERK

Chloranil and preparation method thereof

ActiveCN106866399AStable supplyPrice stabilityOrganic compound preparationQuinone preparation by oxidationSimple Organic CompoundsOrganic solvent

The invention provides chloranil and a preparation method thereof and relates to the field of organic compounds. The method for preparing the chloranil comprises the following steps: a) enabling phenol to react with chlorine so as obtain polychlorophenol; and b) adding oxidation reagents to enable the polychlorophenol to react with chlorine in the presence of an organic solvent, thereby obtaining the chloranil. According to the method, synthesis is performed by taking phenol as a raw material, and the technical problem in the prior art that the chloranil cannot be normally produced because p-diphenol and p-aminophenol are high in price and unstable is solved. According to the method, a two-step synthesis process is adopted, the problems that multiple preparation steps are needed formerly and more wastewater is produced in the process can be solved. The preparation method has the advantages that the raw material cost is low, the process flow is simple, the auxiliary raw materials are readily available, the reacted solvent can be repeatedly used, much wastewater is not produced in the process flow, and the like.

Owner:NANTONG SHUCHUANG PHARMA

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS9331329B2Improve conductivityAvoid separationFinal product manufactureOperating modesLithium iron phosphateCrystal structure

Owner:LG ENERGY SOLUTION LTD

Method for preventing yarn breakage

ActiveCN101932759AFewer tangling and yarn breaksSimplified spinning and washing/neutralization processesArtificial filament washing/dryingMonocomponent polyamides artificial filamentEngineeringBobbin

The invention pertains to the use of a multifilament yarn spinning process comprising individually washing each filament of a multifilament yarn and, if neutralized, individually neutralizing each filament of the multifilament yarn, for preventing yarn breakage during the spinning process, the spinning process comprising spinning of a polymer through a spinneret to obtain the multifilament yarn, washing the yarn, and optionally neutralizing and / or drying the yarn and winding the yarn onto a bobbin Preferably the yarn is washed with jet washers.

Owner:TEIJIN ARAMID BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com