A kind of reducing rutile tio in titanium slag 2 Titanium slag rapid cooling system and method

A rutile-type, rapid cooling technology, applied in the field of metallurgy, can solve problems such as large differences in acidolysis effects, unfavorable acidolysis of titanium slag, and changes in crystal structure, so as to ensure the acidolysis rate of titanium slag, protect titanium slag from oxidation, Improve the effect of application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

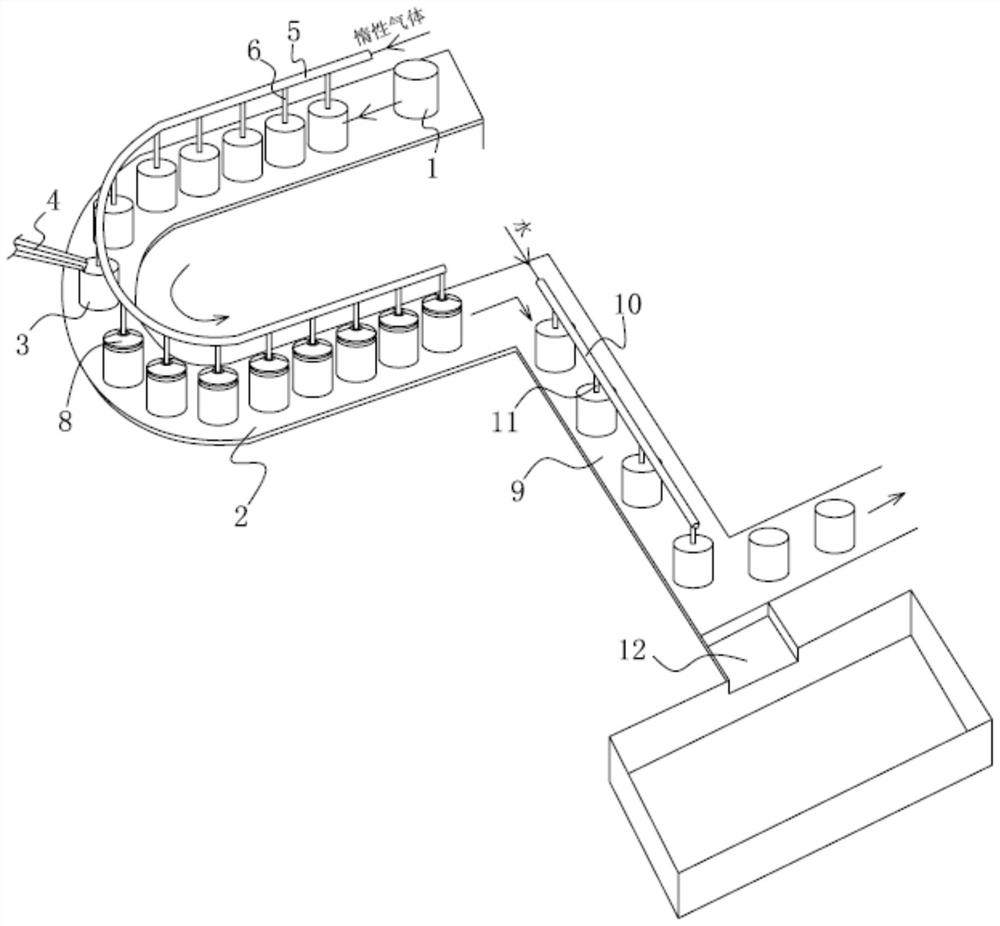

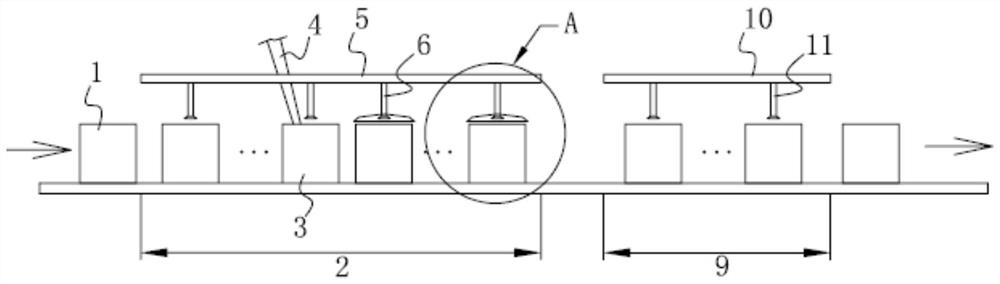

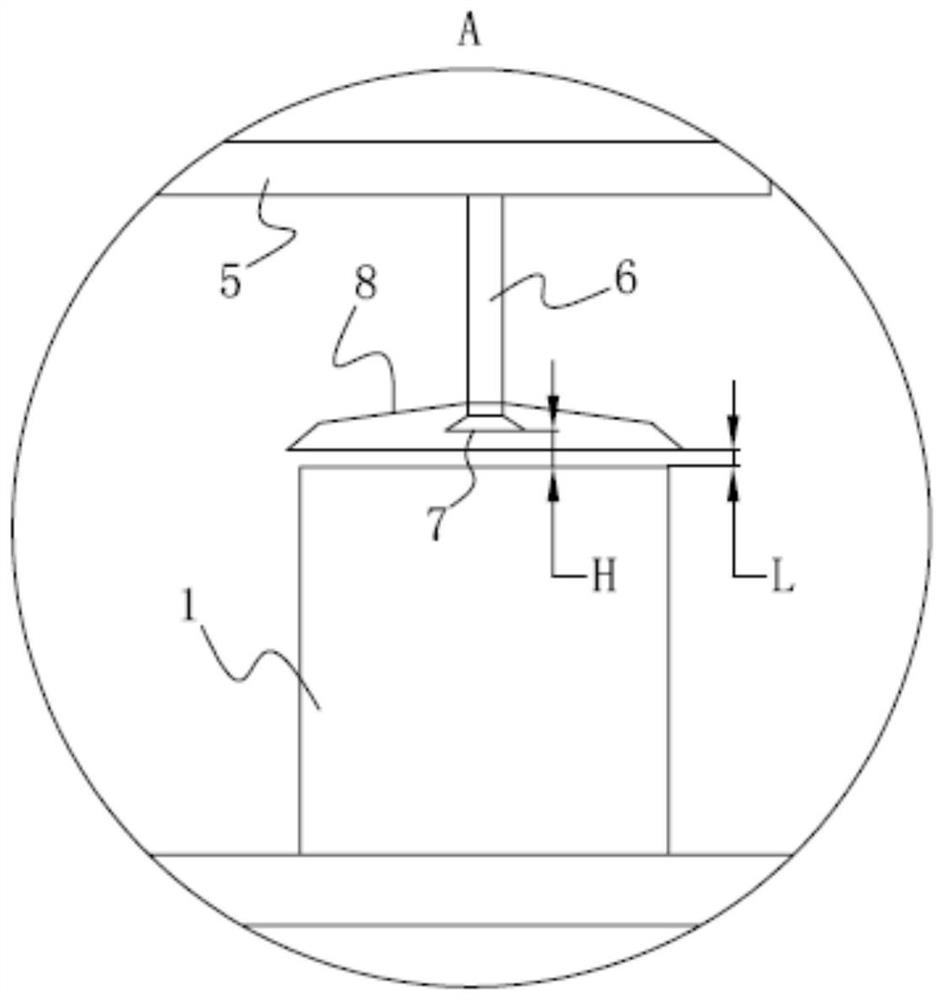

[0049] Before adding the slag into the slag bucket 1, feed N 5 minutes in advance 2 Blowing is carried out to cool the empty slag bucket 1; the titanium slag is released at a temperature of 1657 ° C, and the slag bucket 1 is used to load it. When the titanium slag is loaded to 80% of the volume of the slag bucket, it is transferred to the next slag bucket station and is transferred to the corresponding slag bucket station. Bronchial 6 insufflation N 2 , the next slag bucket 1 is loaded in turn; the slag bucket 1 after the slag is loaded 2 The total blowing time is 2.5h, of which the air flow in the main gas pipe 5 is 3500L / min; then the surface temperature of the titanium slag after spraying is measured by an infrared temperature measuring gun to 978°C; After the initial cooling treatment, the titanium slag is transported to the conveying channel 9 of the water cooling section for water-cooling spray treatment; the total time for cooling the titanium slag is 5 hours, and the ...

Embodiment 2

[0051] Before adding the slag into the slag bucket 1, feed N 5 minutes in advance 2 Blowing is carried out to cool the empty slag bucket 1; the titanium slag is discharged at a temperature of 1668 ° C, and the slag bucket 1 is used to load it. When the titanium slag is loaded to 80% of the volume of the slag bucket, it is transferred to the next slag bucket station and is transferred to the corresponding slag bucket station. Bronchial 6 insufflation N 2 , the next slag bucket 1 is loaded in turn; the slag bucket 1 after the slag is loaded 2 The total blowing time is 3h, among which, the air flow in the main gas pipe 5 is 4000L / min; then the surface temperature of the titanium slag after blowing is measured by an infrared temperature measuring gun to 947°C; After the cooling treatment, the titanium slag is transported to the conveying channel 9 of the water cooling section for water-cooling spray treatment; the total time for cooling the titanium slag by water spray is 5.5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com