Redundant droplet processing device after water cooling of heat-radiating sheet

A processing device and water-cooling device technology, which is applied in the direction of drying gas arrangement, lighting and heating equipment, and drying solid materials without heating, can solve the problems of water drops left over, heat sink rust, large usage, etc. Rust situation, guaranteed dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

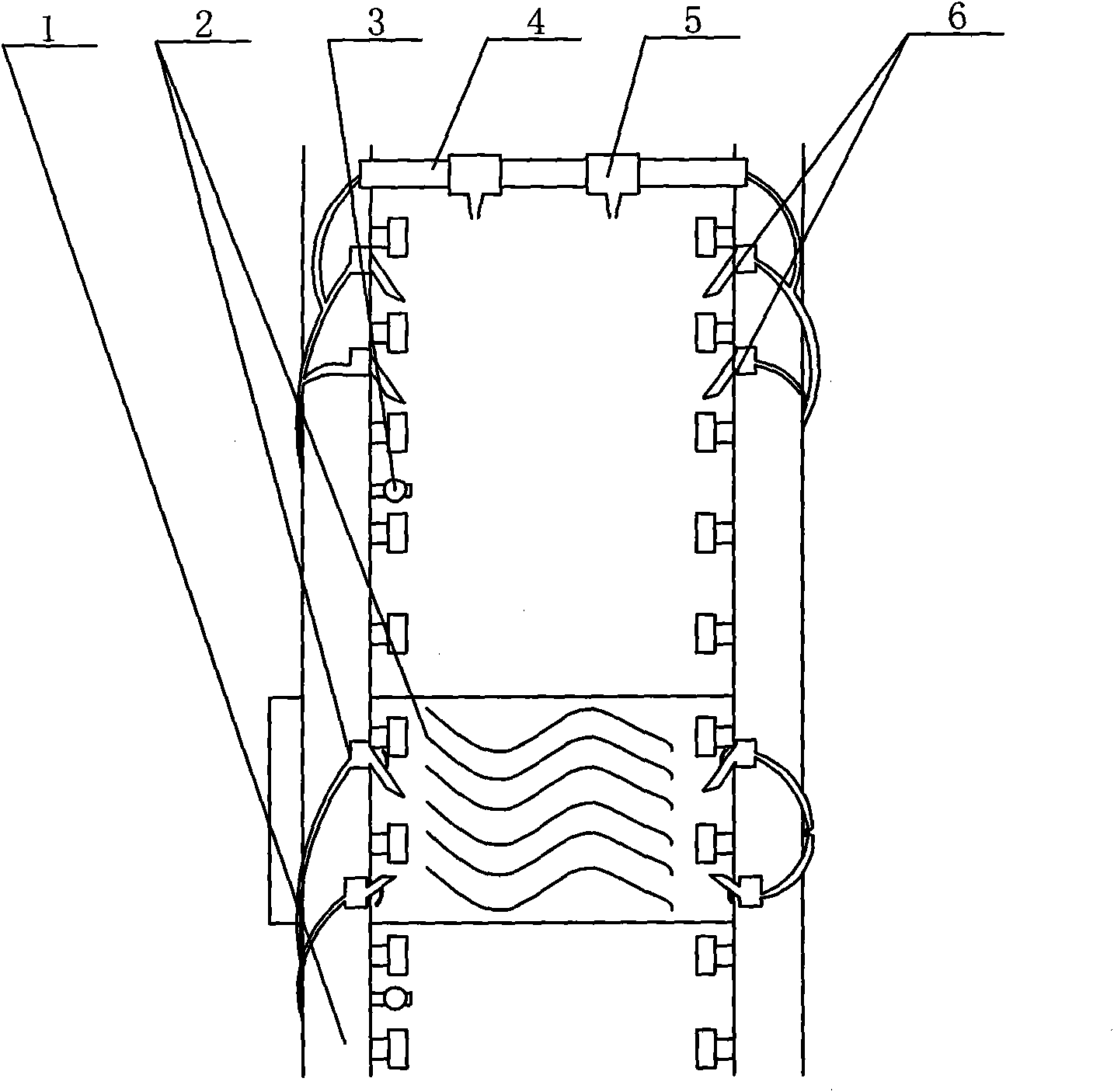

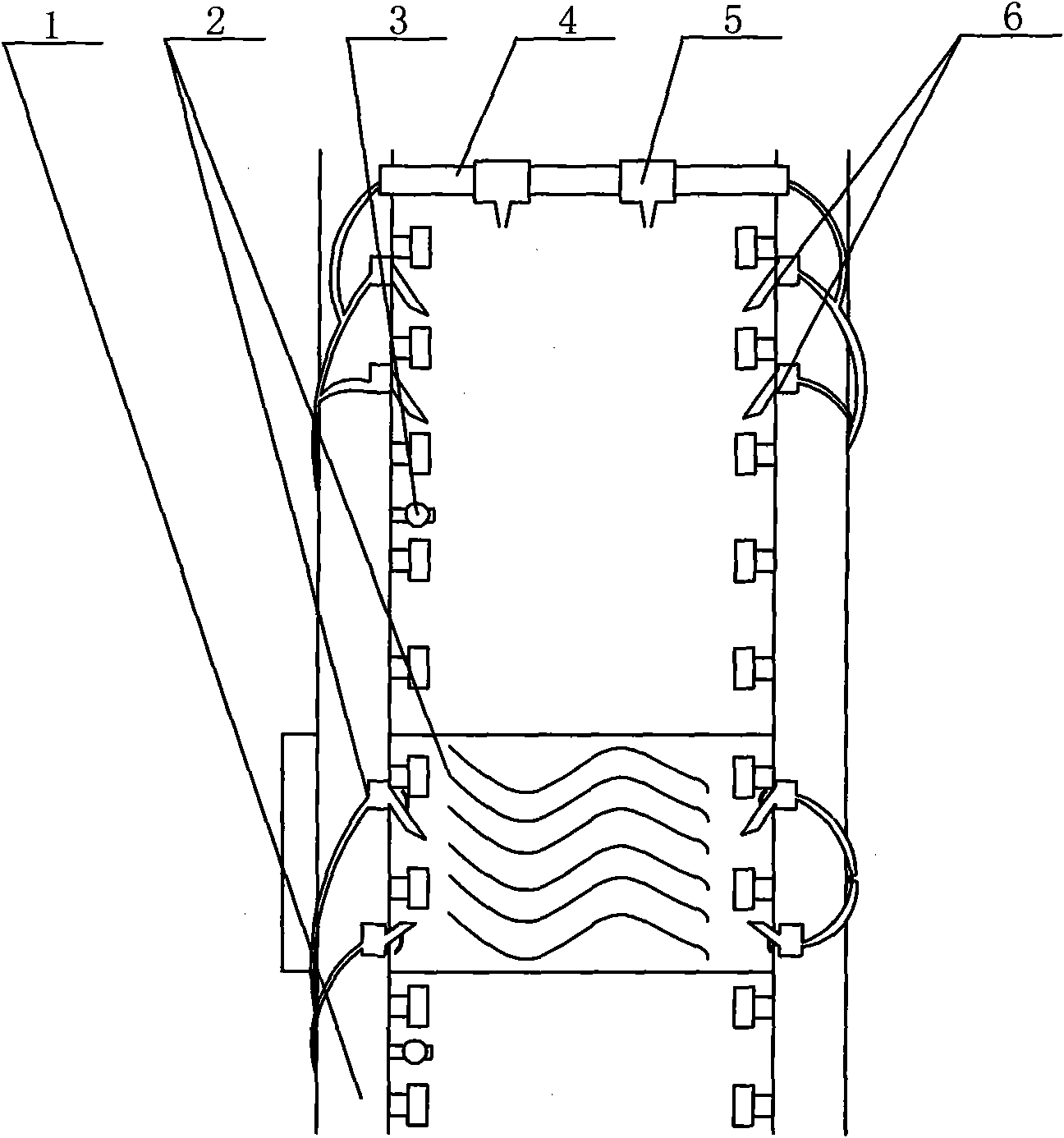

[0008] see figure 1 , the implementation of this tool is to adopt the following technical scheme: it includes a transport track 1, a water cooling device 2, a metal inductor 3, a beam 4, a main air nozzle 5 and a side air nozzle 6; the front end of the transport track 1 is provided with a water cooling device 2, A metal sensor 3 is installed on the inner side of the transport track 1 at the rear of the water cooling device 2, and a pair of side air nozzles 6 are respectively arranged on both sides of the transport track 1 at the rear of the metal sensor 3, and a crossbeam 4 is provided at the rear of the side air spray head 6 On the transport track 1 , a main air spray head 5 is arranged on the beam 4 .

[0009] The main air nozzle 5 and the side air nozzle 6 belong to the same trachea for air supply;

[0010] In this specific embodiment, the water droplets left on the heat sink after water cooling are blown off by a high-pressure air gun, which ensures the dryness of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com