Weaving method for seamless non-snagging warp-knitted panty stockings

A technology for warp knitting pantyhose and pantyhose is applied in warp knitting, textiles, papermaking, knitting and other directions, which can solve the problems of holes in the socks body, embarrassment for wearers, and difficulty in knitting the socks to form patterns, and achieves good ventilation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

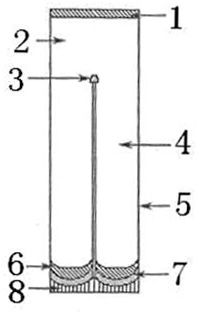

[0023] like Figure 1-9 As shown, a weaving method of warp-knitted pantyhose that is seamless and does not snag, the pantyhose is composed of a trouser waist 1, a trouser body 2, a crotch 3, a sock tube 4, front and rear seams 5, a sock tip 6, and a sock toe 7 and section 8 are made up of eight parts. In this embodiment, the pantyhose is made of porous and fine-denier polyamide fiber filament material, which makes the pantyhose fabric soft to the touch.

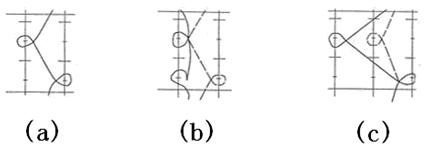

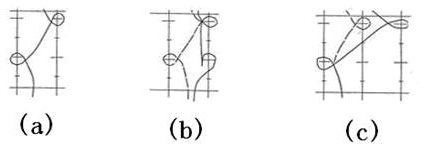

[0024] 1. Each organization of jacquard unit

[0025] Pantyhose is woven on the double-needle bed using the unique knitting rules of warp knitting. In the double-needle bed jacquard system, each jacquard unit has fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com