Washing machine and washing method

A washing method and washing machine technology, which are applied in the field of washing machines, can solve the problems of clothing wear, increased material and manufacturing costs, and complicated washing process, and achieve the effects of increasing contact area, reducing material cost and manufacturing cost, and simplifying washing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

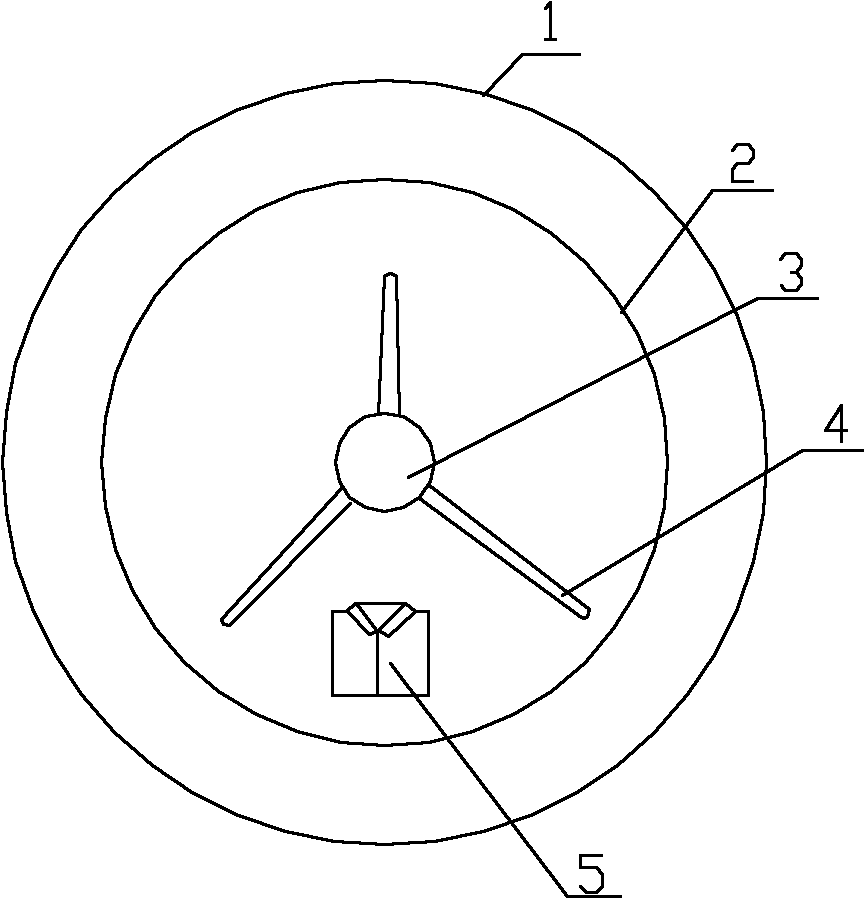

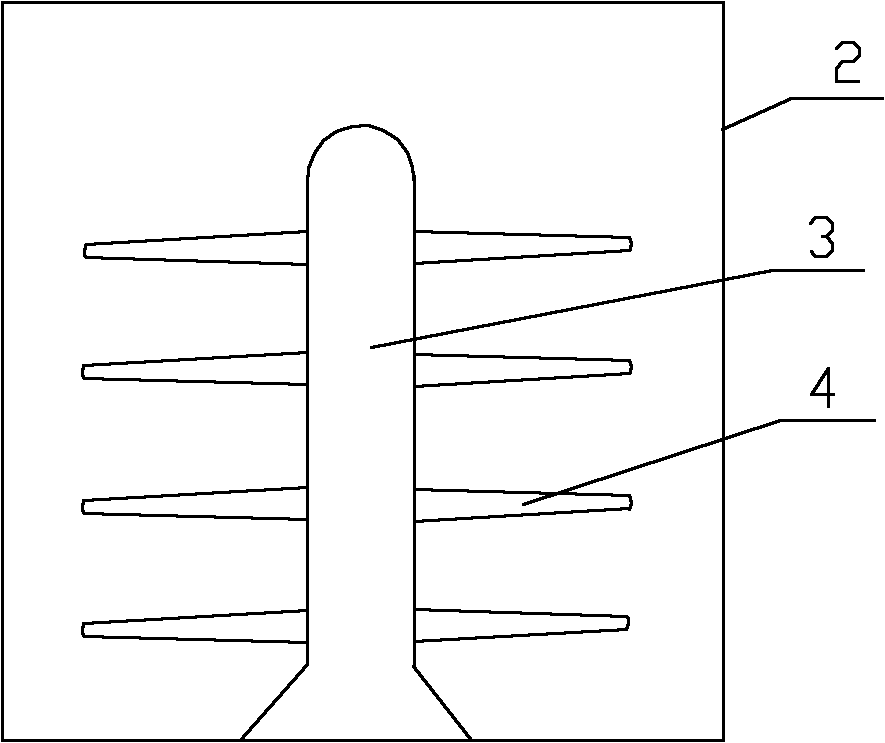

[0033] Such as figure 1 and figure 2 As shown, a washing machine, whether it is a commonly used pulsator washing machine or a drum washing machine, includes a housing (not shown in the figure), and an outer cylinder 1 and an inner cylinder 2 are arranged in the housing, and the outer cylinder 1 is closed. type structure and is fixed and non-rotating. The inner cylinder 2 is arranged on the inner side of the outer cylinder 1. There are several openings (not shown in the figure) for the passage of washing water on the cylinder wall of the inner cylinder 2. The openings The shape can be circular, rectangular, polygonal, etc., and the inner cylinder 2 can be driven to rotate by a driving device. In the case of a pulsator washing machine, the pulsator at the bottom of the inner cylinder 2 is also driven by the driving device, which is driven separately from the inner cylinder 2, and the water flow is stirred by the forward and reverse rotation of the pulsator. A water inlet (not...

Embodiment 2

[0051] The difference from Embodiment 1 is that in the drum washing machine, the central axis 3 and the inner cylinder 2 can also be separately set and driven by the driving device respectively, and the root of the central axis 3 is directly connected with the driving device and directly driven by the driving device. The central axis 3 is controlled by the control device of the washing machine to rotate positively and negatively at a certain time and speed. In this way, the polymer plastic strip 4 is more conducive to stirring the water flow and the clothing 5, further improving the adsorption capacity, and at the same time, it is also conducive to avoiding the clothing 5. winding.

[0052] In the pulsator washing machine, the central shaft 3 can be used to replace the original pulsator, and the central shaft 3 is directly connected to the driving device. Thin plastic bar 4 stirs water flow and clothing 5.

[0053] In the washing step, the difference from Example 1 lies in St...

Embodiment 3

[0055] The difference from Embodiment 1 and Embodiment 2 is that the central axis 3 and the polymer plastic strip 4 can adopt a hollow structure, and polymer solid particles are contained in the middle cavity, and the central axis 3 and the polymer plastic strip 4 is provided with some through holes only for washing water to pass through, and the diameter of the through holes is smaller than the minimum diameter of the particles. Because the diameter of particle is generally between 2-4mm, so, the diameter of through-hole will be less than 2mm, and the diameter of preferred through-hole is between 1-1.5mm, can guarantee that like this wash water can flow smoothly from central shaft 3 and polymer plastic strip 4 inflow or outflow, and can avoid particle leakage.

[0056] In order to increase the adsorption capacity of the particles, the particles adopt a porous structure on the surface. The pores on the surface are not connected to each other and are disconnected from each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com