A kind of method for preparing high acid hydrolysis rate titanium slag

A technology of titanium slag and high acid is applied in the fields of titanium slag production of titanium dioxide, post-treatment of titanium slag and preparation of titanium dioxide, to achieve the effect of simple process and improved acid hydrolysis rate

Active Publication Date: 2022-06-03

PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under the premise of ensuring the particle size of titanium slag and the yield of titanium, it is difficult to effectively separate the silicate phase and black titanite phase by conventional fine grinding and magnetic separation technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0042] Preferably, the amount of nucleating agent added accounts for 2% to 5% of the weight of the titanium slag.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

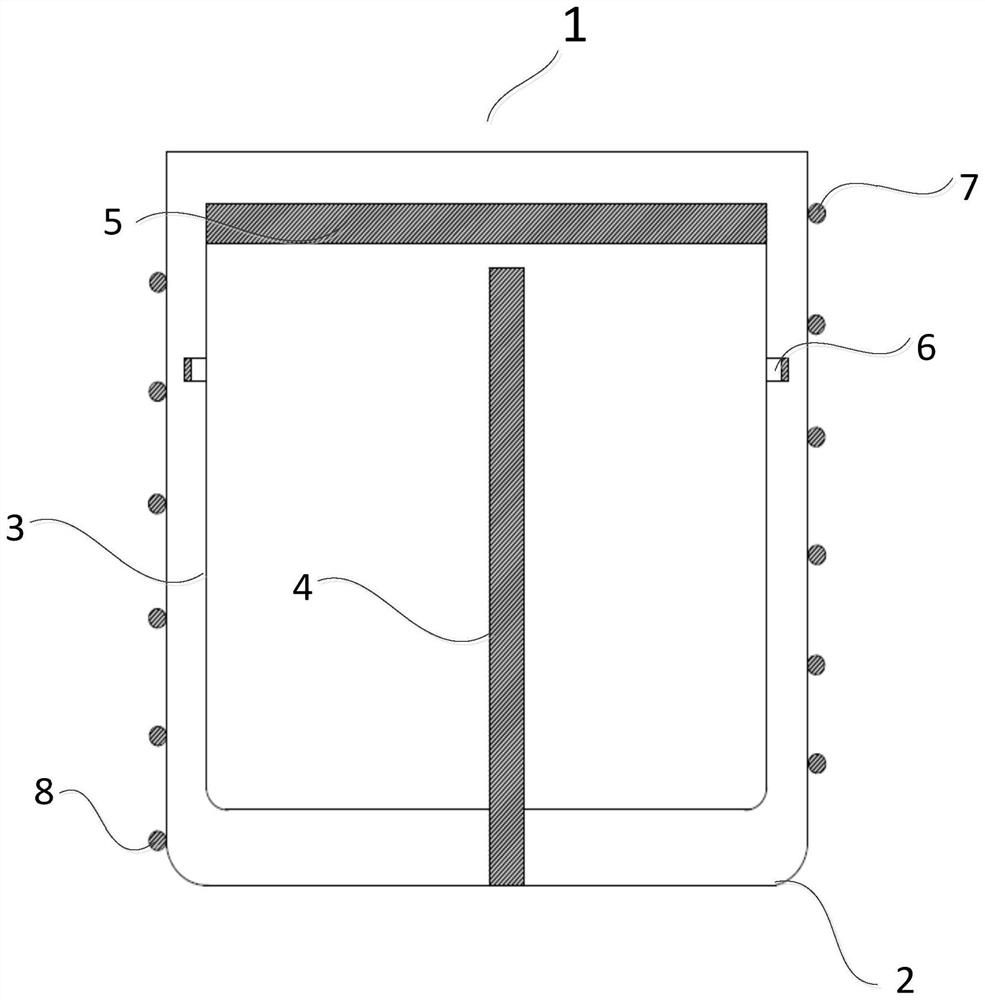

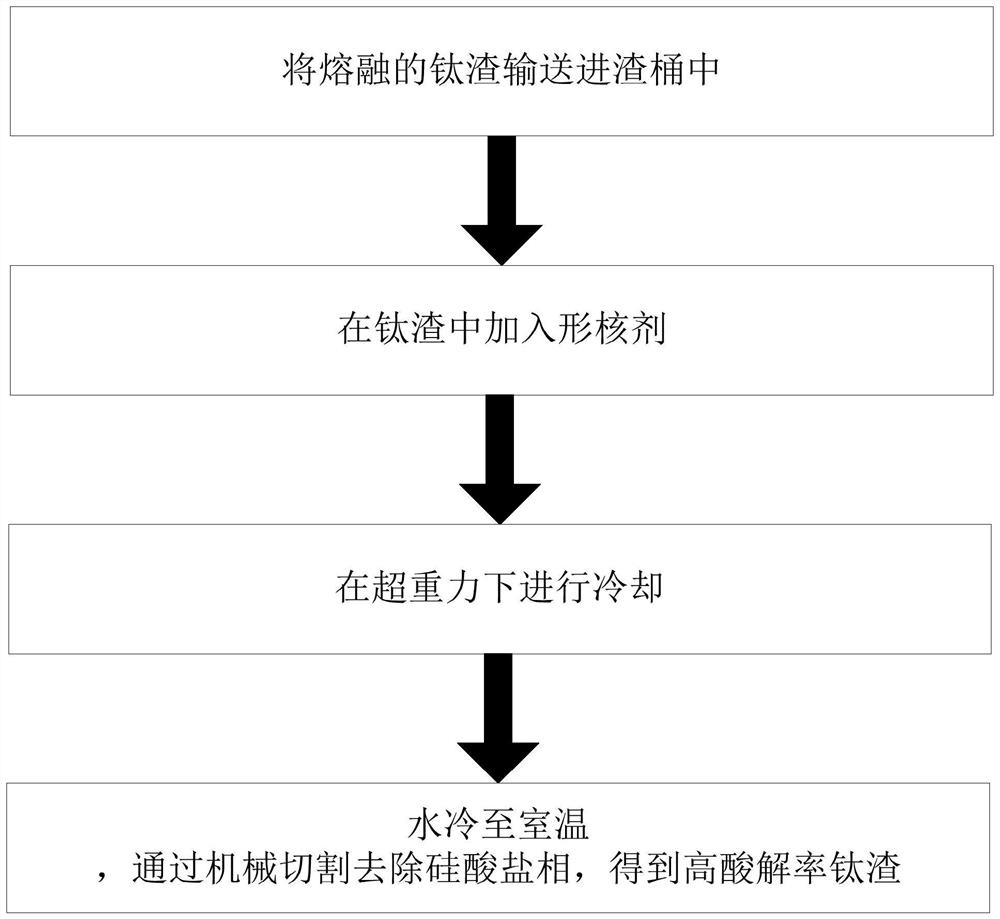

The invention discloses a method for preparing titanium slag with high acidolysis rate. Add a nucleating agent and mix well; (3) cool the mixture in step (2) under supergravity; (4) take out the cooled mixture in step (3) and cool it to room temperature, and remove silicon by mechanical cutting acid salt phase to obtain titanium slag with high acid hydrolysis rate. The method of the present invention introduces the addition of a nucleating agent and a supergravity field into the titanium slag melt, and by controlling the cooling rate, different phases are directional enriched and precipitated in the titanium slag, and by removing the phase silicic acid that affects the acidolysis rate The salt phase greatly improves the acid hydrolysis rate of titanium slag.

Description

A kind of method for preparing high acid hydrolysis rate titanium slag technical field The invention belongs to the field of titanium slag aftertreatment and preparation of titanium dioxide, in particular to a method for preparing high acid hydrolysis rate titanium slag The method is applicable to all fields of titanium slag smelting and titanium slag production of titanium dioxide. Background technique The essence of electric furnace smelting titanium slag is that ilmenite and solid reducing agent anthracite or petroleum coke are mixed and added in electric furnace. In reduction smelting, the oxides of iron in the ore are selectively reduced to metallic iron, and the oxides of titanium are enriched in the slag. After the slag and iron are separated, titanium slag and by-product metallic iron are obtained. The conventionally produced titanium slag is acid-soluble titanium slag for the production of titanium dioxide by the sulfuric acid method. The acidolysis rate of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G23/053

CPCC01G23/053Y02P10/20

Inventor 刘娟肖军李凯茂宋兵

Owner PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com