Lithium-sulfur battery all-solid-state electrolyte and preparation method thereof

A technology of lithium-sulfur batteries and electrolytes, applied in the field of all-solid-state electrolytes, to achieve the effects of high safety performance, low synthesis cost, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

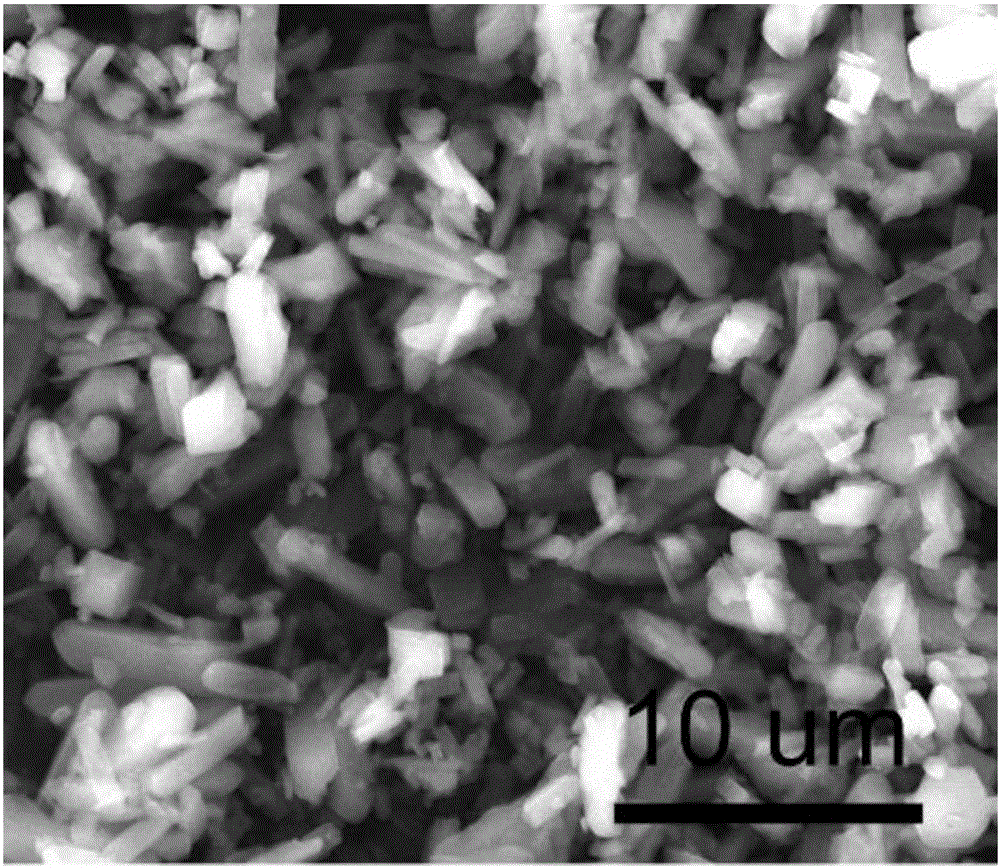

[0042] (1) Preparation of aluminum-based porous coordination polymers

[0043] 1.5g of Al(NO 3 ) 3 and 0.432g of H 2NDC was dissolved in 40mL of deionized water, transferred to a hydrothermal kettle lined with polytetrafluoroethylene, sealed, heated to 180°C in an oven, hydrothermally reacted under airtight conditions for 24 hours to obtain the reaction product, and filtered the reaction product to obtain a light yellow powder , washed with water until the pH is neutral, and vacuum-dried and dehydrated at 150° C. for 12 hours to obtain an aluminum-based porous coordination polymer.

[0044] (2) Preparation of all-solid-state electrolytes for lithium-sulfur batteries

[0045] Add 0.5g of the aluminum-based porous coordination polymer obtained in step (1) into 10mL of a 0.2M lithium isopropoxide hexane solution and immerse for 7d, then vacuum-dry at 80°C and 0.1MPa to remove the organic solution for 24h , to obtain an aluminum-based porous coordination compound rich in lithi...

Embodiment 2

[0052] (1) Preparation of aluminum-based porous coordination polymers

[0053] 1.5g of Al(NO 3 ) 3 and 0.4584g of H 3 BTB was dissolved in 40mL of deionized water, transferred to a hydrothermal kettle lined with polytetrafluoroethylene, sealed, heated to 180°C in an oven, hydrothermally reacted under airtight conditions for 24 hours to obtain the reaction product, and filtered the reaction product to obtain a light yellow powder , washed with water until the pH is neutral, and vacuum-dried and dehydrated at 150° C. for 12 hours to obtain an aluminum-based porous coordination polymer.

[0054] (2) Preparation of all-solid-state electrolytes for lithium-sulfur batteries

[0055] Add 0.5g of the aluminum-based porous coordination polymer obtained in step (1) into 10mL of a hexane solution with a concentration of 0.2M lithium isopropoxide and immerse for 7d, then vacuum-dry at 80°C and 0.1MPa for 24h to remove the organic solution, Obtain an aluminum-based porous coordination ...

Embodiment 3

[0062] (1) Preparation of aluminum-based porous coordination polymers

[0063] 1.5g of Al(NO 3 ) 3 and 0.28 g of H 3 BTC was dissolved in 40mL of deionized water, transferred to a hydrothermal kettle lined with polytetrafluoroethylene, sealed, heated to 180°C in an oven, hydrothermally reacted under airtight conditions for 24 hours to obtain the reaction product, and filtered the reaction product to obtain a light yellow powder , washed with water until the pH is neutral, and vacuum-dried and dehydrated at 150° C. for 12 hours to obtain an aluminum-based porous coordination polymer.

[0064] (2) Preparation of all-solid-state electrolytes for lithium-sulfur batteries

[0065] Add 0.5 g of the aluminum-based porous coordination polymer obtained in step (1) into 10 mL of a 0.2 M lithium isopropoxide hexane solution and immerse for 7 days, then vacuum-dry at 80 ° C and 0.1 MPa for 24 hours to remove the organic solution. Obtain an aluminum-based porous coordination compound r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com