Residual material recovery and nozzle cleaning method of a three-dimensional printing system

A technology of three-dimensional printing and printing materials, applied in the field of three-dimensional printing, can solve the problems of high value of printing materials, time-consuming and labor-intensive, residual printing materials, etc., and achieve the effect of simple and fast recycling method, simple and fast recycling, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

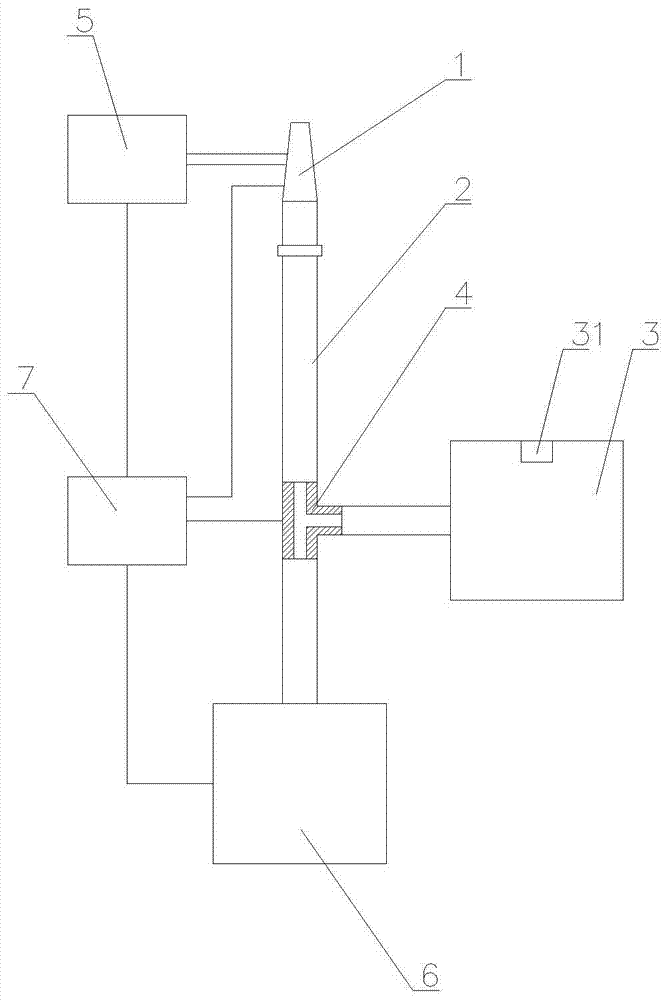

[0017] The three-dimensional printing system includes a nozzle 1, a connecting pipe 2 and a material box 3. The first end of the connecting pipe 2 is connected to the nozzle 1, and the second end is connected to the material box 3. The nozzle 1 extracts the printing material from the material box 3 for jet printing. After the printing is completed, If the remaining printing material in the nozzle 1 and the connecting pipe 2 is not processed in time, it will dry up and affect the next printing quality.

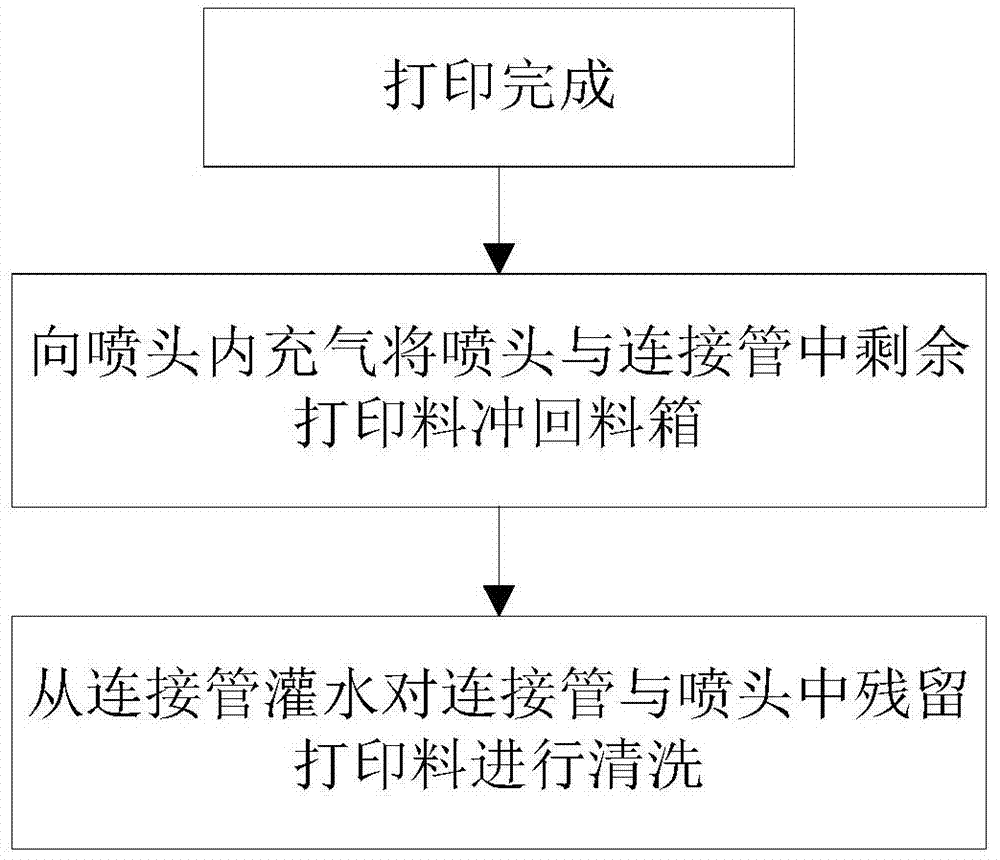

[0018] Such as figure 1 As shown, a method for recycling leftover materials and cleaning nozzles of a three-dimensional printing system proposed by the present invention uses pneumatic flushing and hydraulic flushing to recover and clean residual printing materials, and the specific steps are as follows:

[0019] S1. After the three-dimensional printing is completed, inflate the nozzle 1 to flush the remaining printing materials in the nozzle 1 and the connecting pipe 2 back to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com