A washing machine and washing method thereof

a technology of washing machine and washing method, which is applied in the field of washing machines, can solve the problems of increasing the cost of washing, increasing the time consumption of each washing process, and increasing the cost of cleaning, so as to simplify the washing procedure and improve the cleaning ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

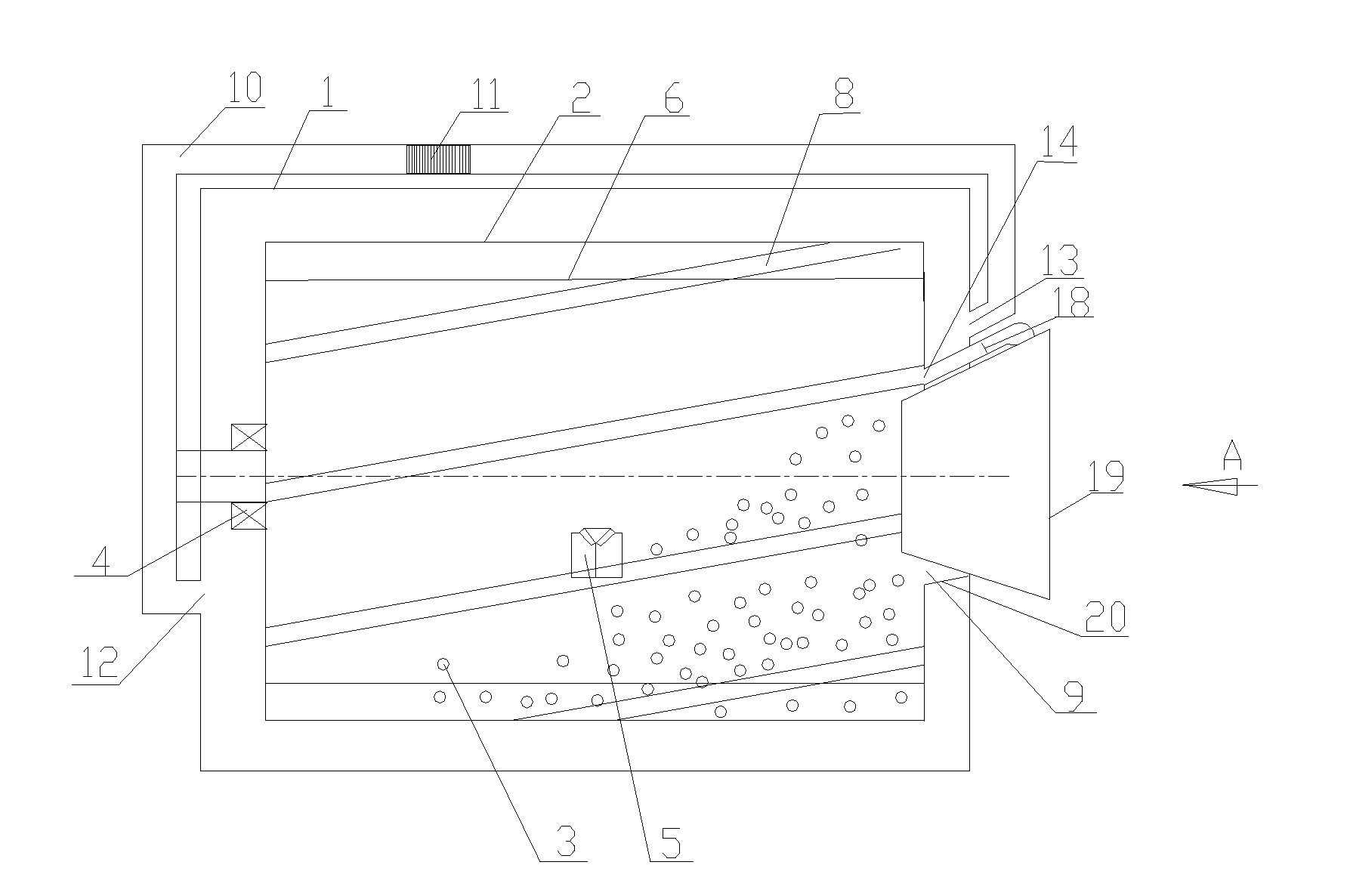

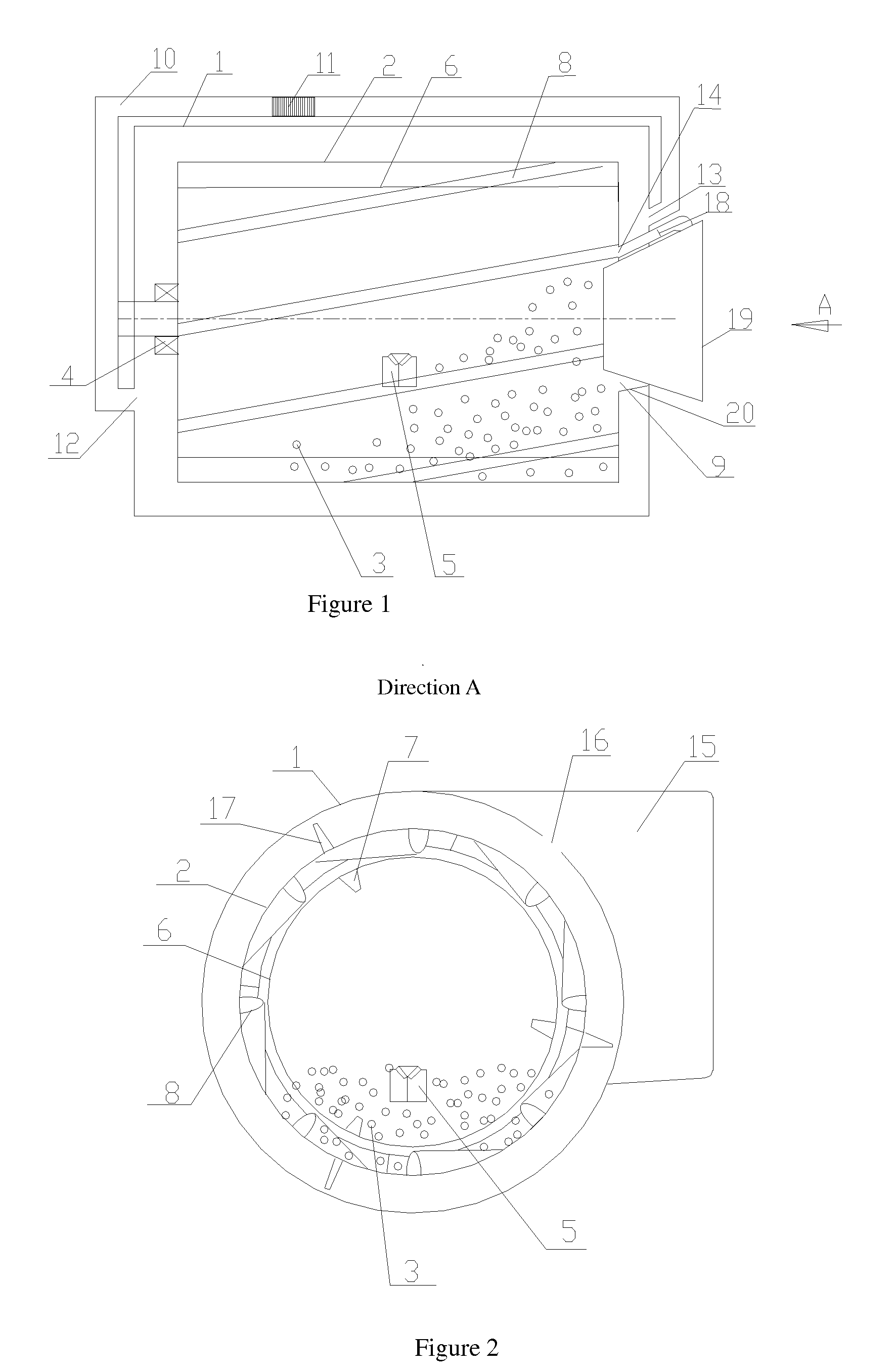

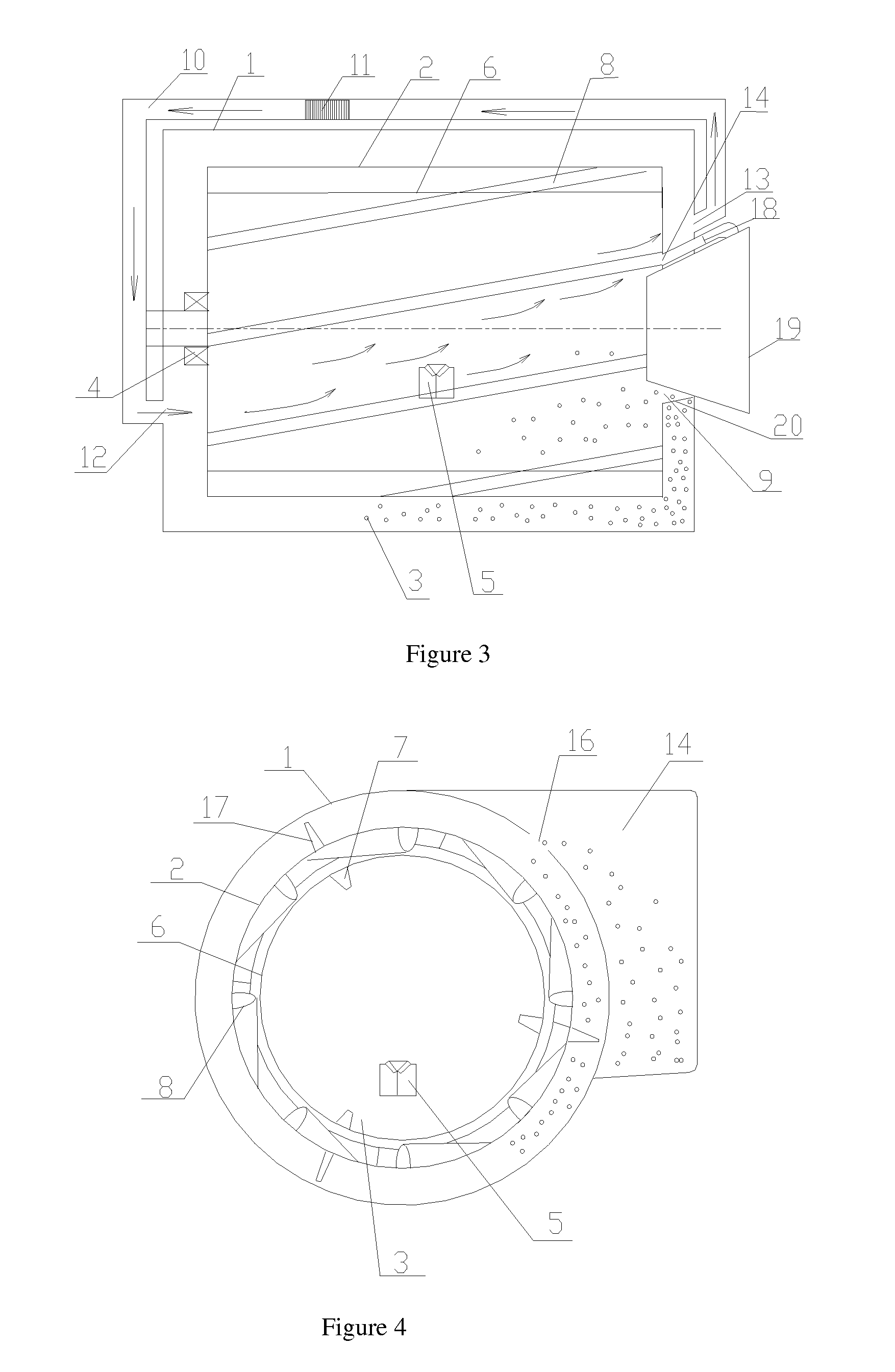

[0038]As shown in FIG. 1 and FIG. 2, a washing machine, taking a roller washing machine as an example for detailed description in the embodiment, comprises a shell (not shown in the figure), an outer tub 1, an inner tub 2 arranged in the shell, and solid particles 3 as washing medium. Wherein, the outer tub 1 is fixed, mainly for holding water, and the inner tub 2 is arranged at the inner of the outer tub 1 for washing and is driven to rotate by a driving device 4. A water inlet (not shown in the figure) is arranged on the upper of the outer tub 1 for water inflow during washing and rinsing, and a water outlet (not shown in the figure) is arranged on the lower of the outer tub 1 for water draining after dewatering.

[0039]To be convenient for separating clothes 5 from particles 3, a circle of isolation tub 6 is arranged along the inner side of the inner tub 2 optionally. The clothes 5 are placed in the isolation tub 6. The bottom and top of the isolation tub 6 are fixedly connected wi...

embodiment 2

[0069]As shown in FIG. 5, the difference from Embodiment 1 is that the air outlet 12 of the air circulation channel 10 is arranged on the rear wall of the outer tub 1 while its air inlet 13 is arranged on the door 19 of washing machine. An air channel 21 for leading the air from the inner tub 2 to the air circulation channel 10 is arranged on the door 19 of the washing machine. One end of the air channel connects with the inner tub 2 while the other end connects with the air circulation channel 10. Thus, no need to arrange the port on the front wall of the inner tub 2, and arranging several ports on the bottom wall of the inner tub 2 is enough.

[0070]The air along the air circulation channel 10 blows into the inner tub 2 from the air outlet 12 on the rear wall of the outer tub 1 via the openings on the bottom wall of the inner tub 2. The air blows toward the clothes 5 and particles 3 in the inner tub 2. And, the clothes 5 are driven to be separated from the particles 3 preliminarily ...

embodiment 3

[0072]As shown in FIG. 6, a channel 22 is set on the door 19 of the washing machine. One end of the channel 22 is communicated with the inner tub 2 via the feeding hole 14 while the other end connected with the feeding channel 18. The channel 22 is slightly tilted upward, avoiding the particles 3 entering the channel 22 during washing.

[0073]When putting in the particles 3, the delivery pump and the feeding valve are started simultaneously. Thus, the particles 3 in the storage tank 15 are put into the inner tub 2 via the feeding channel 18 and the channel 22 on the door 19 of the washing machine by the delivery pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com