Water quality modifier and preparation method thereof

A water quality improver, zeolite powder technology, applied in chemical instruments and methods, water/sewage treatment, animal husbandry wastewater treatment, etc., can solve problems such as poor water quality improvement effect, poor ammonia nitrogen effect, and unfavorable fish survival. Fish and shrimp float, which is beneficial to absorption and enhances the effect of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

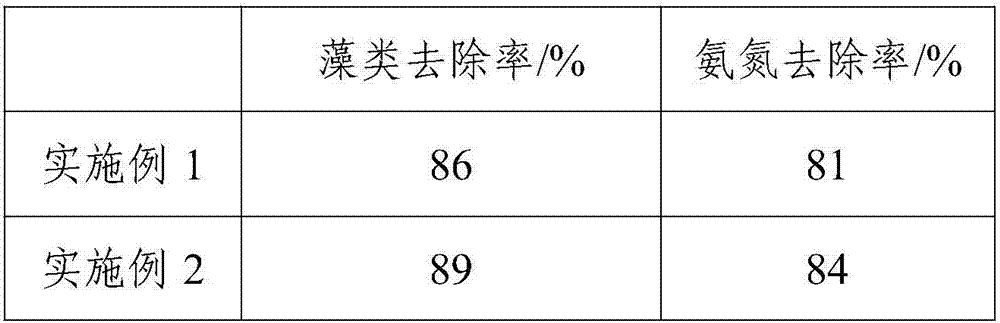

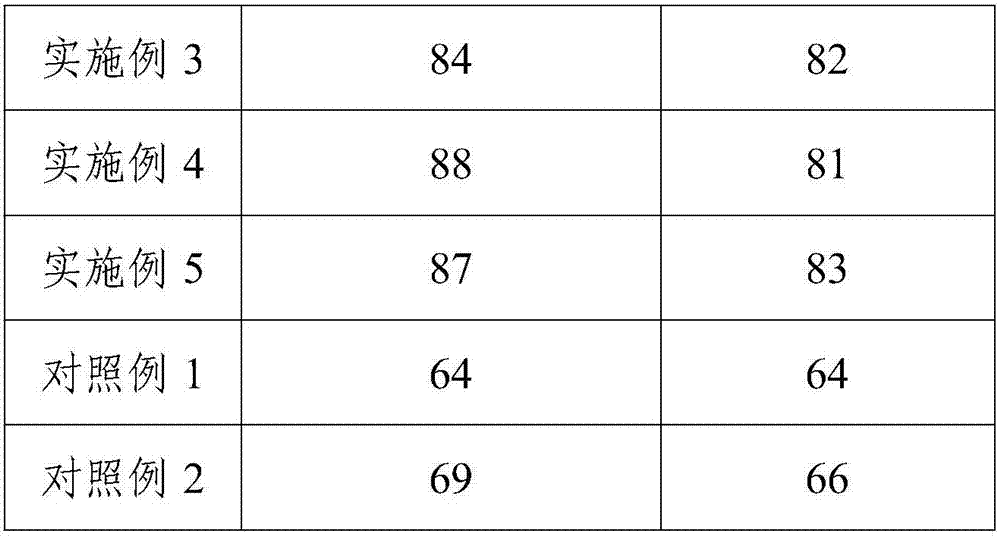

Examples

Embodiment 1

[0022] A water quality improver, made of the following raw materials in parts by weight: 20 parts of zeolite powder, 12 parts of calcium peroxide, 13 parts of lignite, 4 parts of lignin, 5 parts of polyethylene glycol, 4 parts of potassium ferrate, titanium dioxide powder 6 parts, 7 parts of polyethyleneimine.

[0023] A water quality improver, its preparation method comprises the following steps:

[0024] (1) Put zeolite powder and calcium peroxide in the container, add water equal to the sum of the two masses, stir evenly, ultrasonically treat for 10 minutes, and set aside;

[0025] (2) Put the lignite in the container, add an appropriate amount of dilute hydrochloric acid to adjust the pH to 2, and after activating for 1 hour, add sodium hydroxide equal in quality to the lignite for 2 hours, then separate and remove slag, filter, and dry the filter cake to obtain Pure sodium humate, spare;

[0026] (3) Put lignin and polyethylene glycol in the reaction kettle, heat it to ...

Embodiment 2

[0030] A water quality improver, made from the following raw materials in parts by weight: 30 parts of zeolite powder, 25 parts of calcium peroxide, 27 parts of lignite, 11 parts of lignin, 10 parts of polyethylene glycol, 11 parts of potassium ferrate, titanium dioxide powder 13 parts, polyethyleneimine 15 parts.

[0031] A water quality improver, its preparation method comprises the following steps:

[0032] (1) Put zeolite powder and calcium peroxide in the container, add water equal to the sum of the two masses, stir evenly, ultrasonically treat for 15 minutes, and set aside;

[0033] (2) Put the lignite in the container, add an appropriate amount of dilute hydrochloric acid to adjust the pH to 2.5, after 2 hours of activation treatment, add sodium hydroxide equal in quality to the lignite for 2 hours, then separate and remove slag, filter, and dry the filter cake to obtain Pure sodium humate, spare;

[0034] (3) Put lignin and polyethylene glycol in the reaction kettle,...

Embodiment 3

[0038] A water quality improver, made of the following raw materials in parts by weight: 24 parts of zeolite powder, 18 parts of calcium peroxide, 20 parts of lignite, 7 parts of lignin, 7 parts of polyethylene glycol, 6 parts of potassium ferrate, titanium dioxide powder 8 parts, polyethyleneimine 10 parts.

[0039] A water quality improver, its preparation method comprises the following steps:

[0040] (1) Put zeolite powder and calcium peroxide in the container, add water equal to the sum of the two masses, stir evenly, ultrasonically treat for 11 minutes, and set aside;

[0041] (2) Put the lignite in the container, add an appropriate amount of dilute hydrochloric acid to adjust the pH to 2.1, and after 1.2 hours of activation treatment, add sodium hydroxide of the same quality as the lignite for 2 hours, then separate and remove slag, filter, and dry the filter cake Obtain pure sodium humate for subsequent use;

[0042] (3) Put lignin and polyethylene glycol in the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com