Connecting joint for H-section steel partially encased recycled concrete composite column and H-section steel girder

A technology for reclaiming concrete and connecting nodes, which is applied to buildings and building structures, etc., can solve the problems of inapplicable H-beam connections, save steel and resources, improve ductility and seismic performance, and reduce earthquake damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

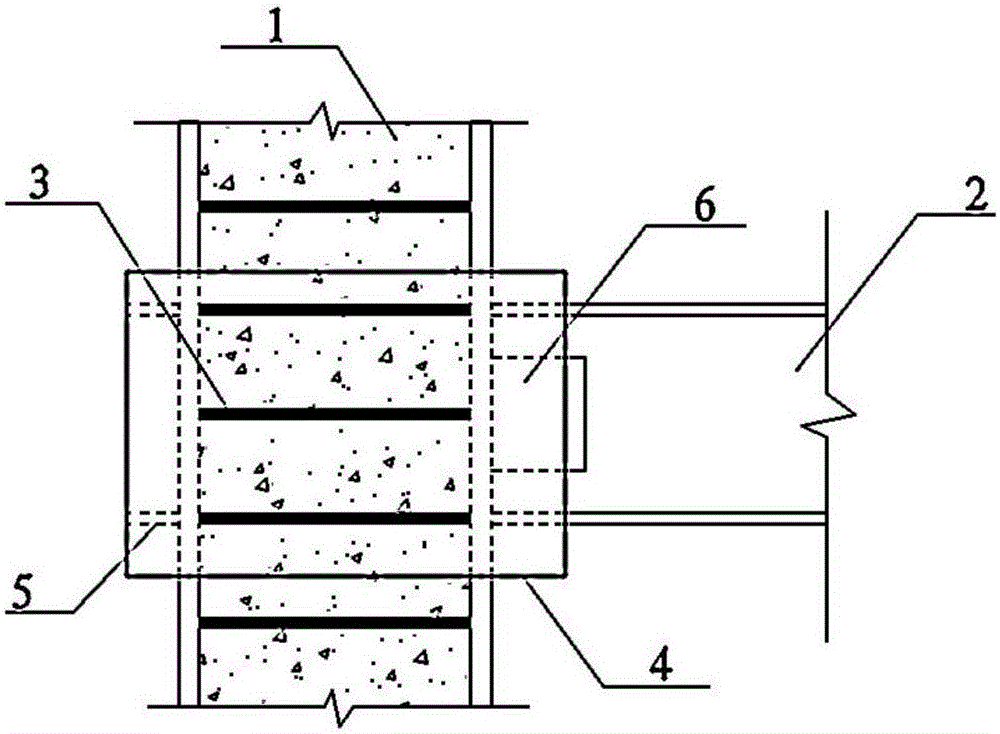

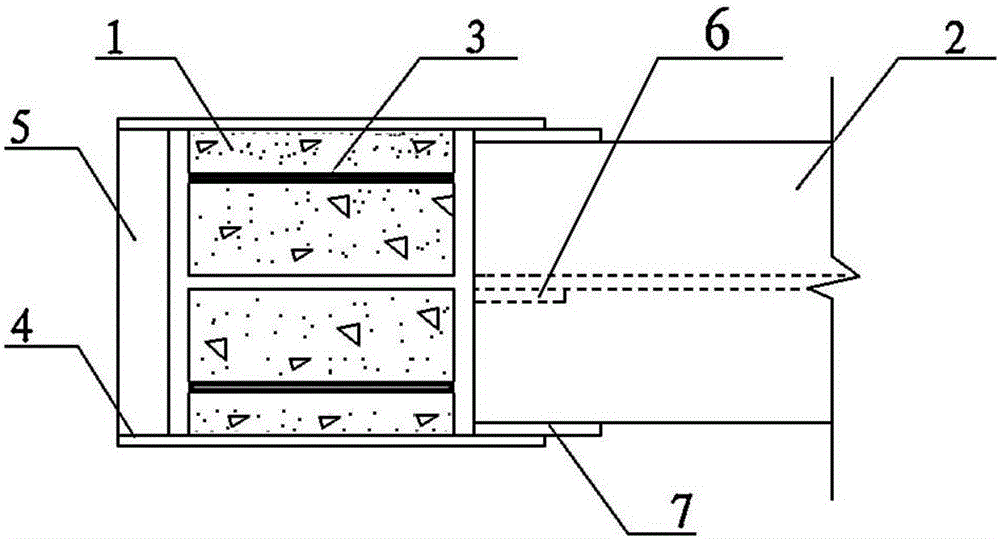

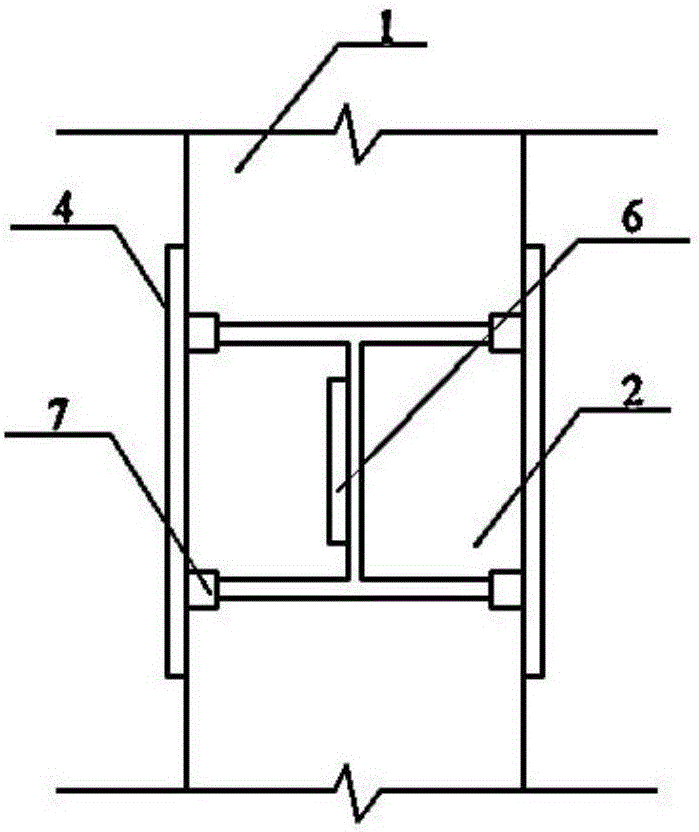

[0018] Such as figure 1 As shown, there is provided a connection node structure between H-shaped steel partly outsourcing recycled concrete composite column and H-shaped steel beam, including H-shaped steel partly outsourcing recycled concrete composite column 1 and H-shaped steel beam 2 which are vertically connected, and H-shaped steel partly outsourcing recycled concrete The composite column welds transverse tie rods 3 on both sides of the column flange plate, welds two side plates 4 on both sides of the column flange plate at the joint of the beam and column, and connects two side plates 4 by welding a reinforced steel plate 5 on the outside of the column flange plate . The H-shaped steel column and the H-shaped steel beam are connected by welding, and an additional plate 6 is welded vertically at the center of the inner flange plate at the joint of the beam-column joint, and the additional plate 6 is welded and connected with the web of the H-shaped steel beam, and the H-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com