Intermittent acidolysis method and device for titanium slag

A technology of titanium slag and acid hydrolysis, which is applied in chemical instruments and methods, titanium and titanyl sulfate, titanium dioxide, etc., can solve the problems of low utilization level of waste acid, high main reaction temperature, and difficult treatment, and achieves the reduction of Risk of pot, lower reaction temperature, mild reaction and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

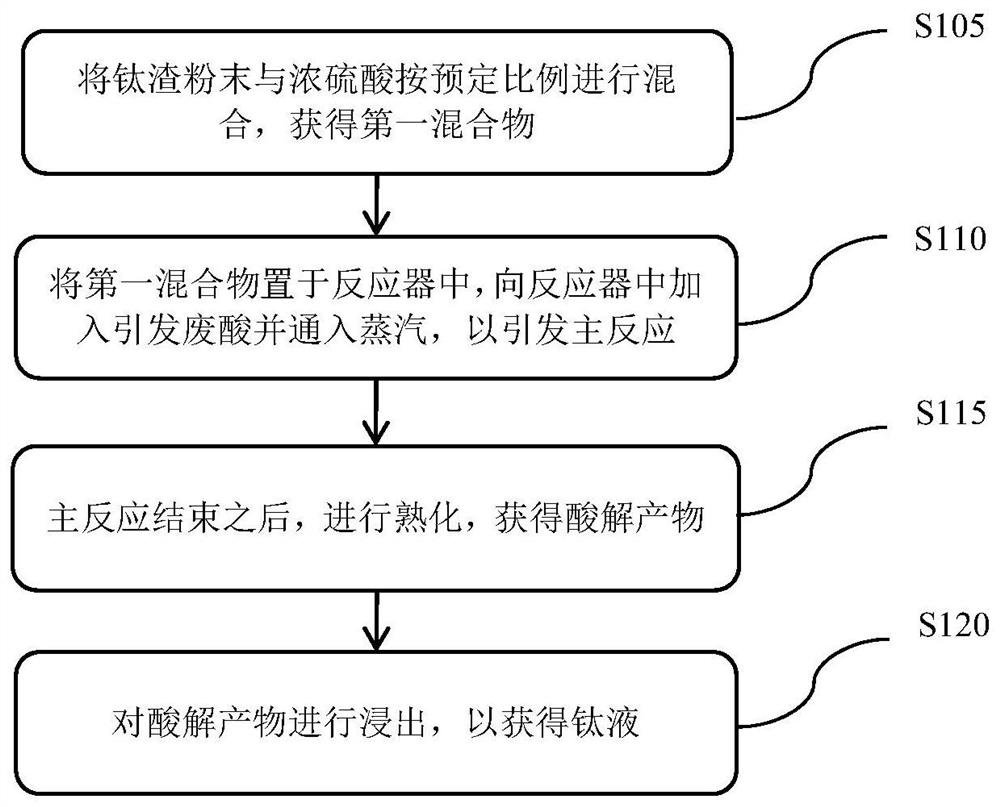

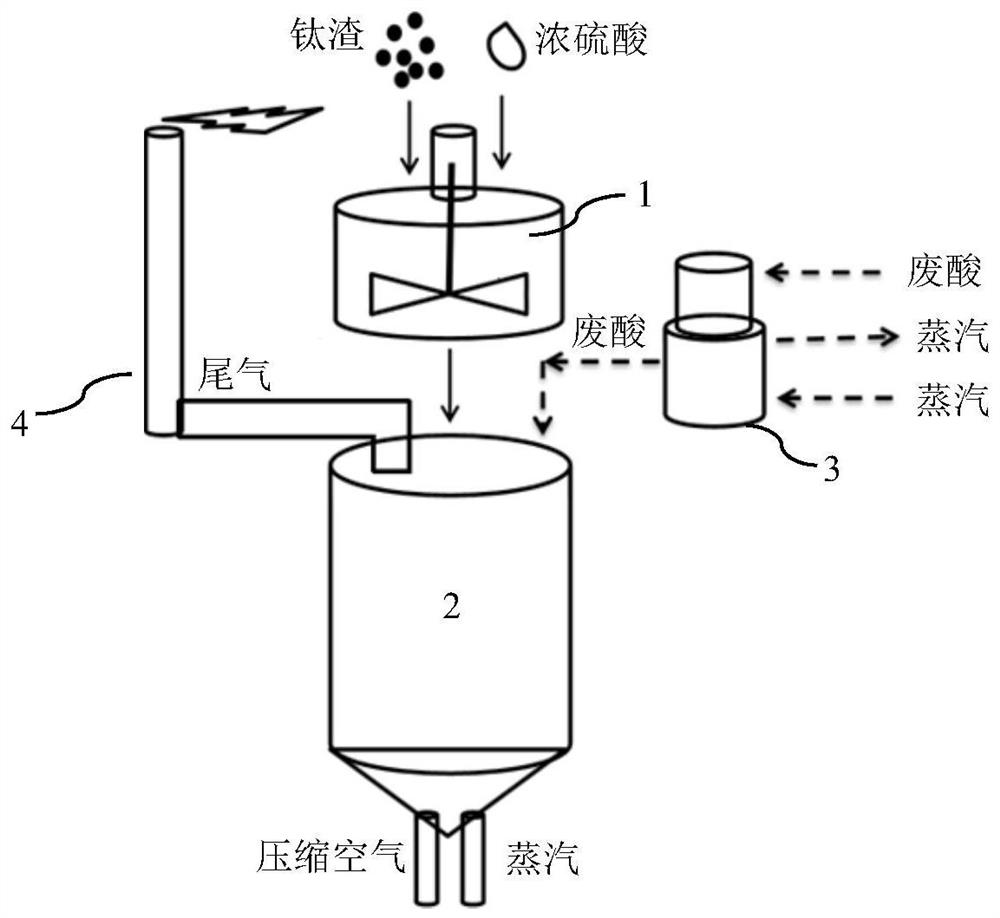

Method used

Image

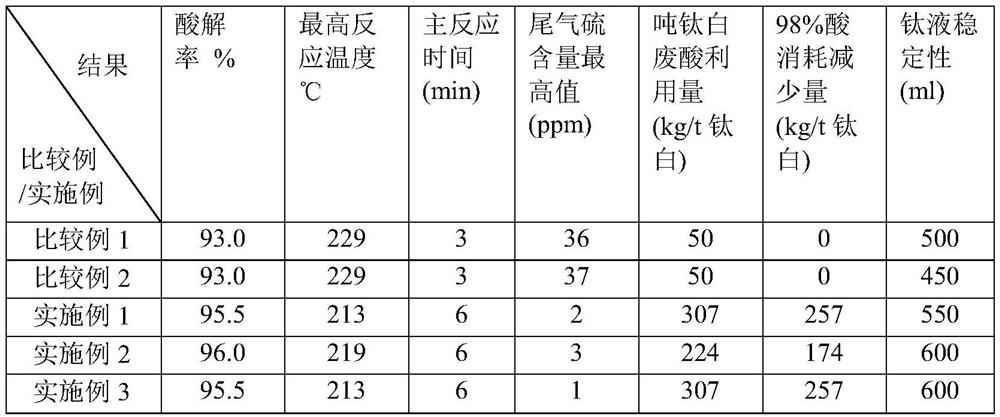

Examples

Embodiment 1

[0068] First, calculate the consumption of 98% concentrated sulfuric acid and 20% initiated waste acid respectively according to acid slag ratio 1.66, 92% acid concentration after mixing 20% initiated waste acid and 98% concentrated sulfuric acid;

[0069]After that, first add corresponding amount of 98% concentrated sulfuric acid into the premixing pot, start the stirring of the premixing tank, then slowly add corresponding amount of titanium slag powder according to the acid residue ratio of 1.66, the premixing time is 30-60min, the premixing temperature Control below 40°C;

[0070] Afterwards, the first mixture obtained by premixing is put into the acidolysis pot, feeds compressed air into the acidolysis pot, after the first mixture discharge is completed, add 20% of corresponding amount to initiate spent acid (temperature is Just above normal temperature, no need to preheat), open the steam valve of the acid hydrolysis pot to feed steam, the steam pressure is 0.2Mpa;

...

Embodiment 2

[0076] First, calculate the consumption of 98% concentrated sulfuric acid and 20% initiated waste acid respectively according to acid slag ratio of 1.70, 20% initiated waste acid and 92% acid concentration after mixing with 98% concentrated sulfuric acid;

[0077] Afterwards, first add corresponding amount of 98% concentrated sulfuric acid into the premixing pot, start the stirring of the premixing tank, then slowly add corresponding amount of titanium slag powder according to the acid residue ratio of 1.70, the premixing time is 30-60min, the premixing temperature Control below 40°C;

[0078] Afterwards, the first mixture obtained by premixing is put into the acidolysis pot, feeds compressed air into the acidolysis pot, after the first mixture discharge is completed, add 20% of corresponding amount to initiate spent acid (temperature is Just above normal temperature, no need to preheat), open the steam valve of the acid hydrolysis pot to feed steam, the steam pressure is 0.2M...

Embodiment 3

[0084] First, calculate the consumption of 98% concentrated sulfuric acid and 50% initiated waste acid respectively according to acid slag ratio 1.66, 50% initiated waste acid (concentrated acid) mixed with 98% concentrated sulfuric acid acid concentration 92%;

[0085] After that, first add corresponding amount of 98% concentrated sulfuric acid into the premixing pot, start the stirring of the premixing tank, then slowly add corresponding amount of titanium slag powder according to the acid residue ratio of 1.66, the premixing time is 30-60min, the premixing temperature Control below 40°C;

[0086] At the same time, 50% of the initiated waste acid was indirectly preheated to a temperature of 47.6°C through steam;

[0087] Afterwards, the first mixture obtained by premixing is put into the acidolysis pot, and compressed air is passed into the acidolysis pot. Acid, open the steam valve of the acid hydrolysis pot to feed steam, the steam pressure is 0.2Mpa;

[0088] When the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com