Acid hydrolysis of cobalt waste and its application in the preparation of high-purity cobalt liquid for tricobalt tetroxide

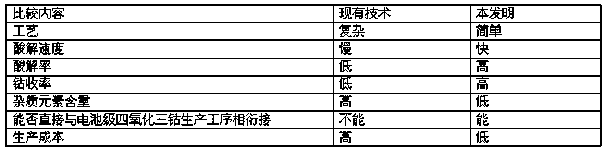

A technology of waste acid and waste, which is applied in the field of acid hydrolysis of cobalt waste and in the preparation of high-purity cobalt liquid for cobalt tetroxide, can solve the problems of not being able to meet the requirements, and achieve low production cost, high purity, and low content of impurity elements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

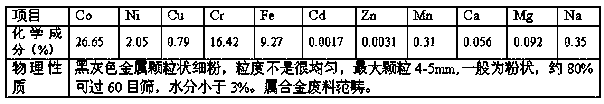

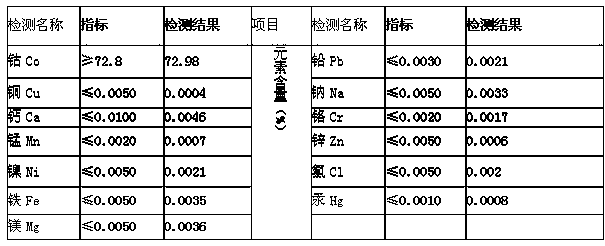

[0031] Example 1: Cobalt waste acid hydrolysis method, the cobalt-containing alloy waste is first acidly hydrolyzed with concentrated sulfuric acid, and then concentrated hydrochloric acid is added to acidolyze with mixed acid to prepare an acidolysis mother liquor.

Embodiment 2

[0032] Embodiment 2: Cobalt waste acid hydrolysis method, the cobalt-containing alloy waste is first acidly hydrolyzed with concentrated sulfuric acid, water is added in advance in the mixing tank, and concentrated sulfuric acid is slowly added according to 10-20% of the water volume in the stirring state, according to the water and containing The mass ratio of cobalt alloy waste is 1: 0.3-0.5, and the cobalt-containing alloy waste is added. After the violent reaction stops, the steam is heated to 60-100°C; Add concentrated hydrochloric acid to 8-15% of the volume, keep at 80-100°C, stir for 2-12 hours, then let stand for 2-10 hours; then filter to obtain the acidolysis mother liquor.

Embodiment 3

[0033] Embodiment 3: cobalt waste acid hydrolysis method, carry out as follows:

[0034] a. Add water in the mixing tank in advance, slowly add concentrated sulfuric acid according to 10% of the volume of water under stirring state, add cobalt-containing alloy waste according to the volume ratio of water and cobalt-containing alloy waste at a ratio of 3:1, and pass through after the violent reaction stops. Steam is heated to boiling;

[0035] b. Insulate and stir the acid hydrolyzate in the above step for 5 hours, then add concentrated hydrochloric acid according to 15% of the total volume, keep at 60°C, stir for 4 hours, and then let stand for 4 hours;

[0036] c. After the mixed acid hydrolysis, the acid hydrolyzate is filtered and washed, the filtrate enters the next process, the washing liquid is returned to the mixed acid hydrolysis section for acid adjustment, and the filter cake is harmlessly treated;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com