Washing machine and washing method

A washing method and washing machine technology, applied in the field of washing machines, can solve the problems of wear and tear of clothes, increased material and manufacturing costs, complicated washing process, etc., and achieve the effects of reduced material cost and manufacturing cost, simple structure, and simplified washing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

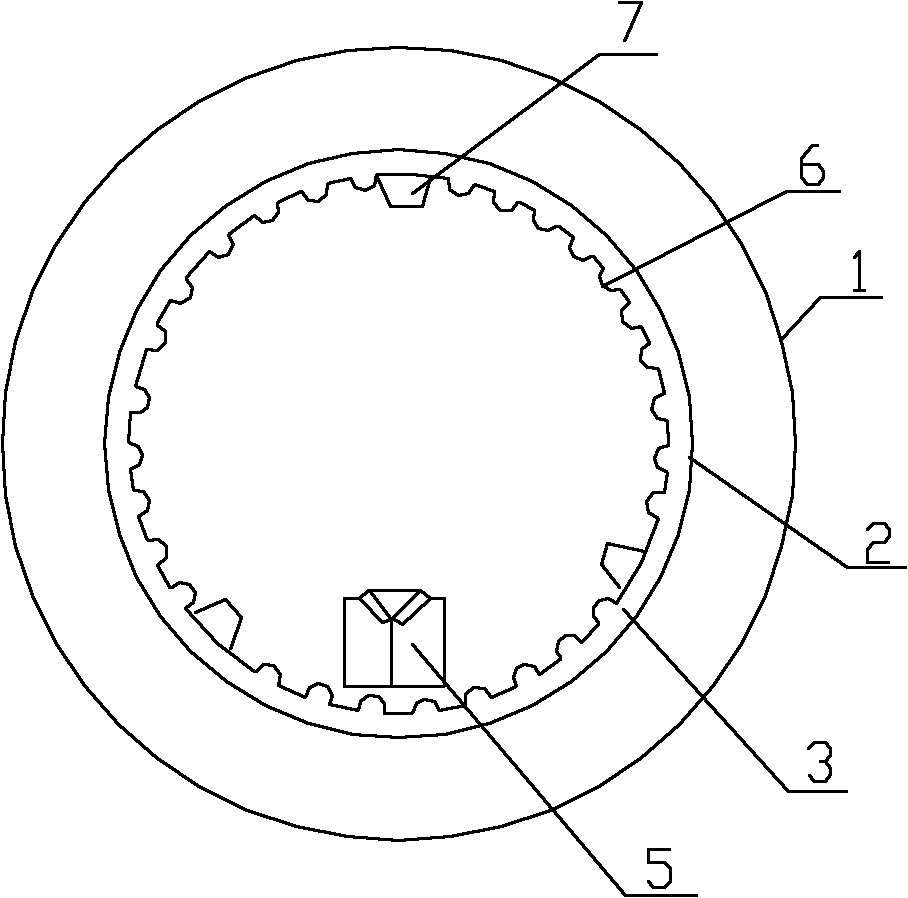

Embodiment 1

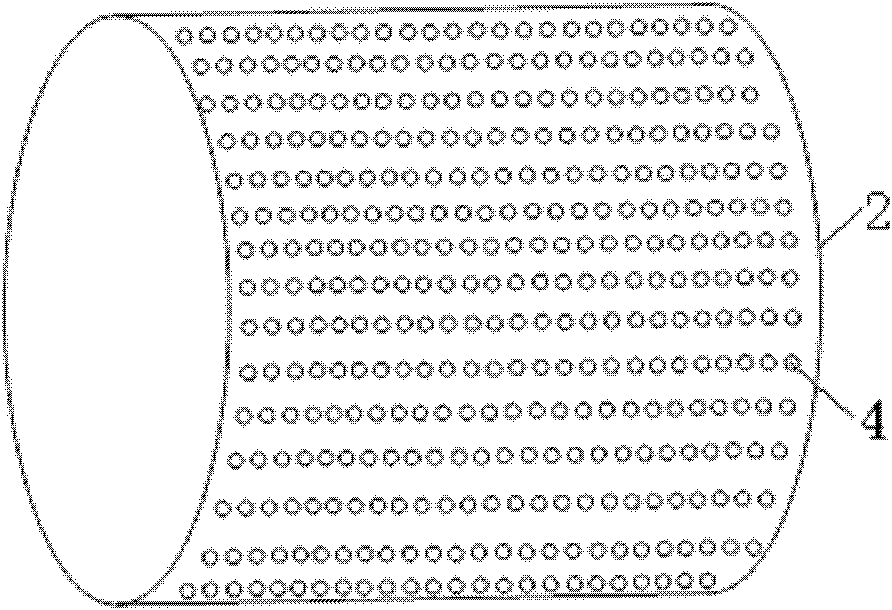

[0042] In this embodiment, the dielectric layer 3 can be coated on the inner side of the cylinder wall of the inner cylinder 2 through a coating process, and the dielectric layer 3 can also be fixedly installed on the cylinder wall of the inner cylinder 2 by fasteners such as screws. On the medium layer 3, like the inner cylinder 2, there are several through holes (not shown in the figure) for the washing water to pass through, and the shape of the through holes is also the same. figure 2 The first opening 4 on the inner cylinder 2 shown is the same, and it can also be round, rectangular, polygonal, etc. The through hole feeds water into the cylinder during washing, and throws the washing water in the cylinder to the outside during dehydration. The inside of the cylinder 1 is discharged from the drain at the lower part of the outer cylinder 1. If the dielectric layer 3 is provided on the cylinder wall of the outer cylinder 1, the dielectric layer 3 is not provided with water-pa...

Embodiment 2

[0057] In the old-fashioned two-cylinder washing machine, the washing drum of the washing part is a single drum structure, and the pulsator alternately rotates clockwise and counterclockwise during the washing time, forming a rotating water stream in the drum, and the washing water removes the clothes. The stains are washed off. In this kind of washing machine, on the inside or outside of the wall of the washing tub, a polymer washing medium layer 3 can be coated on the inner and outer sides. The medium layer 3 is not provided with through holes for passing water. The structure of the medium layer 3 The form is exactly the same as in the first embodiment, and no further detailed description will be given here.

[0058] In this kind of washing machine, since the laundry 5 is dehydrated by another spin-drying drum, the medium layer 3 does not have a dehydration process, and a method of heating and air drying into the drum can be used.

Embodiment 3

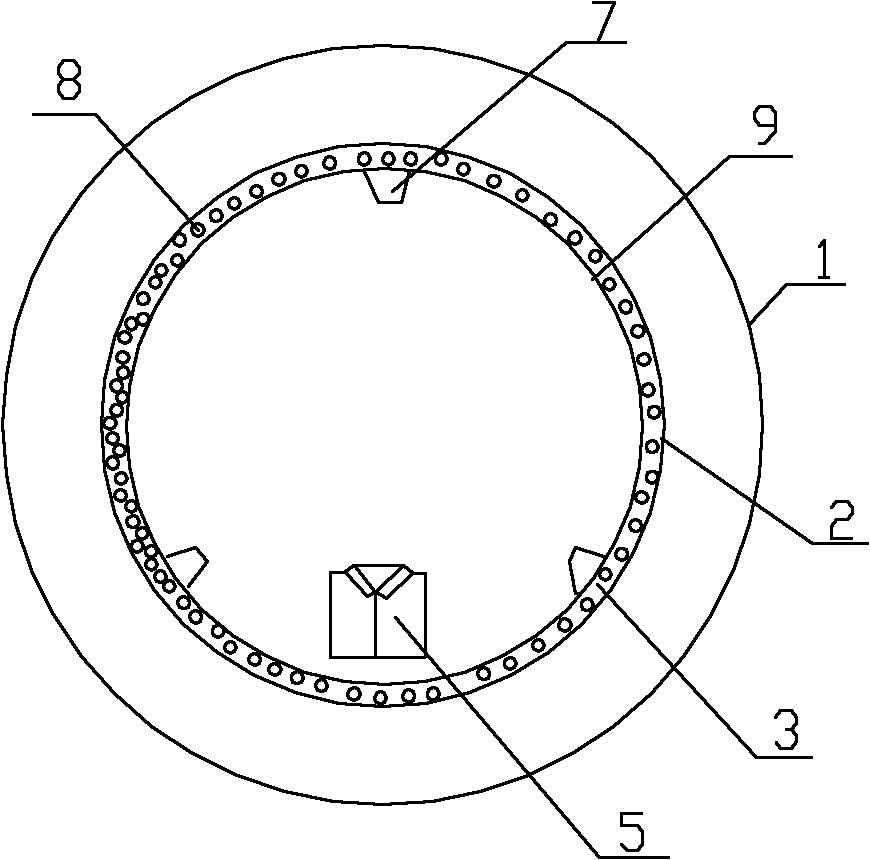

[0060] Such as image 3 As shown, the difference from the first embodiment is that the dielectric layer 3 provided on the inner side of the inner cylinder 2 is a polymer sandwich structure fixed on the inner cylinder 2 with polymer solid particles 8 in the middle. The wall 9 is provided with a through hole (not shown in the figure) for the washing water to pass through, and the medium layer 3 is fixedly connected to the wall of the inner cylinder 2 with fasteners such as screws to ensure that the medium layer 3 and the inner cylinder 2 rotate together.

[0061] In order to prevent particles 8 from leaking from the inner cylinder 2 and the medium layer 3, the diameter of the first opening 4 on the inner cylinder 2 and the through holes on the dielectric layer 3 should be smaller than the smallest diameter of the particles 8, because the diameter of the particles 8 is generally 2 Therefore, the diameter of the first opening 4 and the through hole should be less than 2mm, preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com