Automatic backing-up method of cold-rolled sheet material

An automatic, plate-based technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as recovery troubles, equipment alarms or failures, and complicated operating procedures, so as to eliminate acid spots and corrosion, and improve plate yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

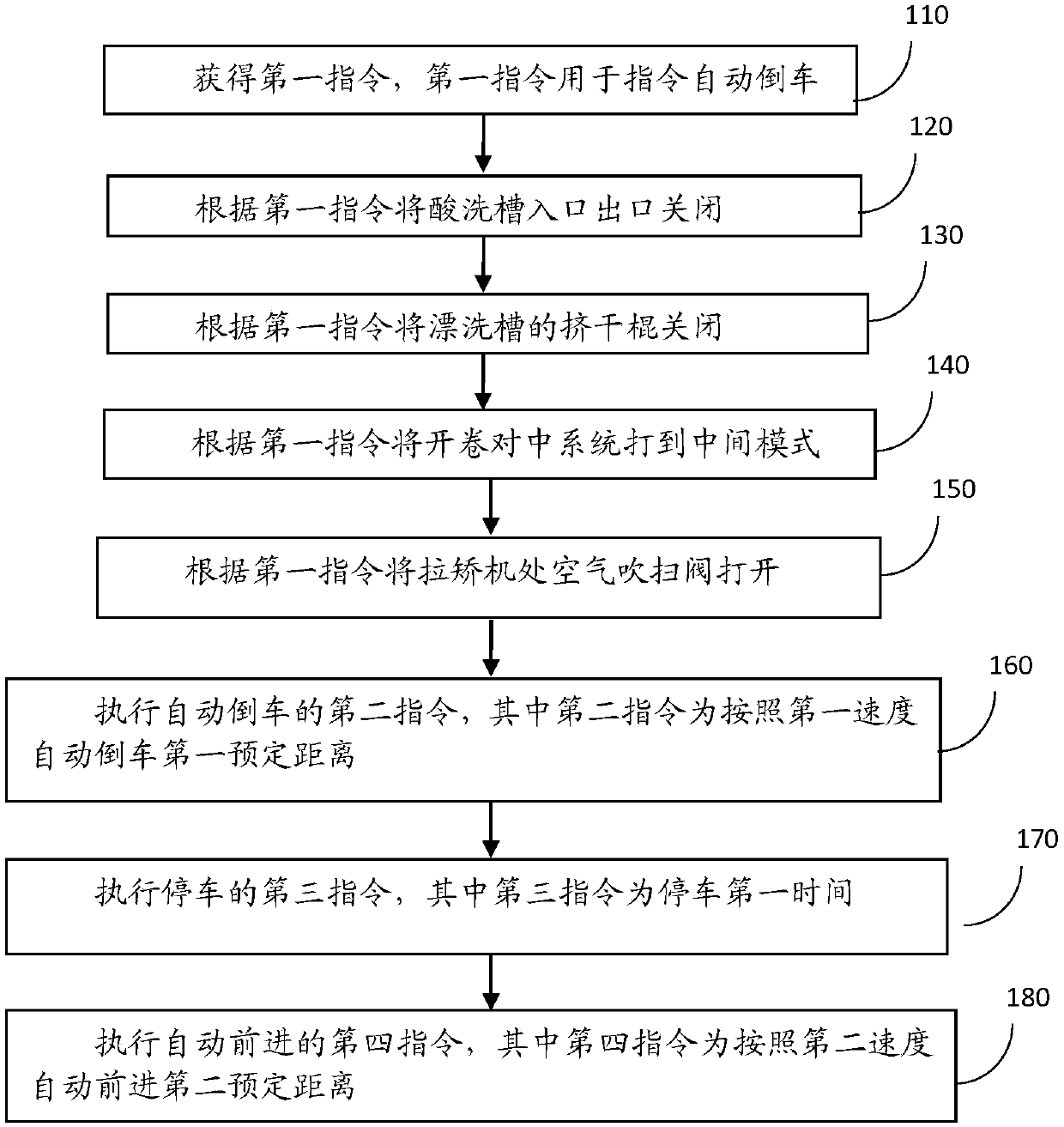

[0024] figure 1 It is a schematic flowchart of an automatic reversing method for cold-rolled plates in an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0025] Step 110: Obtain a first instruction, where the first instruction is used to instruct automatic reverse.

[0026] Specifically, the first instruction refers to the program of starting to execute the command in order to complete the automatic reversing function, that is to say, when the plate needs to eliminate acid spots and rust in the pickling stage, first, the human-machine interface HMI (Human machineinterface) and click the automatic reverse button, at this point, the program can obtain the first instruction and turn on the automatic reverse function.

[0027] Step 120: Close the inlet and outlet of the pickling tank according to the first instruction.

[0028] Specifically, after the program obtains the first instruction, that is, after starting to execute the automatic ...

Embodiment 2

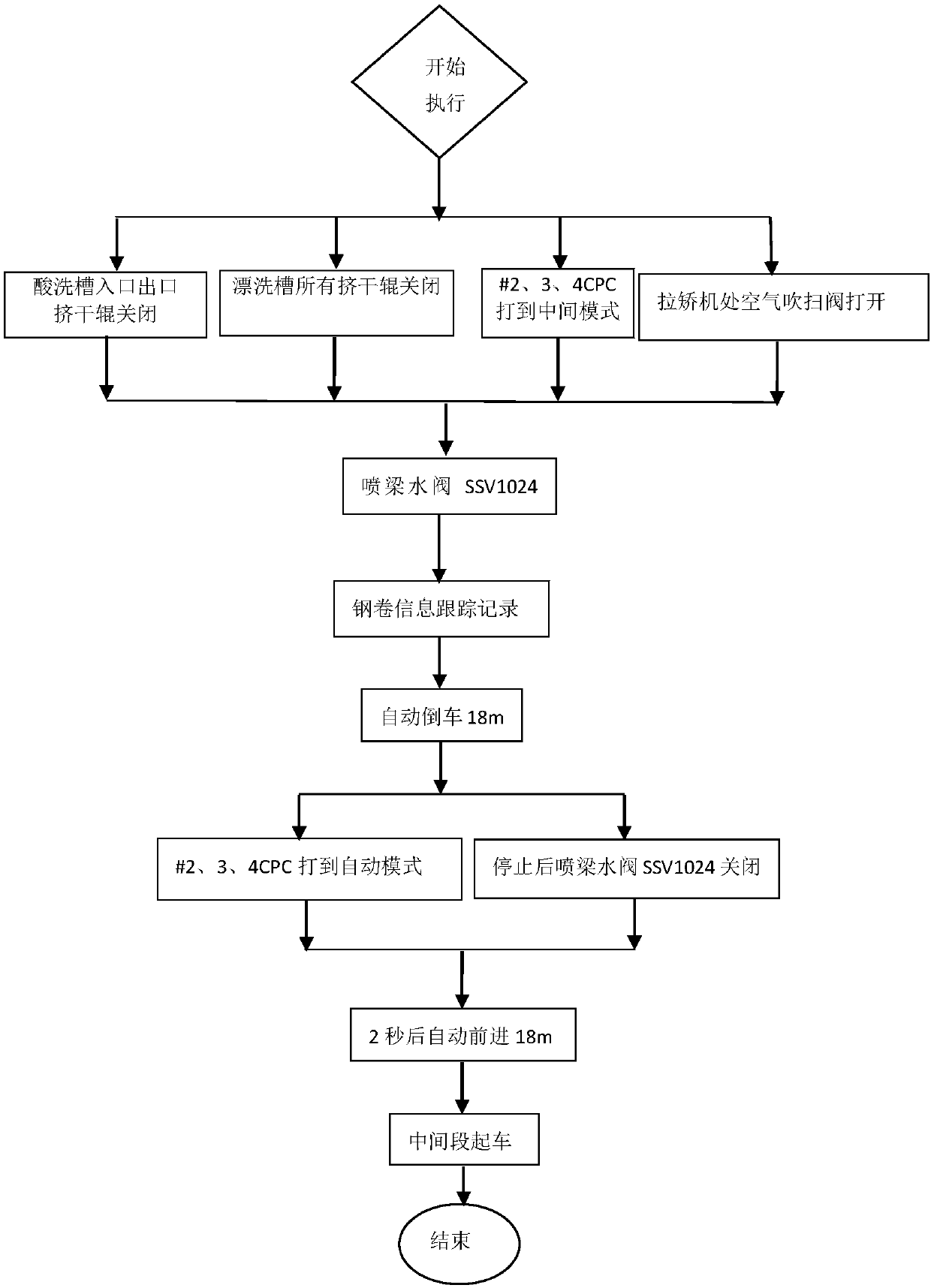

[0046] The automatic reversing method of a kind of cold-rolled plate of the present invention is described in detail below, please refer to figure 2 ,details as follows:

[0047] In order to describe the embodiments of the present invention more clearly, the technical terms involved in this application are explained below:

[0048] 1. μΣNETWORK-100: a communication network with a communication speed of 100Mbps, which realizes high-speed data communication, ensures network load stability, self-diagnosis function, etc., and realizes a highly reliable network. The communication medium is optical cable or double ring network .

[0049] 2. TCP / IP protocol: short for Transmission Control Protocol / Internet Protocol, that is, Transmission Control Protocol / Internet Internet Protocol, also known as network communication protocol, which is the most basic protocol of the Internet and the foundation of the Internet. The protocol and transport layer consist of the TCP protocol. TCP / IP d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com