a leaching tank

A technology of leaching and kettle body, which is applied in the field of metal leaching equipment to achieve the effects of avoiding dead corners of stirring, high efficiency, and saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

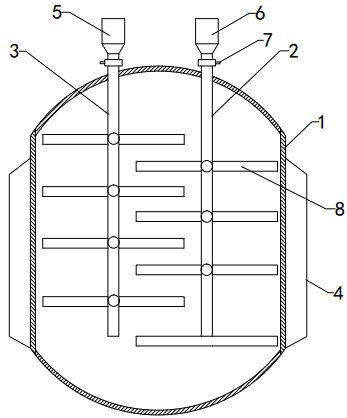

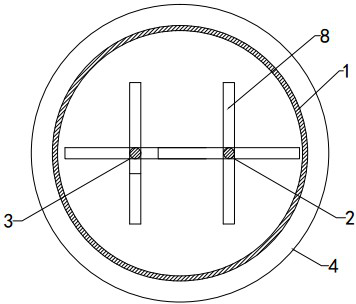

[0018] Refer to attached figure 1 , 2 : A kind of leaching kettle, comprises the kettle body 1 that is provided with jacket 4, is provided with two groups of stirring paddles in the kettle cavity of kettle body 1, and the material of stirring paddles is tungsten electrode material; The first stirring paddle 2 and the second stirring paddle 3 are equipped with multi-layer horizontal stirring pages, and the stirring pages 8 of the two sets of stirring paddles are alternately arranged up and down; the top of the first stirring paddle 2 is connected to the first motor 6 through an insulating part, and the top of the second stirring paddle 3 is connected to the first motor 6 through an insulating part. The second motor 5, the first motor 6 and the second motor 5 are variable frequency motors; the top of each stirring paddle is provided with a carbon brush 7, and the carbon brush 7 is provided with a terminal, and the connection voltage of the terminal is 10V ~ 30V Power supply; a ...

Embodiment 2

[0022] The basic structure is the same as above and attached figure 1 , 2 As shown, the difference is that the electrode plate 3 is made of stainless steel, and the stirring blades 8 include long stirring blades and short stirring blades. The stirring blades and the short stirring blades are arranged alternately up and down on the same stirring paddle. Long stirring pages and short stirring pages at the same height are arranged alternately on the stirring paddle; the top of the first stirring paddle 2 is connected to the first motor 6 through the first gearbox, and the top of the second stirring paddle 3 is connected to the second motor 6 through the second gearbox. The output ends of the motor 5, the first gearbox and the second gearbox are coated with insulating materials;

[0023] After the zinc concentrate is crushed, it is added to the above-mentioned leaching kettle together with the leaching solution, and the zinc content in the zinc concentrate is 43.2% by mass percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com