Super-hydrophobic modification method of mineral admixtures

A technology of mineral admixture and super-hydrophobic modification, applied in the field of super-hydrophobic modification of mineral admixture, can solve the problems of concrete cracking, steel bar corrosion, damage, etc., to increase the contact angle, increase the dispersibility, improve the The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Superhydrophobic modification of zeolite powders with different particle sizes:

[0022] Take 2 parts of 200g zeolite powder (commercially available natural clinoptilolite or mordenite powder can be used, the effect is the same), and use a planetary ball mill to grind to 200 mesh and 1200 mesh respectively for later use.

[0023] Take a 200-mesh zeolite powder sample and add it to 500ml of ethanol, ultrasonically treat it for 10 minutes, add 2ml of water dropwise under stirring conditions, and add 10g of KH-550 coupling agent dropwise after stirring evenly; then cyclohexane-n-butanol mixture ( Volume ratio 1:1) Add 200ml of the above solution and mix evenly, slowly add 25g of methyl silicone oil dropwise while stirring, continue stirring for 1 hour, dry the slurry and grind it to get the required 200 mesh superhydrophobic zeolite powder.

[0024] Another 1200-mesh zeolite powder sample was added to 500ml ethanol, ultrasonically treated for 10 minutes, 2ml wate...

Embodiment 2

[0026] Example 2 Carry out superhydrophobic modification to mica powder and metakaolin powder:

[0027] Take 200g of mica powder and 200g of metakaolin, and use a planetary ball mill to grind to 400 mesh and 2000 mesh respectively.

[0028] Take the ground 400-mesh mica powder sample and add it to 500ml of ethanol, ultrasonically treat it for 10min, add 2ml of water dropwise under the condition of stirring, add 10g of KH-550 coupling agent dropwise after stirring evenly; then cycloethane-n-butanol Add 200ml of the mixed solution (volume ratio 1:1) to the above solution and mix evenly, add 22g of methyl silicone oil dropwise under stirring, continue stirring for 1 hour, then dry the slurry and grind it to obtain the required 400-mesh superhydrophobic mica pink.

[0029] Take a 2000-mesh metakaolin powder sample and add it to 500ml ethanol, ultrasonically treat it for 10 minutes, add 2ml water dropwise under stirring conditions, add 14g KH-550 coupling agent dropwise after stir...

Embodiment 3

[0032] Embodiment 3 water absorption test

[0033] The water absorption rate of the specimen can reflect the difficulty of water entering the interior of the concrete, and then explain the ability of the concrete to resist the erosion of poor water quality.

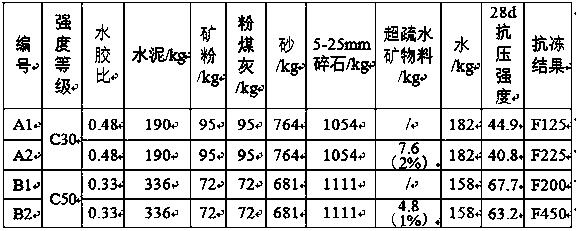

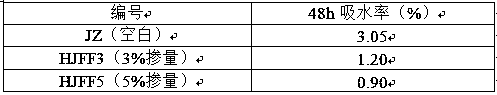

[0034]The superhydrophobic modified mica powder and the superhydrophobic modified metakaolin powder mixture obtained after modification in Example 2 are used as admixtures, and the admixture additions are respectively 3% and 5% of the cementitious material in concrete. In the concrete, concrete flat specimens of 300mm×300mm×50mm were prepared respectively, and the concrete flat specimens without modified admixture were used as blank comparison pieces. After standard curing for 28 days, the initial weight was weighed after drying in an oven at 80°C for 72 hours. Then put the test piece into the water tank with the forming side up, and pad the lower part with a 10mm diameter round steel bar. The height of the test piece su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com