Method for preparing nano silver sol modified by sulfonation cup arene

A technology for sulfonating calixarene and nano-silver sol, which is applied in the fields of nanomaterial chemistry and analytical chemistry, can solve the problems of unsuitable on-site detection, high time-consuming and cost, cumbersome sample processing, etc., and achieves that the modification method is simple, easy and repeatable. The effect of good performance and easy availability of ligands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

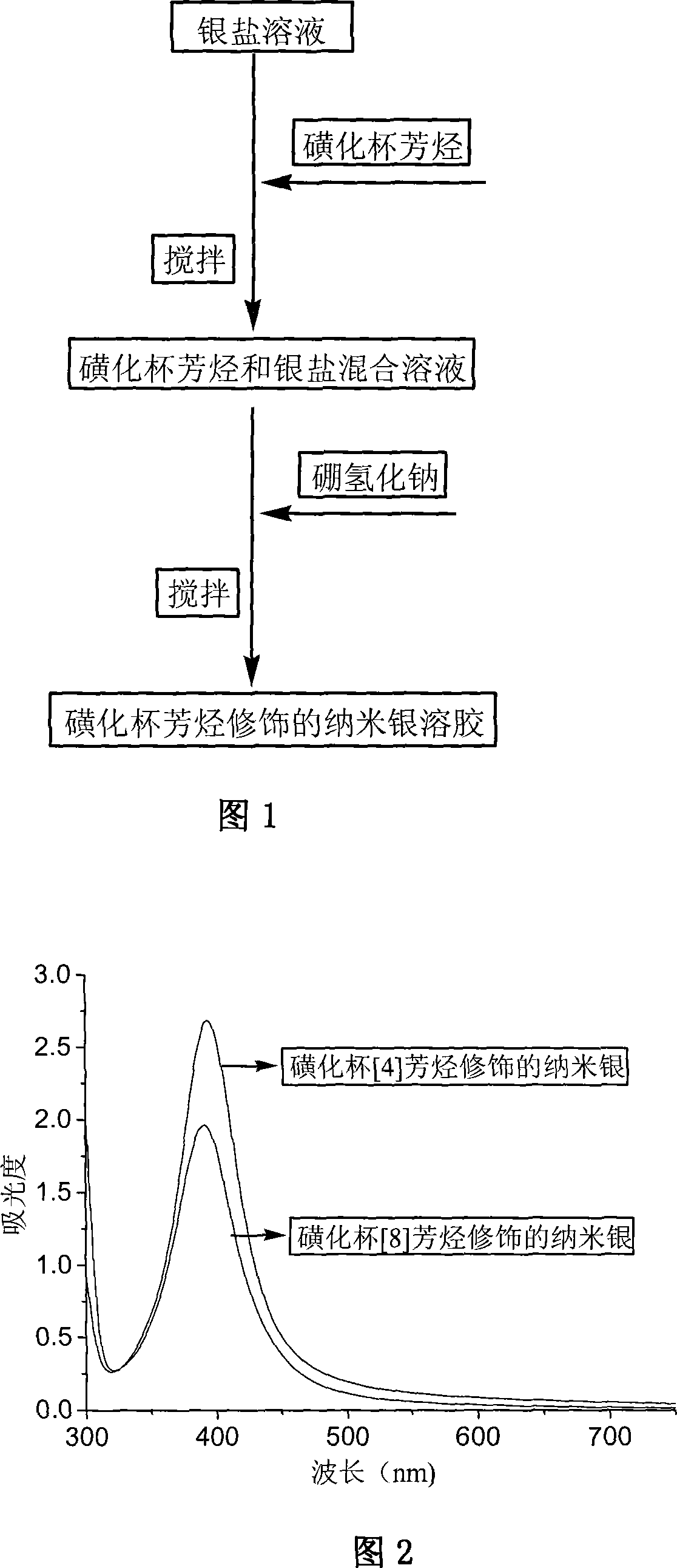

[0035] (1) Preparation of sulfonated calix[4]arene modified nano-silver sol

[0036] At room temperature, take 2 mL of 10 -2 mol / L silver nitrate solution, respectively added to 96mL of twice distilled water and 2 ml of 10 -2 mol / L aqueous solution of sulfonated calix[4]arene, stirred for 20 minutes. Then add 8.8 mg of sodium borohydride, and continue to stir for 5 minutes, so that the nano-silver sol modified by sulfonated calix[4]arene is prepared.

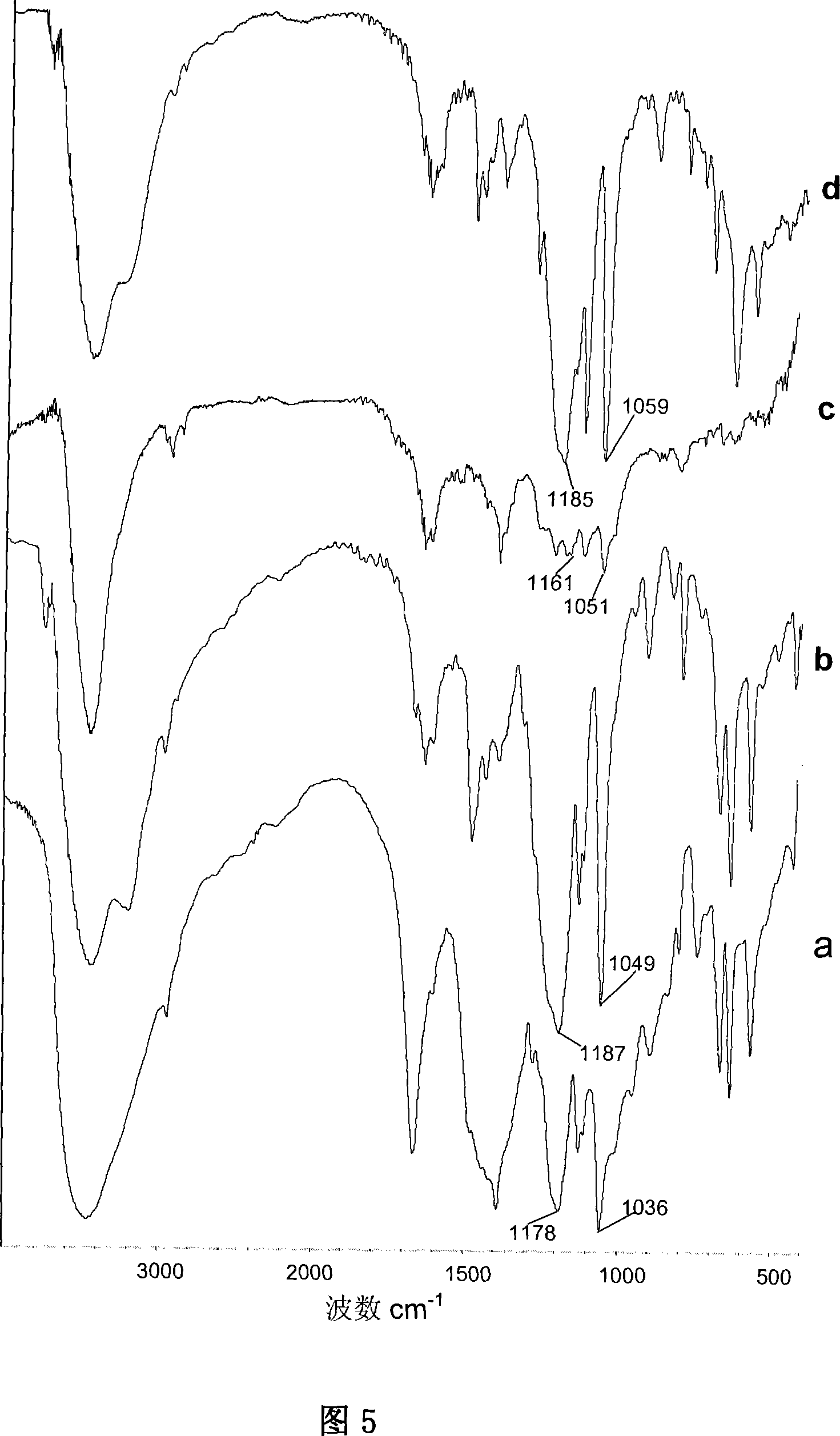

[0037] Colorimetric detection of isocarbophos in sulfonated calix[4]arene modified nano-silver sol:

[0038] 0.5mL different concentrations (10 -3 -10 -7 mol / L) of isocarbophos was added to 2 mL of sulfonated calix[4]arene-modified nano-silver sol, and mixed evenly. After 10 minutes, the color of the solution changed from yellow to red.

Embodiment 2

[0040] (1) Preparation of sulfonated calix[4]arene modified nano-silver sol

[0041] At room temperature, take 2 mL of 10 -2 mol / L silver nitrate solution, respectively added to 96mL of twice distilled water and 2 ml of 10 -2 mol / L aqueous solution of sulfonated calix[4]arene, stirred for 20 minutes. Then add 4.4 mg of sodium borohydride, and continue to stir for 5 minutes, so that the nano-silver sol modified by sulfonated calix[4]arene is prepared.

[0042] Colorimetric detection of isocarbophos in sulfonated calix[4]arene modified nano-silver sol:

[0043] 0.5mL different concentrations (10 -3 -10 -7 mol / L) of isocarbophos was added to 2 mL of sulfonated calix[4]arene-modified nano-silver sol, and mixed evenly. After 10 minutes, the color of the solution changed from yellow to red.

Embodiment 3

[0045] (1) Preparation of sulfonated calix[4]arene modified nano-silver sol

[0046] At room temperature, take 2 mL of 10 -2 mol / L silver nitrate solution, respectively added to 96mL of twice distilled water and 2 ml of 10 -2 mol / L aqueous solution of sulfonated calix[4]arene, stirred for 20 minutes. Then add 8.8 mg of sodium borohydride and continue to stir for 10 minutes, so that the nano-silver sol modified by sulfonated calix[4]arene is prepared.

[0047] Sulfonated calix[4]arene modified nano-silver sol for the detection of isocarbophos:

[0048] 0.5mL different concentrations (10 -3 -10 -7 mol / L) of isocarbophos was added to 2 mL of sulfonated calix[4]arene-modified nano-silver sol, and mixed evenly. After 10 minutes, the color of the solution changed from yellow to red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com