Aluminum alloy profile sleeve connecting device

A technology of aluminum alloy profiles and connectors, applied in the direction of overhead lines, etc., can solve the problems of increasing the load of the catenary, heavy weight, and many fasteners, and achieve the effects of improving production efficiency, reducing weight, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further description of the aluminum alloy profile sleeve connector of the present invention in conjunction with the accompanying drawings and specific embodiments:

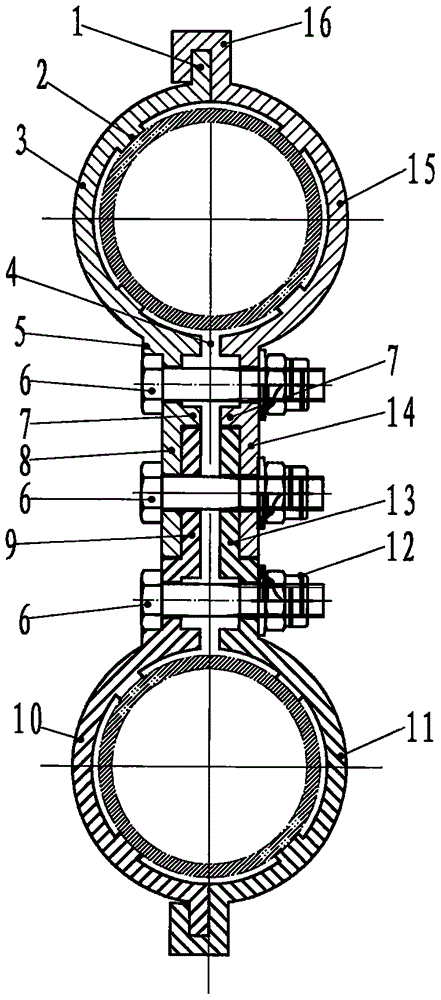

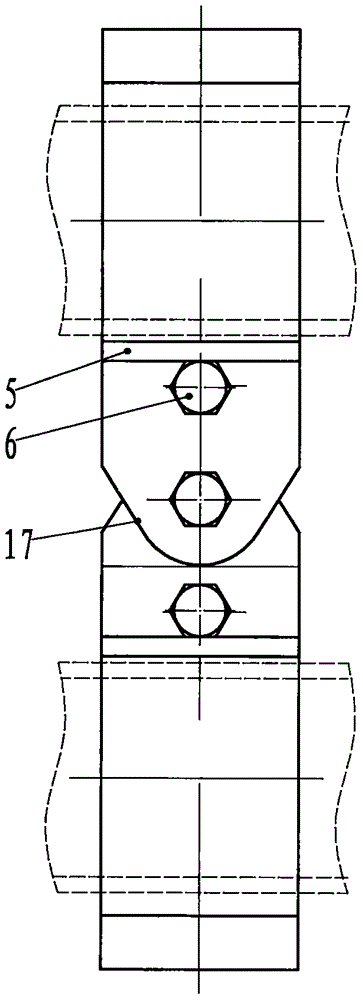

[0019] figure 1 It is a structural schematic diagram of the aluminum alloy profile sleeve connector of the present invention, figure 2 yes figure 1 left view of . In the figure, the aluminum alloy profile casing connector is composed of two casings fixedly connected, that is, the upper casing and the lower casing. The upper casing is composed of the main hoop 3 of the upper casing and the auxiliary hoop 15 of the upper casing. , the upper ring end of the upper casing main hoop 3 semi-circular ring is provided with an upwardly protruding clamping plate 1, and the lower end of the upper casing main hoop 3 semi-circular ring is provided with a downwardly extending upper casing main vertical plate 8 , two upper and lower bolt connection holes are arranged on the main vertical plate 8 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com