Method for producing dephenolizing cotton protein by cottonseed cold press and mixed solvent primary leaching

A technology of mixing solvent and cotton protein, applied in the direction of protein composition of microorganisms, protein food ingredients, protein composition of waste, etc., can solve the problems of unsuitability for large-scale production, complicated cotton blank treatment process, leaching of wet meal residue oil, etc. , to increase the cold pressing section, the equipment versatility is good, and the residual oil of cotton protein is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

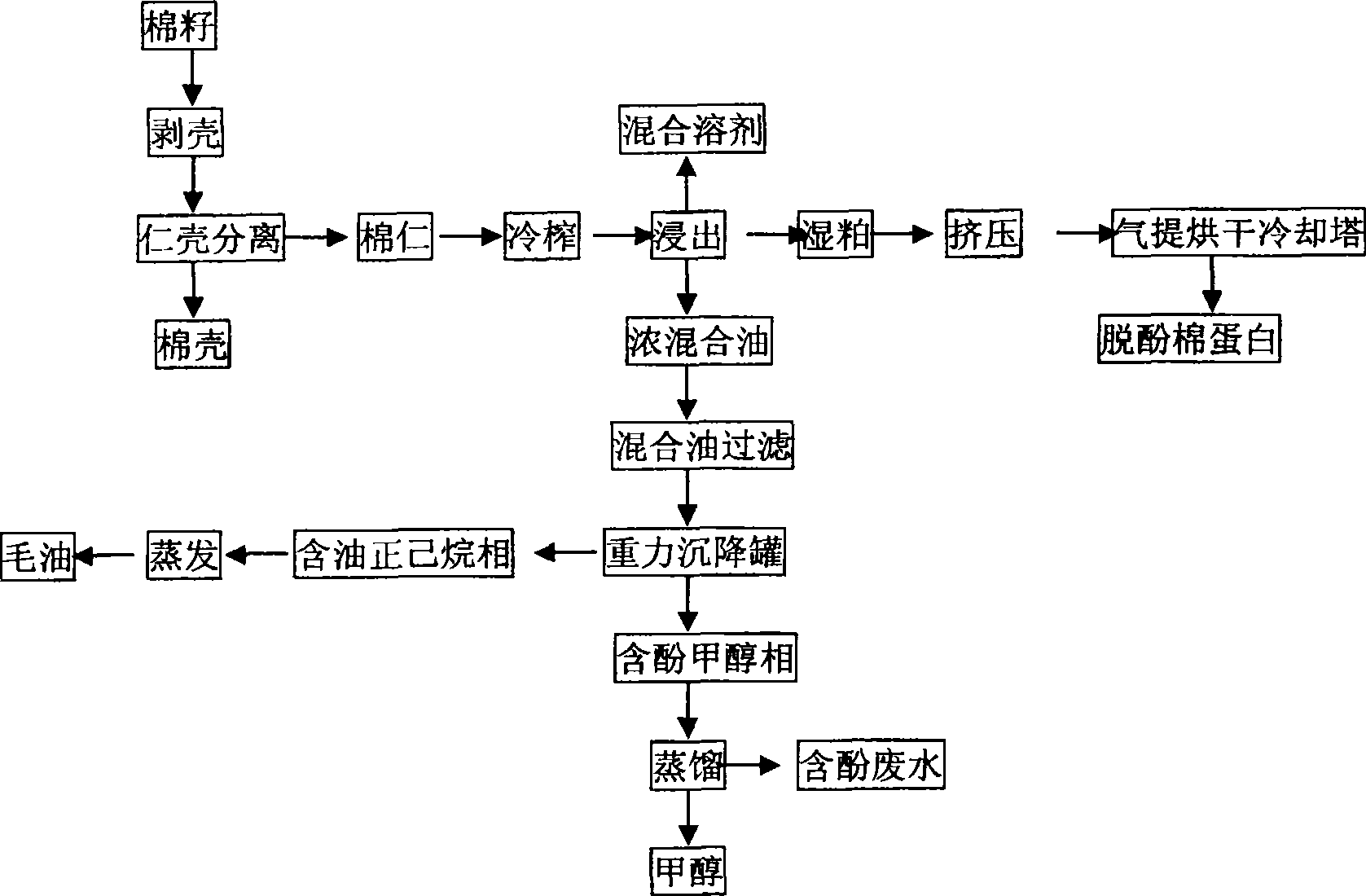

[0043] As shown in the figure, the inventive method is as follows:

[0044] (1) Broken and peeled

[0045] Crush the cottonseed into broken pieces, and the powder degree is less than 7%, so as to ensure the next process of shelling is clean;

[0046] (2) kernel shell separation

[0047] The kernel-hull separation sieve, circular sieve and air sieve specific gravity combination separator are used to form a kernel-husk separation combination system.

[0048] (3) Low temperature cold pressing

[0049] Use a cold press with a cooling device to squeeze the oil, and obtain a cold-pressed cake with 15-20% oil at low temperature, so that 15-25% of the oil can be taken out;

[0050] (4) Mixed solvent leaching

[0051] The cold-pressed cake directly enters the shallow bed leaching device, and two solvents, n-hexane and methanol, are added according to the material-solvent ratio of 1:1.5, and the weight ratio of n-hexane and methanol is 6:2. The method of extracting gossypol to prod...

Embodiment 2

[0060] Method of the present invention is as follows:

[0061] (1) Broken and peeled

[0062] Crush the cottonseed into broken pieces, and the powder degree is less than 10%, so as to ensure the next process of shelling is clean;

[0063] (2) kernel shell separation

[0064] The kernel-hull separation sieve, circular sieve and air sieve specific gravity combination separator are used to form a kernel-husk separation combination system.

[0065] (3) Low temperature cold pressing

[0066] Use a cold press with a cooling device to squeeze the oil, and obtain a cold-pressed cake with 15% oil at low temperature, so that 15% of the oil can be taken out;

[0067] (4) Mixed solvent leaching

[0068] The cold-pressed cake directly enters the shallow bed extractor, and two solvents, n-hexane and methanol, are added according to the material-solvent ratio of 1:1.2, and the weight ratio of n-hexane and methanol is 4:2. The method of extracting gossypol to produce gossypol, in which n-h...

Embodiment 3

[0077] The inventive method is as follows:

[0078] (1) Broken and peeled

[0079] Crush the cottonseed into broken petals, and the powder degree is less than 9%, so as to ensure the next process of shelling is clean;

[0080] (2) kernel shell separation

[0081] The kernel-hull separation sieve, circular sieve and air sieve specific gravity combination separator are used to form a kernel-husk separation combination system.

[0082] (3) Low temperature cold pressing

[0083] Use a cold press with a cooling device to squeeze the oil, and obtain a cold-pressed cake with 16% oil at low temperature, so that 17% of the oil can be taken out;

[0084] (4) Mixed solvent leaching

[0085] The cold-pressed cake directly enters the shallow bed leaching device, and two solvents, n-hexane and methanol, are added according to the material-solvent ratio of 1:1.3, and the weight ratio of n-hexane and methanol is 5:2. The method of extracting gossypol to produce gossypol, wherein n-hexane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com