Method for directly preparing copper sulfate and cathode copper from copper ore concentrate

A technology of copper concentrate and copper sulfate, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve problems such as high operating costs, accumulation of impurities, and difficulty in washing and recycling copper, so as to simplify the copper washing process and ensure the leaching effect. To achieve a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

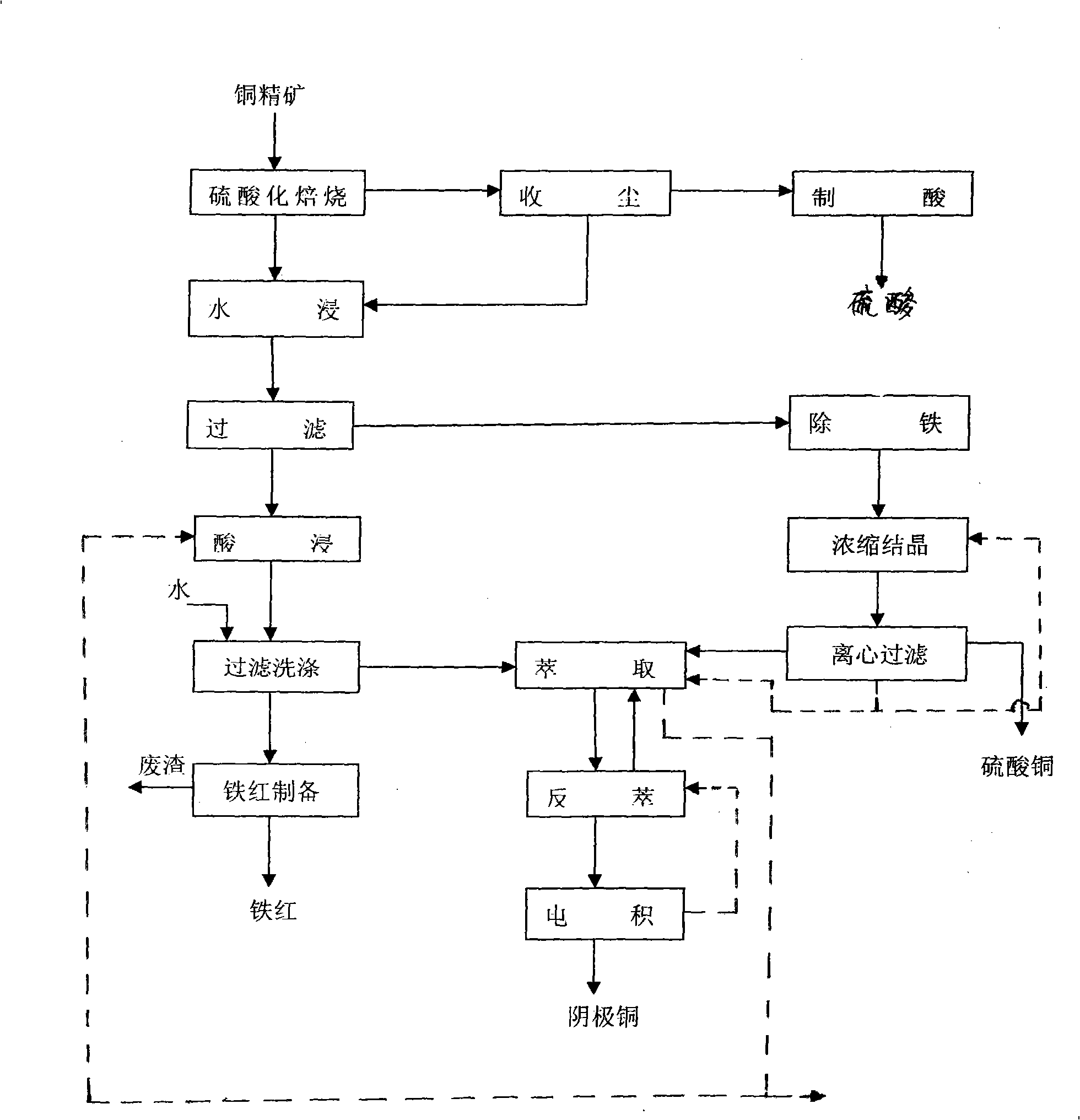

[0028] Embodiment one: if figure 1 Shown, a kind of method for directly producing copper sulfate and cathode copper with copper concentrate, the method comprises following sequential processing steps:

[0029] (a) Sulfation roasting, slurry copper concentrate with 28% sulfur content, 78%-0.074mm particle size, and 13% grade with water and stir evenly, and send it to the boiling furnace at a temperature of 400-900°C and -30-0Pa Sulphate roasting within the range of 1 ~ 5h, and then the dusty SO produced by roasting 2 After the flue gas is collected by the dust removal equipment, acid is produced to produce sulfuric acid as a by-product;

[0030] (b) water immersion, send the calcined sand produced by roasting and the dust collected by dust collection to the water immersion tank together for 0.2-4 hours in the temperature range of 40-95 °C;

[0031] (c) filtering, filtering the water leaching pulp, and then performing iron removal, concentrated crystallization, and centrifugat...

Embodiment 2

[0037] Embodiment two: refer to figure 1 , the method further comprises the following sequential process steps:

[0038] (a) Sulfation roasting, slurry copper concentrate with 28% sulfur content, 78%-0.074mm particle size, and 13% grade with water and stir evenly, and send it to the fluidized bed furnace at a temperature of 500-700°C and -20-0Pa Sulphate roasting within a certain range for 1 to 3 hours, and then the dust-containing SO produced by roasting 2 After the flue gas is collected by the dust removal equipment, acid is produced to produce sulfuric acid as a by-product;

[0039] (b) water immersion, the calcine produced by roasting and the dust collected by dust collection are sent to the water immersion tank together for 0.5-2.5 hours in the temperature range of 60-90 °C;

[0040] (c) filtering, filtering the water leaching pulp, and then performing iron removal, concentrated crystallization, and centrifugation on the filtered high-copper leachate to obtain the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com