Household dry cleaning device, dry cleaning method and dry cleaning solvent recovery method

A technology of dry cleaning device and dry cleaning solvent, applied in the field of dry cleaning, can solve the problems of large equipment volume, complicated process connection, numerous systems, etc., and achieve the effect of simplifying the washing process, reducing equipment volume, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

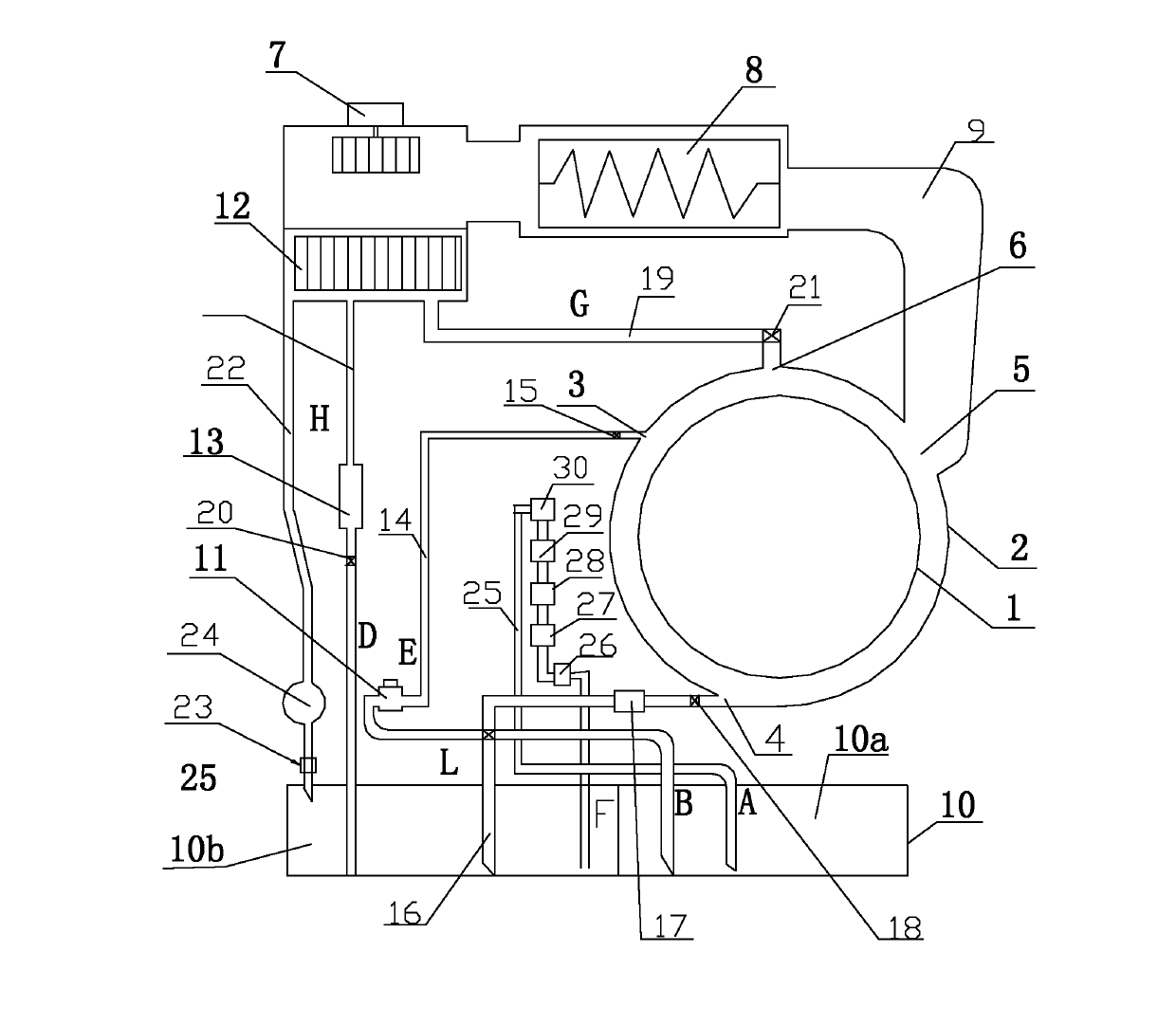

[0038] Such as figure 1 As shown, a dry cleaning machine includes an air supply system, a solvent condensation recovery system, a solvent filtration recovery system and a washing drum.

[0039] Wherein, the washing tub includes an inner tub 1 and an outer tub 2, and several openings (not shown) for solvent passage are arranged on the tub wall of the inner tub 1, and the clothes to be washed are placed in the inner tub 1 and The solvents required for dry cleaning are mixed, the inner cylinder 1 is driven to rotate by the driving device, and the clothes are continuously tumbled in the inner cylinder 1 to complete the washing of the clothes. A liquid inlet 3 , a liquid discharge 4 , an air inlet 5 and an exhaust port 6 communicating with the inner space of the outer cylinder 2 are opened on the wall of the outer cylinder 2 . In order to ensure the smooth inlet and outlet of liquid and gas, the liquid inlet 3 is located at the upper part of the outer cylinder 2, the liquid outlet...

Embodiment 2

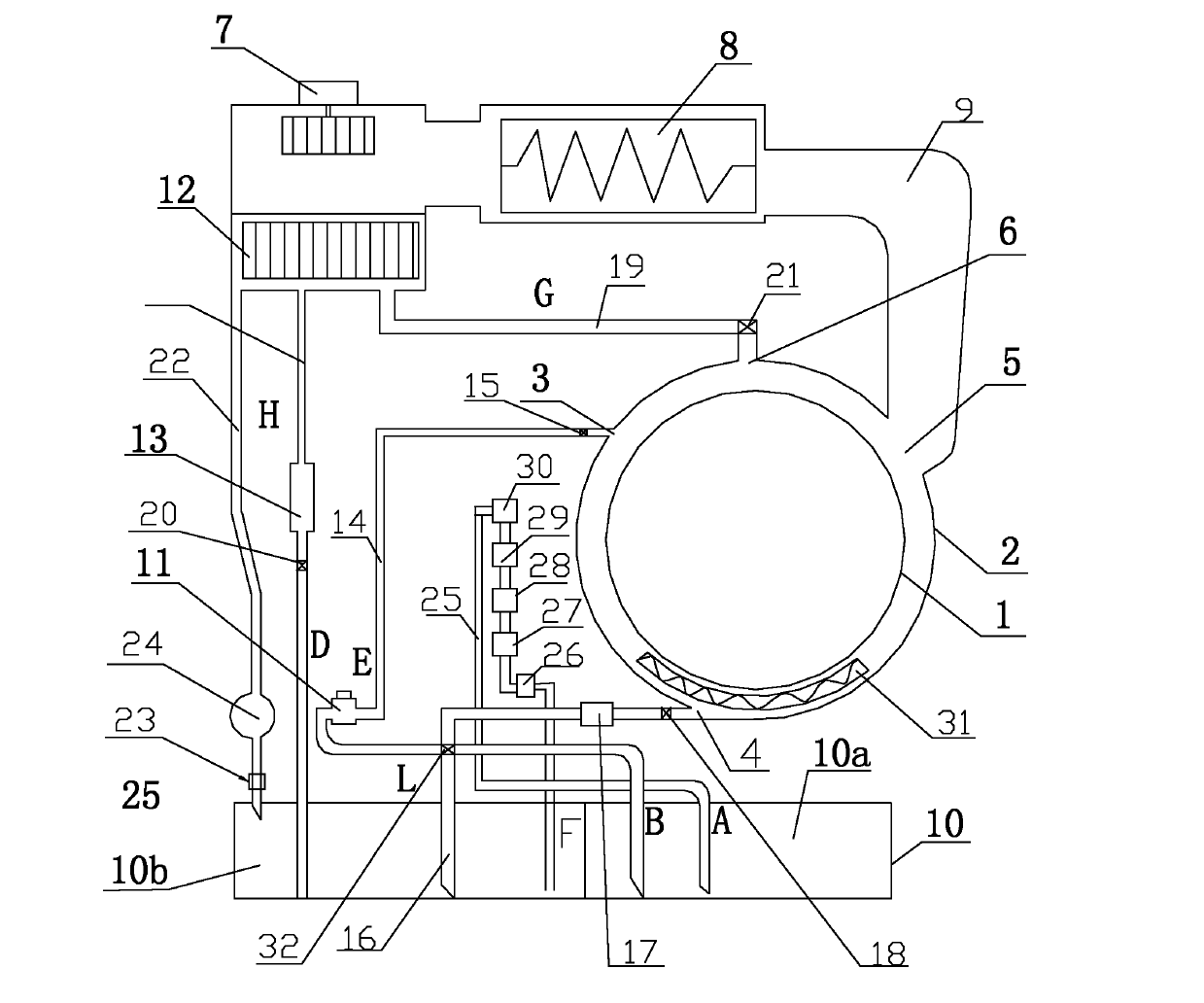

[0067] Such as figure 2 As shown, the difference from Example 1 is that a solvent purification and recovery system is also provided in the dry cleaning device, and the solvent is purified before or after filtration.

[0068] The solvent purification and recovery system includes a heating device 31 for heating and evaporating the solvent. The heating device 31 adopts an electric heater and is set in the space between the wall of the inner cylinder 1 and the wall of the outer cylinder 2, and is arranged on the outer cylinder 2 bottom position.

[0069] When the solvent needs to be purified, the solvent is put back into the outer cylinder 2 along the liquid inlet path before washing, the heating device 31 is activated, the solvent evaporates in the outer cylinder 2, the solenoid valve 21 is opened, and the solvent vapor passes through the exhaust Port 6 and electromagnetic valve 21 enter the G section of the condensation pipeline 19. After being condensed by the condenser 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com