Self-sealing metal flat tube supported solid oxide fuel cell/electrolytic tank structure

A solid oxide and fuel cell technology, applied in the shape/form of fuel cells, fuel cells, fuel cell additives, etc., can solve problems such as excessive internal loss, reduced battery efficiency, and low start-up rate of solid oxide cells , to achieve the effect of improving output performance, increasing the number of cycle starts, and improving the battery start-up rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

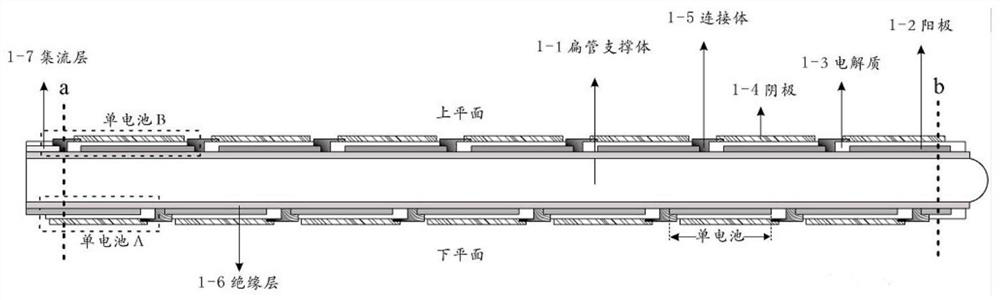

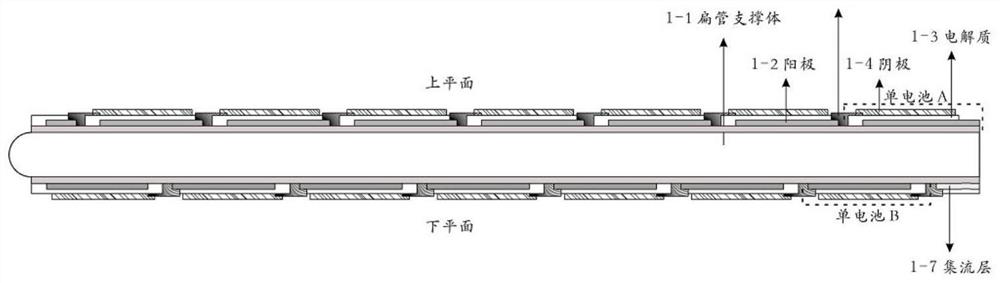

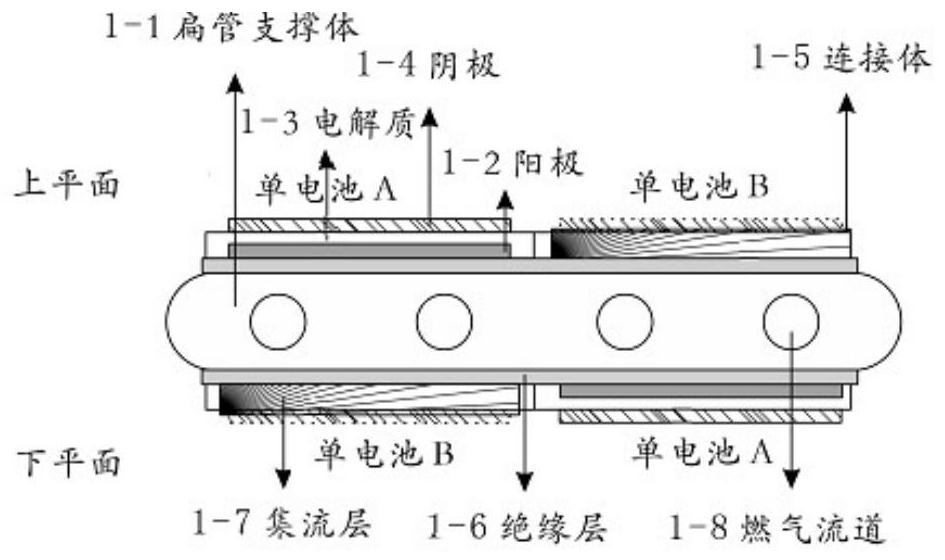

[0083] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the self-sealing metal flat tube support is prepared by sintering. The material of the flat tube support is iron-chromium alloy. The distance between the two planes of the flat tube support is 8mm. 4%, and the porosity of the porous area is 45%. The insulating layer and 108 single cells were prepared by screen printing process on the upper and lower planes respectively, and the length and width of the single cells were 22mm and 15mm, respectively. The insulating layer uses CaO to stabilize ZrO 2 For ceramic materials, the porosity of the surface of the insulating layer covering the battery area is 40%, and the rest is a dense area; the preparation sequence of each functional layer of the single cell is porous anode layer (NiO-GDC), dense electrolyte layer (GDC / YSZ / GDC) , a porous cathode layer (GDC-LSCF) and a dense interconnect layer. Among them, one of the single cells located at the closed end is extende...

Embodiment 2

[0086] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the self-sealing metal flat tube support is prepared by sintering. The material of the flat tube support is iron-chromium alloy. The distance between the two planes of the flat tube support is 10mm. The porosity of the porous area is 5%, and the porosity of the porous area is 45%. The insulating layer and 64 single cells were respectively prepared by screen printing process on the upper and lower planes, and the length and width of the single cells were 20mm and 12mm, respectively. The insulating layer is ZrSiO 4 For ceramic materials, the porosity of the surface of the insulating layer covering the battery area is 45%, and the rest is a dense area; the preparation sequence of each functional layer of the single cell is a porous anode layer (NiO-ScSZ), a dense electrolyte layer (ScSZ prepared by spraying method, silk YSZ), porous cathode layer (YSZ-LSM) and dense interconnect layer were prepared by screen pr...

Embodiment 3

[0089] On the basis of the conception of the above-mentioned technical solution, the present invention also provides another metal flat tube supporting solid oxide fuel cell / electrolyzer and its cell stack structure. Except for the open end (low temperature end), the structure and implementation Example 1 and 2 are the same. details as follows:

[0090] The self-sealing metal flat tube support is prepared by sintering. The material of the flat tube support is pure chromium. The distance between the two planes of the flat tube support is 8mm. The length and width of the flat tube support are 300mm and 40mm respectively, and the apparent porosity in the dense area is 5%. , The porosity of the porous area is 35%. The insulating layer and 32 single cells were prepared by screen printing process in turn on the upper and lower planes, and the length and width of the single cells were 17mm and 15mm, respectively. The insulating layer is made of MgO and MgAl 2 o 4 For the spinel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com