Method for designing prestress adjustable support for detecting and strengthening

A design method and prestressing technology, applied in bridge reinforcement, erection/assembly of bridges, bridge construction, etc., can solve the problems of large steel consumption at the lower edge of the bracket, unrealizable load, and occupation of bearing capacity, so as to reduce self-weight and manufacture The assembly process is simple and feasible, and the effect of reducing the amount of materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

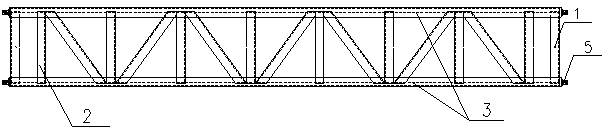

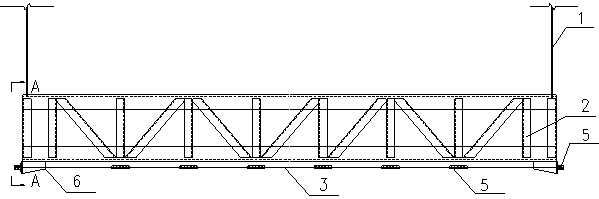

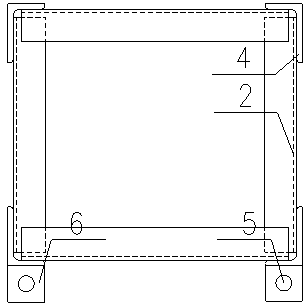

[0024] Embodiment 1: as Figure 1-4 Shown, a kind of method for designing the prestressed adjustable support for detection and reinforcement, the specific steps of the method are as follows:

[0025] 1. Position the four pieces of light alloy material II4 through the four pieces of light alloy material I2 at the end to form the basic skeleton of the bridge detection bracket;

[0026] 2. The light alloy material I2 is used to arrange horizontal, vertical and oblique supports on the side and bottom of the support at equal intervals. On the top surface, only two horizontal supports are arranged on the upper edge of the end of the support to form the purlin part of the truss structure. enhance the local stability of the scaffold;

[0027] Three, according to Determining the tensile control stress of the adjustable prestressed steel beam 3 f pd ; where, M x , M y around the same section x axis and y shaft bending moment, , Take 1.0 for the section plastic development...

Embodiment 2

[0036] Embodiment 2: as Figure 1-4 Shown, a kind of design method of prestressed adjustable support for detection and reinforcement, a kind of design method of prestressed adjustable support for detection and reinforcement, the concrete steps of described method are as follows:

[0037] 1. Position the 4 pieces of space aluminum 6061-L100×50×5 through the 4 pieces of space aluminum 6063-L70×50×5 at the end to form the basic skeleton of the bridge detection bracket;

[0038] 2. Use space aluminum 6063-L70×50×5 to arrange horizontal, vertical and oblique supports on the side and bottom of the support at equal intervals. On the top surface, only two horizontal supports are arranged on the upper edge of the end of the support to form a truss structure The purlin part of the bracket enhances the local stability of the bracket;

[0039] Three, according to Determining the tensile control stress of the adjustable prestressed steel beam 3 f pd ; where, M x , M y around the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com