Steel box concrete slot type girder bridge

A steel box concrete and girder bridge technology, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of large welding residual stress, multiple structures, easy fatigue and other problems, achieve good fatigue resistance, high bearing capacity, improve resistance The effect of fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

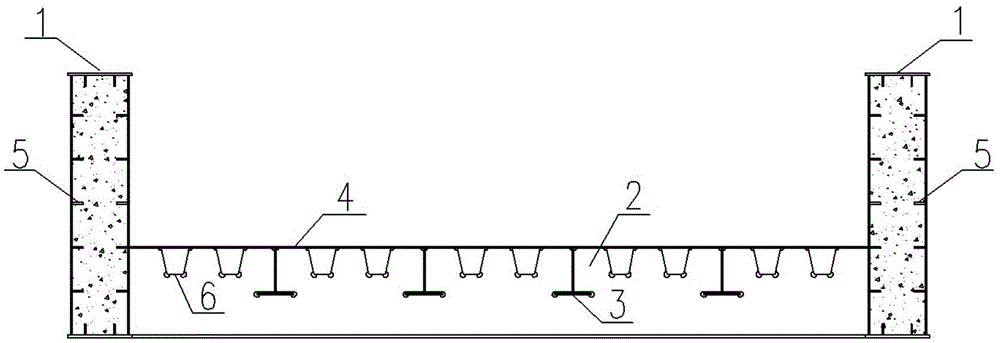

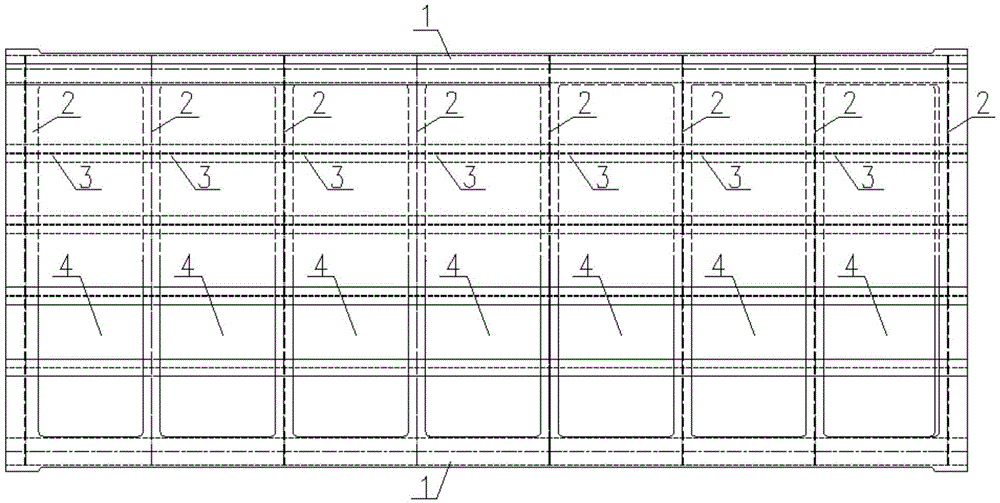

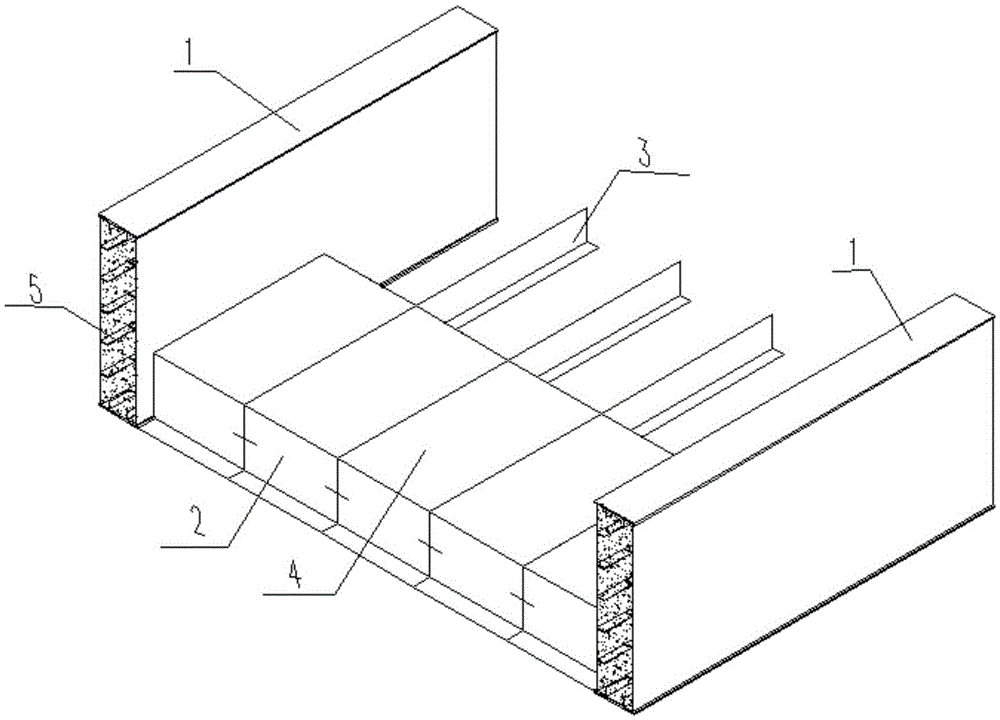

[0017] See Figure 1 ~ Figure 3 , A steel box concrete composite trough beam bridge, comprising at least two steel box concrete main beams 1, and a steel bridge deck structure is fixed between two adjacent steel box concrete main beams 1; The steel box concrete structure main girder 1 includes a steel box structure main girder. The steel box structure main girder is fully built with a concrete structure integrated with it; the steel bridge deck structure is arranged on the steel box concrete structure main girder. At the lower part of the beam 1, the steel bridge deck system and the two steel box concrete main beams 1 on both sides of the beam 1 form a trough structure.

[0018] In this embodiment, the steel bridge deck structure includes a bridge deck 4 and a lattic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com