Rounding method of continuously processing metal round tube based on multiple stations

A multi-station, metal technology, applied in the direction of metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., can solve problems such as offset, low efficiency, and affecting the effect of finished products, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

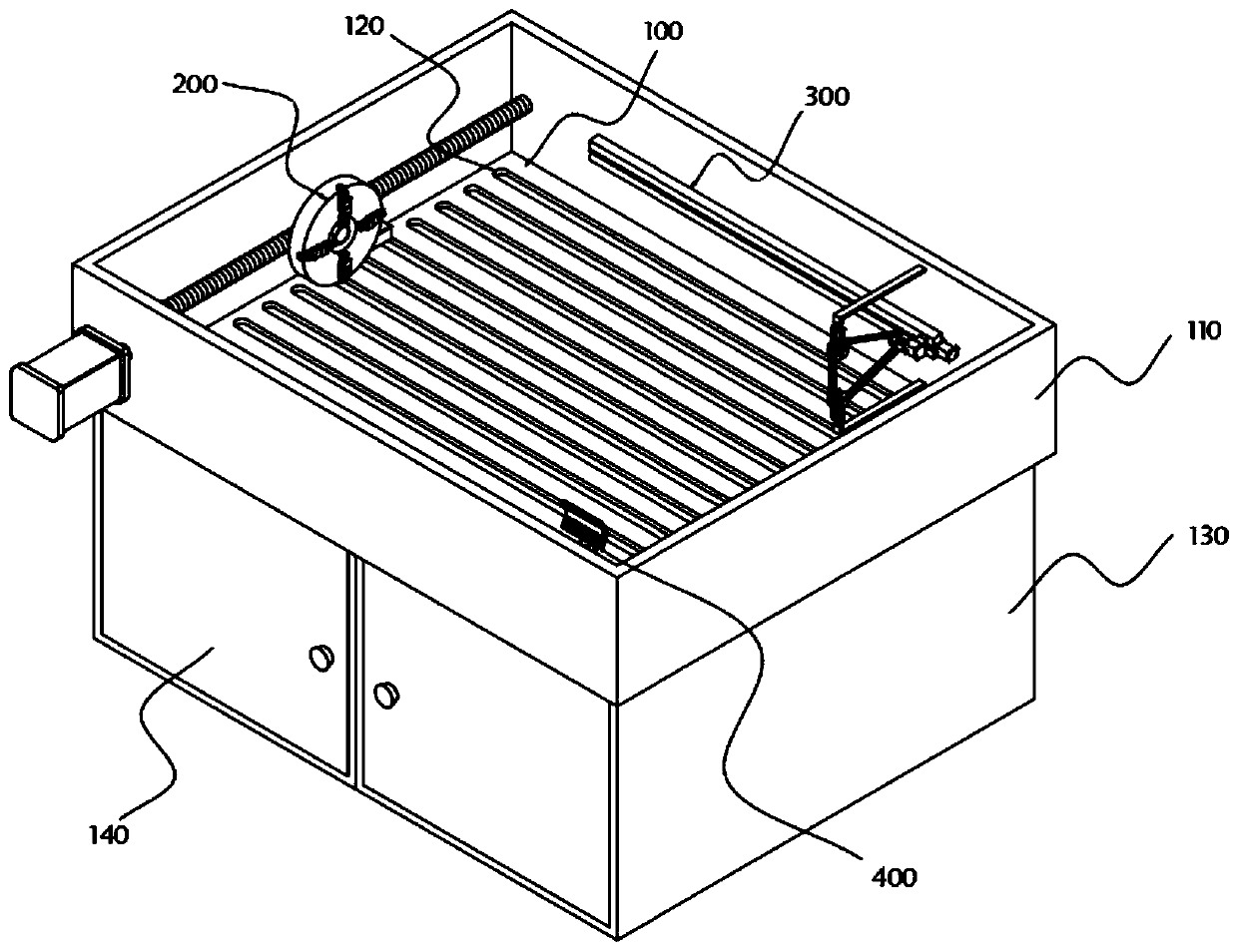

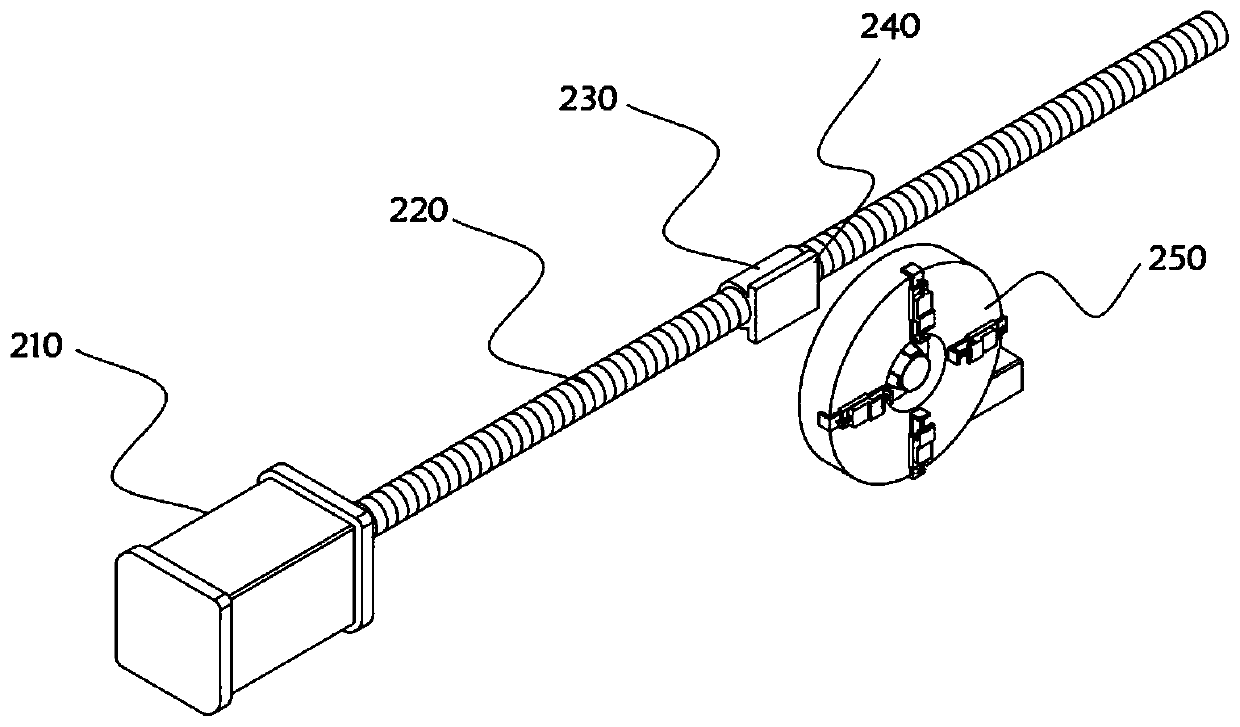

[0075] see Figure 1-Figure 18 As shown, the present invention provides a rounding method based on multi-station continuous processing metal round tubes, comprising the following steps:

[0076] (1) Metal tube positioning stage:

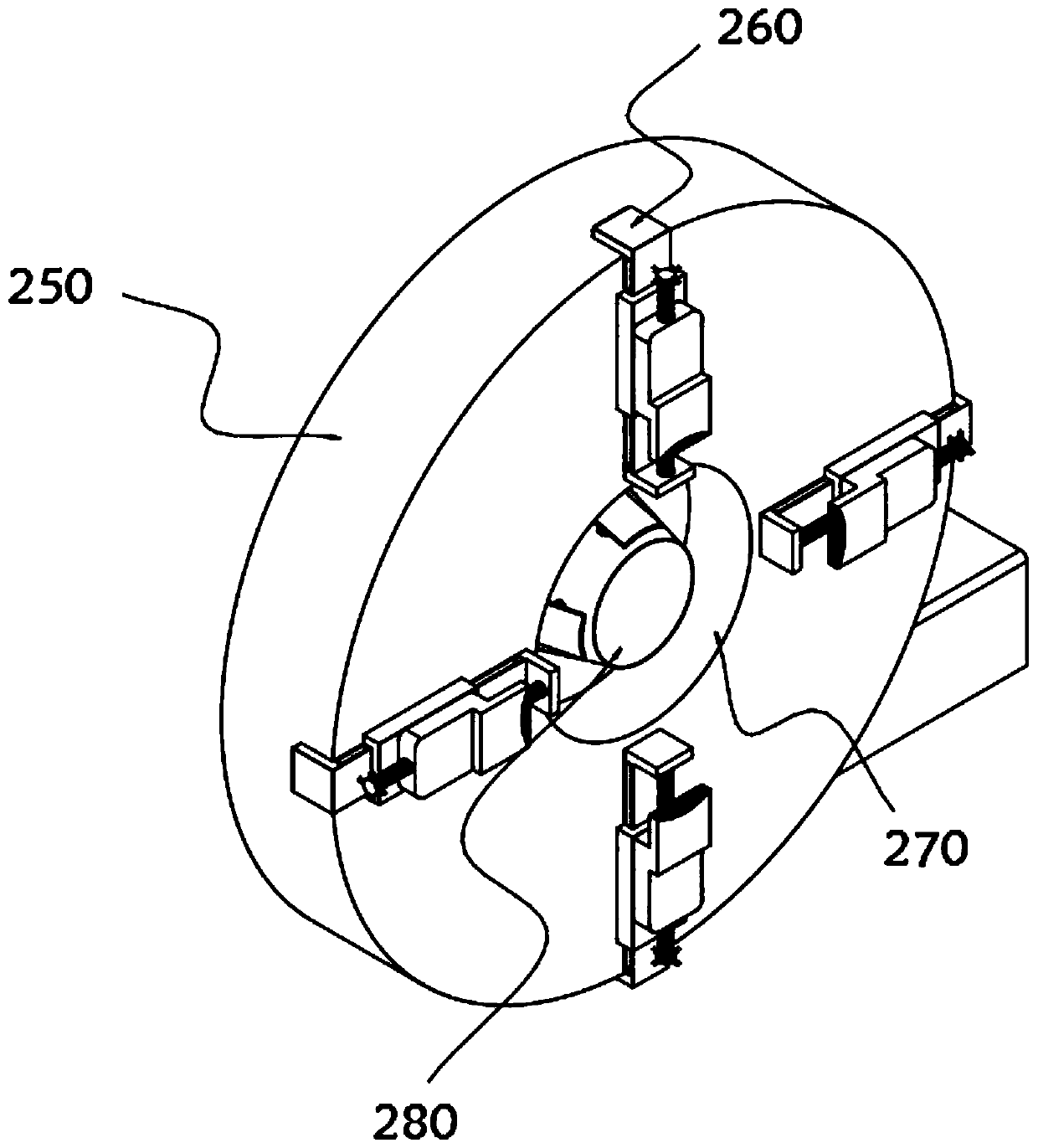

[0077] S1, first place the metal round tube to be processed on the processing table 100, then insert one end of the metal round tube into the positioning groove 270, and insert the inner core of the metal round tube into the inner positioning platform 280 inside the positioning groove 270;

[0078] The processing table 100 is provided with a baffle 110, the baffle 110 is installed around the processing table 100, and the baffle 110 is a rectangular frame structure, which is used to surround the processing table 100 and protect the processing table 100;

[0079] S2. Rotate through the handle 2626, the handle 2626 drives the ball screw 2625 to rotate, the ball screw 2624 slides along the length direction of the ball screw 2625, when the ball screw 262...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com