Watertight packaging type ultrasonic cleaning transducer

An ultrasonic cleaning and transducer technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as low cleaning efficiency, cracks on the front cover, easy cracking of glue, etc., to achieve Effects of reduced acoustic energy transmission loss, wide curing temperature range, and reduced driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

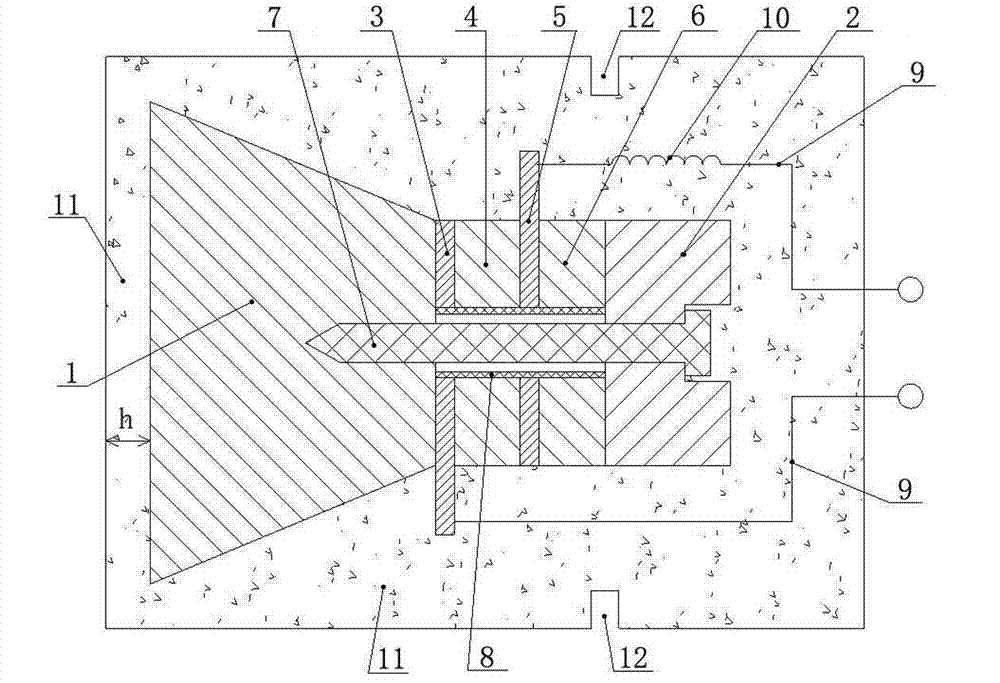

[0039] Such as figure 1 As shown, a water-tight packaging type ultrasonic cleaning transducer includes a front cover 1 and a rear cover 2, and a negative electrode sheet 3, a first Annular piezoelectric ceramic sheet 4, positive electrode sheet 5 and second annular piezoelectric ceramic sheet 6, and front cover plate 1, negative electrode sheet 3, first annular piezoelectric ceramic sheet 4, positive electrode sheet 5, second annular piezoelectric ceramic sheet The electric ceramic sheet 6 and the rear cover plate 2 are locked by a prestressed screw 7; a section of the prestressed screw 7 located on the electrode sheet and the annular piezoelectric ceramic sheet is provided with an insulating sleeve 8, and the electrode sheet and the annular piezoelectric ceramic sheet are covered with an insulating sleeve 8. The sheet is sleeved on the insulating sleeve 8; the positive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com