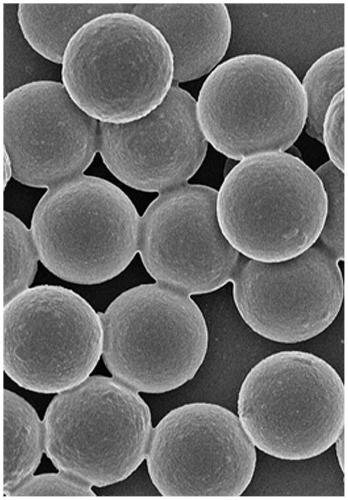

Magnetic fluorescent coding microsphere and preparation method thereof

A fluorescent coding, microsphere technology, applied in the direction of fluorescence/phosphorescence, material analysis by optical means, material excitation analysis, etc., can solve the problem of magnetic fluorescent coding microsphere, microsphere particle uniformity, good fluorescence performance, unfavorable industrial production, process Complex process and other problems, to achieve stable optical properties, good fluorescence performance, reduce quenching and shielding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

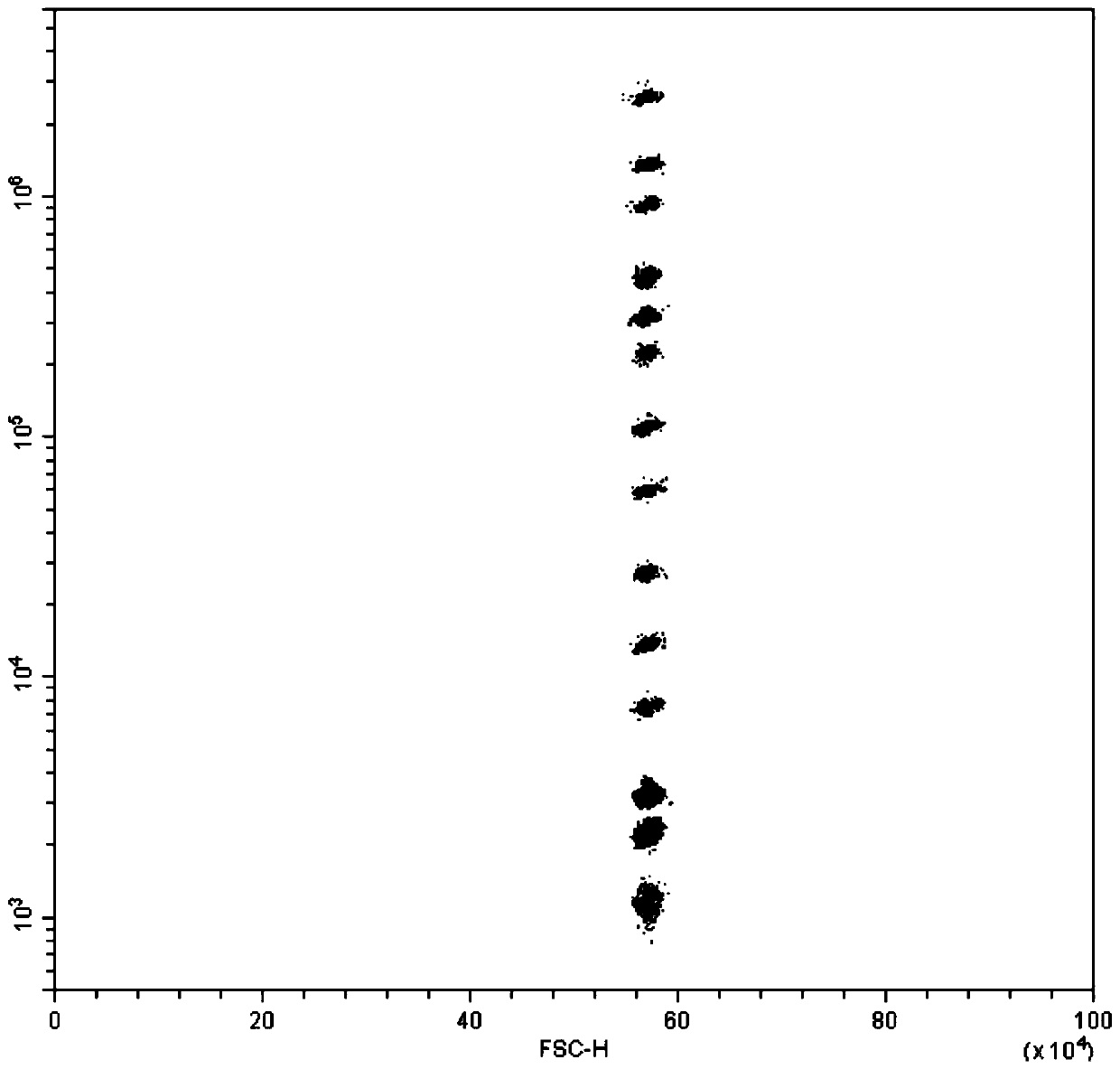

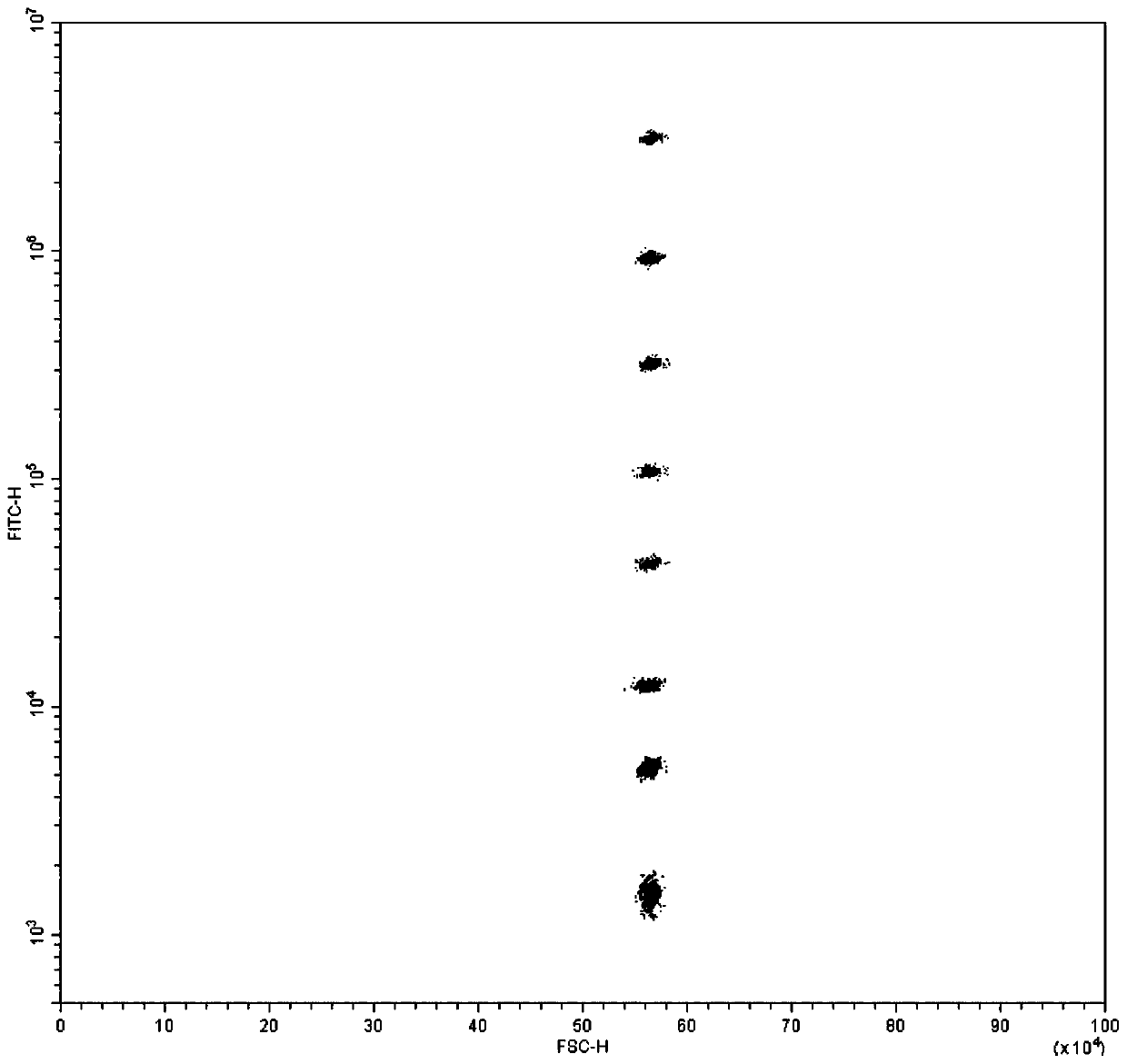

Image

Examples

preparation example Construction

[0044] A method for preparing magnetic fluorescently encoded microspheres, comprising the steps of:

[0045] mixing long-chain fatty acids, medium-short-chain fatty acids and long-chain fatty acid iron, and heating to obtain the magnetic nanoparticles;

[0046] Dissolving monodisperse polymer microspheres in poor solvent α1 to obtain mixture A;

[0047] Dissolving the magnetic nanoparticles in a good solvent β1 to obtain a mixture B;

[0048] Mix the mixture A and the mixture B, and deswell with a poor organic solvent α2 after the reaction to obtain the magnetic polymer microspheres;

[0049] Dissolving the magnetic polymer microspheres in a poor solvent α3 to obtain a mixture C;

[0050] Dispersing the hydrophobic fluorescent dye in a good solvent β2 to obtain a mixture D;

[0051]The mixture C is mixed with the mixture D, and then deswelled with a poor organic solvent α4 to obtain the magnetic fluorescent encoded microspheres.

[0052] Wherein, the volume ratio of the po...

Embodiment 1

[0114] This embodiment provides a magnetic fluorescent coded microsphere and its preparation method

[0115] a. Preparation of long-chain fatty acid iron, such as iron oleate:

[0116] Add 5.4g FeCl to the system 3 , 18.3g sodium oleate, 40mL absolute ethanol, 70mL cyclohexane and 30mL deionized water, reflux at 85°C for 1h. After absorbing the deionized water at the bottom, wash it repeatedly 3 times with deionized water to obtain an iron oleate solution;

[0117] b. Preparation of magnetic nanoparticles with a particle size of 4nm:

[0118] Add 120 mL of octadecene to a solution of long-chain fatty acid iron, such as iron oleate, stir magnetically at 100°C to remove cyclohexane, then add 8 mL of long-chain fatty acid, such as oleic acid and 10 mL of n-octanoic acid, and heat up to 290°C for 8 hours. After stopping the reaction, wash with ethanol to remove octadecene and unreacted substances, and obtain a black precipitate, which is a magnetic nanoparticle with a particle ...

Embodiment 2

[0126] This embodiment provides a kind of magnetic polymer microsphere and preparation method thereof

[0127] a. Preparation of long-chain fatty acid iron, such as iron oleate:

[0128] Add 5.4g FeCl to the system 3 18.3g sodium long-chain fatty acid, such as sodium oleate, 120mL absolute ethanol, 120mL cyclohexane and 120mL deionized water, reflux at 70°C for 96h. After absorbing the deionized water at the bottom, wash with deionized water repeatedly 3 times to obtain long-chain fatty acid iron, such as iron oleate solution;

[0129] b. Preparation of magnetic nanoparticles with a particle size of 10nm:

[0130] Add 120 mL of octadecene to a long-chain fatty acid iron solution, such as iron oleate, and stir magnetically at 100°C to remove cyclohexane, then add 10 mL of long-chain fatty acid, such as oleic acid and 50 mL of n-octanoic acid, and heat up to 320°C for 6 hours. After stopping the reaction, wash with ethanol to remove octadecene and unreacted substances, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com