Method for forming composite material by matched mold

A technology of composite materials and counter molding, which is applied in the field of counter molding composite materials, which can solve problems such as insufficient density and uneven surface of composite materials, and achieve the effects of no mold joint, high product quality, and avoiding material inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

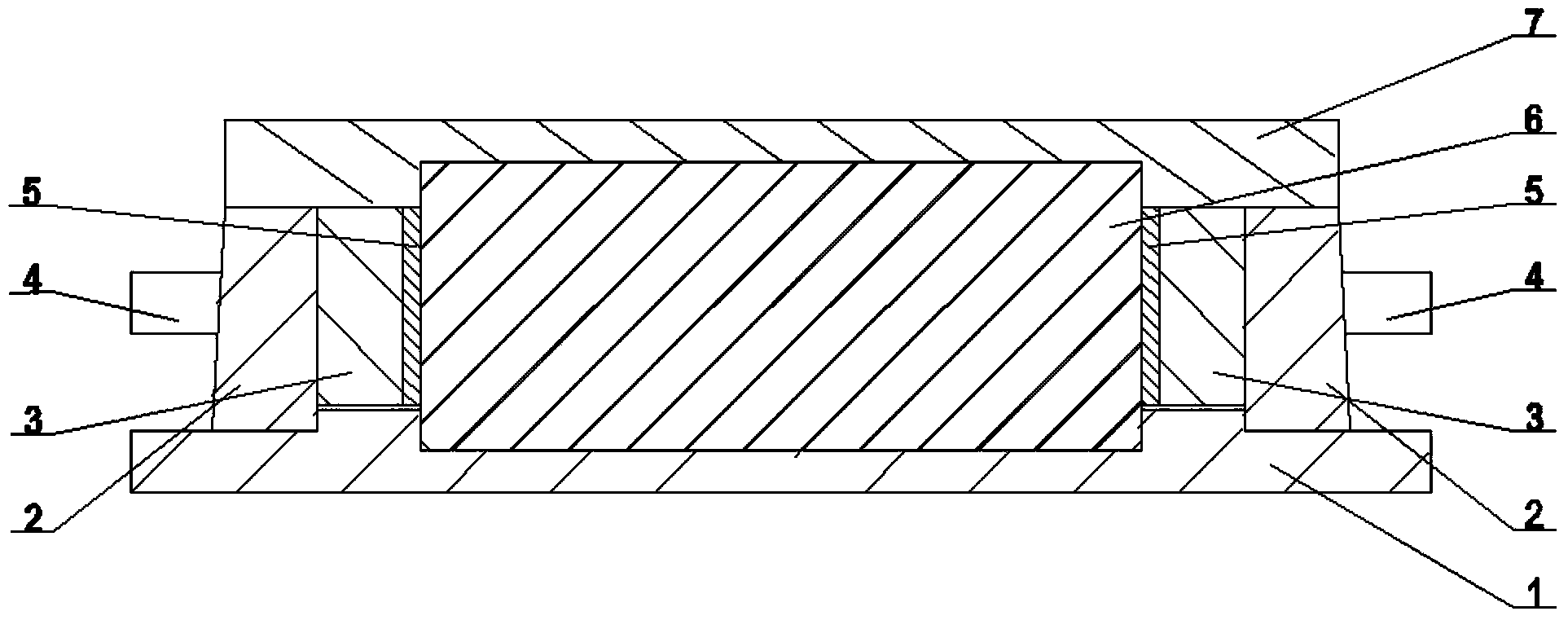

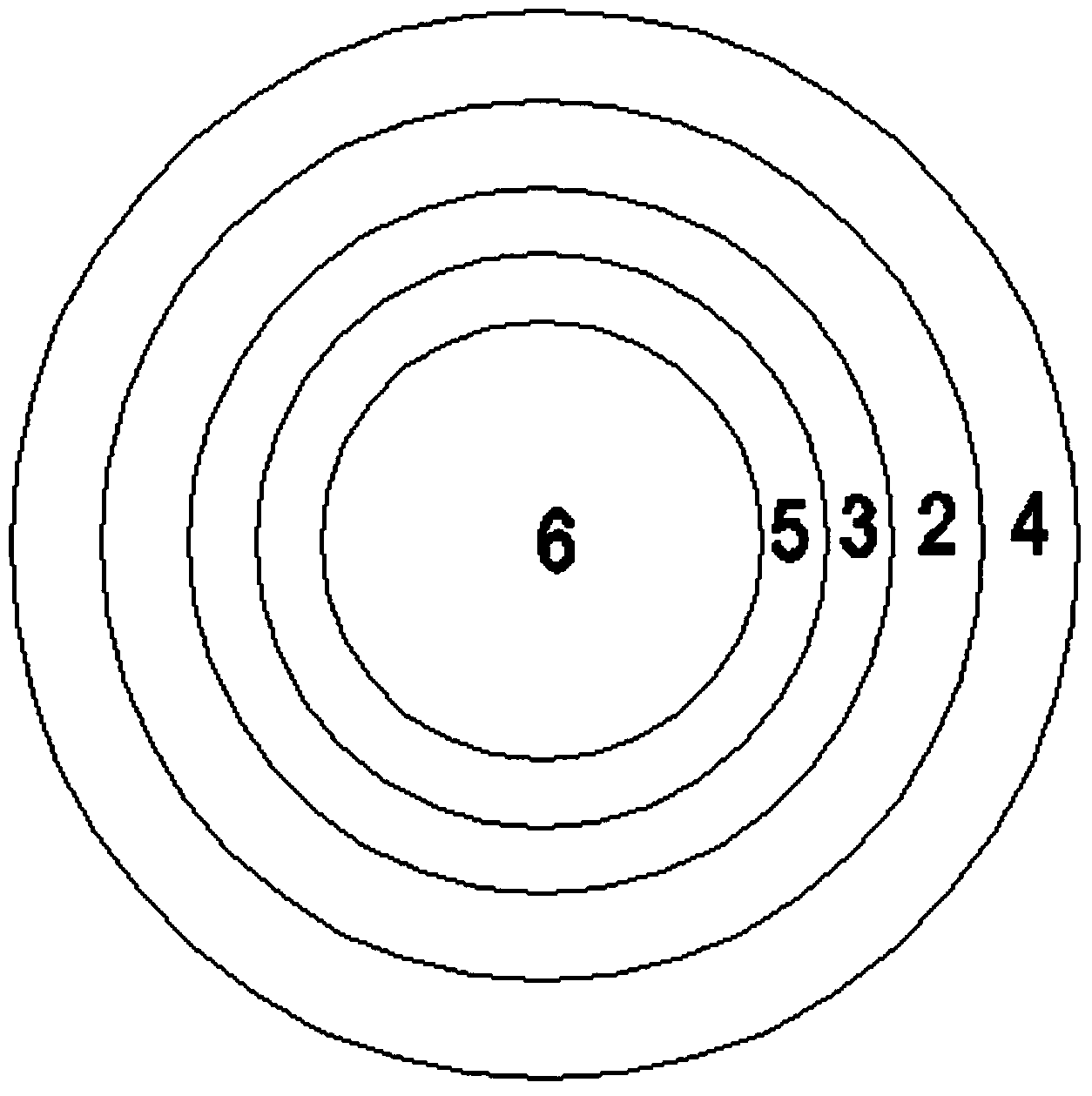

[0012] Embodiment 1: In this embodiment, a method for molding composite materials is carried out according to the following steps:

[0013] 1. Lay a composite material prepreg layer on the surface of the inner mold on the lower mold of the metal mold, and evenly lay expansion rubber on the outside of the composite material prepreg layer; The mold ring fits the outer mold tightly, and the upper mold is tightly covered to obtain the packaged mold; 3. Put the packaged mold in step 2 into the curing furnace, and first cure it at a temperature of 90°C to 100°C for 2 hours to 3h, then cured at a temperature of 120°C to 130°C for 4h to 5h, and finally cured at a temperature of 150°C to 160°C for 2h to 3h to obtain a cured mold; The final mold is taken out, cooled to room temperature, and demolded to obtain a molded composite material. The expansion rubber described in step one is silicon rubber or fluororubber; The expansion coefficient of the expansion rubber described in step one ...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the expansion rubber described in Step 1 is silicone rubber. It is the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the expansion coefficient of the expansion rubber described in step one is 2×10 -4 / °C. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com