Washing machine and washing method thereof

a washing machine and washing method technology, applied in the field of washing machines, can solve the problems of large power consumption, large water consumption, time-consuming washing process, etc., and achieve the effects of reducing material cost and manufacturing cost, simple structure, and simplifying washing procedur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

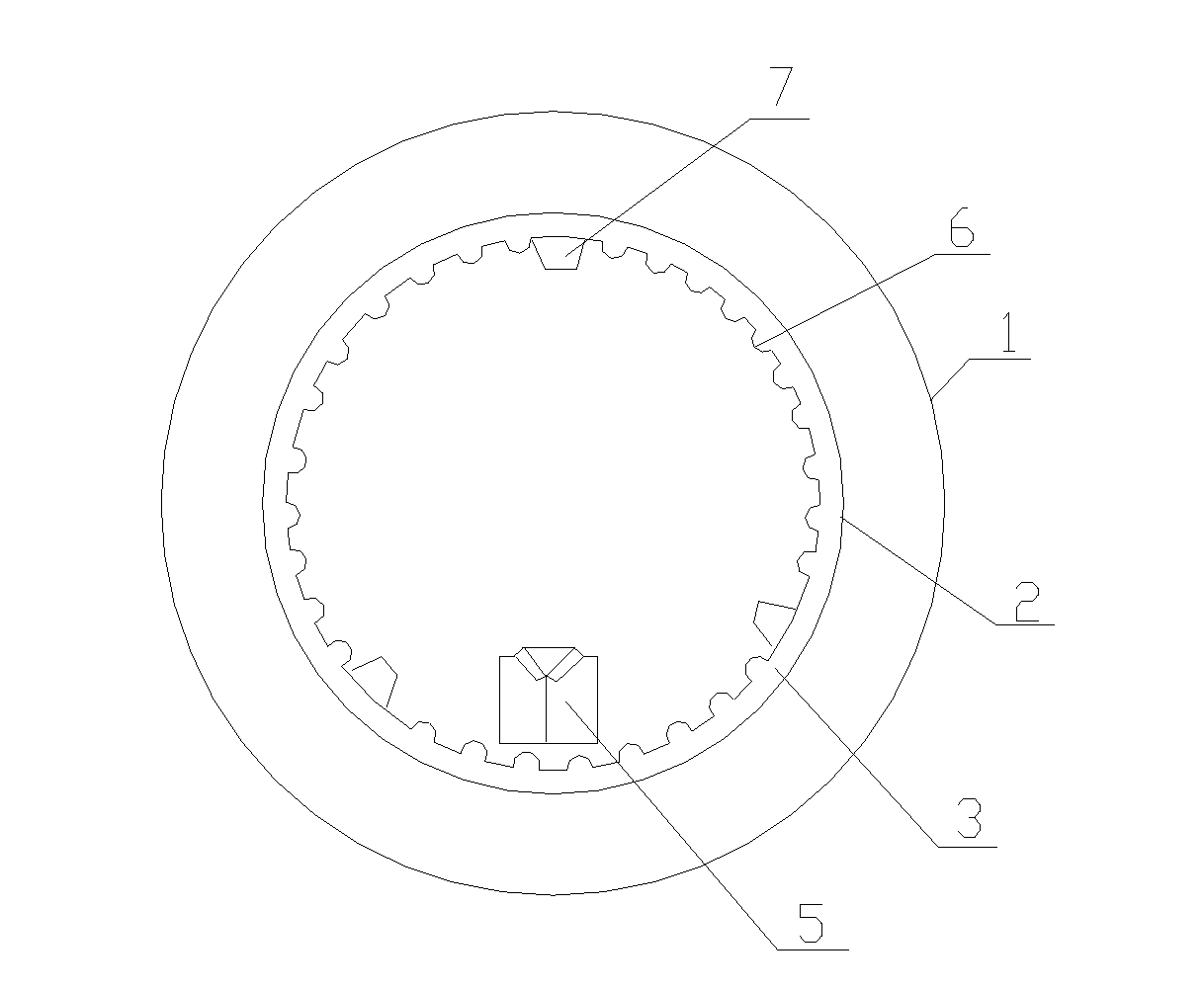

embodiment 1

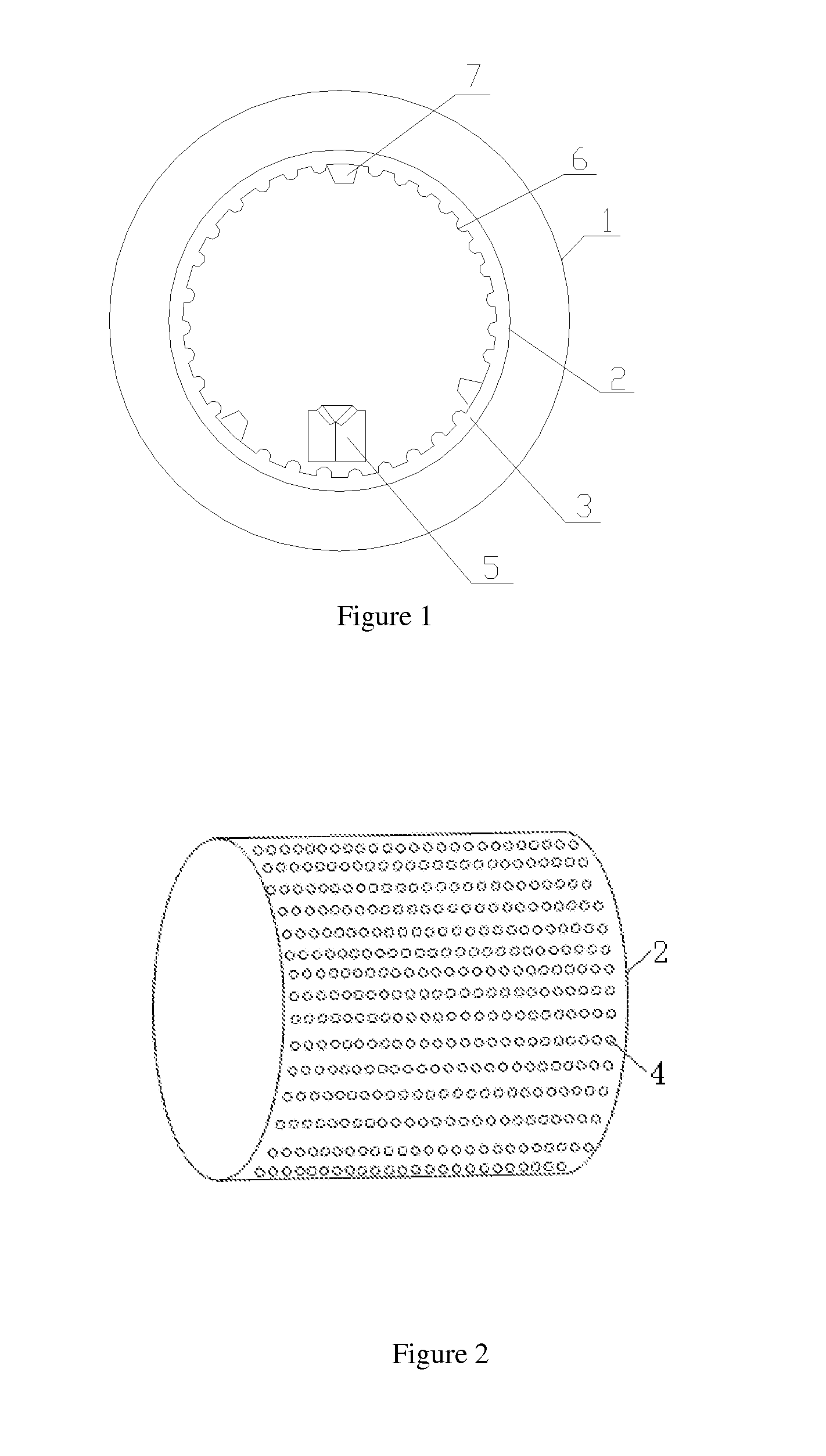

[0041]In the embodiment, the medium layer 3 may be coated on the inner surface of the inner tub 2 via coating technique, or fixedly installed on the wall of the inner tub 2 by fasteners, such as screw. As same with the inner tub 2, the medium layer 3 is provided with a plurality of through-holes (not shown in figure) with round, rectangle or polygon etc. in shape, as the same as the shape of the first opening hole 4 shown in FIG. 2, for the washing water flowing through. The water flows in the tub via the through-holes during washing; the washing water is discharged into the outer tub 1 when dehydration, and finally the water is discharged from the water outlet at the bottom of the outer tub 1. If the medium layer 3 is arranged on the wall of the outer tub 1, the medium layer 3 is not arranged with the through-holes for the water flowing through.

[0042]The medium layer 3 may be coated or installed on the overall wall of the inner tub 2, or coated or installed on a part of the wall of...

embodiment 2

[0055]In an old-fashioned double cylinder washing machine, the washing tub for washing is of single-tub structure, in which a rotating water flow is formed by the pulsator rotating clockwise and anticlockwise alternately during washing. The dirt on the clothes5 is removed by the washing water. In this washing machine, a polymer washing medium layer 3, which is not arranged with through-holes for the water flowing through, may be coated on the inner surface and / or the outer surface of the wall of the washing tub. The structure of the medium layer 3 is as the same as that in Embodiment 1, so it is not described additionally hereby.

[0056]In this washing machine, on account of that the dehydration of the clothes 5 being accomplished in another spin dryer tub, therefore, the medium layer 3 has no the process of dehydration. The method of adding hot wind in the tub may be adopted.

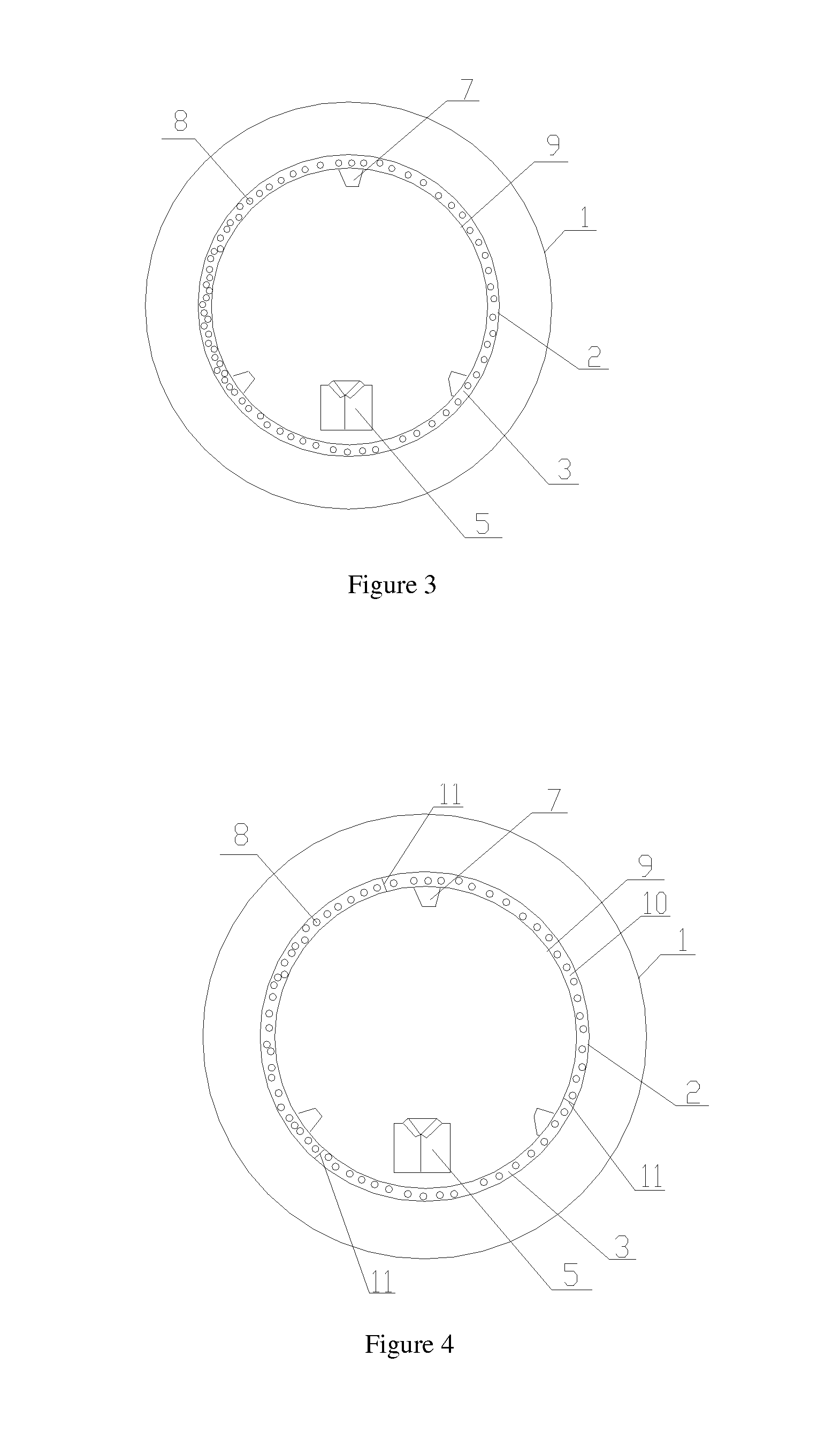

embodiment 3

[0057]As shown in FIG. 3, the difference from the Embodiment 1 is that, the medium layer 3 arranged on the inner surface of the inner tub 2 is an interlayer containing solid polymer particles 8 in the middle and being fixed on the wall of the inner tub 2 An interlayer wall 9 is arranged with through-holes (not shown in figure) for the washing water flowing through. The medium layer 3 is fixed on the wall of the inner tub 2 by the fasteners, such as screw, to ensure that the medium layer 3 rotates with the inner tub 2.

[0058]To avoid the particles 8 leaking out of the inner tub 2 and the medium layer 3, the diameter of the first opening hole 4 on the inner tub 2 and the through-holes on the medium layer 3 are less than the minimum diameter of the particles 8. The diameter of the particles 8 is generally 2-4 mm; therefore, the diameter of the first opening hole 4 and the through-holes are less than 2 mm. Preferably the diameter of the first opening hole 4 and the through-holes is 1-1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com