A method of electrodepositing tungsten alloy

A tungsten alloy and electrodeposition technology, applied in the field of material surface treatment, can solve the problems of high toxicity, pollute the environment, low current efficiency, etc., and achieve the effect of compact and smooth surface, strong coating hardness and stable electrolyte.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

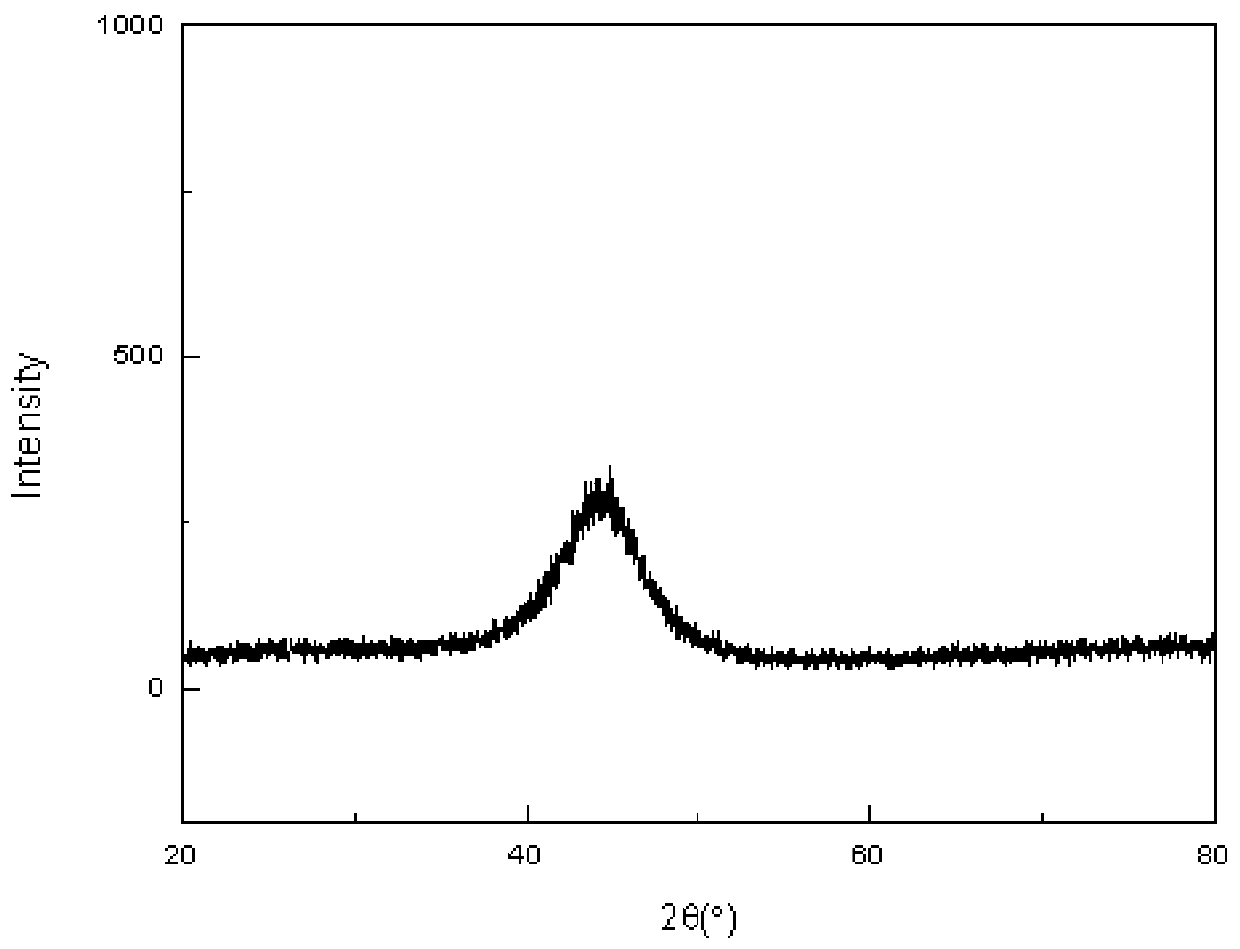

Image

Examples

Embodiment 1

[0016] (1) Configure the electrolyte: in a clean beaker, first add boric acid to dissolve completely; then add sodium tungstate, cobalt sulfate, and nickel sulfate, stir and dissolve to form a salt solution with a molar concentration ratio of tungsten, cobalt, and nickel ions of 3:1:1 ; Then add complex complexing agent citric acid and succinic acid, the molar concentration ratio is 3:1; finally add sodium lauryl sulfate solution, fully stir. The composition of the electrolyte is: sodium tungstate 30g / L, cobalt sulfate 8g / L, nickel sulfate 8g / L, citric acid 58g / L, succinic acid 12g / L, boric acid 4g / L, sodium lauryl sulfate 0.1 g / L. The cathode is a stainless steel plate (30mm×20mm), the anode is a graphite sheet (70mm×25mm), the two electrodes are placed in parallel and the distance between the two electrodes is 20mm. The electrodeposition temperature is 40°C, controlled by a constant temperature water bath, the electrodeposition time is 1h, and the current density is 500mA / d...

Embodiment 2

[0018] (2) Configure the electrolyte: in a clean beaker, first add boric acid to dissolve completely; then add sodium tungstate, cobalt sulfate, and nickel sulfate, stir and dissolve to form a salt solution with a molar concentration ratio of tungsten, cobalt, and nickel ions of 3:1:1 ; Then add complex complexing agent citric acid and succinic acid, the molar concentration ratio is 3:1; finally add sodium lauryl sulfate solution, fully stir. The composition of the electrolyte is: sodium tungstate 99g / L, cobalt sulfate 28g / L, nickel sulfate 26g / L, citric acid 116g / L, succinic acid 24g / L, boric acid 5g / L, sodium lauryl sulfate 0.1 g / L. The cathode is a stainless steel plate (30mm×20mm), the anode is a graphite sheet (70mm×25mm), the two electrodes are placed in parallel and the distance between the two electrodes is 20mm. The electrodeposition temperature is 80°C, controlled by a constant temperature water bath, the electrodeposition time is 5h, and the current density is 750m...

Embodiment 3

[0020] (3) Prepare the electrolyte: in a clean beaker, first add boric acid to dissolve completely; then add sodium tungstate, cobalt sulfate, and nickel sulfate, stir and dissolve to form a salt solution with a molar concentration ratio of tungsten, cobalt, and nickel ions of 3:1:1 ; Then add complex complexing agent citric acid and succinic acid, the molar concentration ratio is 3:1; finally add sodium lauryl sulfate solution, fully stir. The composition of the electrolyte is: sodium tungstate 50 / L, cobalt sulfate 14g / L, nickel sulfate 13g / L, citric acid 87g / L, succinic acid 18g / L, boric acid 6g / L, sodium lauryl sulfate 0.1 g / L. The cathode is a stainless steel plate (30mm×20mm), the anode is a graphite sheet (70mm×25mm), the two electrodes are placed in parallel and the distance between the two electrodes is 20mm. The electrodeposition temperature is 60°C, controlled by a constant temperature water bath, the electrodeposition time is 3h, and the current density is 600mA / dm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com